What is carburetor

A carburetor is a device used in internal combustion engines, such as those in cars, motorcycles, and small engines like those in lawnmowers and chainsaws. Its primary function is to mix air and a fine spray of liquid fuel, usually gasoline, in the right proportions to create a combustible mixture that can be ignited in the engine’s cylinders.

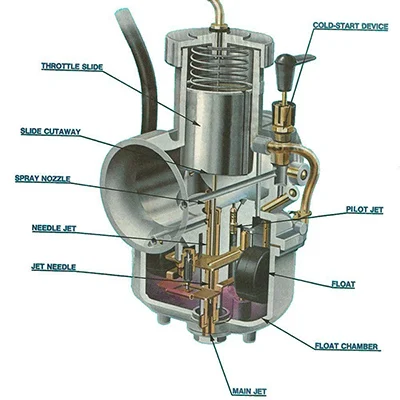

carburetor structure

A carburetor is a critical component in internal combustion engines, responsible for the precise mixing of air and fuel to ensure efficient and reliable engine performance. Its intricate design consists of several key parts that work in concert to deliver the correct air-fuel mixture to the engine cylinders for combustion.

- Throttle Body: At the heart of the carburetor lies the throttle body, a housing that houses various components. The throttle body incorporates the throttle plate or butterfly valve, a movable component that regulates the airflow into the engine. By adjusting the throttle plate’s position, the driver controls the engine’s power output.

- Venturi: Located within the throttle body, the venturi is a critical feature designed to accelerate the airflow passing through it. As the air narrows within this passage, its velocity increases, creating a region of low pressure. This phenomenon, known as the Venturi effect, plays a pivotal role in drawing fuel into the airstream.

- Fuel Bowl: Adjacent to the throttle body, the fuel bowl serves as a reservoir for gasoline. Fuel is supplied to the carburetor from the vehicle’s fuel tank and is stored in this container. A float mechanism within the fuel bowl maintains a consistent fuel level, ensuring a steady supply of fuel to the engine.

- Float: The float is a buoyant device typically crafted from materials like plastic or metal. It rests on the surface of the fuel within the fuel bowl and moves in response to changes in fuel level. As the float rises with increasing fuel volume, it exerts force on a needle valve mechanism, effectively regulating the flow of fuel into the carburetor.

- Needle and Seat: The needle and seat assembly is a crucial component that governs the fuel’s flow from the fuel bowl into the carburetor. As the float rises due to a rising fuel level, it pushes against the needle, sealing the valve and preventing further fuel from entering. Conversely, when fuel is consumed, the float descends, allowing more fuel to enter the carburetor through the opened needle and seat.

- Jets: Carburetors feature small orifices known as jets, which control the precise flow of fuel and air within the device. Typically, there are two primary types of jets: the main jet, responsible for regulating fuel flow at higher engine speeds, and the idle jet, which governs fuel flow at lower engine speeds and idle conditions.

- Choke: An essential feature for starting a cold engine, the choke is a mechanism that temporarily restricts the engine’s air intake. This restriction results in a richer air-fuel mixture, aiding in cold-start combustion. As the engine warms up, the choke gradually opens to permit more air into the carburetor and create a leaner mixture for optimal running conditions.

- Idle and High-Speed Adjustment Screws: Fine-tuning the carburetor’s performance is made possible by the presence of adjustment screws. These screws enable adjustments to the engine’s idle speed and high-speed (or main) fuel mixture, ensuring smooth operation across a range of driving conditions.

- Accelerator Pump: Some carburetors incorporate an accelerator pump, a component responsible for delivering an extra burst of fuel when the throttle is rapidly opened. This function prevents hesitation and engine stalling during quick acceleration, enhancing the overall driving experience.

- Butterfly Valve (Throttle Plate): The butterfly valve, often referred to as the throttle plate, is a circular, flat component that can be rotated within the throttle body. It plays a pivotal role in regulating the airflow into the engine. As the throttle is opened, the butterfly valve also opens, allowing for increased air intake and power production.

