Difference between Water Tube Boiler and Fire Tube Boiler

In today’s article we are going to learn about the difference between water tube boiler and fire tube boiler or in simple words Fire Tube Boiler Vs Water Tube Boiler.

We know that boiler is used onboard for power generation and it is one of the most important thing on ship.

Boiler is broadly categorised into water tube boiler and fire tube boiler. And since they are categorised differently this means that there must be some differences between them either in functioning, maintaining, running or economical differences. This article is all about their differences.

Fire Tube Boiler Vs Water Tube Boiler

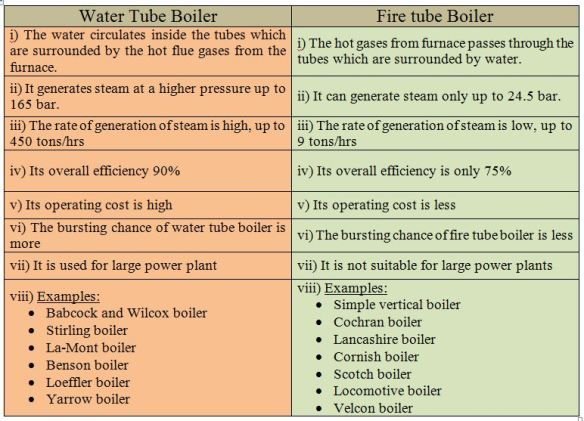

| Water Tube Boiler | Fire Tube Boiler |

| 1. The water flows inside the tube and the hot combustion gases flows outside the tube. | 1. The hot gases flows inside the tube and the water is outside the tube. |

| 2. These are generally high pressure boiler ranging up to 70-100 Bar. | 2. These are generally low or medium pressure boiler up to 25 Bar. |

| 3. Faster rate of steam Production. | 3. Lower rate of steam Production. |

| 4. More efficient | 4. Less efficient |

| 5. These boilers are mostly externally fired. | 5. These are internally fired. The furnace is placed at one end of the Fire tube. |

| 6. Suitable for large scale power plants. | 6. Suitable for small scale power plants. |

| 7. Since the operating pressure is high, the risk of explosion is also high. | 7. Risk of explosion is less, as less operating pressure. |

| 8. Occupies less floor space. | 8. Occupies large floor space. |

| 9. Because of complexity, skilled person is required to operate. | 9. Less complex, less skill required. |

| 10. Easy to clean as it is externally fired | 10. Difficult to clean as internally fired. |

| 11. The shell diameter is less. | 11. The diameter of shell is more. |

| 12. Easy to carry out maintenance. | 12. Difficult to carry out maintenance |

| 13. Since water flows inside the tube, treatment of water is necessary to prevent deposit formation. | 13. Treatment of water is not necessary. |

| 14. More environment friendly | 14. Less environment friendly |

| 15. Operating cost is high | 15. Operating Cost is less. |

| 16. Examples: Babcock and Wilcox Boiler, Stirling Boiler, La-mont Boiler, Benson Boiler, Loeffler Boiler, Yarrow Boiler | 16. Examples: Simple Vertical Boiler, coachran boiler, Lancashire Boiler, Cornish Boiler, Scotch Boiler, Locomotive Boiler, Velcon Boiler. |

Difference between water tube boiler and fire tube boiler in a descriptive format | Fire Tube Boiler Vs Water Tube Boiler

Fire Tube Boiler

In fire tube boiler, as the name suggest Fire Tube (i.e Fire in Tube) the hot combustion gases ( flue gases) are passed through the tubes which are arranged inside the cylindrical drum and the outside of the tubes are surrounded by the water.

The heat transfer takes place between the hot gases and the surrounded water through the tubes. This heats up the water and convert it into steam.

Fire Tube boilers are simple in construction as compared water tube boilers and are used as their alternative because of being cheaper.

These are generally used in small scale industries as the operating pressure of fire tube boilers are low.

Other advantages of fire tube boilers are that they have compact size and have the ability to handle the fluctuations in steam demand more efficiently.

There are also certain disadvantages of Fire tube boiler like it’s efficiency is low, it takes longer time to convert that amount of water into the steam, not able to cope up with sudden increase in load.

Water Tube Boiler

Now coming to the water tube boiler (i.e water in the tube), the water runs inside the tube and the hot gases are passed over the outer surface of the tube.

The heat is transferred from the hot gases to the water in the tubes and it gets converted into steam.

