Scavenging and turbocharging

Scavenging and turbocharging is one of the most important topic of Diesel Engine.

Here you get all types of questions related scavenging and Turbocharging with solutions.

Let’s start all questions of scavenging and turbocharging with answers

Q. What is scavenging? Name the types of scavenge used for large two stroke engine. Describe the

advantage of Uniflow scavenging.

SCAVENGING:

It is the removal of residual exhaust gas and its replenishment with fresh air in an internal combustion of the

engine. The fresh air intake and exhaust gas expel operation are not simultaneous fully but some degrees of overlap period are provided for better efficiency.

There are 3 types of scavenging process.

1. Loop scavenging

2. Cross scavenging

3. Uniflow scavenging

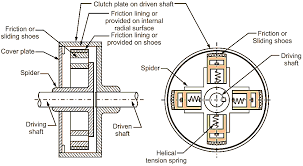

Loop scavenging:

In this type of scavenging air passes over the piston crown and rises to form a loop. Ports are cut in the cylinder liner wall for this operation. The scavenge ports and exhaust ports are in the same side of the liner.

Image credit: Introduction To Marine Engineering by D A TAYLOR

Cross scavenge:

In this type of scavenging the scavenge air is directed upwards and expelled from the opposite side of the liner.

Scavenge and exhaust Ports are cut in the cylinder liner wall for this operation. The scavenge ports and exhaust ports are in opposite side of each other.

Uniflow scavenging:

In this type of scavenging scavenge air enters through ports near the bottom of the liner then travels straight up the liner and forcing the exhaust gas to expel from the top through valve arrangements. This gives maximum efficiency of scavenging.

Advantages of Uniflow scavenging:

• Highest efficiency of scavenging and Very little amount of exhaust and scavenge intermixing.

• Provides higher degrees of overlapping period hence increasing efficiency of the engine.

• Allow simplicity of liner as fewer ports are cut.

• More liner cooling is achieved/Thermal stresses are less compared to other method of scavenging.

• Avoid long piston skirt.

• Make satisfactory & economical of cylinder lubrication/ Cylinder L.O. consumption is reduced.

• Efficient design for long stroke engine.

Follow me on twitter :- Click Here

[…] Must read :- Turbocharging and scavenging […]