There are different types of fasteners which play an essential part in the creation of a variety of things. Assume you’re a regular DIY. In that instance, there’s a good chance you used fasteners to complete your task. They aid in the retention of pieces while reducing vibration and pressure. Fasteners come in a variety of shapes and sizes.

In this post we’ll go through the many types of fasteners, as well as their subcategories. We’ll also provide you some pointers on how to choose the correct fastener for your job. Let’s start by defining fasteners before we get into the details.

What is a Fastener?

A fastener, also known as a fastening, is a hardware device that mechanically joins or affixes two or more objects together. In general, fasteners are used to create non-permanent joints, or joints that can be removed or dismantled without causing damage to the joining components. Welding is an example of a permanent joint.

A fastener is a broad category of mechanical tools/elements used to hold two or more objects together as a rigid attachment. Fasteners enable the pieces to be separated or dismantled without causing any damage. However, they can also be used as permanent joints. Screws, nuts, bolts, nails, washers, and so on are examples of fasteners.

Different Types of Fasteners

- Nuts

- Bolts

- Washers

- Screws

- Rivets

- Studs

- Anchors

- Nails

- Key and key ways

- Inserts

- Retaing rings

- Clevin Pins and cotter pins

1. Nuts

A nut is a fastening device having corrugated hole in the middle. That corrugated holes are known as threads. The point to keep in mind related to nuts is, it is always used with bolts.

The outer parts of the nuts can be designed in any way but it is mostly in hexagonal shape. The inside shape is always circular because this is where the bolt stem fits, and the bolt stem is always cylindrical in shape so that it can easily rotate and fit into the threads. The two partners (i.e., nuts and bolts) are held together by a combination of thread friction, a slight stretch of the bolt, and part compression to join together.

Types of Nuts

Hex – Nuts

Hex nuts are hexagonal ( hex shape ) in outer structure having internal thread In them. These are the most common type of nuts and are used in almost all industries for a variety of purposes. They are inexpensive and simple to assemble with a wrench.

Lock nuts

Locknuts are fasteners that are specially designed to prevent loosening due to vibrations. Lock nuts, also known as prevailing torque nuts, are used in automotive and washing machines where vibration issues have a tendency to loosen parts.

Coupling nuts

Coupling nuts are also hex-shaped nuts. This hollow threaded fastener connects two male threads and is also known as an extension nut. They are widely used in the installation of plumbing pipes.

Flange nuts

A flange nut is a nut with a wide flange on one end that functions as an integrated washer. This distributes the nut’s pressure over the part being secured, reducing the possibility of damage to the part and making it less likely to loosen due to an uneven fastening surface.

It is also known as Tee nuts.

Wing nuts

A wingnut, also known as a butterfly nut, is a type of nut with two large metal “wings,” one on each side, that allow it to be tightened and loosened by hand without the use of tools. A wing screw or wing bolt is a similar fastener with a male thread.

What is a wing nut used for

Wing nuts function similarly to most other nuts in that they are intended to hold two or more objects together when used in conjunction with a bolt. To prevent the connected objects from pulling apart, twist a wing nut onto the end of the bolt.

Slot nuts

With the help of a cotter ping, sections of slotted nuts are cut out to create a locking mechanism.

Where it is used for

Slotted nuts are used in applications where vibration or torque could cause the assembly to unfasten. They are a type of locknut that, in most cases, can be used interchangeably with castle nuts.

Castle nut

A castellated nut, also known as a castle nut, is a nut with slots cut into one end. The name derives from the nut’s resemblance to a medieval castle’s crenellated parapet. Castellated nuts are sometimes incorrectly referred to as castigated nuts.

Speed nut

A speed nut, also known as a sheet metal nut or Tinnerman nut, is a type of locknut with two sheet metal prongs that function as one thread. When the fastener is tightened, the arched base of the nut elastically deforms and applies a force to the fastener, preventing it from loosening under vibrations.

Some more types of nuts are :-

- U- nuts

- Axle nut

- Jam nut

- Push nut

- Rivet nut

- Barrel Nuts

- Weld nuts

- Shear nuts

- Wheel nuts

- Tri-groove nuts

- Knurled thumb nuts

- Keps-k lock nuts

2. Bolts

A bolt is a type of threaded fastener with an external male thread that requires a nut with a matching pre-formed female thread. Screws and bolts are very similar.

