In this article, we are going to learn about Autocollimator, what it is used for, its working principle, how it works, different types of auto collimator, and its advantages and disadvantages.

What is Autocollimator ?

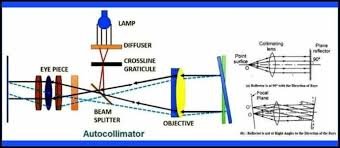

The autocollimator is an optical instrument which is used for the measurements of small angular differences, changes or deflections. It is also used to determine straightness, flatness, alignment, etc.

An autocollimator is a device that uses optics to measure small angular variations. This device is extremely sensitive to very small angle changes and can measure angular deviations accurately. It’s essentially a collimator and an infinity telescope combined. Autocollimators are used to align the various components of a system and measure their mechanical or optical deflections.

Parts of an Autocollimator

Six parts of Autocollimator are :-

- Light source

- Reflecting surface

- Diverging lens

- Beam splitter

- Target graticule

- Micrometer microscope

1. Light source

The light source is used to generate light rays so that it reaches the reflector.

2. Reflecting Surface

It is the surface that serves as a workpiece for the autocollimator. The angle of tilt of this reflecting surface is to be measured using the autocollimator. It reflects the parallel light rays that pass through the objective lens.

3. Diverging Lens

The diverging lens, also known as the objective lens, is used to parallelize the light rays that come through the beam splitter so that they reach the reflector in parallel.

4. Beam Splitter

The beam splitter is used to split the light rays and direct it towards the objective lens.

5. Target Graticule

The light rays that have been reflected reach this target graticule, and the distance between the incident and reflected rays is traced in this target graticule.

6. Micrometer Microscope

It is used to clearly see the incident and reflected ray points in the target graticule and measure the distance between them.

Autocollimator Working Principle

An Autocollimator working incorporates two optical principles:

- The projection and reception of a parallel beam of light by a lens,

- And the change in direction of a beam reflected from a plane surface with changing of angle of the surface.

When a monochromatic light source’s beam of light rays falls on a beam deflector, the beam is deflected 90 degrees towards the converging lens. The converging lens parallelizes the beams and directs them to the object or reflecting surface.

To keep the light beam parallel, keep the beam deflector close to the focus of the converging lens. The parallel rays are then directed to strike a reflecting surface or an object. If there are no angular deviations on the object’s surface, the rays reflect back and proceed along the same path, in the opposite direction, eventually converge at the receiver kept at the focal distance from the converging lens. If the object is inclined at an angle, the reflected ray forms an angle with the incident beam of 2(α) degrees.

Let us understand by a example

Imagine, first of all, a converging lens with a point source of light O at its principal focus, as in Figure (a). When a beam of light strikes a flat reflecting surface, a part of the beam is absorbed and the other part is reflected back. If the angle of incidence is zero, i.e. incident rays fall perpendicular to the reflecting surface, the reflected rays retrace the original path as in Figure (a).

When the surface is tilted at any other angle, the total angle through which the light is deflected is twice the angle through which the mirror is tilted, and is brought to a focus in the same plane as the light source but to one side of it, as in Figure (b). Obviously,

OO’ = 20f= x (say), where f is the focal length of the lens.

Thus, by measuring the linear distance QO'(x), the inclination of the reflecting surface o can be determined.

The position of the final image does not depend upon the distance of the reflector from the lens. That is, the separation x is independent of the position of the reflector from the lens. If, however, the reflector is moved too long, the reflected ray will then completely miss the lens and no image will be formed.

In actual practice, the work surface whose inclination is to be obtained forms the reflecting surface and the displacement x is measured by a precision microscope that is calibrated directly to the values of inclination Θ.

Working of Autocollimator

Let’s understand how does an autocollimator work. In autocollimators, the reflective surface is the surface whose inclination is to be measured using this device. A micrometer microscope is used to measure the distance between the source of light and the reflected ray in the focal plane.

First, the light source is illuminated, and the light line’s rays are extracted from the intersection points of the cross line target gratitude, which is placed in the objective lens’s focal plane.

After that, a ray of light reach the beam splitter and the v ray beam is the gate that will direct the light rays towards the objective lens.

The objective lens will parallelize the light rays and the light rays will move towards the reflector.

Now there can be two cases:

Case 1: The reflector is perpendicular to the ray of light.

When parallel light rays reach a reflector that reflector is perpendicular to the light rays, the light rays are reflected back to their original paths. These light rays are then brought into focus in the plane of the target graticule at the intersection of the graticule’s cross lines. Because some of the reflected light passes straight through the beam splitter, the return image of the target crossline is visible through the eyepiece, allowing the telescope to operate as if it were focused at infinity.

