When it comes to engine components that are critical in achieving optimal performance, few are as essential as connecting rods. In this section, we will explore in detail the topic of connecting rods. We will define what they are, discuss the various types available, explore their different parts, highlight their crucial function in an engine, and emphasize their importance in various applications.

Let’s start with the basics. What exactly is a connecting rod? In simple terms, it is a component that connects the piston to the crankshaft of an engine. It is responsible for transmitting the linear force generated by the piston to the rotational motion of the crankshaft, which ultimately converts it into the rotary motion that powers the engine.

Understanding Connecting Rods

Connecting rods play a crucial role in the operation of an engine. They are responsible for connecting the piston to the crankshaft, thus transferring the linear motion of the piston to rotational motion at the crankshaft. This motion is what generates power within the engine.

The connecting rod bearing sits between the connecting rod and the crankshaft, providing a smooth surface for the two components to rotate against each other. The piston connecting rod assembly consists of the piston, piston pin, and connecting rod, which work together to convert the linear motion of the piston into the rotational motion of the crankshaft.

When the piston moves upwards, it pulls the connecting rod with it, causing the crankshaft to rotate. When the piston moves downwards, it pushes the connecting rod down, again causing the crankshaft to rotate. This back-and-forth motion of the piston and connecting rod is what creates the rotational motion of the crankshaft.

The harmonious relationship between the connecting rod and other engine components is essential for efficient engine operation. It is crucial to ensure that the connecting rod is of the correct size and material for the engine’s intended use. Failure to choose the right connecting rod can lead to engine damage or failure.

Overall, the connecting rod is an integral component in an engine system, enabling the engine to generate power effectively and efficiently.

Anatomy of a Connecting Rod

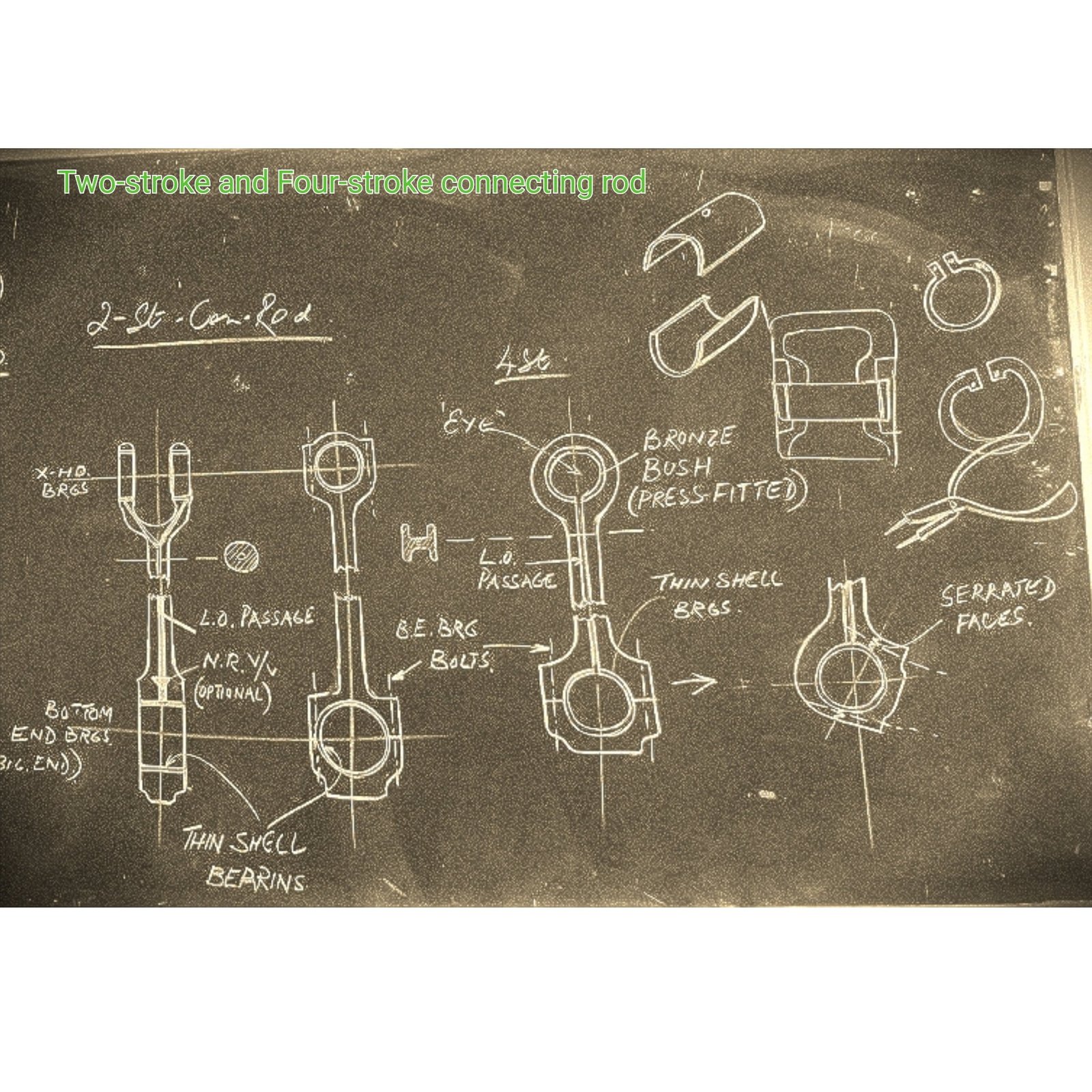

In order to understand the construction and design of a connecting rod, it is important to consider the materials used in manufacturing. Connecting rod manufacturers and suppliers prioritize materials that are strong, durable, and lightweight. Steel and aluminum alloys are the most commonly used materials for connecting rods.