There are numerous types of bolts available on the market. The following are the most common types of bolts used in industrial applications:

Types of bolts

Carriage bolts

A carriage bolt, also known as a coach bolt or round-head square-neck bolt, is a type of bolt used to connect metal to metal or, more commonly, wood to metal. In Australia and New Zealand, this type of bolt is known as a cup head bolt.

Carriage bolts with domed or countersunk heads use a square component under the head to prevent the bolt from moving (pulling through) while tightening the nut. Carriage bolts are self-locking bolts that are commonly used to secure metals to wood.

Hex – bolt

They have six-sided heads with machine threads that extend halfway or all the way to the bolt head. Hex bolts are widely used in construction and machinery because they can be easily tightened with a wrench. Hex bolts, also known as hex cap screws, are used in conjunction with a tapped hole or a nut.

What hex bolt is uses for

They can be used to fasten wood, steel, and other construction materials and have a variety of finishes, lengths, and thread styles, so they aren’t limited to on-site use. Hex bolts are commonly used in docks, bridges, highway structures, and buildings.

U – bolt

A U-bolt is a bolt in the shape of the letter U with screw threads on both ends. U-bolts have primarily been used to support pipework, or pipes through which fluids and gases pass. As a result, U-bolts were measured using pipe-work engineering jargon. The size of the pipe it was supporting would be used to describe a U-bolt.

What u-bolt is used for

U-bolts have screw heads on both ends and are shaped like the letter “U.” The U-bent bolt’s section is unthreaded. They are widely used in piping, plumbing, and HVAC work to secure the position of pipes and tubes without causing damage to them.

Eye bolt

Eye bolts have a threaded end and a loop on the other.

A bolt with an eye at one end is referred to as an eye bolt. They are used to securely fasten a securing eye to a structure so that ropes or cables can be attached to it.

Lag bolts

These bolts are used without the use of a nut. Lag bolts are extremely strong and durable, and they can withstand a great deal of weight. They are used for heavy-duty tasks such as installing frames, framing lumber, and so on.

Flange bolts

Flange bolts, which are used in automotive, plumbing, and other applications, have a washer-like flange beneath the bolt head that speeds up production and distributes the clamping load, protecting the mating surface.

Allen bolts

a bolt with a hexagonal socket in its head, intended for use with an Allen wrench The Allen bolt is a part of the crank and stays in place even when the crank is removed from the spindle.

These fasteners take up less space.

Some of the bolts are

- Anchors bolts

- Blind bolts

- Double end bolt

- Penta head bolt

- Round head bolts

- Shoulder bolts

- T -head bolts

- Square head bolts

- Plow bolts

3. Washers

A washer is a thin plate with a hole used to distribute the load of a threaded fastener, such as a bolt or nut. Other applications include spacers, springs, wear pads, preload indicating devices, locking devices, and vibration reduction. Washers are typically made of metal or plastic.

Other applications of washers are

1. Isolation of Components

2. Reduced leakage

3. friction reduction, and

4. Preventing loosening during vibration.

Types of Washers are

Flat washers

Flat washers are used for protecting the surface by distributing torque evenly, when a bolt or screw is tightened. They keep a steel screw and an aluminum surface from corroding. A nylon washer can be used to reduce noise and abrasion while also providing electrical insulation beneath a machine screw.

Types of flat washers

- Torque washer

- Fender washer

- Shoulder washer

- C-washer

- Finishing or countersunk washer

Spring washers

Spring washers, also known as disc springs, are a type of washer. They contribute mechanical properties to the material’s distinct profile: when subjected to a load, the irregularities of the washer compress with proportionate resistance to return to their predeflected shape.

These fasteners work like a spring, developing axial flexibility to make the joint more elastic. This can help to prevent unintentional loosening during vibration.

Types of spring washers are following :-

- Belleville or conical washer

- Dome spring washer

- Wave spring washer

- Finger spring washer

- Crescent spring washer

Locking washer

Lock washers are which are designed for tightening the required torque beneath a regular fastener. They provide spring tension, preventing the fastener from vibrating loose. They are typically attached to the fastener’s nut side.

This type of washer employs a variety of mechanisms to keep nuts, screws, and bolts from loosening. Lock washers are far superior to spring washers.