Since the steam is generated in the tubes , the water tube boilers can operate at higher pressure than the fire tube boilers and hence they are used in large scale production that requires high pressure and high steam output.

Advantages

Water tube boilers are generally provided with more than one burner and we can use these burner either individually or in parallel combination for a single furnace.

This provides a way to have controlled shutdowns so that maintenance can be carried out without shutting off the boiler entirely.

Also the burners can be used to operate at different loads.

Water tube boilers are also provided with Programmable Logic Controller for controlling and maintaining proper functioning of the burners provided.

They also control the super heater and feed water systems.

As the volume of area of production of steam is less in water tube boiler the water tube boilers are able to produce high pressure steam and at a faster rate than the fire tube boiler.

They can also produce super heated or saturated steam according to the design and the place where they are required. They are able to operate at higher pressure.

The water tube boiler can be constructed to use high-ash fuels in conjunction with the soot blowers and proper Ash handling and flue gas cleanup equipment to maintain environmental regulations.

Disadvantages

Though we have seen the various advantages of the water tube boiler but there are certain disadvantages also.

The capital cost of water tube boiler is very high and the size of the water tube boiler is large as compared to fire tube boiler which bring it to a point that it is mostly constructed on the site where it has to be used.

Because of the use of control systems the complexity and it’s cost increases more.

And for working on it a proper training is required.

Now that we have seen the descriptive difference between water tube boiler and fire tube boiler.

Now it is more easy to remember in point form rather than the description, though the description gives you a better understanding of the differences.

People also ask

Which is better fire tube boiler or water tube boiler?

Between the two types of boiler, Water tube boilers are more significantly more efficient than fire tube.

It will be clear you after reading following reasons :-

1.Water converts into steam very Quickly. When the water flow through the tubes ,it is only surrounded by heat rather than the other way around.

Since the tube holds less water than the tank of fire tube boiler so ,it takes less time to convert that water into steam and thus less consumption of fuel.

The water tube boiler did the work of producing steam in as little as five minutes, compared to an hour or more for the fire tube boilers. As a result, fuel savings costs can be significant over time

2.Water tube boilers require less water. By heating water in the tube via a once-through design, water tube boilers don’t need to store as much water to produce steam, making them more environmentally friendly by design.

3.Water-tube boilers can adapt to change loads more easily. Water tube boilers can respond more quickly to changes in demand for steam, by heating less water at one time.

Individual units configured modularly can power up or down as required. This means we only use fuel and water as needed, greatly reducing energy waste in the process.

4.Water tube boilers seem to last longer. The ability to operate more effectively also ensures that boilers for water tubes have a longer life expectancy than their counterparts for fire tubes.

Where are water tube boiler used ?

Water tube boilers are most commonly used where high pressures of steam are required and may exceed 3,000 psi.

Water tube boilers can generate saturated or superheated steam that is useful for applications such as steam turbine power generation. In addition, such boilers are commonly used in process industries, including chemical, refining and pulp and paper manufacturing.

Why water tube boiler is more efficient than fire tube boiler ?

In fire tube boilers, flue gases need to heat up a large amount of water and are therefore slow and inefficient.

Because of their slow operation, more heat is lost to the surroundings. In the water tube boilers, flue gases pass through the water tubes and deal with less water.

They’re fast in operation, therefore, and less heat is wasted in the surroundings.

So, They’re more efficient.

Why can’t a fire tube boiler be made with a high capacity as a water tube boiler ?

Fire tube boilers are used for small capacity & less pressure boilers because the heat is explored to evaporate the water is less available also the heat is less available. But in the water tube Boilers area available to heat the water is more because the flue gas flows around the tubes. It is therefore used for higher capacity and high pressure of approximately 127 Kg/cm2 or more.

What are the differences between a tank boiler and a water tube boiler?

You may be referring to “Fire-tube” vs. “Water tube” In the former, the entire tank is filled with pressurized water and steam with fire flowing through the tank in pipes. This form is no longer used except in historic installations.

Excessive pressure due to technological malfunction or operator error may cause the entire tank to burst, killing people nearby. The sort of water pipe will never explode because all the pressure is in the pipes and the tank has hot gases. If the tube splits, the steam spills harmlessly into the firebox.

So these were some of the basic difference between Water tube Boiler and Fire tube Boiler which are covered in this article in tabular as well as descriptive form. Fire Tube Boiler Vs Water Tube Boiler is one of the common things that people generally ask. If You liked this article, please share it with your friends and give your feedback in the comment below.

Check Out Other Important Topics