What is a punch ?

Types of Punches, Punching, Punching Machines, How to use punching machine, Advantages and disadvantages – These are the outlines of the topic that is being covered in this article.

A punch is used in a bench work for making out work, locating centers etc. in a more permanent manner.

A punch is a tool, which is used to make an indent or a hole in a hard surface. They are typically made of a hard metal rod with a narrow tip on one end and a broad flat “butt” on the other.

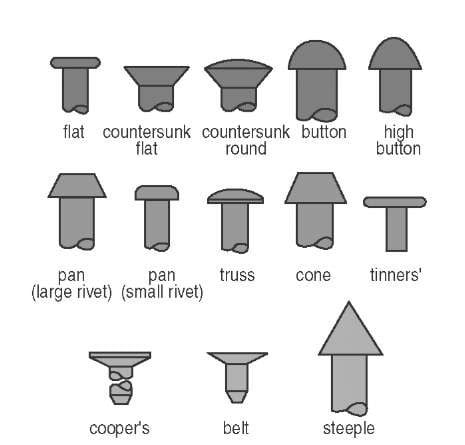

These are known to be made of hard metal rod with a pointy tip on one end and a dulled end on the other, and they are frequently used in conjunction with other tools such as a hammer or chisel to cut and shape blocks of materials. There are various types of punches that can be used for drilling, drawing circles, punching holes, removing damaged rivets, bolts, or pins, and many other things. Punches are the most common type of device used to make a hole with their points.

Types of Punches

Following are the types of punches with description :

1. Center Punch

A center punch is a hand punch made of a short steel bar with a hardened conical point at one end that is used to mark the centers of holes to be drilled.

A center punch is a tool that is used to mark the center of a point. When drilling holes, it is typically used to mark the center of the hole. If a drill does not begin in a recess, it has a tendency to “wander.” A center punch creates a large enough dimple to “guide” the drill tip. The tip of a center punch has an angle ranging from 60 to 90 degrees. Drilling a pilot hole is usually required when drilling larger holes where the drill bit is wider than the indentation produced by a center punch.

Note :- An automatic center punch does not require the use of a hammer.

The center punch looks like a prick punch. Its point has an angle more obtuse than that of the prick point, this angle usually being 60°. The center punch is used only to make the prick-punch marks larger at the centers of holes that are to be drilled, hence the name center punch. A strong blow of the hammer is needed to mark the point.

In its body Port the punch is a steel rod 90 to 150 mm long and 8 to 13 mm in diameter.

These are made up op high carbon steel and it is made hard and given temper treatment.

Applications :- These types of punches are used to make a center at the drilling point so that the drill bit’s point can properly rest there. If this center is not made with a center punch, the point may slip and drill at the incorrect point.

2. Prick Punch

A prick punch is similar to a center punch, but it is used to mark out areas. It has a more acutely angled tip, resulting in a narrower and deeper indentation. The indentation can then be enlarged for drilling with a center punch. A prick punch has a 40-degree tip (the angle depends on what type of prick punch one is using). It is also referred to as a dot punch.

In today’s professional world, the prick punch is the most widely used and one of the most common among all the types of punches. The majority of people use this punch to transfer dimensions from a paper pattern to metal and then use them as a point of reference for cutting or fabricating. Prick punches are similar to center punches in that they can have a narrow point and are also used to mark a design or layout.

Shifting the dimensions is mostly done when placing the paper pattern directly on the metal in order to properly and accurately select its orientation. The pattern is outlined on the metal by lightly striking the punch with a hammer, resulting in slight indentations.

3. Solid punch

Solid punches are one-piece rod-shaped metal tools that are designed to be struck with a hammer. These types of punches are typically used to drive objects such as pins or to make impressions on a work piece. The diameter, length, and tip of solid punches can vary depending on the job at hand.

In blacksmithing and sheet metal operations, a solid punch is used to bore holes. Depending on the job, these are used in various measurements. These are hardened and tempered high carbon steel.

It is critical to cool these down in cold water when using them in hot jobs. Because holes made with a solid punch are not precisely measured and are not clean, they are used in rough work.

4. Transfer punch

A transfer punch is a punch ( generally found in an index set ) with a specific outer diameter that is not tapered and extends the entire length of the punch (except for the tip). It is used to precisely transfer the center of an existing hole to another surface by tightly fitting the tolerances of an existing hole. It can be used to precisely set locations for threaded holes (created by drilling and tapping) to bolt an object to a surface, or it can be used to duplicate the hole patterns in a part.

