Saws can be very simple cutting tools or more advanced machines that use power. The types of saws you need depends on your work or hobbies. People who work in construction might need many different saws for different situations, while some are made for just one job. Carpenters or people who do woodworking at home will need other types of saws, but there might be some that both groups use.

What is a saw ?

A saw is a tool that consists of a strong blade, wire, or chain with a sharp toothed edge. It is used to cut through material, most commonly wood, but also metal and stone. Place the toothed edge against the material and move it forcefully forward and less forcefully back or continuously forward to make the cut. This force can be applied by hand or by a power source such as steam, water, electricity, or another. A powered circular blade on an abrasive saw is designed to cut through metal or ceramic.

For thousands of years, saws have been used to achieve desired needs such as shape, design, and functions. Saws have changed so quickly in the last few hundred years that it is difficult for anyone to be familiar with all types of saws.

Types of Saws

A saw is a tool that can be used by hand or with power to cut materials like wood, metal, or plastic. People have been using saws for a very long time, so there are many kinds with special designs for different jobs. When you learn about the different types of saws, you can use them the right way. Knowing the best tool for a task helps you do a great job on your do-it-yourself projects.

Hand saw

Hand saws, also known as “panel saws,” are used in woodworking and carpentry to cut pieces of wood into various shapes. This is typically done to join the pieces and carve a wooden object. They typically work by utilizing a series of sharp points made of a substance that is harder than the wood being cut. The hand saw is similar to a tenon saw, but it only has one flat, sharp edge.

Backsaw

A backsaw is a type of handsaw with a stiffening rib on the edge opposite the cutting edge that allows for better control and more precise cutting than other types of saws. Backsaws are typically used in woodworking for precise work like cutting dovetails, meters, or tenons in cabinetry and joinery. Backsaws can only cut to a certain depth because of the stiffening rib. Backsaws typically have teeth that are relatively close together, with little or no set.

These types of saws are also known as dovetail saws because they are ideal for making precision and accurate dovetail joints. Because of their fine teeth and narrow blades, these saws are ideal for making precise cuts. Back saws benefit from a stiff piece of metal attached to the opposite side of the cutting edge, such as brass or steel. This gives them greater control and allows them to cut with less force.

Bow saw

A modern bow saw is a metal-framed crosscut saw shaped like a bow and equipped with a coarse wide blade. This saw is also known as a Swede saw, a Finn saw, or a bucksaw. It is a rough tool for cross-cutting branches or firewood with a diameter of up to six inches (150 mm). The name ‘Swede saw’ is most likely derived from the ovate metal tubular frame version invented in the 1920s by the Swedish company Sandvikens Jernverk, as well as additional patents obtained by two Swedish immigrants to the United States. These features are shared by all modern versions.

What is a bow saw good for ?

A bow saw is a much smaller saw designed for single-person use, and it is ideal for cutting logs for a wood stove or open fireplace. It has a “C” shaped frame fitted with a blade lined with rough teeth, suitable for cutting quickly through logs of 5 inches or more, and is typically 2 to 3 feet long.

Coping saw

A coping saw is a type of bow saw used in woodworking or carpentry to cut intricate external shapes and interior cut-outs. It is commonly used to cut moldings in order to create coped rather than meter joints. It is occasionally used to make fretwork, but it cannot match the intricacy of cut of a fretsaw, especially in thin materials. Coping saw blades are always thicker and cut much coarser than standard fretsaw blades and many of their relatives. Coping saws, on the other hand, can cut slight bends in the work, allowing for the cutting of circles if used carefully.

What is special about Coping saw ?

A coping saw is simply a C-shaped steel frame with pivoting blade holders that catch pins on the blade’s ends. The blade is tightened by a few twists of the handle. This tensions the blade, allowing it to cut fast, tight curves in nearly any material.

What is the main purpose of coping saw ?

Coping saws have a thin, narrow blade that allows them to be highly maneuverable and cut tight turns in wood and other materials. Trim carpenters use coping saws to create coped joints, and woodworkers use coping saws to create curved shapes and finish the bottom of dovetail joints.

Crosscut saw

The crosscut saws (thwart saw) are the types of saws which are designed to cut wood perpendicular to (across) the grain. Crosscut saws can be small or large, with small teeth close together for fine work like woodworking or large for coarse work like log bucking, and can be hand or power tools.