Types of locking washers are following :-

- Tab washer

- Spring lock washer

- Internal tooth lock washer

- External tooth lock washer

Beveled washer

Beveled washers have an angled bearing surface to compensate for surface imperfections in structural applications such as fastening bolts into I-beams.

These washers ,which are used for add stability during attaching unparallel surfaces.

Structural washers

Structural washers are made of medium carbon steel that has been heat treated and hardened to 35-41 HRC. Structural Washers are designed for steel-to-steel structural connections such as building and bridge construction and are intended for use with Structural Bolts.

4. Screw

These are the types of fasteners that produce their own threads as they fasten into the material. They typically have a shank with helical threads and a head. There are various head styles and recess or drive styles available, such as slotted, Pozidriv, Phillips, hex, Torx, and Robertson.

A screw is a combination of simple machines: it is, in essence, an inclined plane wrapped around a central shaft, but the inclined plane (thread) also has a sharp edge around the outside that acts as a wedge as it pushes into the fastened material, and the shaft and helix also form a wedge at the point.

Common types of screws are following :-

Machine screws

A machine screw is a fastener that, like other types of fasteners, is used to connect two or more objects. Machine screws, on the other hand, are distinct due to their size.

Self Drilling Screw

A self-tapping screw is one that can tap its own hole as it is driven into the material. Self-tapping is used only to describe a specific type of thread-cutting screw intended to produce a thread in relatively soft material or sheet materials, excluding wood screws.

Sheet Metal Screw

Sheet metal screws are types of screws which are used to connect together thinner metal objects or to join metal to wood, plastic, and other materials.

Wood Screw

Wood screws are sharp-pointed screws that are used for nonstructural, wood-to-wood fastening. Wood screws have coarse threads and an unthreaded shank near the head, allowing the screw to tightly grip the wood pieces.

Wood screws are useful for quickly constructing jigs and clamping forms, joining cabinet and furniture parts, mounting hardware and trim, and much more. Screws provide strong connections between parts made of solid wood, plywood, and other sheet goods without the need for cut joinery.

Grub Screw

A set screw, also known as a blind screw or a grub screw, is a type of screw used as a detent to secure an object within or against another object, typically without the use of a nut.

Other types of screws are

- Countersunk screw

- Hex lag screw

- MDF screw

- Drywall screw

- Masonary screw

- Deck screw

5. Rivets

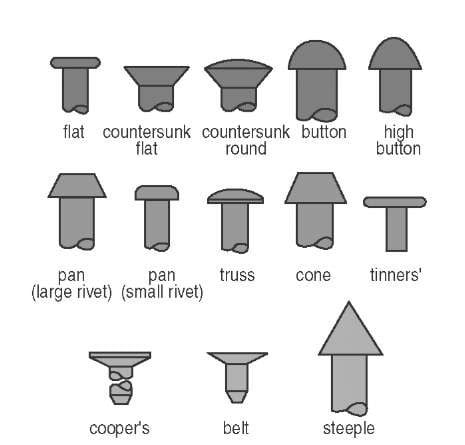

These types of fasteners are permanent mechanical fastener. A rivet is made up of a smooth cylindrical shaft with a head on one end before it is installed. The tail is the end opposite the head.

Rivets are permanent fasteners because they form a permanent joint between two objects. Rivets, which consist of a cylindrical shaft with a head on one end and a tail on the other, provide excellent resistance to shearing forces. These types of fasteners are both lightweight and extremely durable. Installing rivets necessitates the use of a unique tool known as a rivet gun. Rivets cannot be reused after they have been removed.

Types of rivets are following :-

- Split rivets

- Drive rivets

- Colored rivets

- strucural rivets

- Large flange rivet

- Tri-fold rivet

- Semi tubular rivet

- Solids rivet

- Blind rivets

- Multi grip rivets

- Pop rivets

6. Studs

These types of fasteners are also known as a headless bolt. A stud is a relatively long rod with threads on both ends, which may extend the entire length of the rod. The stud is tightened in the hole of the part that will be joined to it first, and then a nut is tightened on it.

Its main advantage is that we can easily separate the upper part while keeping the lower part intact by simply opening the nut. These studs are primarily of three types.

The middle portion of the round stud is also round. The middle portion of a square stud is kept square. The third type is a collar that is made slightly away from the center. It is frequently used in automobile cylinder heads.