Transfer punches are known to have a fixed shank diameter that is specifically designed to transfer the geometry of several tapped holes by fitting the bore with close tolerances and also marking the center of the hole on any other surface.

A transfer punch can be used to easily make drill-locating holes in a template. A transfer punch’s size is typically kept around 4-inches, which is sufficient to transfer the location of holes on metal using a pattern or a template. The transfer punch has a point that tapers at first and then runs straight for a shorter distance. These types of punches have a pointy tip which is similar to a prick punch in some ways.

As soon as, we have determined the right punch which is suitable for our site then you must find out that, working with those punches tools feels so amazing. Punches are generally known to be the indentation tools. Once you strike the blunt head of this narrow shaft with the help of a hammer, the opposing end of the tool is found creating an indented mark in a metal work piece.

5. Drift Punch

A drift “punch” is a contradiction in terms; it is not used as a punch in the traditional sense. A drift punch, also known as a drift pin or lineup punch, is a tool used to help align bolt or rivet holes before inserting a fastener. A drift punch is a tapered rod with the hammer acting on the large end of the taper.

The long end of a drift punch is inserted into the semi-aligned bolt holes of two different components and driven into the hole. The taper forces the two components into alignment as it is driven in, allowing for easy fastener insertion. Force is never (and should never be) applied to the tip or end of a drift pin, unlike most punches.

Drift punches, also known as drift pins, are commonly used to align bolt or rivet holes so that fasteners can be inserted properly. A drive punch is required to remove damaged rivets, bolts, and pins that have become stuck in holes.

Drift Punch should be labeled as an anti-drift tool because this member of the punch family is specifically designed to align fastener holes. Using these, gently hammer this punch into the holes until it is properly aligned and prepped for the fasteners, whether a rivet or a bolt. Once tapered, the body can be used to widen the aligned holes.

A drive punch usually has a flat face rather than pointy ends. The width of this punch’s face is used to determine the type of punch, whereas the sides of this punch are responsible for tapering down the face in some situations where a punch with a straight shank would be required. A drift punch is a punch with a straight shank that is very common.

6. Pin Punch

A pin punch has a straight shank and which has various applications in removing bolts or pins. The primary purpose of a pin punch is to complete the removal of bolts or pins from a hole that has already been loosened by a drive punch.

A pin punch can completely drive rivets and pins from a hole until they are removed, which can not be done by drive punches. The drive and pin punches are the only tools that can remove bolts or pins from holes. Pin punches are commonly used to drive a pin into a mating bore.

When a small metal shaft becomes stuck in a hole, a pin punch can be used to free it. If a rusted chain becomes entangled with its linkages, the pin punch knocks that tiny shaft free. A heavier version of this tool, known as a drive punch, is used to force out damaged fasteners and rivets, as well as to disassemble short projects.

7. Roll Pin Punch

The roll pin punch has a small projection in the center of the pin tip to hold the roll pin’s periphery. These punches have non-flat tips and are used to drive roll pins. It is also famous for its spring punches.

When using a roll pin punch, make sure that the shank axis of the punch matches the axis of the roll pin. Close the roll pin punch on both sides. If you hit a roll pin punch on the top of its head, it will bend the shank.

Roll Pin Punch Set is a great set of tools designed to remove and re-use roll pins without causing major damage to the pins.

8. Ejector Pin Punch

Ejector punches are the types of punches which are used to knock out material or eject parts after a pressing or stamping operation. A punch is certainly made of a similarly rigid metal and is shaped like a pen.

9. Marking Punch

Marking punches are punches that are used to emboss or create a particular texture on the surface of a material or work piece.

Hand-held metal marking punch is a simple and low-cost tool for indenting metal with a letter, number, or symbol. Pryor’s standard products come in a variety of sizes, characters, and styles, but custom designed punches can be made with any design.

10. Hollow Punch

A hollow punch is a mechanical device made of hardened carbon steel. These instruments are intended to pierce a surface, such as a metal sheet or leather, in order to create a hole. To protect the work surface from damage, the working end can be different in shape or size.

These types of punches can be found in screw mounting plates, drain valves, locks and keys, and many other places.

