Have you ever wondered how engines come to life when you turn the key or press the start button? The answer lies in a vital component called the starter motor. In this comprehensive article, we’ll explore all about it starting with the definition of starter motors, their types, parts, construction, working principles, and the advantages they offer.

Whether you refer to it as a starter motor, engine starter, or starting motor, this essential device plays a vital role in getting your engine up and running smoothly. By the end, you’ll have a clear understanding of how starter motors work and what are its advantages.

What is Starter Motor?

A starter motor, also known as a starting motor or cranking motor, is an electrical motor that helps to start the engine. It does this by turning the crankshaft, which in turn moves the piston back and forth.

The starting motor is placed on the engine’s flywheel housing. It is designed to operate at low voltages but with high currents. Its main job is to generate a strong rotational force, or torque, when starting the engine at low speeds.

To handle the high currents without overheating, the armature and fields of the motor are built using thick wire, which reduces resistance. As the motor runs faster, it requires less current. On the other hand, when it runs slower, it produces more torque.

In a typical passenger car, the motor draws around 60 amperes when running without any load, and about 600 amperes when slowly starting the engine. However, this high current supply is only needed for a short duration of time.

Must Read : Fleming’s Right Hand Rule

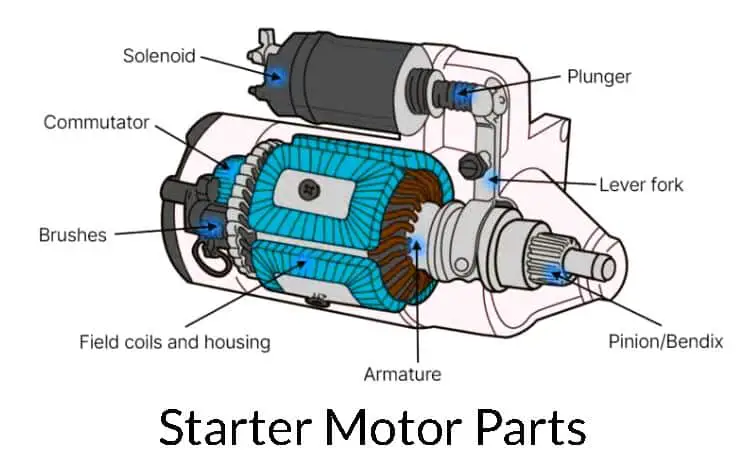

Starter Motor Parts

The following are the parts of a starter motor that are required for its operation:

- Armature

- Commutator

- Solenoid

- Brushes

- Plunger

- Lever fork

- Pinion

- Field coils

Armature

The armature is a component in the starter motor that acts like an electromagnet. It guides the driveshaft or bearings and is made up of a laminated soft iron core. It is wound or looped with multiple conductors to create an electromagnetic field.

Commutator

Located at the back of the housing, the commutator is a part of the shaft that allows the brushes to make electrical contact. It consists of two plates mounted on the armature’s axle and connects the coil of the electromagnet.

Solenoid

The solenoid has two wire coils wrapped around a core. It serves as a switch, controlling the electrical connection between the starter motor and the vehicle’s battery. It can connect or disconnect the power supply.

Brushes

Brushes are used to transfer electrical current from a stationary conductor to a moving conductor. They make contact with the commutator and help conduct electricity as they rub against it.

Plunger

In the starter motor, the plunger has the important task of pushing forward to engage the pinion. This action initiates the motor’s operation.

Lever Fork

The lever fork is connected to the plunger. When the lever fork is pushed forward along with the plunger, it causes the pinion to engage.

Pinion

The pinion is a device that includes a gear and springs inside. It engages with the flywheel teeth immediately after starting the engine, allowing the motor to turn the engine.

Field Coils

The field coils consist of two or more coils connected in series. They are securely held in the motor’s housing using screws. These coils are powered by the battery and create an electromagnet. As a result, a magnetic field forms around the armature, enabling its rotation.

