What is Hydrophore System on ship ?

hydrophore system : It is a type of water supply system that uses a pressure tank to store water under pressure, providing a consistent water supply to the multiple areas of the vessel at distinct heights in all lines and on all vessel floors.

You Should read about fresh water generator

Why is hydrophore System on board compulsory?

The Hydrophore System is an essential component on board vessels for maintaining a stable and efficient freshwater supply. Here’s why it is compulsory:

1. Stabilizes Water Pressure:

On vessels, freshwater demand varies greatly across different areas such as cabins, galleys, and machinery spaces. Without a hydrophore system, directly using a pump would cause constant pressure fluctuations, especially during periods of low water consumption. The hydrophore system provides a pressurized reservoir that maintains system pressure within a specific range, ensuring stable water supply despite changes in demand.

2. Reduces Pump Cycling:

A centrifugal pump connected directly to the freshwater line would frequently turn on and off (cycle) due to fluctuating demand. This frequent cycling leads to wear and tear on the pump, reducing its lifespan and efficiency. The hydrophore system acts as a buffer, reducing the need for the pump to start and stop frequently, thereby preventing excessive cycling and extending the pump’s lifespan.

3. Ensures Consistent Supply:

The system provides compressed air assistance to pressurize the water supply, ensuring that all areas of the ship have access to consistent water pressure, regardless of the number of users. This is critical for areas like showers, sinks, and machinery that require constant water flow for proper functioning.

4. Increases System Efficiency:

By maintaining constant pressure and reducing the strain on the pump, the hydrophore system helps in optimizing the efficiency of the entire freshwater distribution system on board. This leads to less energy consumption, lower maintenance costs, and smoother operation.

5. Protects the Plumbing System:

The hydrophore system acts as a buffer, preventing pressure surges that could damage the plumbing lines, fixtures, and fittings. This makes it a crucial component in protecting the integrity of the vessel’s freshwater distribution system.

Conclusion: The hydrophore system is compulsory on vessels because it ensures reliable water pressure, prevents pump overuse, maintains system efficiency, and protects the vessel’s plumbing infrastructure from damage due to fluctuating demand. This makes it a vital part of the ship’s water management system.

Working of Hydrophore System

Working of the Hydrophore System:

The hydrophore system provides a consistent and reliable water pressure for various systems on board, such as freshwater supply, fire lines, and sprinkler systems. The system leverages the fact that while water cannot be compressed, air can be, offering a smart solution for maintaining stable pressure without constant pump operation.

Here’s a step-by-step breakdown of how the hydrophore system works:

- Water and Air Interaction:

- The hydrophore tank contains both water and compressed air. Since water cannot be compressed, the pressure regulation is achieved by compressing the air in the tank, which, in turn, pressurizes the water inside.

- As the tank is filled with water, the air is compressed, building up the required pressure in the system.

- Pump Operation:

- A pump fills the hydrophore tank with water. Once the water reaches a certain level and the air is compressed to a preset pressure, the pump turns off.

- The compressed air now acts as a cushion, pressurizing the water, allowing it to be distributed throughout the ship without the need for the pump to be constantly running.

- Pressure Regulation:

- As water is consumed or used in different parts of the ship, the air expands, maintaining the pressure within the system. The system can supply water to various outlets like sinks, showers, or fire lines, all at consistent pressure, without having to constantly restart the pump.

- When the water level in the tank drops to a certain point, and the air pressure begins to fall below a set limit, the pump reactivates, refilling the tank with water, compressing the air again.

- Avoiding Constant Pump Cycling:

- Without a hydrophore system, the pump would have to cycle frequently to maintain pressure, especially during low water demand periods. This cycling leads to excessive wear and tear on the pump.

- By using the air-water balance in the hydrophore tank, the system avoids the need for constant pump activation, ensuring the pump operates less frequently, leading to increased pump longevity and system stability.

- Consistent Water Pressure:

- The compressed air in the hydrophore system allows for consistent water pressure across the system, even with fluctuating water demands. Whether the demand is high or low, the system maintains a steady pressure, ensuring all areas of the ship receive the required water pressure for efficient operation.

Advantages of the Hydrophore System:

- Prevents pump wear and tear by reducing the need for frequent cycling.

- Maintains stable pressure in systems like freshwater lines, fire suppression, and sprinklers.

- Efficient use of energy, as the pump runs less frequently, only when the tank needs to be refilled.

- Reduces pressure fluctuations, ensuring a smooth and reliable water supply.

Charging of Hydrophore System

Charging of the Hydrophore System:

Charging a hydrophore tank is essential to ensure the proper balance of air and water for maintaining stable pressure. The process involves adding compressed air to the tank after filling it with water, which helps pressurize the system. Here’s a step-by-step guide:

Steps to Charge the Hydrophore System:

- Release Existing Pressure:

- Open the vent to release any air or pressure that may already be in the hydrophore tank. This ensures you start with a tank that is ready to be filled and charged.

- Fill the Tank with Water:

- Start the pump to begin filling the tank with water.

- Monitor the sight glass to see the water level. Fill the tank until it reaches about 70% capacity. This leaves space for the air to be compressed, which is necessary for pressurizing the system.

- Close the Vent:

- Once the tank is filled to the desired level, close the vent to seal the system and prevent further air from escaping.

- Add Compressed Air:

- Open the valve for low-pressure air supply to begin adding compressed air to the hydrophore tank.

- Quickly charge the tank to 4.5 bar air pressure. This initial pressurization ensures the system starts operating at a safe pressure level.

- Gradually Increase Pressure:

- Gradually increase the air pressure to reach 5 to 5.5 bar, or the level recommended by the manufacturer. Be cautious to avoid over-pressurizing the system, which could cause problems, such as excessive water coming out of the taps.