What is the crosscut saw used for ?

A crosscut saw is a type of saw best for cutting across the grain of wood. For a clean and accurate notch, its teeth angle backward with a beveled edge while cutting on both the push and pull strokes. Crosscuts can be used to cut logs perpendicular to the grain or in conjunction with a saw hook.

How does the cross cut saw work ?

In general, crosscut saws work by combining one or more sets of cutting teeth with a set of rakers; the cutting teeth, sharpened on opposite sides, sever the fibers on each side of the kerf, while the raker follows behind and planes out the chip. Depending on their intended use, crosscut saws come in a variety of styles.

Fret saw

The fretsaw is a bow saw that is used for intricate cutting work that frequently includes tight curves. Although the coping saw is frequently used for similar tasks, the fretsaw can handle much tighter radii and more delicate work. It has a distinct appearance due to the depth of its frame (typically between 10 and 20 inches), which, combined with the relatively short five-inch blade, makes this tool appear out of proportion when compared to most other saws.

The fret saw, which is most similar to a coping saw, has a long, thin blade for making intricate cuts. These types of saws have a longer, larger frame that allows it to cut farther from the edges, but the blade cannot be rotated, resulting in more tedious and difficult cutting positions when performing intricate scrollwork.

Hacksaw

A hacksaw is a fine-toothed saw that was originally and primarily designed to cut metal. A bow saw is the name given to the equivalent saw for cutting wood.

The majority of hacksaws are hand saws with a C-shaped walking frame that tensions the blade. Such hacksaws have a handle, typically a pistol grip, with pins for attaching a thin disposable blade. The frames may also be adjustable to accommodate different-sized blades. To tension the thin blade, a screw or other mechanism is used.

What is a hacksaw used for ?

A hacksaw is a small-toothed, hand-powered saw used for cutting metal pipes, rods, brackets, and so on. Plastic can also be cut with a hacksaw. The hacksaw is made of a U-shaped frame with a handle on one end. Hacksaws have small pins on each end of the frame that hold the blade.

Is hack saw used for metal ?

A hacksaw is a fine-toothed saw that was originally and primarily designed to cut metal. The blade on a hacksaw, like most frame saws, can be mounted with the teeth facing toward or away from the handle, resulting in cutting action on either the push or pull stroke.

Hole saw

A hole saw (also spelled holesaw), and known as a hole cutter, is a saw blade with an annular (ring) kerf that cuts a hole in the workpiece without removing the core material. It is employed in the construction of a drill. A pilot drill bit (arbor) is typically located in the center of a hole saw to prevent the saw teeth from walking. For relatively large holes (especially those larger than 25 millimeters (1.0 inch), the fact that a hole saw creates the hole without requiring the core to be cut up makes it preferable to twist drills or spade drills. The same hole can be dug faster and with less force.

What is a hole saw used for ?

A hole saw can cut holes much larger in diameter than a standard drill bit. They drill a hole in the workpiece without removing any of the core material. The hole saw is attached to your power drill by an arbor, which also holds other moving tool components.

Japanese saw

The Japanese saw, also known as the nokogiri, is a type of saw used in woodworking and Japanese carpentry that cuts on the pull stroke, as opposed to most European saws, which cut on the push stroke. Pull saws from Japan are the most well-known, but they are also used in China, Iran, Iraq, Korea, Nepal, and Turkey.

What is the purpose of hand Japanese saw

Japanese saws remove less wood, produce less sawdust, and require less muscle power because thin blades produce thin kerfs. You can cut for longer periods of time, more precisely, and with less fatigue. For a beginner, cutting wood the Japanese way is much easier.

Why are Japanese saw better ?

A Japanese saw has a thinner kerf than a Western saw (which may be an advantage in some situations) Because the saw plate on a Japanese saw is so thin, the teeth on it dull and break off more easily than those on a Western saw.

Keyhole saw

A keyhole saw (also known as a pad saw, alligator saw, jab saw, or drywall saw) is a long, narrow saw that is used to cut small, often awkward features in a variety of building materials. Keyhole saws are typically divided into two types: fixed blade and retractable blade.