The design of a connecting rod is also a crucial factor in its strength and reliability. The rod must be able to withstand the tremendous forces generated during engine operation, which requires careful attention to its shape and dimensions. Connecting rod design varies depending on the type of engine and the intended application.

Connecting rods typically consist of three main parts: the big end, the small end, and the shank. The big end attaches to the crankshaft, while the small end connects to the piston pin. The shank serves to connect these two ends, transmitting the linear motion of the piston to the rotational motion of the crankshaft.

When designing and manufacturing a connecting rod, there are several factors that must be considered. The weight of the rod is a critical consideration, since heavier rods can increase engine stress and reduce overall performance. Connecting rod design must also consider factors such as piston stroke, rod length, and engine displacement.

The Function of Connecting Rods

Connecting rods play a crucial role in the operation of an engine, serving as the link between the piston and the crankshaft. The connecting rod’s primary function is to transfer the linear motion of the piston into rotational motion at the crankshaft.

During the combustion process, the fuel-air mixture inside the cylinder is ignited, creating an explosion that pushes the piston downward. This linear motion of the piston is then transmitted through the connecting rod to the crankshaft, which converts it into rotational motion.

Without connecting rods, an engine will not be able to generate power, and its operation will fail. Therefore, connecting rods are essential components in the design of any internal combustion engine.

Importance of Connecting Rods

Connecting rods are an essential component in internal combustion engines (IC engines) and play a critical role in powering various industries. The importance of connecting rods is evident in their contribution to engine efficiency, reliability, and overall performance. The function of connecting rods is to transfer the linear motion of the piston to rotational motion at the crankshaft, enabling the engine to generate power. This power is then used for various applications, including powering vehicles, machinery, and electrical generators.

The connecting rod in an IC engine is crucial in ensuring the smooth operation of the engine. The connecting rod connects the piston to the crankshaft and transmits the power generated by the combustion of fuel to the wheels or other systems. Without a connecting rod, the engine would not work efficiently, leading to poor performance, increased fuel consumption, and higher emissions.

Connecting rods also play a significant role in high-performance engines, such as those used in racing applications. These engines require components that can withstand high levels of stress and pressure without failing. Connecting rods made from forged steel or other high-strength materials are essential in achieving the necessary power output and efficiency in these engines.

Applications

Connecting rods are critical components in various engine applications, enabling the smooth transfer of power from the piston to the crankshaft. Here are some common applications of connecting rods:

- Automotive engines

- Motorcycles and ATVs

- Aerospace engines

- Power generators

- Marine engines

- Racing engines

Connecting rods must be designed and manufactured according to the specific requirements of each application. For example, racing engines require connecting rods that are stronger and lighter than those used in everyday automotive engines. High-performance engines also require connecting rods with specific shapes and dimensions to optimize their power output.

Thanks to their versatility, connecting rods have many applications across various industries. They are a crucial component in ensuring the smooth and efficient operation of different types of engines.

Conclusion

Connecting rods are essential components in engine systems, serving a crucial role in the transfer of power from the piston to the crankshaft. In this article, we have provided a comprehensive overview of connecting rods, including their definition, different types, parts, and function. We have also emphasized the importance of connecting rods in various engine applications, such as automotive and performance engines, and explored their wide-ranging applications in different industries.

By understanding the intricacies of connecting rods, readers can gain a deeper appreciation for the inner workings of engines and their crucial role in performance and reliability. Whether you are a mechanic, engine builder, or simply interested in the technical aspects of engine design, the knowledge provided in this article can be a valuable resource in your endeavors.

FAQ

What is a connecting rod?

A connecting rod is a vital component in an engine that connects the piston to the crankshaft. It plays a crucial role in transferring the linear motion of the piston to rotational motion at the crankshaft, thus enabling the engine to generate power.

What are the different types of connecting rods?

There are various types of connecting rods available, but one common distinction is between forged connecting rods and performance connecting rods. Forged connecting rods are known for their strength and durability, making them ideal for high-performance applications.

What are the parts that make up a connecting rod?

A connecting rod consists of several components, including the rod cap, big end, small end, connecting rod bearing, and connecting rod bolts. These parts work together to ensure the proper functioning and stability of the connecting rod within the engine.

What materials are commonly used to make connecting rods?

Connecting rods are typically made from steel or aluminum alloys. The choice of material depends on various factors, such as the desired strength, weight, and heat resistance for a specific application.

What is the function of connecting rods?

The primary function of connecting rods is to transfer the linear motion of the piston to rotational motion at the crankshaft. This motion conversion is essential for generating power in an engine.

Why are connecting rods important?

Connecting rods are crucial components in engine systems as they contribute to engine efficiency, reliability, and overall performance. They play a vital role in maintaining the smooth operation of the engine and ensuring its longevity.

Where are connecting rods used?

Connecting rods have various applications, ranging from everyday automotive engines to high-performance racing applications. They are essential components in internal combustion engines used in cars, motorcycles, boats, and other machinery that require internal combustion for power generation.