Tappet clearance is a crucial aspect of vehicle engine maintenance that should not be ignored. It refers to the clearance or gap between the camshaft and valve in an engine. It plays a significant role in ensuring optimal engine performance and longevity. Regular tappet clearance adjustment can prevent engine damage, increase fuel efficiency, and reduce engine noise.

Without adequate tappet clearance, there is a risk of valve damage and potential harm to the engine. Therefore, it is necessary to maintain the appropriate clearance to keep the vehicle running smoothly. In this article, we will provide you with a comprehensive guide on tappet clearance, its purpose, and the importance of regular maintenance. We will also discuss how to check and adjust the valve tappet -clearance and the common signs of tappet- clearance issues.

What is Tappet clearance?

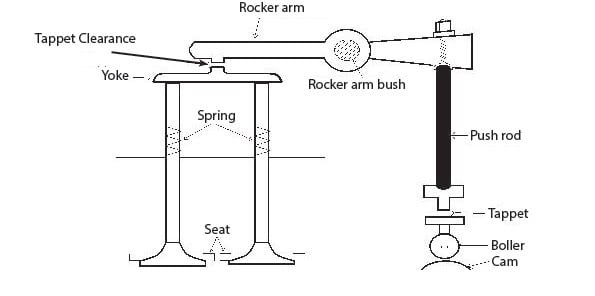

Tappet clearance is the small gap between the rocker arm and the top of the valve stem (Yoke). It is an important factor in determining the timing and duration of valve opening and closing, which affects engine performance and efficiency.

Some Other Definitions are mention below :

It is nothing but a gap between the rocker arms and the point where they rest on the stem of valves. These Both surfaces are flat.

Note :- It is also known as valve lash (in some book ).

Conditions for Tappet clearance?

It can be only adjusted when the valves are closed and the engine is cooled during the compression stroke. It is taken when the inlet and outlet valves are in closed position & engine at the cooled condition at the compression stroke.

When Tappet Clearance of Inlet and exhaust Valve is taken ?

As with any engine maintenance task, checking tappet clearance should be done at particular intervals or when certain conditions arise. To ensure that the engine valve mechanism performs optimally, tappet clearance must be inspected and adjusted according to the following conditions:

- According to running hours mentioned in the engine manual. Running hours depend on the types of engine. , model or size: Checking tappet clearance after every running is recommended. This interval can vary depending on the make and model of the vehicle, so it’s essential to consult the owner’s manual to determine the right maintenance schedule. Regular inspections can prevent significant damage and expense down the line.

- Unusual engine noise: Abnormal engine noises, such as clicking or ticking sounds, can indicate that the tappet clearance is not correct. A quick inspection can help diagnose the problem before it becomes more serious.

- Engine overheating: If the engine overheats frequently, it can cause wear and tear on the engine’s components, including the valve mechanism. In such cases, it’s wise to check the tappet clearance and adjust it if necessary.

- Low engine compression: Low engine compression can lead to poor acceleration, fuel economy, and other performance issues. It’s essential to check the tappet clearance in such cases as incorrect clearance can cause compression loss.

By keeping an eye out for these conditions and adhering to the set maintenance schedule, you can ensure proper tappet clearance and optimal engine performance.

Tappet Clearance Purpose ?

The purpose of Tappet Clearance is to allow some mechanical expansion and lengthening of the valve stem and push rods when the engine warms up.

The primary function of tappet clearance is to allow for a small expansion gap between the valve stem and pushrods to accommodate the effects of a heated engine.

If this is not done, the valve will not sit properly as the engine heats up. As previously stated, this could eventually result in power loss, engine irregularities, and other issues.

why tappet clearance is required ? Why it is Required ?

The requirement of clearance is answered as, to maintain correct timing ( change in clearance will lead to an early or delayed opening of the inlet or exhaust valves ).

Note :- It needs to be adjusted for proper opening and closing of valves of the diesel engine.

The valve is one of the most critical parts of the engine. It controls the flow of air and fuel into the engine and the exhaust gases out of the engine. The valve opens and closes by the movement of the rocker arm, which is connected to the camshaft. Tappet clearance affects the valve operation by controlling the timing and duration of valve opening and closing.

- Timing: Tappet clearance plays a crucial role in determining the timing of valve opening and closing. The correct tappet clearance ensures that the valve opens and closes at the right time, allowing the engine to operate efficiently.

