Cylinder liners are a critical component in internal combustion engines that help to ensure optimal performance and longevity. These cylindrical sleeves provide a wear-resistant surface for the piston to move against while also dissipating heat generated during combustion. The selection of the right type of cylinder liner and material is essential to ensure efficient engine operation and maximum longevity.

In this article, we’ll take an in-depth look at cylinder liners, including their definition, function, types, and materials. Whether you’re a seasoned mechanic or simply curious about the inner workings of engines, this article will provide valuable insights into this critical engine component. So let’s dive in and explore everything you need to know about cylinder liners.

What is Cylinder Liner?

Cylinder liners, also known as cylinder sleeves, are an essential component in internal combustion engines. They are cylindrical sleeves that fit inside the engine block and provide a wear-resistant surface for the piston to move against. Cylinder liners are typically made of cast iron, but can also be made of materials such as aluminum, steel, and ceramic.

The primary function of cylinder liners is to provide a durable surface for the piston to move against while also dissipating heat generated during combustion. Without cylinder liners, the piston would move directly against the engine block, causing excessive wear and heat buildup that could lead to engine failure.

What is the need of cylinder liner In an IC Engine?

The cylinder liner, also known as the cylinder sleeve, is an essential component of an internal combustion (IC) engine. It serves as a replaceable cylindrical surface that fits inside the engine block, forming a cylinder where the piston reciprocates.

The primary purpose of the cylinder liner is to provide a durable and wear-resistant surface for the piston to move against. Without a cylinder liner, the piston would slide directly against the metal surface of the engine block, leading to rapid wear and eventual engine failure.

What are the functions of cylinder liner?

Cylinder liners are an integral part of internal combustion engines, performing several essential functions. Here are some of the key functions of cylinder liners:

- Providing a wear-resistant surface for the piston: The primary function of cylinder liners is to provide a durable surface for the piston to move against. This helps to reduce friction and wear between the piston and the engine block, ensuring optimal engine performance and longevity.

- Dissipating heat generated during combustion: Cylinder liners also play a crucial role in dissipating the heat generated during combustion. The liner helps to transfer heat away from the piston and into the engine coolant, preventing overheating and damage to the engine.

- Supporting the cylinder walls: Cylinder liners provide structural support to the engine block’s cylinder walls, preventing them from flexing and bending under the force of the piston. This helps to maintain the engine’s structural integrity and prevent damage or failure.

- Reducing engine noise: Cylinder liners can also help to reduce engine noise by dampening vibrations caused by the piston’s movement. This helps to create a smoother and quieter engine operation.

What are the types of Cylinder Liner ?

There are mainly two types of cylinder liner used in internal combustion engines. Each type has its own advantages and disadvantages, and the choice of liner type depends on the specific engine design and the desired performance characteristics. Some of the most common types of cylinder liner include:

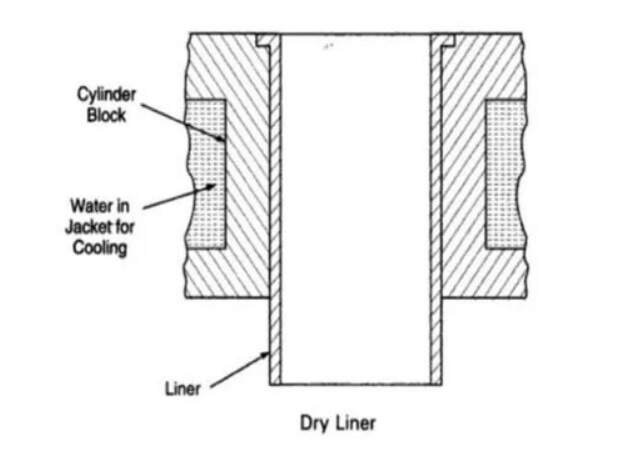

- Dry liners – Dry liners are a type of cylinder liner that are not in contact with any coolant. They are typically made from cast iron and are designed to fit inside the engine block with a small gap between the liner and the block. Dry liners are used in many types of engines, from small single-cylinder engines to large multi-cylinder engines.

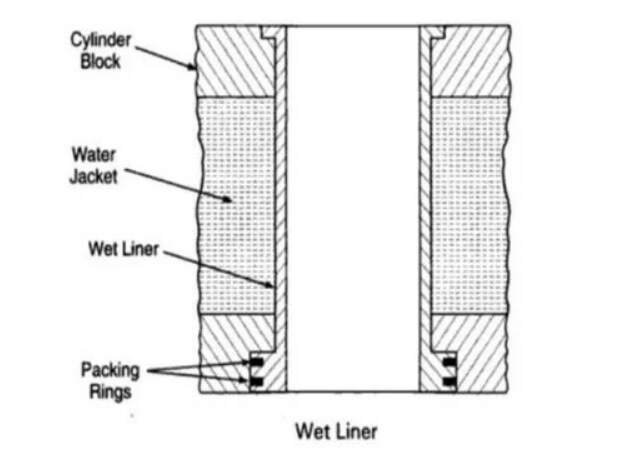

- Wet liners – Wet liners, also known as coolant liners, are a type of cylinder liner that are surrounded by engine coolant. They are typically made from cast iron or steel and are designed to fit inside the engine block, with a small gap between the liner and the block. Coolant flows through this gap, which helps to keep the liner cool and prevent overheating.