These intricately designed components within a carburetor highlight the device’s vital role in internal combustion engines, showcasing its ability to precisely control the air-fuel mixture to optimize engine performance. While modern vehicles have transitioned to more advanced fuel injection systems, carburetors remain a testament to the engineering ingenuity that powered the automotive industry for many decades.

how carburetor works

A carburetor is a mechanical device used in internal combustion engines to mix air and fuel in the correct proportion for efficient combustion. Here’s a step-by-step explanation of how a typical carburetor works:

- Air Intake: The process begins when the engine’s throttle is opened. This action allows air to enter the carburetor through the throttle body. The amount of air entering is controlled by the position of the throttle plate or butterfly valve, which can be adjusted by the driver using the accelerator pedal.

- Venturi Effect: Inside the carburetor, there is a narrowing passage called the venturi. As air flows through the venturi, its speed increases, creating a low-pressure area according to Bernoulli’s principle. This low-pressure area effectively sucks in fuel from the fuel bowl, which is a reservoir holding gasoline.

- Fuel Supply: The fuel bowl contains gasoline supplied from the vehicle’s fuel tank. A float mechanism within the fuel bowl helps maintain a consistent fuel level. As the float drops due to fuel consumption, it opens a valve called the needle and seat, allowing more fuel to enter the carburetor. When the float rises and reaches a certain level, it closes the needle and seat, preventing excess fuel from entering.

- Mixture Formation: The low-pressure area created by the venturi draws fuel through a calibrated jet, known as the main jet, which controls the flow rate of fuel based on engine demands. The fuel is mixed with the incoming air in the venturi, creating a homogeneous air-fuel mixture.

- Choke (During Cold Starts): In cold conditions, an engine requires a richer air-fuel mixture for efficient combustion. A choke mechanism in the carburetor restricts the air intake, increasing the fuel-to-air ratio. This helps the engine start and run smoothly in cold weather. As the engine warms up, the choke gradually opens to allow more air to enter, leaning out the mixture.

- Idle Circuit: At low engine speeds and during idling, a separate idle circuit provides a stable and slightly richer air-fuel mixture to keep the engine running smoothly. This circuit is controlled by an idle jet and adjustment screws.

- Throttle Control: The driver controls the engine’s power output by manipulating the throttle. When the throttle is opened wider, more air enters the carburetor, and the engine receives a larger amount of the air-fuel mixture, resulting in increased power and acceleration. When the throttle is closed, less air flows through, reducing power.

- Accelerator Pump (Optional): Some carburetors include an accelerator pump, which provides an extra shot of fuel when the throttle is rapidly opened. This prevents hesitation and ensures smooth acceleration by compensating for the momentary delay in fuel flow from the main jets.

In summary, a carburetor operates by using the Venturi effect to create a low-pressure area that draws in fuel from the fuel bowl. The amount of air and fuel mixed together is regulated by the position of the throttle, allowing the engine to receive the appropriate air-fuel mixture for its operating conditions. While carburetors have been largely replaced by fuel injection systems in modern vehicles, they remain an essential component in some smaller engines and older vehicles, serving as a testament to the ingenuity of early internal combustion engine technology.

types of carburetor

Carburetors come in various types and designs, each tailored to specific engine applications and requirements. Here are some of the common types of carburetors:

- Updraft Carburetor: Updraft carburetors are a type of carburetor where the air intake is positioned below the fuel bowl. This design was prevalent in the early days of the automotive industry and found extensive use in agricultural and industrial engines as well. The operation of an updraft carburetor involves the upward flow of air into the engine. Fuel is mixed with this incoming air at the upper section of the carburetor. While these carburetors have become increasingly rare in modern vehicles due to design limitations and space constraints, they hold historical significance as a technology that played a crucial role in the early development of internal combustion engines.