A keyhole saw is a precision cutting tool with a long, thin blade that is typically used to cut tight curves and small holes in soft wood, plastic, or drywall.

Why it is called keyhole saw ?

The keyhole and pad saw is a related type of saw that is used for very different tasks. A keyhole and pad saw is used to cut interior circles and other shapes that are much smaller than what a standard compass saw can do, hence the name “keyhole.” The “pad” refers to the saw’s handle, which holds the blade.

Pole saw

Pole saws, unlike other common saws we’ve seen, are chainsaws attached to telescoping pole handles. A pole saw is used to prune or trim high tree branches. When the shaft and telescoping handles are removed, they can be converted to chain saws for regular cutting. We can use a variety of pole saws.

The pole saw’s name should be self-explanatory. It has power sources such as gas, electricity, or a battery. However, pole saws are also available in manual form.

The saw pole, which has a pruning saw attached to it, is used for cropping trees. These types of saws are also used to make holes and punctures in panels. Additionally, used for making starter holes that can later be used for power tools.

Pruning Saw

A pruning saw is a tool with the same sharp teeth as a saw used to cut lumber. Pruning saws, on the other hand, are intended for trimming live shrubs and trees.

Pruning saws come in a variety of shapes and sizes, each designed for a specific branch or stem. Pruning saws should all have hard-point, heat-treated teeth, but they come in a variety of sizes and shapes. Using a pruning saw that is appropriate for the task at hand makes it easier to do a good job.

What are they used for ?

They are designed to assist you in trimming larger shrubs and smaller tree branches. Here’s a good rule of thumb to follow if you’re wondering when to use pruning saws. Consider using a hand pruner if the branch or trunk you want to trim is less than 1.5 inches (3.81 cm) in diameter. If the wood is that thick or thicker, a pruning saw should be used.

Pruning saws are more commonly found in the toolbox of a homeowner, but they are also widely used by tree surgeons, lawn service providers, and landscapers.

Rip cut saw

A rip saw is a type of wood saw that is specifically designed for making rip cuts, which are cuts that are made parallel to the direction of the wood grain.

What a rip cut saw used for ?

A rip saw, also known as a tooth saw, is an all-purpose tool for making rough cuts in woodworking. The teeth alternate between left and right bends, acting like a chisel to cut parallel to the grain. To create a clean cut along the grain, a rip saw only cuts on the push stroke.

Verner saw

The veneer saw is a small, double-edged tool used to cut thin hardwood veneer. Its narrow curved blade allows for precision work, and its elevated offset handle allows for cutting flush with a surface. The blade is typically 75 or 100 millimeters (3 or 4 in) long, with 13 teeth per inch (approximately 2 mm between each tooth).

What is the purpose of veneer saw ?

The Veneer saw is used to cut veneers, which are thin sheets of wood ranging in thickness from 0.4 to 0.6 mm that have been cut or peeled off a log by a veneer cutting machine. These types of saws are mostly glued to a stable backing material, such as lumber-cored plywood, ply, particle board, MDF-board, or other manufactured wood products.

How do you sharpen veneer saw ?

To sharpen a veneer saw, hold it perpendicular to the bench and sharpen the teeth with a fine file, following the angles that have already been established. Then, with the saw flat on the edge of the bench, file a bevel onto the outside edge of the blade so that each tooth is sharp.

Wallboard saw

The wallboard saw is most likely comparable to the keyhole saw. It is a standard handsaw tool that is small in size and has wider blades. It is usually of the double-edged variety.

The advantage of using a wallboard saw is that it can be used with both single and double-edged blades. It is designed to pierce through paneling or drywall, and it is also used to create starter holes for powered equipment.

Bone saw

Handheld bone saws, also known as “butcher’s saws,” are similar to hacksaws in design. Unsurprisingly, they are used for cutting through bones – most commonly by deer and other big game hunters. To avoid corrosion from animal blood, look for all stainless-steel construction.

Wire saw

Wire saws, which are popular among survivalists and ultralight backpackers, are similar to reciprocating or band saws in that they use abrasion to cut wood rather than saw teeth. Handheld models are extremely lightweight, but even small cuts can take a long time and a lot of effort to complete. Look for models with comfortable handles, or your fingers will suffer greatly.

