what is Gas Turbine Power Plant

A gas turbine power plant, also known as a gas-fired or combustion turbine power plant, is a type of electricity generation facility that uses gas turbines to convert natural gas or other combustible gases into mechanical energy, which is then used to generate electricity. Gas turbine power plants are widely used for their efficiency, reliability, and flexibility in meeting varying electricity demand.

components of Gas Turbine Power Plant

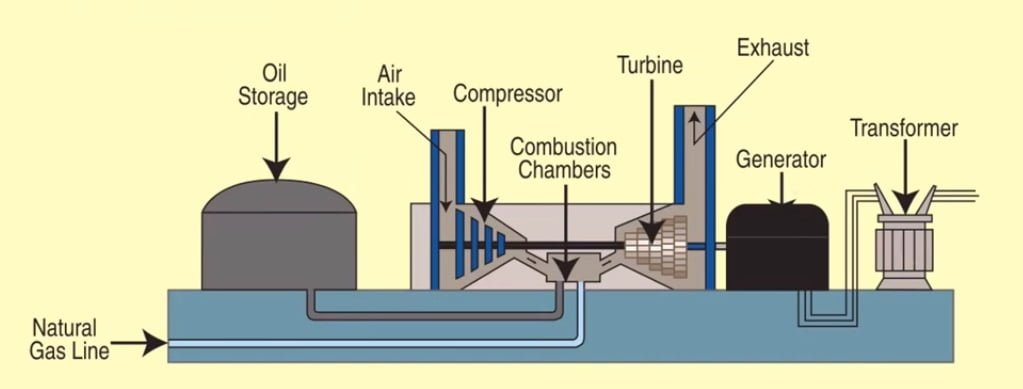

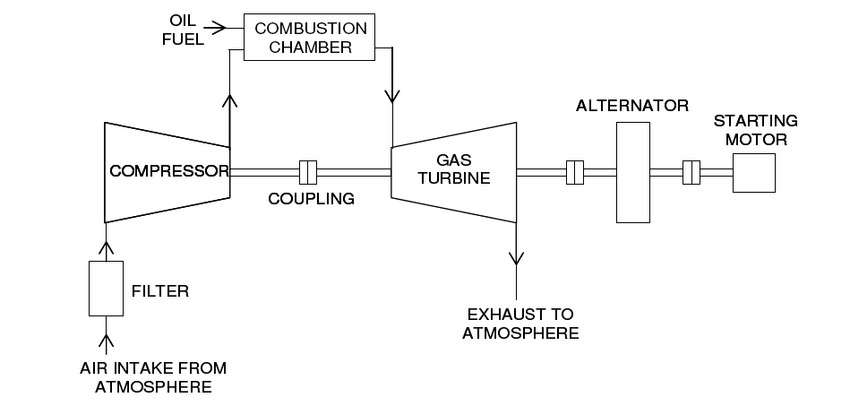

A gas turbine power plant consists of several key components that work together to generate electricity efficiently. Here are the primary components of a typical gas turbine power plant:

- Gas Turbine: The gas turbine is the heart of the power plant. It operates on the Brayton cycle and consists of the following main parts:

- Compressor: The compressor section intakes ambient air and compresses it to high pressure. This compression increases the air’s temperature and density, preparing it for combustion.

- Combustion Chamber: The compressed air is mixed with fuel (usually natural gas, but it can be other gases or liquid fuels) and ignited in the combustion chamber. This process generates high-temperature, high-pressure gases.

- Turbine: The hot gases produced in the combustion chamber are expanded through a series of turbine blades. As the gases pass over the turbine blades, they drive the turbine’s rotor, which is connected to the generator to produce mechanical energy.

- Generator: The mechanical energy produced by the gas turbine is used to turn a generator. This generator converts the mechanical energy into electrical energy, typically generating alternating current (AC) electricity.

- Power Turbine (Optional): In some gas turbine power plant configurations, especially those with combined-cycle systems, there may be a power turbine downstream of the gas turbine. The power turbine is used to extract additional work from the high-temperature, high-pressure exhaust gases, which can be used to drive a separate generator, often in a steam turbine.

- Exhaust System: After passing through the turbine(s), the exhaust gases exit the gas turbine and enter the exhaust system. This system may include components like exhaust ducts and silencers to manage the flow of exhaust gases and reduce noise.