7. Anchors

The anchor bolts are the types of fasteners which are used to attach one or more objects to a concrete surface. Because concrete is brittle, conventional bolts can be used for applications like this. Anchor bolts must be used to ensure that the connected object or objects remain in place.

Anchors are fasteners, and their function is similar to that of a boat’s anchor, which inserts itself into the seabed to keep the ship from moving. It is typically used to secure something to a surface such as drywall or concrete. They embed themselves in the material and hold the object to which you are affixing.

8. Nails

Another object on the list of different types of fasteners are nails. A nail is a small metal object used as a fastener, a peg to hang something, or sometimes as a decoration in woodworking and construction. Nails typically have a sharp point on one end and a flattened head on the other, but headless nails are also available.

It’s a small metal spike with a wide flat head that’s pushed into the wood to hold things together or to serve as a hook. Nails have been used since ancient times and are now common household items.

9. Key and Key Ways

A key and key ways is a fastener used for making Keyed joint that secure the hub and the shaft, preventing relative movement between a power transmitting shaft and an attached component. Gear drives, Pulleys, and Sprockets, for example, are secured to the power transmitting shaft using keys.

Or we can say

A key is a machine component that connects a rotating machine component to a shaft and allows torque transmission. The key aids in the prevention of relative motion between two parts. As shown in the diagram below, the shaft must have a keyway in order for the key to fit on it.

A key is required to move a gear or pulley on its shaft, but the shaft and gear or pulley move as one unit. In the keyway, a key is inserted between a shaft and a wheel.

As a result, the shaft and gear or pulley (or “wheel”) become one unit. To withstand (bear) the stresses, keys are typically made of high-quality steel.

10. Inserts

These are the strong threads that are typically cylindrical in shape and are used for a variety of purposes such as securing a long-lasting connection between various materials or repairing stripped threads. These types of fasteners are commonly used to distribute loads from a small diameter screw to a larger diameter insert.

11. Snap rings

Snap Rings, also known as circlips or seeger rings, are a stamped tapered section retaining ring. These axially installed rings are frequently used in external applications to secure parts on grooved shafts, pins, or studs.

A retaining ring is a one-time use fastener that holds components or assemblies onto a shaft or in a housing/bore when installed – typically in a groove. Once installed, the exposed portion serves as a shoulder that holds the specific component or assembly in place. Circlips are an example of a retaining ring.

12. Clevin Pins and Cotton Pins

These are fasteners that are further made from steel pins or with a cylindrical shaft. A cotter pin is inserted and bent into a hole in the shaft to act as a staple. These are used to keep machine components in precise position or alignment.

Advantages of Different Types of Fasteners

- The use of fasteners reduces the component’s weight.

- They are capable of producing high-strength steel with tensile strengths of up to 1500 MPa.

- Fasteners take up very little space within the appliance.

- Fastener equipment maintenance is simple and easy.

- They are simple to install in any workplace.

Disadvantages of Different Types of Fasteners

- The weight of the component will be increased if fasteners are used.

- They usually need the holes in order to fit a fastener, which weakens the components.

- They can work at specific points in all types of loads, causing fatigue.

- It’s difficult to fasten again once it’s been fastened.

- They are frequently corroded as a result of their use.

Materials used for Various Types of Fasteners

A variety of materials are used to make fasteners. The working environment, weight, expected life, reusability, magnetic properties, and reusability should all be taken into account when selecting a fastener material. Fasteners are typically made from the following materials:

- Copper

- Stainless-steel

- Titanium

- Nickel

- Inconel

- Brass and Bronze

- Aluminium

- Nylon and plastics

- Monel

- Brass and Bronze

Selection of Fasteners

Since we see there are different types of fasteners so it is important to choose right kind of fasteners for our work. A number of factors must be considered when selecting fasteners for industrial applications. Some of them include :-

- Construction material (stainless steel, carbon steel, or alloy steel).

- Materials to be joined

- The environment, including temperature, water exposure, and potentially corrosive elements.

- Re-usability

- Process of installation

- Weight restrictions

- Load applied in the fasteners.

- Stiffness of the fastener

- Special process conditions (special coatings or plating).

With such a huge variety of fasteners on the market today, selecting the appropriate one for your application can be difficult. In this post, we’ve almost finished discussing the many types of fasteners and their applications.

If you have any further questions about “types of fasteners,” please post them in the comments section and I will respond. If you enjoyed this article, please tell your friends about it.

Check Out Other Important Topics