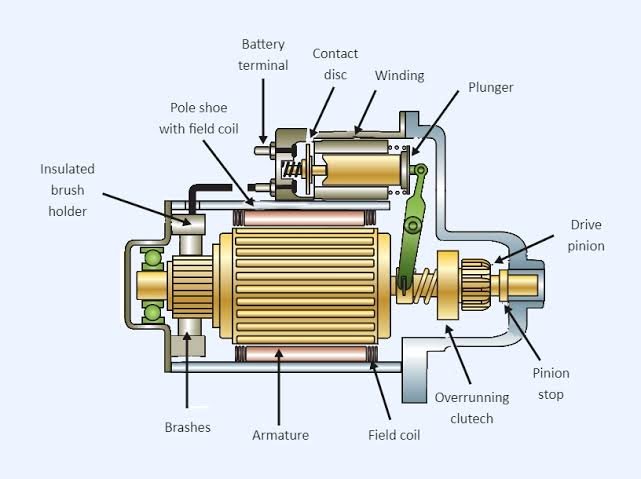

Starter Motor Construction

The construction of a starter motor is similar to that of a generator, but with some differences. The winding brush terminals in the starter motor are designed to handle heavy currents, so they are made heavier. Unlike the carbon brushes used in generators, the brushes in the starter motor are made of low-resistance materials like copper.

The main components of a starter motor include the casing, armature, commutator, field winding brushes, poles, and terminals. At the end of the armature shaft, there is a drive mechanism that is responsible for starting the engine.

There are two types of field windings used in starter motors: two-field windings or four-field windings. In the case of a motor with two field windings, the current from the battery splits into two branches, each leading to a separate field winding.

The current is then directed to the armature’s commutator through the two insulated brushes from the fields. As the current flows through the armature, it creates four poles next to the four field poles, generating attractive and repulsive forces that turn the armature.

The armature current is then returned to the battery through the two grounded brushes. In the case of a starting motor with four field windings, which is commonly used in larger engines to produce more torque, it operates in a similar manner to the two-winding type.

Starter Motor Working

The working of a starter motor is quite straightforward, although many people are unaware of the mechanics behind it. When the ignition key or button is pressed, the transmission should be in either the park or neutral position. At this point, the battery voltage flows through the starter control circuit, activating the solenoid.

The solenoid then supplies power to the starter motor. This causes the starter gear to move forward and engage with the engine’s flywheel. Since the flywheel is connected to the engine’s crankshaft, when the starter motor turns, it rotates the flywheel and, in turn, the crankshaft. Once the engine starts running, the system disengages from the flywheel.

Inside the starter motor, there are four field windings that are mounted and internally connected to the housing. The field coils, along with the armature (the rotating parts), are connected in series using carbon brushes.

It’s important to note that some starters use magnetic fields instead of field coils. Additionally, there is a small gear connected to the front of the armature through an overrunning clutch mechanism.

Types of Starter Motors

The following are the main types of starter motors:

- Direct drive starter motor (DD)

- Planetary gear (PLGR)

- Permanent magnet gear reduction (PMGR)

- Permanent magnet direct drive (PMDD)

- Off-set gear reduction (OSGR)

- Inertial starter

Direct Drive Starter Motor (DD)

The direct drive starter motor is the most common and traditional type of starter motor. It is operated by a solenoid and has a simple design compared to other types.

When the ignition switch or key is turned on, the vehicle’s battery supplies power to the solenoid. This activates the lever, controlled by a plunger, which moves the pinion gear. The pinion gear meshes with the engine flywheel. As a result, when the starter motor turns, it also turns the flywheel, initiating the engine’s combustion process.

Planetary Gear (PLGR)

Planetary gear starter motors have become increasingly popular and have largely replaced direct drive types. These motors transfer power between the armature and the pinion shaft using a permanent magnet. The armature spins faster and with more torque.

The main purpose of the planetary gear system is to provide gear reduction, which reduces the demand for high current. At the end of the armature, there is a sun gear, while three planetary gears are housed inside a stationary ring gear. The design of planetary gears allows for significant gear reduction because the ring gear holds the sun gear and transfers power through the planetary gears.

Permanent Magnet Gear Reduction (PMGR)

The permanent magnet gear reduction starter motor is designed to be lightweight, simple to construct, and generate less heat. Instead of using field coils, it features four to six magnet field assemblies.

This type of starter motor has three terminals on the 12V solenoid and is considered heavy-duty, requiring lower current. Since there are no field coils, the current is directed from the commutator and brushes directly to the armature.

Permanent Magnet Direct Drive (PMDD)

PMDD starter motors are similar to direct-drive starter motors in many ways. However, in the case of permanent magnet direct drive starters, the field coil is replaced with permanent magnets.