- Heat Recovery Steam Generator (HRSG – in Combined-Cycle Plants): In combined-cycle gas turbine power plants, a heat recovery steam generator is used to capture waste heat from the exhaust gases. It generates steam from this waste heat, which is used to drive a steam turbine connected to another generator, significantly increasing the overall efficiency of the power plant.

- Air Intake System: The air intake system ensures a continuous supply of ambient air to the compressor section of the gas turbine. It may include filters to remove contaminants and moisture from the incoming air.

- Fuel System: The fuel system supplies the required fuel to the combustion chamber. It includes components like fuel pumps, fuel control systems, and fuel nozzles for efficient combustion.

- Lubrication System: Gas turbines have various rotating parts that require lubrication to reduce friction and wear. The lubrication system provides oil to these components and includes filters and cooling systems.

- Control and Monitoring System: Gas turbine power plants rely on sophisticated control systems to manage the operation of the turbine, monitor various parameters, and ensure safe and efficient performance. These systems include sensors, instrumentation, and control panels.

- Cooling Systems: Gas turbines can become extremely hot during operation. Cooling systems, such as air-cooling or water-cooling, are employed to maintain safe operating temperatures for critical components.

- Auxiliary Systems: Various auxiliary systems support the gas turbine’s operation and include systems for starting the turbine, controlling emissions, managing vibration, and handling fuel and waste products.

- Grid Connection: The generated electricity is transmitted through a substation and connected to the electrical grid for distribution to consumers.

These components work together to efficiently convert the energy from the combustion of fuel into electrical power, making gas turbine power plants a versatile and widely used technology for electricity generation. The specific configuration and components of a gas turbine power plant may vary depending on factors such as capacity, fuel type, and the intended application.

how gas turbine power plant work

A gas turbine power plant operates on the principles of the Brayton cycle to generate electricity. The process begins with an air intake system that draws in ambient air, which is then compressed in the compressor section of the gas turbine.

This compression increases the air’s pressure and temperature, preparing it for combustion. Next, fuel, typically natural gas, is injected into the compressed air in the combustion chamber, where it ignites. This combustion produces a high-temperature, high-pressure gas stream.

The hot gases are then expanded through a set of turbine blades in the turbine section, driving the turbine’s rotor and converting thermal energy into mechanical energy.

This mechanical energy is used to turn a generator, which transforms it into electrical energy, generating alternating current (AC) electricity.

Finally, the exhaust gases exit the turbine and are expelled into the atmosphere through an exhaust system. In some cases, a heat recovery system may be integrated to capture waste heat from the exhaust for additional power generation.

Gas turbine power plants are known for their efficiency, quick start-up capabilities, and flexibility in responding to fluctuations in electricity demand, making them integral components of modern power generation systems.

in gas turbine power plant regenerator increases

In a gas turbine power plant, a regenerator, also known as a heat recovery system or a heat exchanger, is a component that is designed to increase the thermal efficiency of the plant by capturing and reusing waste heat from the exhaust gases. The main purpose of a regenerator is to preheat the incoming air before it enters the combustion chamber. This preheating process reduces the amount of fuel needed for combustion, resulting in improved overall efficiency.

Here’s how a regenerator increases efficiency in a gas turbine power plant:

- Heat Recovery: After the high-temperature exhaust gases exit the gas turbine, they still contain a significant amount of thermal energy. Instead of letting this heat go to waste, a regenerator captures it.

- Preheating the Air: The captured waste heat is used to preheat the incoming air from the atmosphere before it enters the combustion chamber. By raising the temperature of the air, less energy from burning fuel is needed to reach the desired combustion temperature.

- Reduced Fuel Consumption: Because the incoming air is preheated, it requires less heating during combustion to achieve the necessary high temperatures. As a result, the combustion process is more efficient, and less fuel is needed to generate the same amount of power.

- Improved Efficiency: The reduction in fuel consumption leads to a significant improvement in the overall thermal efficiency of the gas turbine power plant. This means that a greater portion of the energy from the fuel is converted into useful mechanical work to drive the generator, resulting in more electricity production for the same amount of fuel input.

- Lower Emissions: The improved combustion efficiency, which is facilitated by the regenerator, also contributes to lower emissions of pollutants such as nitrogen oxides (NOx) and carbon dioxide (CO2), making the power plant more environmentally friendly.