Razor saw

The razor saw, which is popular among hobbyists and model train enthusiasts, has finely pitched crosscut teeth that can make clean cuts in very soft woods used for model trains, planes, and boats. Razor saws, unlike other members of the backsaw family, are frequently used to cut plastics, soft metals, and soft woods.

Carcass saw

The carcass saw, which refers to the framework carcass of a cabinet rather than an animal, is strikingly similar to a tenon saw. Because of their stiff blades and crosscut filed teeth, they are useful for precise cuts across wood grain. These types of saws are highly specialized and designed for smaller jobs that a tenon saw can’t handle accurately.

Pocket chain saw

Take the chain from a standard gas-powered chainsaw, split it at one point, and add handles to both ends, and you have the foundation of a pocket chainsaw. It is like the wire saw, a favorite of survivalists and backpackers due to its lightweight and compact design. They are slightly heavier than wire saws, but they cut with teeth rather than friction, making them faster and easier to use.

Camping Saw

There are numerous types of camping saws available, each with its own set of features and design. The most important features for most people who will need a saw while camping are that it is versatile and capable of cutting a variety of materials, as well as that it is compact and lightweight for easy portability. The folding camping saw meets all of these requirements, and it is small enough to fit into a pocket or a bag. They take up very little space and are useful for cutting firewood, trimming branches, and making a variety of other cuts you might encounter in the wilderness.

Fine saw

The main purpose of a fine saw is to assist you in making those precise cuts that are difficult to make with larger saws.

A fine saw typically has a small and thin blade, allowing you to make precise cuts. On top, a bar provides the necessary stability for a narrow leaf.

Power saw

A power-saw is a machine tool that uses a toothed or abrasive disc or blade to cut various materials using a rotary motion spinning around an arbor. A hole saw and ring saw both use a rotary motion but are not the same as a circular saw. Circular saws can also be used to make the blade.

What are power saws used for ?

A power saw is a portable mechanical machine that can be used for both industrial and do-it-yourself projects. It is a power tool with strong blades, chains, wire, a set of teeth, and so on. It is primarily used in large cuts for the work piece. It is capable of cutting wood, plastic, metals, concrete, and other materials such as tiles and bricks.

Band saw

A bandsaw (also spelled band saw) is a power saw that cuts material with a long, sharp blade made of a continuous band of toothed metal stretched between two or more wheels. These types of saws are primarily used in woodworking, metalworking, and lumbering, but they can cut a wide range of materials. Advantages include the ability to cut irregular or curved shapes like a jigsaw and the ability to cut uniform cutting action as a result of an evenly distributed tooth load.

What is a band saw good for ?

A band saw can be used to cut curves, even in thick lumber, as in the creation of cabriole legs, as well as to rip lumber and crosscut short pieces. The band saw, on the other hand, is most commonly used to cut irregular shapes. The second most common application is to resaw or rip lumber into thinner slabs.

What is a band saw used to cut ?

A band saw can cut wood or metal in curves or straight lines with the right blade. Blades are available in a range of widths and tooth counts. Narrower blades work well for tighter curves, whereas wider blades work well for straight cuts.

Chain saw

A chainsaw, as the name suggests, employs a linked chain with numerous specially designed ripping teeth.

A chainsaw (or chain saw) is a portable gasoline-, electric-, or battery-powered saw have a set of teeth attached to a rotating chain driven along a guide bar. This is used for tree felling, bucking, pruning, cutting firebreaks in wildland fire suppression, and harvesting firewood. As tools for chainsaw art and chainsaw mills, chainsaws with specially designed bar-and-chain combinations have been developed. During construction projects, specialized chainsaws are used to cut concrete. Chainsaws are occasionally used to cut ice, as in ice sculpture and winter swimming in Finland.

Chop saw

The chop saw, one of the largest portable circular saws, is available in both metal and masonry cutting versions. A connection for a water line is often included with the concrete cutting saw to reduce dust while cutting.

Both types of chop saws use toothless blades made with specially designed abrasives for the materials to be cut. Cut-off saws, concrete saws, and abrasive saws are other names for chop saws.

These stationary saws only move up and down, as opposed to the meter saw, which can make angled cuts. Woodworkers prefer the versatility of miter saws to the extreme vertical precision and power of a chop saw, so you’ll mostly find them in metal shops.