- Down-draft Carburetor: Down-draft carburetors are the most common type used in modern automobiles. In a down-draft carburetor, the airflow direction is downward, with air entering from the top and fuel being mixed with the air as it descends into the engine. This design is favored in contemporary vehicles for its compatibility with the layout of most engine compartments, providing efficient use of space. Down-draft carburetors are equipped with various components and adjustments to ensure precise control over the air-fuel mixture, thereby optimizing engine performance and fuel efficiency.

- Side-draft Carburetor: Side-draft carburetors are characterized by their air intake on the side, which differentiates them from the more common down-draft design. This unique configuration offers several advantages, particularly in high-performance and racing applications. Side-draft carburetors provide improved engine breathing by allowing for a more direct and streamlined airflow path. This design is often found in sports cars, racing vehicles, and motorcycles, where maximizing power output and responsiveness are paramount. Side-draft carburetors can be tuned to enhance performance, making them a popular choice among enthusiasts and motor racing teams.

These three main types of carburetors each have their own advantages and limitations, and the choice of which one to use depends on factors such as the engine’s intended application, space constraints, and desired performance characteristics. While carburetors have become less common in modern vehicles, they continue to be an important part of automotive history and are still found in various small engine applications and vintage cars.

application of carburetor

Carburetors were widely used in various applications where internal combustion engines were employed. While they have become less common in modern vehicles and machinery due to the widespread adoption of fuel injection systems, carburetors can still be found in certain applications. Here are some common applications of carburetors:

- Automobiles: Carburetors were a standard component in automotive engines for many decades. They were responsible for mixing air and fuel in gasoline-powered cars, trucks, and motorcycles, providing the combustible mixture needed for engine operation. However, modern vehicles typically use electronic fuel injection systems for better fuel efficiency and emissions control.

- Motorcycles: Many motorcycles, especially older models, utilize carburetors to control the air-fuel mixture. Some smaller and simpler motorcycle engines continue to use carburetors due to their cost-effectiveness and ease of maintenance.

- Small Engines: Carburetors are commonly found in small engines used in lawnmowers, chainsaws, leaf blowers, and other outdoor power equipment. These engines are often simple and cost-effective, making carburetion a practical choice for them.

- Aircraft: Some older aircraft engines, particularly those in vintage or light aircraft, use carburetors for fuel-air mixture control. More modern and complex aircraft typically employ fuel injection systems for better performance and safety.

- Marine Engines: Inboard and outboard boat engines, particularly in older vessels, may feature carburetors for fuel mixing. However, newer marine engines are increasingly adopting fuel injection technology for improved efficiency and emissions compliance.

- Industrial Equipment: Certain industrial equipment, such as generators and pumps, use carbureted engines for simplicity and reliability, especially in regions with limited access to advanced technology.

- Racing Vehicles: In some motorsports, particularly in categories with less restrictive rules, carburetors are still used in high-performance racing engines. Racers prefer carburetors for their tunability and the ability to fine-tune the air-fuel mixture for specific racing conditions.

It’s important to note that while carburetors remain in use in these applications, many industries and vehicle types have transitioned to electronic fuel injection systems. Fuel injection offers more precise control over the air-fuel mixture, resulting in better fuel efficiency, lower emissions, and improved overall engine performance.

advantages of carburetor

Carburetors have been widely used in internal combustion engines for many years, and while they are less common in modern vehicles due to the prevalence of fuel injection systems, they do offer certain advantages in specific situations. Here are some of the advantages of carburetors:

- Simplicity: Carburetors are mechanically simpler than fuel injection systems. They have fewer components and are easier to manufacture and maintain. This simplicity can make them more cost-effective, especially for small engines and in applications where budget constraints are a concern.

- Cost-Effective: Carburetors are generally less expensive to produce and install than complex fuel injection systems. This makes them an attractive choice for applications where cost is a primary consideration, such as small engines used in lawnmowers, chainsaws, and other outdoor equipment.

- Ease of Maintenance: Carburetors can often be more straightforward to service and repair compared to fuel injection systems, which involve electronic components and sensors. Mechanics and DIY enthusiasts with basic automotive knowledge can work on carbureted engines more easily.

