Bearings are used to reduce friction and prevent damage of working surfaces. In this article we are going to learn about Journal Bearing / Plain Journal Bearing.

What is Journal Bearing ?

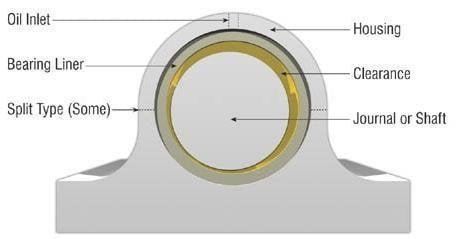

Journal Bearings are also known as Sliding Bearing. It consist of a journal which rotates inside a bearing. Here journal refers to the shaft. The part of the shaft which rotates inside the bearing is known as journal.

It is very simple in construction with no rolling surfaces. The journal slides over the bearing surface and therefore it is also known as Plain bearing for being very simple construction wise.

Journal Bearing Types Based on Lubrication / Journal Bearing Lubrication

1. Hydrodynamic Lubrication

2. Hydrostatic Lubrication

3. Thin Film Lubrication

4. Dry Lubrication / No film Lubrication

1. Hydrodynamic Lubrication

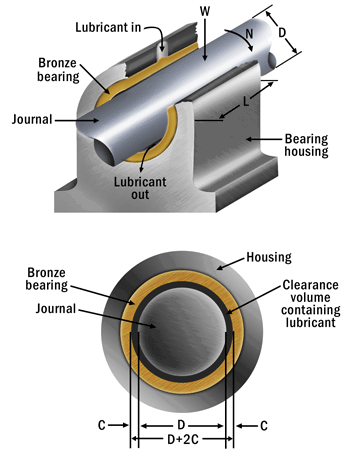

In hydrodynamic journal bearing an oil wedge is formed between the two surfaces. Initially the shaft or the journal rests on the bearing surface. The oil is supplied externally to the bearing.

When the shaft rotates , because of the rotation, the oil starts to form a film between the shaft and the mating surface and because of the squeezing action an oil wedge is formed . This lifts the shaft and now the journal rotates freely without touching the mating surface.

These type of bearings are widely used in high load carrying shafts like compressors or turbines. These are the most widely used type of Journal Bearings.

2. Hydrostatic Lubrication

In hydrostatic journal bearing Lubrication also an oil film is present to avoid the contact between the two surfaces . But in this case the oil is inserted into the bearing with a pressure. This pressure creates a Uniform film across the journal thus preventing contacts between the surfaces. The oil is pressurized using a pump and then transferred to the bearing.

3. Thin Film Lubrication

In Thin Film Lubrication, a very thin layer of oil film is created between the two surfaces to make them contactless.

4. Dry Lubrication

As the name suggest, in such type there is no any oil film created. The shaft rotates inside the bearing without having any fluid in between them, only fine clearances are maintained.

Types of Bearing on basis of Construction

1. Integral / Solid Journal Bearing

Integral plain journal bearings are built into the object of use as a hole prepared in the bearing surface. Integral bearings are not used widely because of restriction in their changeability. Since they are not replaceable once they got wear down as they are integral part of the machine, their use have become very less over a period of time.

Integral plain bearings are generally made up of cast Iron or Babbitt and consist of a hardened steel shaft. The type of materials used in construction makes it very cheap but for the fact that it cannot be replaced it is not so popular.

Example of an Integral bearing is “Hinge”. It comes into both thrust as well as journal bearing.

2. Bushed Journal Bearing

Bushed Journal Bearing is a type of Plain Bearing which is inserted into a housing and act as bearing surface, widely used in Rotary Applications. It is also known as Bush.

This modified version of Solid Bearing is constructed with cast Iron with a rectangular base and two holes provided so that it can be fixed to ground or onto a plate. And is surmounted by a cylindrical base at the top.

It is the modified form of solid bearing and is made up of cast iron rectangular base with two holes to be fixed up on ground or on a plate. A cylindrical block is surmounted at the top of the base.

Materials used in its construction are : Babbitt, Bi-material, brass or bronze. It’s Internal diameter matches with the external diameter of the shaft . It is pressed full tight into the bore preventing any rotation.

The reason of it’s popularity is that the bushes can be replaced when they wear down due to friction. Also for the lubrication, a small hole is made on top of cylindrical block to the shaft.