Hollow punches are used to create a hole by puncturing a surface such as sheet metal or leather. The “exit hole” near the working end of a hollow punch makes it easy to identify. The punched material can be removed and discarded through the exit hole.

11. Dot Punch

A tool similar to a center punch, but thinner, lighter, and with a sharper tip, used to mark the center of a hole to be drilled or (more broadly) to make an indentation in the surface of an object.

Dot punch can be considered of as a lighter version of a center punch, which is used for similar types of work but is used where the required intensity for the indentation is less. This type of punch is prioritized because it is found to be more accurate than the center punch.

A ball peen hammer is used to strike the head of the punch, which delivers enough force directly to the point of the punch to leave a small indentation in the surface of any material. It should be noted that both the dot and the center punch have applications that are similar.

What is the angle of Dot punch ?

Dot Punches are similar to Centre Punches, but have a sharper point that can be ground to a 60-degree angle by holding it tangentially to a Tool Grinder and rotating it (i.e. in a similar manner to a Scriber)

12. Bell Punch

A bell punch is a mechanical device used for punching that has an accurate self-Centre on a round bar material. These instruments come in a variety of sizes, with the maximum diameter of a bell punch being 35mm. A bell punch is completely machined in steel in order to produce a punch that will not fail. It is quite simple and easy to use this instrument by placing the sheet that needs to be punched, after which the hardened punch is centralized.

It has the shape of a small bell, as its name suggests. Its size is determined by the circumference of the bell. It is used to determine the center of round jobs as well as for light marking.

A punch, similar to a center punch, is fixed in this circumference with the help of a spring. Its head is hit with a hammer for use, and it raises on its own due to the punch spring.

13. Letter Punch

Letter punches, also known as letter stamps or number stamps, are used to emboss the impression of a letter or number into a workpiece. They are most commonly made in reverse image, which allows the end result to be immediately readable, but they can also be made in positive image.

This types of punches are typically made of a short rod of steel that is shaped differently depending on the requirements of work

A letter punch, also known as a letter stamp in common usage, is a tool that is commonly used in our daily lives as well as in a variety of industries. A letter punch works primarily by embossing the letters or numbers into the work piece. The most common feature of this type of punch is that they are mostly reversed images, which produce results in an easily readable format.

14. Tablet Punch

This punch is also known as a tablet press. Unlike most punches, tablet press punches have a curved end that conforms to the desired tablet shape. This tablet press has lower and upper punches to compress the powder between them.

15. Pilot Punch

A pilot punch has a ball on the tip and is used to punch hollow pins such as split pins. The ball engages in the hollow, ensuring proper contact to push the pin out without damaging the pin or the surface of the hole from which it is being driven.

Pilot punches have an inner pin that is used to align the punch into an existing hole or to allow the outer point to cut out a larger hole. These types of punches are very similar to solid or regular punches in that they have a solid flat point with no voids or internal bores.

16. Straight Punch

Straight punches are mechanical devices that are used to cut through metal sheets or other sheet materials such as leather or plastic. These punches are simple and easy to use, and they can be found in the leather and plastic industries.

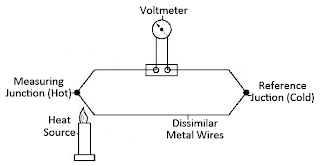

17. Automatic Punch

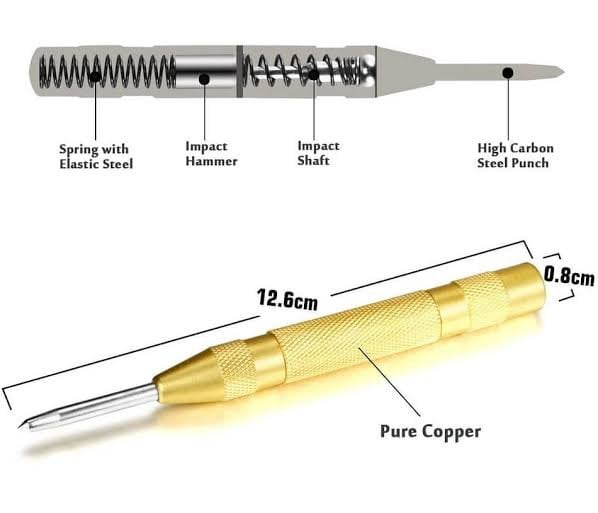

An automatic center punch is a hand tool used to create a dimple in a workpiece. It serves the same function as a standard center punch, but without the need for a hammer.