Off-Set Gear Reduction (OSGR)

Off-set gear reduction starter motors operate at high speeds with low currents. They are easier to assemble due to their lightweight and compact design. These starters are commonly used in four-wheel-drive vehicles as they provide a boost in cranking torque.

Inertial Starter

An inertial starter is an electric type of starter motor that is capable of performing all the functions of other starters. It excels in cranking performance and ensures the safety of the motor components.

When it comes to quick and powerful engine starting, the inertial starter is the ideal choice. The starter’s weight has minimal impact on its ability to generate torque.

How Can You Test Starting Motor System?

If the starter motor is not functioning, there are several things you should check. First, examine the charge level of the battery and ensure the terminals and cables are securely connected. When you turn the key to the START position, one indication of a weak battery is the dimming of dash lights.

The next step is to test the starter control circuit. A reliable mechanic may begin by checking the battery voltage at the starter solenoid control terminal when the key is in the START position.

If there is no voltage, it indicates a problem with the starter control circuit, which includes components such as the neutral safety switch, starter relay, ignition switch, and control wire.

On the other hand, if there is battery voltage at the starter solenoid control terminal but the starter motor does not work, it suggests a faulty starter motor. It is also crucial to verify that the starter solenoid control terminal is correctly connected.

What is the principle of starter motor ?

The principle of a starter motor is to convert electrical energy from the battery into mechanical energy to initiate the engine’s cranking process. It relies on the fundamental principle of electromagnetism and the interaction between magnetic fields and electric currents.

The starter motor is a direct current (DC) motor specifically designed to generate a high amount of torque for starting the engine. It consists of several key components, including the armature, field coils, commutator, brushes, and a solenoid.

When the ignition key is turned to the “start” position, an electrical current from the battery is sent to the starter motor through the solenoid. The solenoid acts as a switch, connecting the battery to the motor.

The electrical current flows through the field coils, which are electromagnets, creating a magnetic field. The field coils are designed to produce a strong magnetic field when energized.

Inside the motor, the armature, which is a rotating component, is positioned between the field coils. The armature consists of a core made of laminated soft iron and conductive windings.

As the electrical current flows through the armature windings, it creates another magnetic field that interacts with the magnetic field produced by the field coils. This interaction generates a force, known as torque, which causes the armature to rotate.

The rotation of the armature is transferred to the engine’s flywheel through a pinion gear mechanism. The pinion gear engages with the flywheel’s teeth, allowing the starter motor to turn the engine’s crankshaft.

Once the engine starts running, the ignition system takes over, and the starter motor disengages from the flywheel. The solenoid releases the pinion gear, and the electrical current to the starter motor is interrupted.

What are the advantages of starter motor?

The starter motor offers several advantages that contribute to the smooth and efficient operation of an engine. Some of the key advantages of a starter motor are:

- Ease of Starting: The primary advantage of a starter motor is its ability to start an engine with minimal effort. Unlike manual methods of cranking, which can be physically demanding and time-consuming, a starter motor provides a convenient and effortless way to initiate the engine’s operation.

- Quick Engine Startup: It enables rapid engine startup. With a simple turn of the ignition key, the starter motor swiftly engages, cranks the engine, and initiates the combustion process. This saves valuable time, particularly in situations where prompt engine startup is essential, such as in emergency vehicles or critical machinery.

- Increased Safety: By eliminating the need for manual cranking, the starter motor enhances safety during engine startup. Manual cranking methods can be risky, especially if there is a backfire or sudden engine kickback. It minimizes the potential for personal injury and provides a safer and more controlled starting process.

- Consistent Performance: It is designed to deliver consistent and reliable performance. They are constructed to withstand the demanding conditions of engine starting, including the generation of high torque and the ability to handle high currents. This ensures that the engine starts smoothly and consistently, regardless of external factors or environmental conditions.

- Energy Efficiency: Starter motors are engineered for energy efficiency. They are designed to operate efficiently, consuming only the necessary amount of electrical energy from the battery to start the engine. This helps to conserve battery power and optimize overall energy usage in the vehicle or machinery.

- Longevity and Durability: It is built to be durable and long-lasting. They are subjected to rigorous testing and quality control measures to ensure their reliability and endurance. This allows the starter motor to withstand the demands of frequent engine startups over an extended period, contributing to its overall longevity.