Cut-off saws are power tools used to cut hard materials such as wood, metal, tile, or concrete, among others. These tools are fitted with an abrasive disc, which is why saws are also known as abrasive saws or chop saws.

Circular saw

A circular saw is also known by the name skill saw. Its teeth have a diameter of about 7.25 to 9 inches and can cut through wood, plastic, and metal with precision. These saws are readily available in your local markets.

It also has the ability to be adjusted in height. The height, on the other hand, can be adjusted using the lever. It is useful for cutting to a precise depth. It can also be used to cut aluminum sheets.

Miter saw

A Miter saw, also known as a Miter saw, is a saw that is used to make precise crosscuts and miters in a workpiece by positioning a mounted blade on a board. In its earliest form, a Miter saw was a back saw in a Miter box, but in modern implementation, it is a powered circular saw that can be positioned at a variety of angles and lowered onto a board positioned against a backstop known as the fence.

What a Miter saw good for ?

These types of saws are specialized tools that allows you to cut at various angles. To make angled cuts, the saw has a blade mounted on a swing arm that pivots left or right. A Miter saw can be used to quickly cut crown moulding, picture frames, door frames, window casings, and other items.

The Miter saw, one of the few saws designed to specifically mimic a hand saw, is ideal for use in trim or other jobs requiring precise measurements and angle cuts.

A simple Miter saw can pivot up to 45 degrees to either side of a straight 90-degree cut and can be used in conjunction with tables to cut long mitered ends.

Compound mitre saw

This is a Miter saw on a much larger scale. Straight, miter, and compound cuts are made with a compound saw. Instead of pivoting up and down as a miter saw does, the blade is mounted on an arm that can be adjusted for complex angles, such as cuts for intricate scrollwork and trim.

When it comes to trimming out windows or adding crown molding, a compound miter saw is one of the best time savers.

Flooring saw

A flooring saw, as the name implies, is a portable unit designed to re-saw flooring (hardwood, engineered, bamboo, or laminate) to fit. It’s a fairly specialized tool that essentially replaces a table saw, miter saw, and other flooring-cutting accessories.

The portability factor is its main advantage because you won’t have to spend a lot of time moving materials from the garage to the room and vice versa when installing flooring.

Jig saw

A jigsaw is a saw that uses a reciprocating blade to cut irregular curves in wood, metal, or other materials, such as stenciled designs. Jigsaws first appeared in the nineteenth century and used a treadle to operate the blade. Scintilla AG introduced the modern portable jigsaw in 1947.

What is a jigsaw used for

Jigsaws are best for cutting shapes and curves in wood with their narrow blades, which are held in place by a spring-loaded clamp at the front of the tool. A higher TPI produces a smoother cut that necessitates less sanding. Lower TPI blades produce faster cuts that are ideal for rough work.

Why do they call it jig saw

The term jigsaw is derived from the special saw known as a jigsaw, which was used to cut the puzzles until the saw was invented in the 1880s. Jigsaw puzzles became popular with both adults and children around the mid-nineteenth century.

Oscillating saw

A multitool, also known as an oscillating tool, is a power tool that oscillates (rather than rotating or reciprocating) and is powered by a battery or mains. The term “multi-tool” refers to the numerous functions that this tool can perform with the various attachments available. In North America, “Master Tool” is also a trade name for Fein’s original tool, the Multi-Master. Sawing, sanding, rasping, grinding, scraping, cutting, and polishing attachments are available.

What it is used for

An oscillating tool is a small, portable power tool that accepts a variety of interchangeable blades and can be used to sand, cut, scrape, grind, and polish.

Panel saw

A panel saw is any sawing machine that cuts sheets into sized pieces. Panel saws can be vertical or horizontal in orientation. Vertical saws typically take up less floor space.

Horizontal machines are large table saws with a sliding feed table that pushes the material through the blade. Sheet goods can also be cut with table saws that do not have a sliding feed table.

Vertical saws are classified into two price ranges: low and high. Cross cutting occurs when the saw travels through the sheet’s short side in both types. Lower-cost models require the user to slide the material through the saw when cutting lengthwise (rip), whereas higher-cost models require the saw to travel through the stationary material.