The main punch has a spring attached to its body. The spring is held in place by a lever head. When marking is required, the lever head is pressed. The main punch would be pressed and the marking would be done as a result of this pressure.

The punch’s blow can be limited or controlled with the lever head. Its main punch has a 60° or 90° angle. Figure shows this type of punch.

How it works ?

When it is pressed against the work piece, the energy is stored in the spring and eventually released when it has an impulse that drives the punch to produce the hole. The continuous impulse provided to the point of the punch allows for uniform impressions to be made.

What is Punching ?

Punching is a forming process that uses a punch press to shear a hole in a workpiece by forcing a tool called a punch through it. Punching can be used on a wide range of sheet materials, including sheet metal, paper, vulcanized fiber, and some types of plastic sheet.

What is Punching Machine ?

A punching machine is a machine tool used to punch and emboss flat sheet materials in order to produce form-features required as mechanical elements and/or to increase the static stability of a sheet section.

How Punching Machine Works ?

- Punching works on the principle of converting rotary motion into linear motion.

- The main motor is in charge of supplying the power to drive the flywheel.

- The flywheel drives the crankshaft or eccentric gear with the help of a clutch and a connecting rod.

- It converts circular motion to linear motion where a transfer point is required within the slider and connecting rods.

- There are two types of designs that convert circular motion to linear motion I.e the spherical type and the pin or cylindrical type.

- The drive mechanism drives the rams upwards and downwards, which opens and closes the upper and lower dies. Between the die shoes is a strip of metal sheet.

- When the punch moves down and applies pressure to the metal sheet, cutting a hole, the detached portion moves away from the die opening.

Applications of Punching

Here are some punching applications that everyone should be aware of. So let’s get started to learn more:

- Punching is commonly used in a variety of industries, but it is most commonly used in the metalworking industry.

- Punching is used in a variety of industries to create holes in work pieces such as those used in automobiles, aerospace, the manufacturing industry, defense equipment, and so on.

- In the food and restaurant industry, punching is used to cut chapati, puri, and papad from atta sheets.

- Punching is also used in our daily lives to punch holes in papers.

Advantages of Punching

1. Stable and Highly Accurate

Punching instruments and their components, such as crankshafts, gears, and rams, are made at high temperatures to harden them and provide stability as well as high wear and tear resistance. This results in them being extremely stable and also allowing them to work accurately.

2. Reliable and Safe Operation

Punching machines have two types of brakes: one type standard and and another one is emergency. The emergency brake is designed to stop the machine in an emergency. Once technology advances, these machines will be equipped with more advanced sensors to ensure the user’s safety and reliability.

3. High Productivity, Reduce Labor Work, and Automatic Production

Punching machines are referred to as highly productive machines because they reduce manual labor, which reduces costs while increasing efficiency. As technology advances, it is expected that machinery will be fully automated, requiring no manual labor.

Disadvantages of Punching

- Punching machines used in factories are quite large and require a significant initial investment.

- Because these machines operate at such high speeds, they generate a lot of noise.

- The parts of such punching machines are found to be complex, making repair time consuming. Even minor faults may necessitate the services of an expert.

- Massive punching machines cannot be used to complete the small-scale production process.

Precautions During Punching

The following precautions should be taken to ensure correct and accurate marking with any type of punch:

- The punch should be chosen based on the job or metal’s make-up.

- A light hammer should be used for a light punch.

- Do not use a regular punch or a hard metal.

- After determining its angle, use a punch.

- If the punch’s point is damaged, it should be repaired before using it.

- Hollow punches should not be used on thick sheets.

Precautions During Punching Machine

To avoid huge losses, the following precautions must be taken when working on a punching machine, particularly in industries:

- Ensure that all of the parts are properly lubricated.

- Ensure that the mold is properly installed.

- Check the compressor’s air pressure.

- Check the switch button

- Allow the machine to idle for a while to check the operation of the parts such as the brake clutch, etc.

- Treat the abnormal heat, vibration, or sound as soon as possible (if observed).

- Check that the flywheel rotates in the same direction as the rotary mark.

We covered different types of punches, their uses, about punching and it’s advantages and disadvantages. If you liked this article, please share it with your friends.

Check Out Other Important Topics