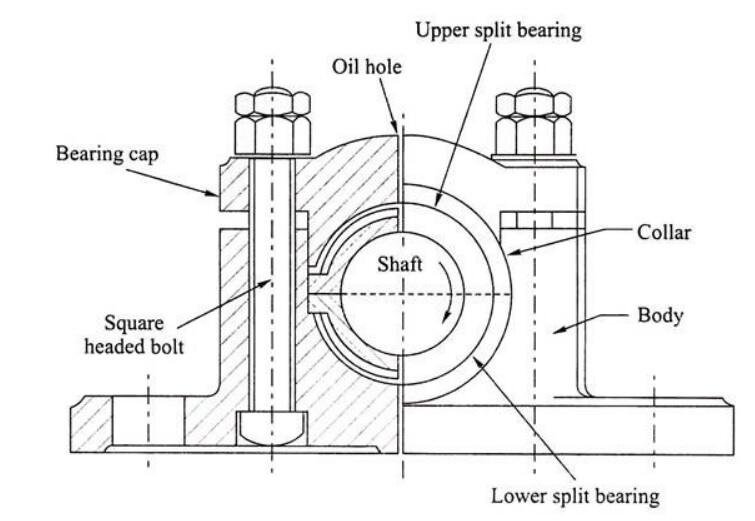

3. Plummer Bearing / Split Journal Bearings

Plummer Bearings are also known as Split Journal Bearings. These are mostly used for large diameters as found in crankshafts. It is constructed into two parts. The lower bottom part which is known as pedestal is constructed of cast Iron. And the upper Part is known as Cap. Both of these parts are connected to each other using two square-headed bolts.

The joining of both the parts forms a hole in the central part of it which is equal to the external diameter of the shaft. A bush of gun metal in two halves is fitted in the hole. To avoid any shifts in bearing dur to rotation along with the shaft a snug is fitted at the bottom part. There are two holes provided in the pedestal base to make it grounded.

Journal Bearing Materials

The Journal Bearings are made from materials which are durable, have low friction, Low wear rate , are able to retain its properties at higher temperatures, and are resistant to corrosion. In general, the bearings consist of minimum two constituents out of which one is soft and the other is harder. The harder the surfaces in contact, lower the chance of seizure because of low coefficient of friction between them.

How does a Journal Bearing Work?

The shaft is fitted inside the journal Bearing in its Shell which is generally made up of soft or porous bearing material. The shaft rotates inside this bearing shell. To reduce friction Lubricants like Oil, Grease or PTFE are added in between the two surfaces. And the Shell is fitted firmly to its Static Housing part so that it does not rotate with the rotation of shaft.

Why Do We Use Split Journal Bearings ?

Split Bearings which are mostly suitable for the areas where it is required for removal of cap in order to do servicing or replace a bearing. Using split type eliminate the removal of pulleys and couplings from the shaft whenever we are replacing the bearing. There is an arrangement of shims provided with the angular parting of cap to compensate for any wear and tear and adjustments.

Journal Bearing Uses

Journal or Plain bearings are most widely used types of Hydrodynamic Bearings. They are used in:

- Supporting a rotating shaft

- Supporting crankshaft

- Supporting Camshafts

- Used in rocker shaft of rocker arm valve train systems

Journal Bearings Vs Ball Bearings

Journal or Plain bearing uses fluid films to support the shaft and avoid any contact between the two mating surfaces. While in Ball bearing the same function is done with the mechanical arrangement of balls to avoid any contact and reduce the friction as well.

Frequently Asked Questions

What is a journal in a bearing ?

Journal Bearings consist of a journal which rotates inside a bearing. The part of the shaft which rotates inside the bearing is known as journal.

What is the use of journal bearing?

These are most widely used of it – Supporting a rotating shaft, Supporting crankshaft, Supporting Camshafts and are Used in rocker shaft of rocker arm valve train systems

What are the types of journal bearing?

There are three main types of journal Bearings on the basis of construction – Solid Bearing, Bushed Journal Bearing, Plummer Bearing

What is the difference between journal bearing and thrust bearing?

Journal bearings are used to handle radial loads (perpendicular to the axis of rotation). While Thrust bearings are used to handle axial loads (along the axis of rotation).

Suggested Read : Functioning of Pistons

Read more : Easiest way to Calculate Brake Horse Power

Check Out Other Important Topics

| IC Engine | Important PDFs | Boilers | Synergy Maritime Exam | Naval Arch | MEO Class 4 |

| Interview Questions | Difference Between | Types of Pumps | Auxiliary Machines | Types of Valves | Home |

[…] This varieties of lubrication primarily happen in journal bearing. […]