Case 2: The reflector is tilted at some angle.

If the reflector is tilted at an angle, the parallel light rays reflect at an angle twice the angle of tilt.

After the reflection, light rays are focused in the plane of the target graticule but linearly displaced from the intersection of crosslines by a distance of 2 * (angle of tilt) *. (focal length of the objective lens).

Depending on whether a visual or digital autocollimator is used, the linear displacement of the graticule image is measured using an eyepiece graticule and a micrometer microscope or an electronic detector system.

Most autocollimators are calibrated so that the distance measured does not need to be converted into the angle of inclination. This is converted in the autocollimator, and the angle of inclination can be read directly there. The focal length and effective aperture of an autocollimator are the factors that determine its basic sensitivity and angular measuring range.

Types of Autocollimator

There are mainly two types of Autocollimator :

1. Visual Autocollimator

In visual autocollimator, the angle of tilt of the reflecting surface is measured by viewing a graduated scale through an eyepiece. As the focal length of the visual autocollimator increases, the angular resolution increases and the field of view decreases. Visual autocollimators can also measure multiple surfaces simultaneously, making them perfect for alignment tasks like checking the parallelism of optical components.

2. Digital Autocollimator

In digital autocollimator, the micrometer adjustment is provided for the setting but the coincidence of setting graticule and the target image is detected photo-electrically. This autocollimator is used in the lab. Digital or electronic autocollimators are used for precise tasks such as calibrating rotary tables, checking angle standards, and providing angular feedback. These devices are significantly more accurate than visual autocollimators, offering up to 100 times greater precision. They also improve repeatability, meaning measurements can be consistently reproduced, and they reduce the time needed for measurements.

What is the formula for the autocollimator?

Mathematical formula for the autocollimator : In the above autocollimator diagram, the angle of the y-axis mirror displacement ( α ) is calculated using the formula α = Δy/2f where f = focal length of the autocollimator.

Applications of Autocollimator

Autocollimators are widely used in the optical industry and by mechanical engineers for various applications. Their specific functions include precision alignment, detecting angular movement, verifying angle standards, and monitoring angular changes over long periods.

Testing Applications

Autocollimators are employed in testing:

- Parallelism with a collimator and telescope

- Opaque wedges and plane parallel plates

- Transparent wedges

- Angles in glass prisms

- The accuracy of rotary tables and index tables

- Camera objectives

These optical instruments are also used for testing the flatness of reflecting surfaces, controlling wedges and plane parallel plates, and measuring the parallelism of cylindrical bores.

Measurement Applications

In addition to testing, autocollimators are used to measure:

- The radius of concave and convex spherical surfaces

- The back focal length of lenses and optical systems

- Centration error of spherical surfaces

- Centration error of lenses in transmission

- Parallelism or perpendicularity of two surfaces

Additional Applications

Autocollimators also serve in:

- Measuring the radius of concave and convex spherical surfaces

- Measuring the relative angular error of prisms

- Measuring pitch and yaw of slides

- Setting rolls in parallel

- Checking the straightness of machine tool slideways

- Measuring very small angles

- Checking parallelism

- Checking the squareness of a column to its base

- Checking the flatness of bed plates and surface tables

- Measuring very small displacements

- Checking small linear displacements

Advantages of Autocollimator

- It has very high accuracy.

- It can measure a wide range of angles.

- It is very easy to install and operate.

- Calibration surpassing international standards.

- It can be used to visually or electronically view the result, i.e., on the computer screen.

- A wide range of available accessories and levels.

Disadvantages of Autocollimator

- Maintenance is required regularly.

- It is time-consuming.

- It requires sample cutting and processing for tracing by the detector.

We have tried to cover all the topics related to Autocollimator, from definition to advantages, disadvantages, types and working principle. If you liked the article , Please share it with your friends.

Frequently Asked Questions – Autocollimator

What is Autocollimation method?

In autocollimation, a collimated beam (of parallel light rays) leaves an optical system and is reflected back into it by a plane mirror. It’s used to determine the minor tilting angles of the mirror.

What is autocollimator used for?

Autocollimator is used for checking straightness, flatness, alignment, and similar measurements in both mechanical and optical systems.

Is autocollimator used for flatness?

Yes, an autocollimator is used to measure flatness. It helps in detecting very small angular deviations and can determine the flatness of surfaces by measuring how much they deviate from a perfectly flat reference plane.

Check Out Other Important Topics

Cast Iron – Properties, Types & Uses

Recovery Recrystallization and Grain Growth – Working Process