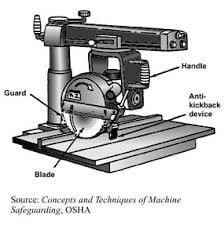

Radial arm saw

A radial arm saw is a type of cutting machine that consists of a circular saw mounted on a horizontal sliding arm. The radial arm saw, invented by Raymond DeWalt in 1922, was the primary tool used for cutting long pieces of stock to length until the introduction of the power miter saw in the 1970s.

These types of saws can be configured with a dado blade to make cuts for dado, rabbet, or half lap joints in addition to length cuts. Furthermore, some radial arm saws allow the blade to be turned parallel to the back fence, allowing for a rip cut.

Reciprocating saw

A reciprocating saw is a type of machine-powered saw that cuts by using a push-and-pull (“reciprocating”) motion of the blade. Sawzall is a common name and an example of a generic trademark. This name comes from Milwaukee Electric Tool, which produced the first tool of this type in 1951, and it is widely and colloquially applied to tools of this type in the United States.

What it is used for

A Reciprocating Saw is a portable saw that is commonly used in demolition and remodeling. It can cut through a variety of materials, including wood, metal, PVC, and nails. Prepare to demolish the house!

The reciprocating saw can be used effectively to cut the wood in a straight line. You won’t have to wonder how to use a reciprocating saw to cut wood straight again if you use the right blade and the right technique.

Rotary saw

A rotary saw, spiral cut saw, RotoZip, or cut out tool is a mechanically powered saw which is used for making accurate cuts in wallboard, plywood, or another thin, solid material without the need for a pilot hole.

This type of tool was originally designed to make drywall cut-outs, but it was later discovered that it could easily cut a variety of other materials as well.

What it is used for

A rotary saw is a powerful tool that spins a bit, drum, or small wheel to create clean cutout holes. It is most useful for cutting accurate holes in drywall, sidings, and fixtures made of wallboard and plywood. It is also known as a spiral cut saw or cut out tool.

Scroll saw

A scroll saw is a small electric or pedal-powered saw that is used to cut intricate curves in wood, metal, or other materials. Because of the fineness of its blade, it can cut more delicately than a power jigsaw and more easily than a hand coping saw or fretsaw. It, like those tools, can create curves with edges by pivoting its table.

The scroll saw got its name from its traditional use in making scrollwork, sculptural ornaments with scroll-head designs.

These types of saws are frequently used to cut intricate curves and joints, which they can do quickly and accurately. They are also useful for cutting dovetail joints and are a common tool for thicker intarsia projects.

Table saw

A table saw (also known as a sawbench or bench saw in the United Kingdom) is a type of woodworking tool that consists of a circular saw blade mounted on an arbor and powered by an electric motor (either directly, by belt, or by gears). The blade protrudes through the top of a table, which provides support for the material being cut, which is usually wood.

On small and long boards, table saws cut straighter lines and make smoother cuts. DIY projects that necessitate the use of a table saw typically necessitate a more precise cut than handheld or machine saws. These types of saws are very versatile power tool and can be used by both serious woodworkers and crafters.

Table saws are outstanding for making a large number of rip cuts or preparing a large number of identically sized pieces. These saws accept metal and masonry blades, but make sure the blade design corresponds to the motor rpm.

Tile saw

A tile saw is primarily used to cut tile as well as other building materials like ceramic, porcelain, and stone. It’s well-known for leaving a clean edge. Because it is stationary, you will need to cut your building materials and transport them to the job site.

Many people use the wet tile saw process, which involves wetting the materials and the blade before cutting to avoid damaging the blade or the materials.

A tile saw (also known as a wet saw) is similar to a miter saw in design, and it uses a diamond-coated blade and a water cooling system to cut through tiles like butter. It is used to quickly cut multiple ceramic or porcelain tiles to the desired shape or size, and it employs a miter to ensure straight cuts along your cut marks.

Track saw

Track saws are those types of saws that are used for simple and precise cuts. This is a modified circular saw that is designed to perform tasks that a circular saw cannot.

What it is used for

The track saw is excellent for ripping boards, trimming trim, and making splinter-free cuts across panels. When used as a plunge saw, the track saw is also excellent because you can set it to a precise depth and it will not fail you. When working on wood flooring or subflooring, for example, you have complete control.