- Duration: The duration of the valve opening and closing is also affected by tappet clearance. The appropriate clearance ensures that the valve stays open for the right amount of time, allowing enough air and fuel to enter the engine.

Therefore, maintaining the correct tappet clearance is essential for optimal engine performance and longevity. It helps ensure that the engine runs smoothly, efficiently, and with minimal wear and tear.

In simple, it is required to maintain proper timing of opening and closing of valve without any delay or early inlet opening.

Effect of Incorrect Tappet Clearance of Exhaust Valve

Having incorrect tappet clearance in a vehicle’s engine can lead to a host of issues affecting the overall performance and longevity of the engine. Let’s take a look at some of the effects that can result from improper tappet clearance:

- Valve Damage: Insufficient tappet clearance can cause the valves to remain partially open, leading to overheating and ultimately damaging the valves.

- Decreased Engine Performance: Incorrect tappet clearance can reduce engine power and torque output, resulting in poorer overall performance.

- Increased Fuel Consumption: When tappet clearance is too tight, the engine has to work harder to operate, resulting in increased fuel consumption and higher expenses for the vehicle owner.

- Noisy Engine: When tappet clearance is too loose, it can cause the engine to produce a knocking or ticking sound, which can be annoying and an indication of a more severe underlying problem.

It is essential to maintain the correct tappet clearance to avoid these issues and ensure that your vehicle’s engine operates smoothly and efficiently for as long as possible.

What Will Happen if Tappet Clearance Less :-

If the clearance decreases– The valve will open early and close late.

The valve will open sooner and close later if the clearance decreases. This is due to the rocker arm remaining connected to the valve for an extended period of time. We get a larger contact area between the valve stem and rocker arm with less clearance. As a result, the rocker arm pushes the valve down for a longer period of time, keeping the valve open for longer.

- Valve will open early and close lately.

- Air induced in combustion chamber for combustion through an inlet valve may leak out. So, less air will be available for combustion.

- Power of the engine will be reduced.

- Fuel consumption by engine will increase, and engine may become unbalanced and the exhaust temperature will be very high.

- The valve may remain open, in worst conditions, resulting in loss of compression pressure of the engine, burning of the exhaust valve and increase in turbocharger fouling.

What will happen if Tappet clearance is more :-

If the clearance increases– The valve will open late and close early.

If the clearance increases, the valve will open slowly and close quickly. Because there is more clearance, the contact area between the valve stem and rocker arm is smaller. As a result, the valve remains open for a shorter period of time but closed for a longer period of time (which explains the delayed opening).

- The valve will open lately and close early.

- It reduces the maximum lift of the valve.

- Less heat energy to the turbocharger of engine, cause reduction in the scavenge air and hence power decrease.

- There is no proper removal of the exhaust gas.

- Hammering of the v/v stem cause damage to the valve stem.

- It causes noise and eventually damage the working surface.

How to check Tappet clearance ?

Tappet Clearance is checked by using feeler gauge by putting in between the space of rocker arm and the Space where valve stem sit.

Checking the tappet clearance is a crucial part of engine maintenance. It ensures that the valve is opening and closing at the correct time, and the engine is running smoothly. Here is a step-by-step guide on how to check the tappet clearance:

- First, make sure the engine is cool before checking the tappet clearance. This will prevent any damage to the components.

- Locate the valve cover and remove it from the engine.

- Locate the camshaft, which is responsible for opening and closing the valves, and the rocker arm, which pushes on the valve stem to open and close the valve.

- Identify the valve that needs to be checked and find the corresponding rocker arm. Use a wrench to loosen the lock nut on the rocker arm.

- Insert a feeler gauge between the rocker arm and the valve stem. The feeler gauge should be a tight fit but not too tight that it cannot be inserted. Measure the clearance by noting the thickness of the feeler gauge.

- If the clearance is too tight or too loose, adjust it by tightening or loosening the lock nut on the rocker arm. Recheck the clearance to ensure it is within the manufacturer’s recommended specifications.

- Repeat the process for each valve in the engine.

- Once all the valves have been checked, replace the valve cover and start the engine. Listen for any abnormal noises or vibrations. If everything sounds normal, you have successfully checked the tappet clearance!

Regularly checking the tappet clearance can prevent issues such as valve damage and poor engine performance. It is recommended to check the tappet clearance every 10,000 miles or as specified by the manufacturer.

How to Know Which Unit is at TDC?

To check clearance, first sure that the unit you are going to check should be in Top Dead Centre ( TDC ).