- Monitor the Water Level:

- Ensure there is always water visible in the gauge glass during operation. This indicates that the balance between air and water is being maintained correctly.

- Transfer the System to Auto Mode:

- Once the tank is properly charged, switch the system to auto mode.

- In this mode, the pump will:

- Cut in (start) at 4.5 bar (or 2.5 bar in smaller vessels or industries).

- Cut out (stop) at 5 to 5.5 bar, ensuring that the system maintains steady pressure without overloading the pump.

- Avoid Overloading:

- Ensure the tank is not overloaded with air pressure, which can cause water to come out of the taps due to excessive pressure in the system.

Key Points to Remember:

- Ensure the water level is around 70% before charging with air.

- Gradually increase air pressure to 5-5.5 bar as per manufacturer recommendations.

- Avoid over-pressurizing, which can damage the system or cause operational issues.

- Always monitor the system while charging to ensure proper pressure and water balance.

By following these steps, you ensure that the hydrophore system operates smoothly and efficiently, providing stable water pressure with minimal wear on the pump.

By following these steps, you can manually charge the hydrophore tank and set it to auto mode, allowing the system to regulate the water pressure and pump operation. Remember to consult the manufacturer’s recommendations for specific pressure settings and guidelines.

Video

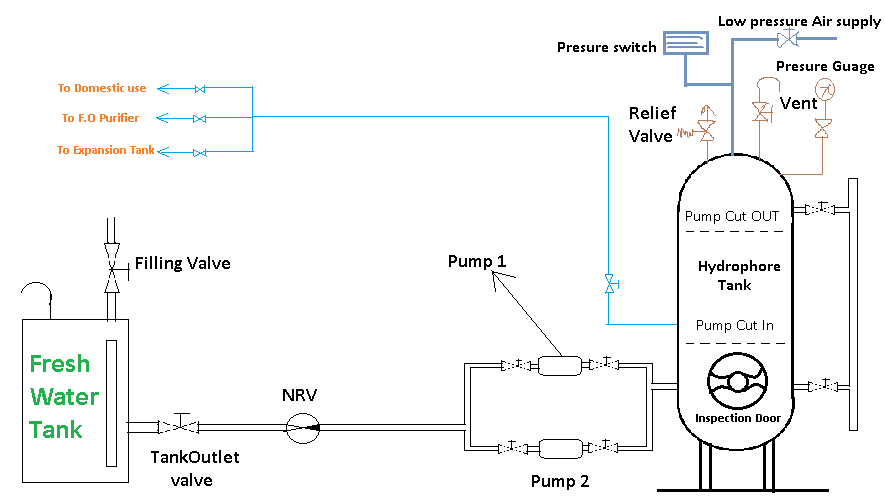

Mountings Of Hydrophore System

These are Mountings fitted on Hydrophore System;

- Fresh water pump ( 1 and 2)

- Vent

- Suction and discharge valve

- Non return valve

- Hydrophore tank

- Low pressure air line (4.5 bar)

- Pressure switch

- Fresh water tank

- Pressure gauge

- Inspection gauge

- Gauge glass

- Relief valve

What is the reason why the hydrophore pump is running continuously?

Continuous operation of the hydrophore pump can lead to inefficiencies and increased wear and tear on the system. Here are the main reasons why a hydrophore pump may run continuously:

1. Inadequate Air Pressure:

- Insufficient Charging: If the air pressure in the hydrophore tank is too low, it will not effectively pressurize the water, causing the pump to run continuously to try to maintain the required system pressure.

- Charging Air Correctly: It’s essential to follow the manufacturer’s instructions for charging the air to ensure optimal performance. If the air pressure is below recommended levels, the pump will cycle frequently.

2. Incorrect or Defective Pressure Switches:

- Pressure Switch Issues: If the pressure switches are incorrectly calibrated or defective, they may not signal the pump to shut off when the desired pressure is reached. This can lead to continuous operation even when it is not necessary.

- Calibration Problems: Regular maintenance and calibration of pressure switches are vital to ensure they function correctly and provide accurate readings.

3. Pump Problems:

- Loose Suction Lines: If the suction line has loose connections, it can lead to air leaks or insufficient water intake, causing the pump to work harder and run continuously.

- Low Capacity: A pump that is not functioning at its rated capacity due to wear or damage will struggle to maintain pressure, leading to extended operation times.

- Increased Water Consumption: If there is an unexpected increase in water consumption (e.g., more outlets being used simultaneously), the pump may not be able to keep up with the demand, resulting in continuous operation.

4. Additional Factors:

- Blocked Filters or Valves: Clogged filters or closed valves in the system can restrict water flow, causing the pump to operate continuously in an effort to maintain pressure.

- Faulty Components: Other components in the hydrophore system, such as check valves or air separators, could be malfunctioning, contributing to the continuous running of the pump.

What is a hydrophore system?

It is a system system used in tall buildings and Ship to maintain water pressure at Different height.

What is hydrophore tank in ship?

A hydrophore tank is a pressurized vessel used for drinking or technical water supply when the pipeline pressure is low.

How does a fresh water generator work?

Fresh Water Generator Works on the Principle of Decreasing Boiling Point of Water by decreasing the Pressure.

For More Information :- Fresh Water Generator

How does hydrophore tank work?

The hydrophore system is based on one of the most basic principles known as “Water is incompressible.” Water is stored in the engine room’s hydrophore tanks, which are then pressurized with compressed air from the air bottle via a pressure reducing valve.

How do you adjust a hydrophore pressure switch?

Pressure is adjusted by adjusting pressure knob provided on pressure switch.

Is fresh water generator water safe to drink?

Yes

must read : Tappet Clearance

Follow me on Twitter