It is generally used in woodworking to cut large boards into smaller rectangular sections. One of the main functions of a track saw is to provide mobility and ease of use, as well as accurate cutting.

Gas or electric pole saw

The pole saw, also known as a “pole chainsaw” or “pole pruner,” is useful for trimming branches in difficult-to-reach areas that would be dangerous to climb to while holding a chainsaw. Depending on the model, they can extend to lengths ranging from 8 to 15 feet.

Masonary saw

A diamond saw blade, also known as a concrete saw, road saw, slab saw, or masonry saw, is required for the heavy-duty work that these saws encounter. The most common types are handheld and resemble a circular saw, but stationary chop saws are rare. Many masonry saws will use water to cool the blade and reduce airborne dust due to the increased friction experienced when cutting stone.

Cold saw

Cold saws are circular saws that are specifically designed for cutting metal. They are available in both handheld and stationary models. Sheet metal roofers use them the most because they have a slower rotational speed and toothed blades made of thermal-resistant materials that allow them to stay cool.

Abrasive Saw

Abrasive saws, which use an abrasive disk rather than a toothed saw wheel, are available in handheld, tabletop, and walk-behind models. These types of saws are a versatile tool for heavy-duty construction and demolition job sites because they specialize in grinding through hard materials such as concrete and metal.

Straight flush saw

The straight flush saw, a relative newcomer to the handheld saw market, offers a specialized take on the classic circular saw, allowing for cuts directly adjacent to posts, studs, headers, and more. This zero-clearance cutting style is enabled by a recessed mounting point for the circular saw blade, which often eliminates the need for a reciprocating saw to clean up after a circular saw.

Toe kick saw

It doesn’t get much more niche than the handheld toe-kick saw – a small, flush-cutting circular saw that allows you to cut under cabinet toe-kick panels to remove flooring without removing the cabinet. They’re so specific, in fact, that renting one instead of buying one may be more cost effective.

Diamond blade wall cutter / stroke

These “wall chasers,” which are used to cut narrow grooves in hard-surfaced walls, are most commonly used for laying electrical cable. Wall cutters are outfitted with a pair of abrasive discs that allow them to grind through concrete and metal.

Jamb saw

The jamb saw, also known as a “undercut saw,” is another hyper-specialized tool used for cutting out a small section of door jamb or molding. As a result, rather than the jamb or molding, you can lay flooring flush with the wall. It’s another tool that’s often better to rent rather than buy.

Biscuit joiner

A biscuit joiner, which is part saw and part gluing box, can be used to make edge-to-edge or perpendicular joints. Before clamping the boards together, a circular saw blade cuts a hole in opposite edges of two pieces of wood, where a wooden “biscuit” is covered with glue and inserted. Typically, the resulting joints are as strong as mortise and tenon joints.

Domino joiner

The domino joiner is a modified version of Festool’s biscuit joiner that cuts mortises to be filled with proprietary Festool brand tenons. They enable faster joinery in commercial carpentry and produce a stronger joint than a biscuit joiner – but they are more expensive and produce a lot of noise and dust.

Alligator saw

When cutting through tougher materials like timber, hollow clay blocks, or aerated concrete, an alligator saw can help you make straight cuts.

It has two long-lasting saw blades that rotate in opposite directions. This composition enables you to make precise and straight cuts through even the most difficult surfaces.

Chain beam saw

Chain beam saws can be quite costly. However, they will save timber framers and log builders a significant amount of time.

That is why they are such a valuable piece of equipment, as they will save you a significant amount of time and reduce the amount of work you have to do.

At the same time, they resemble a circular saw with a downward chainsaw that you can hold in your hands, despite the fact that this piece of equipment is quite unique.

Saber saw

Saber saws are among the most commonly used saws on the market. They’re particularly well-known for having a thin blade that can be used to cut through almost anything.

They’re known for their portability and the ability to change the blades, allowing you to make different types of cuts through different materials.

They’re also quiet and comfortable to use, making them a favorite among woodworkers.

This was all about the different types of saws which finds importance in varied form of application. If you loved this article please share it with your friends.

Check Out Other Important Topics