Recovery recrystallization and grain growth are microstructural changes that occur during annealing after cold plastic deformation and/or during hot working of metals.

Recovery Recrystallization and Grain Growth

Plastic deformation, which distorts the crystal lattice and breaks up the blocks of initial equiaxed (having axes of approximately the same dimensions) grains to produce fibrous structure or thin plates, increases the energy level of metal.

Deformed metal, in comparison with its undeformed state, is in a nonequilibrium, thermodynamically unstable state. Therefore, spontaneous processes occur in strain-hardened metal, even at room temperature, which bring it into a more stable condition.

If the temperature is raised sufficiently, the metal attempts to approach equilibrium through three processes : (a) recovery, (b) recrystallisation, and (c) grain growth.

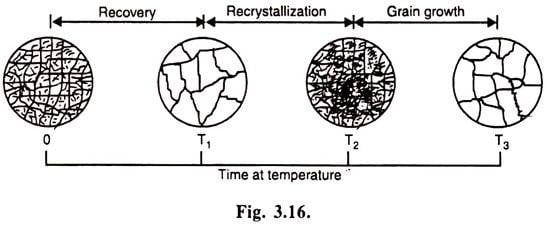

Figure 3.16 depicts a systematics of these processes with time variation. New grains begin to nucleate from cold worked grains at time T1; grain nucleation will continue and grow until time T2. By this point, all of the cold worked grains will have nucleated into new grains. At time T3, the size of these new grains grows at a slower rate.

A schematic drawing indicating recovery, recrystallisation and grain growth and the chief property changes in each region is shown in Fig. 2.9.

Recovery

What is Recovery ?

It is a low-temperature phenomenon that results in the restoration of physical properties without noticeable change in microstructure. The recovery is critical for releasing internal stresses in forging, welded, and fabricated equipment without reducing the strength gained during and after working.

Working

If a strain-hardened metal is heated to a comparatively low temperature, the elastic distortions of the crystal lattice are reduced due to the increase in amplitude of thermal oscillation of the atoms. This heating will slightly lower the strength of the strain-hardened metal but the elastic limit and ductility will increase, though they will not reach the values possessed by the initial material (before strain-hardening).

No changes in microstructure are observed in this period. This partial restoration of the original properties, produced by reducing the distortion of the crystal lattice without noticeable changes in microstructure, is called recovery.

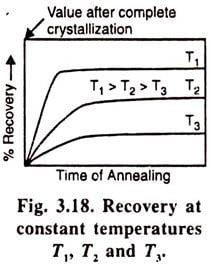

At given a temperature the rate of the recovery is fastest initially and drops off at longer times. Thus the amount of recovery that occurs in a practical time increases with increasing temperature. In a given cold worked metal the individual properties recover at different rates and attain various degrees of completion.

Characteristics Curve of Recovery

Figure 3.18 depicts the characteristics of the recovery process. The figure shows that I the rate of recovery is fast at first and then slows down with time, and (ii) the amount of recovery increases with increasing temperature. Individual properties recover at different rates in metals.

By recovery, stresses are relieved from cold worked alloys which prevent stress corrosion cracking. It is possible to relieve stress without significantly affecting mechanical properties. A high recovery temperature is required to completely remove residual stresses. This high-temperature treatment is beneficial for cast or welded parts.

Recrystallisation

What is Recrystallisation ?

It is a process in which distorted grains of cold worked metal are replaced by new strain free grains when heated above a temperature known as the recrystallization temperature. Recrystallization causes a sharp decrease in hardness and strength while increasing ductility.

Working Process

The formation of new equiaxed grain in the heating process, instead of the oriented fibrous structure of the deformed metal, is called recrystallisation. Equiaxed crystals are crystals that have axes of approximately the same length. Equiaxed grains can be an indication for recrystallisation. Equiaxed crystals can be achieved by heat treatment, namely annealing and normalizing

This is illustrated in Fig. 2.10. The first effect of heating is to form new minute grains as shown in white in (a), and these rapidly enlarge until further growth is restricted by grain meeting another as shown in (b) and (C). Ultimately, the original system of grains go out of the picture and the new crystallized structure is shown at (d), the original grains being indicated in the drawing by dotted lines. Recrystallisation, in fact, does not produce new structures but produces new grains or crystals of the same structure.

Recrystallisation, in essence, consists in having the atoms of the deformed metal overcome the bonds of the distorted lattice, the formation of nuclei of equiaxed grains and subsequent growth of these grains due to transfer of atoms from deformed to undeformed crystallites. In fine, grains are refined and acquire a shape resembling fibers as shown in Fig.2.11.