- Durability: Carburetors can be robust and reliable when properly maintained. They are less prone to certain electronic and sensor-related failures that can affect fuel injection systems. This durability is particularly advantageous in some industrial and small engine applications.

- Adaptability: Carburetors can be adapted or modified for specific performance requirements, making them popular in some racing and high-performance applications. Enthusiasts can fine-tune carbureted engines to optimize power output and fuel delivery for racing conditions.

- Instant Responsiveness: Carbureted engines often exhibit quick throttle response, which can be advantageous in certain situations, such as off-road vehicles and racing. This responsiveness can make them feel more connected and engaging to drive.

- Availability: While fuel injection systems have become standard in modern vehicles, carburetors and replacement parts are still widely available, making them a viable option for restoring or maintaining older vehicles.

It’s important to note that while carburetors have these advantages, they also have limitations. They are less precise in controlling the air-fuel mixture compared to fuel injection, which can result in lower fuel efficiency and higher emissions. Additionally, they may struggle to meet stringent emissions standards, making them less suitable for modern vehicles that prioritize environmental performance and efficiency.

disadvantages of carburetor

Carburetors have been widely used in the past, but they come with several disadvantages compared to modern fuel injection systems. Here are some of the disadvantages of carburetors:

- Limited Precision: Carburetors are less precise than fuel injection systems in controlling the air-fuel mixture. Achieving the ideal air-fuel ratio under all operating conditions can be challenging, leading to inefficiencies in fuel combustion. This imprecision can result in reduced fuel efficiency and higher emissions.

- Cold Start Problems: Carbureted engines often experience difficulties during cold starts. Getting the right air-fuel mixture for a cold engine can be tricky, leading to rough idling, stalling, and increased emissions until the engine warms up.

- Altitude and Temperature Sensitivity: Carburetors are sensitive to changes in altitude and temperature. As atmospheric conditions change, the air density varies, affecting the air-fuel mixture. This sensitivity can lead to engine performance issues, particularly in mountainous or extreme temperature environments.

- Emissions Control: Meeting modern emissions standards is challenging with carburetors. Controlling pollutants like nitrogen oxides (NOx) and hydrocarbons (HC) to the levels required by environmental regulations is much more difficult with carburetion compared to precise fuel injection.

- Fuel Efficiency: Carbureted engines are generally less fuel-efficient than their fuel-injected counterparts. Inefficient fuel combustion can lead to wasted fuel and reduced miles per gallon (MPG).

- Adaptability: Adjusting or fine-tuning a carburetor for different operating conditions can be time-consuming and require mechanical expertise. This is in contrast to fuel injection systems, which can often self-adjust to changing conditions.

- Maintenance Requirements: While carburetors are mechanically simpler than fuel injection systems, they still require regular maintenance. Components such as jets and floats can become clogged or wear out over time, affecting engine performance. Cleaning and adjusting a carburetor can be a labor-intensive task.

- Decreased Performance: In high-performance applications, carburetors may not provide the same level of precision and control over the air-fuel mixture as fuel injection. This can limit the engine’s ability to deliver maximum power and torque.

- Modern Vehicle Compatibility: Carburetors are not suitable for modern vehicles with advanced engine management systems, emissions controls, and electronic components. Newer vehicles require the precision and adaptability offered by fuel injection.

While carburetors have been reliable and cost-effective in many applications, advancements in technology have made fuel injection systems the preferred choice for most modern vehicles due to their ability to deliver better fuel efficiency, lower emissions, and improved overall engine performance.

Carburetor vs. Fuel Injection

Carburetors and fuel injection systems are two distinct methods for delivering fuel to internal combustion engines. Each has its own set of advantages and disadvantages. Here’s a comparison of carburetors and fuel injection systems:

Carburetors:

- Simplicity: Carburetors are mechanically simpler than fuel injection systems. They have fewer components and are easier to manufacture and maintain. This simplicity can make them more cost-effective, especially for small engines and in applications where budget constraints are a concern.