The position of piston is At TDC checked by

- The flywheel marking

- The fuel pump mark

- The checking the camshaft fuel

- The valve cam position.

If it is not at TDC then we use turning gear to make that unit at TDC. ( Note :- During turning make sure that indicator cock is open ).

Usually, there are 6-8 units in four stroke engines. So at the same time, the flywheel will show two units at TDC.

To make sure that particular unit is on the compression stroke and not at the power stroke, you can turn the push rods of both units by hands to check.

The one with free push rods is the one which is at compression stroke and the one with tight push rods is at power stroke.

So avoid the one which is at power stroke.

Now you need good filler gauges of different thickness.

Now gently try to push these filler gauges between the clearance of valve and rocker arm.

You may have to try different thickness. Just check in the manufacturer manual as for how much standard clearance should be.

Now you know that your clearance is less or more

How to Adjust Valve Tappet clearance / Adjustment Procedure

Prepare the following tools for Checking and Adjusting Tappet clearance of Valve :-

Feeler gauge of different thicknesses.

Adjusting the valve tappet clearance requires precision and careful attention. Here are the steps to follow:

- Start by removing the valve cover from the engine. This will expose the valves and valve springs.

- Rotate the engine until the camshaft lobe for the valve you wish to adjust is facing upwards.

- Insert a feeler gauge between the valve stem and the rocker arm. You should feel a slight drag when sliding the gauge back and forth.

- If the clearance needs adjustment, use an appropriate wrench to loosen the lock nut on the rocker arm and turn the adjustment screw until you achieve the desired clearance. Typically, the clearance specs can be found in the vehicle owner’s manual.

- Once the clearance is set, hold the adjustment screw in place and tighten the lock nut to secure the adjustment. Double-check the clearance with the feeler gauge to ensure it matches the desired specification.

- Repeat these steps for all the valves you need to adjust.

- Once you finish the adjustment, replace the valve cover and all other components you removed earlier.

Remember, precise measurements and adjustments are essential for optimal engine performance. If you are unsure or lack experience, it is best to consult a professional mechanic to perform tappet clearance adjustments.

Note:- When you move filler gauges while adjusting for particular clearance, you should be able to slide it smoothly (not too tight and not too loose ).

Importance of Regular Tappet Clearance Maintenance

Maintaining the proper tappet clearance is essential for the optimal performance and longevity of a vehicle’s engine. Regular maintenance of the tappet clearance should be a part of every vehicle’s maintenance schedule. Neglecting this maintenance can lead to numerous issues, such as decreased engine performance and fuel efficiency, increased engine noise, and in severe cases, valve damage or engine failure.

By incorporating tappet clearance maintenance into your regular vehicle maintenance routine, you can prevent these issues and ensure your engine runs smoothly. Periodic tappet clearance adjustments and inspections can help to optimize fuel efficiency, reduce engine noise, and extend your engine’s lifespan. Additionally, regular maintenance can save you money in the long run by preventing costly repairs due to engine damage resulting from neglected maintenance.

Make sure to consult your vehicle’s owner manual for the recommended tappet clearance maintenance schedule. Regular maintenance will keep your engine running smoothly, protect your investment, and provide a more enjoyable driving experience.

Common Signs of Tappet Clearance Issues

Regular maintenance of tappet clearance is crucial for optimal engine performance. Failure to maintain the correct clearance can lead to various engine problems. Here are some common signs that may indicate tappet clearance issues:

- Excessively loud or unusual engine noises, especially when accelerating or idling

- Inconsistent or rough engine performance, including misfires or hesitation

- Decreased fuel efficiency

- Increased engine vibrations or shaking

If you observe any of these signs, it is important to check the tappet clearance as soon as possible. Ignoring these symptoms can lead to more severe engine damage and costly repairs. Regular inspection and adjustment of tappet clearance can prevent these issues from occurring in the first place, ensuring smooth engine operation and prolonged engine life.

Tools and Equipment for Tappet Clearance Adjustment

Adjusting the tappet clearance in a vehicle’s engine requires specific tools and equipment to ensure accurate measurements and adjustments are made. Here are some of the essential items needed:

- Feeler Gauges: These are used to measure the tappet clearance accurately. They come in different thicknesses, depending on the clearance required for a particular engine.

- Wrenches: Different types of wrenches, such as a socket wrench or an adjustable wrench, may be needed to access and adjust the tappets.