It’s important to note that regenerators are commonly used in combined-cycle power plants, where they work in conjunction with both gas turbines and steam turbines to maximize efficiency. The waste heat recovered by the regenerator can be used to generate steam, which drives a steam turbine to produce additional electricity. This combined-cycle configuration further enhances the overall energy conversion efficiency of the power plant.

In summary, a regenerator in a gas turbine power plant increases efficiency by capturing waste heat from the exhaust gases and using it to preheat the incoming air, reducing the amount of fuel required for combustion and improving the overall thermal performance of the plant.

Application of Gas turbine power plant

Gas turbine power plants find a wide range of applications in various industries and sectors due to their versatility, efficiency, and ability to provide reliable power. Here are some common applications of gas turbine power plants:

- Electricity Generation: Gas turbine power plants are commonly used for electricity generation. They can be used for both baseload and peaking power generation, depending on the design and configuration of the plant. Gas turbines are often deployed to meet peak electricity demand quickly and efficiently due to their rapid start-up capability.

- Combined Heat and Power (CHP) or Cogeneration: Gas turbine power plants are utilized in combined heat and power systems, where they not only generate electricity but also capture waste heat for heating or industrial processes. This improves overall energy efficiency and reduces energy costs in industrial facilities, hospitals, universities, and district heating systems.

- Aircraft Propulsion: Gas turbines, also known as jet engines, are used in aviation for propelling aircraft. They provide the thrust needed to propel airplanes and helicopters. These engines are highly efficient and reliable, making air travel possible on a large scale.

- Marine Propulsion: Gas turbine engines are used in naval vessels, commercial ships, and fast ferries to provide propulsion. They offer high power-to-weight ratios, making them suitable for applications requiring speed and maneuverability.

- Oil and Gas Industry: Gas turbines are employed in the oil and gas sector for various purposes, including driving compressors, pumps, and electrical generators on offshore platforms and in natural gas processing plants.

- Industrial Applications: Gas turbines are used in various industrial processes, such as driving machinery, generating process heat, and providing backup power in critical industries like petrochemicals, manufacturing, and food processing.

- Distributed Generation: Smaller gas turbine power plants are often used for distributed generation, providing power to remote areas, islands, or locations with unreliable grid connections. They can also serve as backup power sources for critical facilities like data centers and hospitals.

- Military Applications: Gas turbine engines are widely used in military aircraft, naval vessels, and ground vehicles due to their high power density, reliability, and rapid response capabilities.

- Space Exploration: In space exploration, gas turbines are used as part of propulsion systems for launching spacecraft into orbit and conducting interplanetary missions.

- Emergency Standby Power: Gas turbine generators are commonly installed in hospitals, data centers, and critical infrastructure facilities as emergency backup power sources. They ensure uninterrupted power supply in the event of grid outages.

- Utilities and Grid Support: Gas turbines can be used to support the stability and reliability of the electrical grid. They can quickly respond to fluctuations in demand or supply, helping to balance the grid during peak load conditions or when renewable energy sources are intermittent.

Gas turbine power plants continue to evolve with advancements in technology, making them more efficient and environmentally friendly. Their flexibility and reliability make them a valuable asset in meeting diverse energy needs across various sectors.

advantages of gas turbine power plant

Gas turbine power plants offer several advantages that make them a popular choice for electricity generation and various industrial applications. Here are some of the key advantages of gas turbine power plants:

- High Efficiency: Gas turbines are known for their high thermal efficiency, especially when used in combined-cycle configurations. This efficiency results in more electricity generation for a given amount of fuel compared to some other power generation technologies.

- Quick Start-Up and Shutdown: Gas turbine power plants can be started up and shut down rapidly, making them well-suited for meeting sudden changes in electricity demand, known as peaking power generation. This flexibility is essential for grid stability.

- Fuel Flexibility: Gas turbines can run on a variety of fuels, with natural gas being the most common. They can also operate on diesel, aviation fuels, and other combustible gases. This flexibility allows power plants to adapt to fuel availability and cost fluctuations.

- Low Emissions: Compared to many other fossil fuel power plants, gas turbine power plants produce lower emissions of greenhouse gases and pollutants like sulfur dioxide and particulate matter. Their combustion process is relatively clean.

- Compact Footprint: Gas turbines have a relatively small physical footprint, making them suitable for locations with limited space or for adding capacity to existing power plants.