- Cost-Effective: Carburetors are generally less expensive to produce and install than complex fuel injection systems. This makes them an attractive choice for applications where cost is a primary consideration, such as small engines used in lawnmowers, chainsaws, and other outdoor equipment.

- Ease of Maintenance: Carburetors can often be more straightforward to service and repair compared to fuel injection systems, which involve electronic components and sensors. Mechanics and DIY enthusiasts with basic automotive knowledge can work on carbureted engines more easily.

- Durability: Carburetors can be robust and reliable when properly maintained. They are less prone to certain electronic and sensor-related failures that can affect fuel injection systems. This durability is particularly advantageous in some industrial and small engine applications.

- Adaptability: Carburetors can be adapted or modified for specific performance requirements, making them popular in some racing and high-performance applications. Enthusiasts can fine-tune carbureted engines to optimize power output and fuel delivery for racing conditions.

- Instant Responsiveness: Carbureted engines often exhibit quick throttle response, which can be advantageous in certain situations, such as off-road vehicles and racing. This responsiveness can make them feel more connected and engaging to drive.

Fuel Injection Systems:

- Precision: Fuel injection systems offer precise control over the air-fuel mixture, resulting in better fuel efficiency, lower emissions, and improved overall engine performance. They can adjust the mixture in real-time based on various engine parameters.

- Cold Start: Fuel injection systems perform better during cold starts, as they can adjust the air-fuel ratio to provide an optimal mixture for combustion in cold conditions. This results in smoother and more reliable starts.

- Altitude and Weather Insensitivity: Unlike carburetors, fuel injection systems are less affected by changes in altitude and weather conditions. They can adapt to varying air densities, ensuring consistent engine performance.

- Emissions Control: Fuel injection systems are more effective at controlling emissions, making them better suited for modern vehicles that must comply with stringent environmental regulations.

- Fuel Efficiency: Fuel injection systems are generally more fuel-efficient than carburetors because they can precisely adjust the air-fuel mixture to match engine demands. This leads to better mileage.

- Adaptability: Fuel injection systems are compatible with advanced engine management systems and technologies, such as electronic control units (ECUs) and sensors. This adaptability allows for greater control and optimization of engine performance.

In summary, while carburetors have their advantages, fuel injection systems have become the preferred choice in modern vehicles due to their precision, adaptability, and better performance. They offer improved fuel efficiency and emissions control, making them essential for meeting environmental standards. However, carburetors can still be found in specific applications where their simplicity and cost-effectiveness outweigh their limitations.

Certainly, here’s a comparison of carburetors and fuel injection systems in a table format for easier reference:

| Aspect | Carburetor | Fuel Injection |

|---|---|---|

| Simplicity | Mechanically simpler | More complex |

| Cost-Effective | Generally less expensive | More expensive |

| Maintenance | Easier to service and repair | Requires specialized skills |

| Durability | Robust when properly maintained | Prone to electronic failures |

| Adaptability | Can be modified for performance | Precise control for efficiency |

| Throttle Response | Quick response | Responsive but controlled |

| Cold Start Efficiency | May require manual adjustments | Adapts to temperature changes |

| Altitude/Weather | Sensitive to changes | Insensitive to conditions |

| Emissions Control | Limited control, less efficient | Effective at meeting standards |

| Power/Torque | Typically lower | Generally higher |

| Adaptability | Limited integration with advanced technology | Easily integrates with advanced systems |

Please note that while this table provides a general overview, specific performance and characteristics can vary depending on the design and application of the carburetor or fuel injection system. Modern vehicles primarily use fuel injection due to its advantages in efficiency and emissions control, but carburetors may still be found in certain smaller engines and older vehicles.

Check Out Other Important Topics

| IC Engine | Important PDFs | Boilers | Synergy Maritime Exam | Naval Arch | MEO Class 4 |

| Interview Questions | Difference Between | Types of Pumps | Auxiliary Machines | Types of Valves | Home |