Bad Symptoms of Starter Motor

The starter motor in your car plays a crucial role in ensuring a smooth start. However, it can become a nightmare if it starts to fail. Like other important parts of your car, a failing starter motor exhibits signs and symptoms that indicate trouble.

Here are 5 common symptoms of a failing starter motor to help you take action before it becomes too late:

- Engine won’t start: One of the most obvious signs is when you turn the key, but the engine fails to start. This could be a clear indication of a problem with the starter motor.

- Starter cranks, but the engine is unpowered: Another symptom is when the starter motor is spinning or cranking, but the engine does not engage or start running. It suggests an issue with the connection between the starter motor and the engine.

- Grinding noises: If you hear grinding noises when starting the car, it could mean that the starter motor’s gears are not properly engaging with the flywheel. This grinding sound is a sign of potential starter motor failure.

- Smell or smoke while starting: If you notice a strange smell or see smoke coming from the engine area when starting the car, it could indicate overheating or electrical issues with the starter motor. This should be addressed promptly to prevent further damage.

- Dimming of lights when starting: When you start the car, if you observe that the lights inside or outside the vehicle become dimmer, it may indicate a problem with the starter motor drawing excessive power from the battery.

Additionally, you may hear a whirring noise from the starter motor, which could indicate worn-out or damaged components.

Solutions for Starter Motor Issues

There are a few methods you can try to address starter motor issues:

Taking a Closer Look Under The Hood

Inspect the battery and battery cables of your vehicle to ensure they are in good condition. Sometimes, the issue may be related to faulty cables or a weak or dead battery.

Tap the Starter

Gently tapping the body of the starter motor with a light tool, like a wrench or hammer, can sometimes help resolve minor issues. Be careful not to apply excessive force to avoid damaging the component.

Transmission Adjustment

If you have an automatic transmission, try shifting from “Park” to “Neutral” if the starter motor fails to engage. In some cases, starting the car in neutral instead of park can bypass any technical issues preventing it from starting.

Checking the Fuel Gauge

In modern combustion engines, there is a possibility that a vehicle may not start if the fuel tank is empty due to the installed sensor. Make sure to check the fuel gauge to ensure there is sufficient fuel for the engine to start.

What is starter solenoid ?

The starter solenoid is an essential component in the starting system of a vehicle. It acts as a switch between the battery and the starter motor. The solenoid is typically located on the starter motor itself or in close proximity to it.

The solenoid is an electromagnetic device that consists of a coil of wire and a movable plunger. When the ignition key is turned to the “start” position, an electrical current is sent from the battery to the solenoid. This current energizes the coil, creating a magnetic field.

The magnetic field then attracts the plunger, which is connected to the starter motor. As the plunger moves, it pushes a set of contacts together, completing the circuit between the battery and the starter motor. This allows a large amount of electrical current to flow from the battery to the starter motor, enabling it to crank the engine and start the vehicle.

Once the engine starts running, the ignition key is released from the “start” position, and the current to the solenoid is interrupted. This causes the magnetic field to collapse, releasing the plunger and separating the contacts. As a result, the circuit between the battery and the starter motor is broken, and the starter motor disengages from the engine’s flywheel.

Source : Wikipedia

starter motor : FAQs

What is a starter motor?

A starter motor is an electric motor that is used to initiate the engine’s operation by cranking the engine to start the combustion process.

Which motor is used as a starter motor?

A direct current (DC) motor is commonly used as a starter motor due to its ability to generate high torque at low speeds, which is necessary for engine cranking.

What is the use of a starter motor?

The primary use of a starter motor is to start the engine of a vehicle or machinery. It provides the initial rotational force to turn the engine’s crankshaft, allowing the combustion process to begin.

Is a starter motor AC or DC?

A starter motor is typically a DC motor. Direct current is used because it provides the required torque and control for efficient engine cranking.

What are the advantages of a starter motor?

The advantages of a starter motor include ease of starting the engine, quick engine startup, enhanced safety compared to manual cranking, consistent performance, energy efficiency, and long-lasting durability. These benefits contribute to the smooth and efficient operation of the engine.

Conclusion

In conclusion, the starter motor is a crucial component of a combustion engine, offering numerous benefits over manual cranking. It enhances engine lifespan, fuel efficiency, and provides reliability and safety. Therefore, maintaining a starter motor in good condition is vital for ensuring smooth and efficient engine operation.