The temperature at which crystallization takes place, that is, new grains are formed, is called recrystallisation temperature. This is defined as that temperature at which 50 per cent of the cold-worked material will recrystallize in one hour.

Grain Growth

What is Grain Growth ?

It refers to the increase in average grain size caused by additional annealing after the material has recrystallized. Small grains have less free energy than large grains. Smaller crystals with higher energy atoms tend to become a part of larger crystals. This proclivity promotes grain growth.

Working Process

Just after a metal has recrystallized, the grains are small and somewhat regular in shape. The grain will grow if the temperature is high enough or if a the temperature is allowed to exceed the minimum required for recrystallisation. This growth is the result of a tendency to return to more stable and larger state, and appears to depend primarily on the shape of the grain.

For any temperature above the recrystallization temperature, normally there is practical maximum size at which the grains will reach equilibrium and cease to grow appreciably, no matter how long they are held at the temperature. There are, however, certain kinds of abnormal grains growth that occur as a result of applied or residual gradients of strain due to nonuniform impurity distribution, and which permit growing very large single grains.

Factors Affecting Controlling Grain Size

1. Degree of Prior Deformation

The increased amount of prior deformation promotes nucleation and reduces final grain size. Before recrystallization can occur, a certain amount of deformation is required. This is approximately 2.8 percent of the total deformation. When deformation is small (but greater than the minimum deformation), the grain size is coarse because a small number of nuclei are formed. As deformation increases, the number of distorted points increases, and thus grain size decreases.

2. Temperature

There is a temperature below which recrystallization does not occur. The grain size gradually increases above this temperature.

3. Heating

The effect of heating time on grain size is determined by the temperature at which recrystallization occurs. Recrystallization takes a certain amount of time to complete, but this amount of time decreases as temperature rises. The finer the grain size, the shorter the annealing time. The grain becomes coarser as the annealing time increases. Slow heating promotes grain growth by forming new nuclei, resulting in coarse grain.

4. Impurities

Finer grain size will be present with a greater amount and finer distribution of impurities. Impurities promote nucleation and act as a barrier to grain growth.

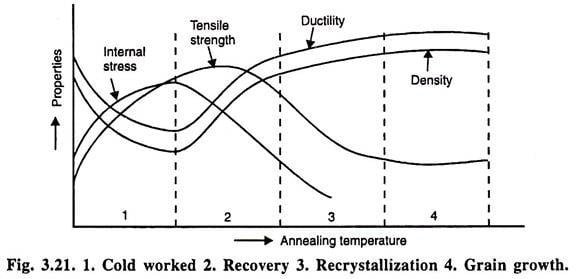

Effect of Temperature on Recovery Recrystallisation and Grain Growth

Fig. 3.21 summarizes the effect of various phenomena on mechanical and physical properties.

Q. In which of the following processes does recovery recrystallization and grain growth take place?

a) Surface hardening

b) Tempering

c) Strengthening

d) Annealing

Answer :- D

Explanation :- In the process of annealing, the crystal goes through three stages which are called recovery recrystallization and grain growth in order.

Frequently Asked Questions

What is the difference between recovery and recrystallization?

Recovery – A low-temperature annealing heat treatment designed to eliminate residual stresses introduced during deformation without reducing the strength of the cold worked material.

Recrystallization temperature – The temperature above which the effects of strain hardening are eliminated during annealing.

What is the difference between recovery recrystallization and grain growth?

Recovery occurs at low temperatures and reduces or eliminates work hardening effects.

Recrystallization occurs when sufficient thermal energy is available to drive the creation and strain-free growth of new grains in the existing matrix.

Grain growth is the result of continued high temperatures past recrystallization as the grain boundaries are eliminated, resulting in an increase in the present grain size regardless of its prior austenitic grain size.

Why is cold work required for recovery?

Cold working increases the strength of a material, but decreases its ductility and electrical conductivity. In addition, residual stresses are introduced into the material because of the over-lapping and tangling of dislocations.

What are the driving forces for recrystallization and grain growth?

The driving force for grain growth, being it continuous (normal grain growth) or discontinuous (abnormal grain growth), is the energy of the high angle boundaries. The main driving force for recrystallization to occur is the stored energy during straining in the form of crystalline defects.

Check Out Other Important Topics

Foundry Tools And Equipment – List, Names & Images

Sand Testing Methods – Full Process

Types of Casting Defects – Complete Overview

Moulding Sand – Properties, Types, Process, MCQs

Plant Layout – Types, Objectives, Principles, Advantages

| IC Engine | Important PDFs | Boilers | Synergy Maritime Exam | Naval Arch | MEO Class 4 |

| Interview Questions | Difference Between | Types of Pumps | Auxiliary Machines | Types of Valves | Home |