- Screwdriver: A flat-head screwdriver may be necessary to adjust the tappets, depending on the engine’s design.

- Valve Cover Gasket: The valve cover gasket must be removed to access the tappets, and a new gasket is essential when reassembling the engine.

- Shop Towels: It is crucial to keep the engine clean during the adjustment process. Shop towels can be used to wipe any excess oil or debris that may be present.

When performing tappet clearance adjustment, it is essential to follow the manufacturer’s instructions and guidelines carefully. It is also important to take necessary safety precautions, such as wearing gloves and protective eyewear.

Overall, having the right tools and equipment for tappet clearance adjustment is crucial in maintaining a vehicle’s engine performance and longevity. Regular maintenance and adjustments can prevent costly repairs and ensure optimal engine efficiency.

Tappet Clearance Tool

The valve tappet clearance is measured by

A. Vernier Calliper

B. Feeler gauge

C. Screw Pitch Gauge

D. Engineering Scale

Ans :- B. Feeler gauge

what is Tappet clearance

Tappet clearance refers to the small gap or space between the engine valve and the tappet, which is a component that helps control the valve operation. It is an essential adjustment that ensures smooth and efficient engine performance.

How much is tappet clearance?

It’s value is such that does not affect the the engine performance. The clearance taken is typically between 0.2mm and 0.6mm, depending on the inlet and exhaust valves and engine manufacturer.

Why is tappet clearance important?

Tappet clearance is necessary to prevent valve damage, optimize fuel efficiency, and reduce engine noise. Incorrect tappet clearance can lead to various engine problems, which can be costly to repair.

What is the purpose of tappet clearance?

The purpose of tappet clearance is to control the timing and duration of valve opening and closing. It allows for proper fuel combustion, optimal power delivery, and helps prevent valve damage. Maintaining the correct clearance ensures efficient engine operation and prolongs the engine’s lifespan.

Why is tappet clearance necessary?

Tappet clearance is necessary for several reasons. It helps prevent valve damage by ensuring the valve closes completely and does not contact the piston. Correct clearance also optimizes fuel efficiency by promoting proper combustion. Additionally, it reduces engine noise by preventing valve striking and improves overall engine performance.

When should tappet clearance be checked?

Tappet clearance should be checked under specific conditions or situations. It is recommended to check it during routine engine maintenance, after a significant change in engine temperature, if abnormal engine noise is detected, or after certain running hours. Checking tappet clearance regularly helps identify any necessary adjustments.

What are the effects of incorrect tappet clearance?

Incorrect tappet clearance can lead to various issues. If the clearance is too tight, the valve may not fully close, resulting in poor compression and power loss. On the other hand, too much clearance can cause noisy valve operation, reduced engine performance, and increased fuel consumption. It is crucial to maintain the correct clearance for optimal engine function.

How do I check tappet clearance?

To check tappet clearance, you will need a feeler gauge and a service manual for your specific vehicle. Start by removing the valve cover, locate the tappets and valves, and follow the manual’s instructions to measure the clearance using the appropriate gauge. It is important to perform this task with the engine at the correct temperature and in the recommended sequence outlined in the manual.

How do I adjust valve tappet clearance?

Adjusting valve tappet clearance requires precision and following the manufacturer’s guidelines. Typically, it involves loosening the locknut and using a wrench or screwdriver to adjust the clearance to the recommended specification. After adjustment, tighten the locknut to secure the setting. It is crucial to recheck the clearance after completing the adjustment.

What are the common signs of tappet clearance issues?

Common signs of tappet clearance issues include excessive engine noise, ticking or clicking sounds, decreased power, rough idling, and poor fuel economy. If you notice any of these symptoms, it is advisable to have your tappet clearance checked and adjusted if necessary to avoid further engine complications.

What tools and equipment are needed for tappet clearance adjustment?

To adjust tappet clearance, you will typically need a feeler gauge, a wrench or screwdriver for locknut adjustment, and a service manual specific to your vehicle. It is also recommended to have a clean workspace, gloves, and safety glasses for protection during the adjustment process.

Check Out Other Important Topics

| IC Engine | Important PDFs | Boilers | Synergy Maritime Exam | Naval Arch | MEO Class 4 |

| Interview Questions | Difference Between | Types of Pumps | Auxiliary Machines | Types of Valves | Home |

Also Read : Bearing Temperature Detector

I’m satisfied by why we should do valve clearance and procedure.

I want to learn more.