- Reliability: Gas turbines are known for their reliability and long operational lifespans, with minimal maintenance requirements compared to some other types of power generation equipment.

- Modularity: Power plants can be built with multiple gas turbine units, allowing for scalability. New units can be added as needed to meet growing electricity demand.

- Cogeneration Capabilities: Gas turbine combined heat and power (CHP) systems can simultaneously produce electricity and useful heat, increasing overall energy efficiency. This is particularly valuable in industrial applications and district heating.

- High Power Density: Gas turbines have a high power-to-weight ratio, making them suitable for applications where space and weight constraints are critical, such as aircraft propulsion.

- Lower Water Usage: Gas turbine power plants typically require less water for cooling compared to some other power generation technologies, such as steam turbines. This can be advantageous in regions with water scarcity.

- Low Noise and Vibration: Gas turbines are generally quieter and produce less vibration compared to some other power generation technologies, making them more suitable for urban or noise-sensitive areas.

- Reduced Transmission Losses: Gas turbine power plants can be located closer to urban centers, reducing the need for long-distance transmission lines and minimizing transmission losses.

- Grid Stability: The quick response of gas turbines to changes in electricity demand and their ability to provide ancillary services, such as frequency regulation and voltage support, contribute to grid stability.

Gas turbine power plants have a wide range of applications, from large utility-scale electricity generation to industrial processes and aviation. Their efficiency, flexibility, and relatively low environmental impact make them an important component of the global energy mix.

disadvantages of gas turbine power plant

Gas turbine power plants offer several advantages that make them a preferred choice for various applications. Here are some of the key advantages of gas turbine power plants:

- High Efficiency: Gas turbine power plants can achieve high thermal efficiency, especially when used in combined-cycle configurations. Combined-cycle plants integrate a gas turbine with a steam turbine, allowing them to capture and utilize waste heat, resulting in superior overall efficiency.

- Quick Start-Up: Gas turbines can be brought online rapidly, often within minutes. This rapid start-up capability makes them well-suited for meeting sudden increases in electricity demand or providing backup power during emergencies.

- Fuel Flexibility: Gas turbines can run on a variety of fuels, including natural gas, diesel, aviation fuels, and biofuels. This flexibility in fuel choice allows for adaptation to changing energy markets and availability.

- Lower Emissions: Compared to some other fossil fuel power generation technologies, gas turbines typically produce lower emissions of greenhouse gases, sulfur dioxide (SO2), and nitrogen oxides (NOx). The combustion process can be controlled to minimize emissions further.

- Low Maintenance: Gas turbines are known for their reliability and require relatively low maintenance, especially when compared to certain other power generation technologies, such as coal-fired power plants.

- Modularity: Gas turbine power plants can be designed with multiple gas turbine units, allowing for scalability. Additional units can be added to increase capacity as needed, making them adaptable to changing energy demands.

- High Power Density: Gas turbines have a high power-to-weight ratio, making them suitable for applications where space and weight constraints are significant factors, such as aircraft propulsion and mobile power generation units.

- High Load-Following Capability: Gas turbines can operate efficiently across a wide range of load conditions, allowing them to respond quickly to fluctuations in electricity demand. This load-following capability is crucial for grid stability.

- Combined Heat and Power (CHP): In combined heat and power applications, gas turbines can simultaneously generate electricity and useful thermal energy (e.g., steam or hot water), increasing overall energy efficiency and reducing energy costs for industries and district heating.

- Reliability: Gas turbines have a history of reliable operation, making them suitable for critical applications like backup power generation for hospitals, data centers, and military facilities.

- Reduced Water Usage: Unlike some power plants, gas turbine power plants do not require large amounts of water for cooling, which can be an advantage in water-scarce regions.

- Reduced Transmission Losses: Gas turbine power plants can be located close to areas of high electricity demand, reducing transmission and distribution losses compared to plants located far from load centers.

It’s important to note that while gas turbines offer many advantages, they also have limitations and considerations, including fuel costs, emissions, and efficiency at partial loads. The choice of power generation technology should be based on specific project requirements, environmental considerations, and economic factors.

Check Out Other Important Topics

| IC Engine | Important PDFs | Boilers | Synergy Maritime Exam | Naval Arch | MEO Class 4 |

| Interview Questions | Difference Between | Types of Pumps | Auxiliary Machines | Types of Valves | Home |