What are Dry Liners ?

Dry liners, also known as “cast-in liners,” are a type of cylinder liner that are cast directly into the engine block. Unlike wet liners, which are removable and placed inside the engine block, dry liners are permanently fixed into the block during the casting process.

Dry liners are typically made of cast iron or aluminum and are designed to be thin, lightweight, and able to withstand high levels of stress and wear. They are often used in high-performance engines and racing applications, where weight reduction and durability are critical factors.

Advantages of Dry Cylinder Liners

One of the main advantages of dry liners is their ability to dissipate heat efficiently. The direct contact between the liner and the block allows heat to transfer quickly from the liner to the block, which helps to keep the engine operating at a safe temperature.

They offer several advantages over wet liners, including:

- Improved durability – Dry liners are designed to withstand high levels of wear and tear, making them more durable than wet liners.

- Reduced weight – Dry liners are generally lighter than wet liners, which can help to improve the overall performance of the engine.

- Increased engine rigidity – Dry liners can help to increase the rigidity of the engine block, improving its overall strength and reducing the risk of flexing or warping under high stress.

- Easier installation – Dry liners are typically easier to install than wet liners, as they do not require additional coolant passages or fittings.

Another added advantage of dry liners is their ability to be machined to very tight tolerances during the casting process. This helps to ensure consistent piston-to-liner clearance and optimal engine performance.

However, dry liners also have some disadvantages. Because they are cast directly into the engine block, they cannot be easily replaced if they become damaged or worn.

Disadvantages of Dry Cylinder Liners

- Poor heat dissipation – Dry liners do not have coolant flowing around them, which can lead to poor heat dissipation and increased risk of overheating.

- Increased engine noise – Dry liners can be noisier than wet liners due to the lack of coolant surrounding them.

- Limited coolant flow – Without coolant flowing around the cylinder liner, the cooling of the engine can be less efficient.

In addition, the casting process can be complex and costly, making dry liners a more expensive option than wet liners.

What Are Wet Liners ?

Wet liners, also known as coolant liners, are a type of cylinder liner used in some internal combustion engines. As the name suggests, wet liners are surrounded by engine coolant, which helps to keep them cool during operation.

Wet liners are typically made from cast iron or steel and are designed to fit inside the engine block, with a small gap between the liner and the block. Coolant flows through this gap, which helps to keep the liner cool and prevent overheating.

Advantages of Wet Cylinder Liners

There are several advantages to using wet liners in an engine, including:

- Improved heat dissipation – Wet liners have coolant flowing around them, which helps to dissipate heat and prevent overheating.

- Increased engine life – Wet liners can help to prolong the life of the engine, as they reduce the risk of overheating and wear.

- Reduced engine noise – The presence of coolant around the cylinder liner can help to dampen engine noise, making the engine quieter overall.

- Improved sealing – Wet liners can help to improve the sealing of the engine, as they create a tight seal between the liner and the block.

Disadvantages of Wet Cylinder Liners

However, there are also some disadvantages to using wet liners, including:

- Increased weight – Wet liners are generally heavier than dry liners, which can have a negative impact on the overall performance of the engine.

- Increased complexity – Wet liners require additional coolant passages and fittings, which can make the engine more complex and difficult to work on.

- Increased risk of corrosion – The presence of coolant around the cylinder liner can increase the risk of corrosion and rust, which can lead to premature failure.

What are Flanged liners ?

Flanged liners are a type of cylinder liners that have a flange on one or both ends. The flange is an extended part of the liner, which provides additional support and stability to the liner. Flanged liners are typically used in engines that operate at high speeds and under high pressure.

The flange helps to prevent the liner from moving or shifting within the engine block, which can lead to catastrophic engine failure. The flange also helps to distribute the forces and stresses evenly throughout the liner, reducing the risk of cracking or warping.

Flanged liners are often made from materials that can withstand high temperatures and pressures, such as cast iron or steel. The flange is usually machined or cast as part of the liner, but in some cases, it can be a separate component that is bolted or welded onto the liner.

One advantage of flanged liners is that they are relatively easy to install and remove, as they can be simply bolted or screwed into place. They also offer good heat transfer properties, which can help to keep the engine cool and improve overall performance.

However, one disadvantage of flanged liners is that they can be more expensive to manufacture than other types of liners, due to the additional machining or casting required to create the flange. They can also be more difficult to replace if they become damaged, as the flange may need to be removed or replaced along with the liner.

What are Finned liners ?

Finned liners are a type of cylinder liners that have fins or ridges along their outer surface. These fins or ridges increase the surface area of the liner, which improves heat dissipation and helps to keep the engine cool. Finned liners are often used in engines that operate at high temperatures or under high loads.

The fins or ridges on a finned liner can be either cast or machined into the liner, depending on the manufacturing process. The fins can be arranged in different patterns and orientations to optimize heat dissipation and improve airflow within the engine block.

Finned liners are typically made from materials that have good heat transfer properties, such as aluminum or copper alloys. These materials can also be lightweight, which can help to reduce the overall weight of the engine and improve fuel efficiency.

One advantage of finned liners is that they can help to prevent overheating and improve the longevity of the engine. The increased surface area of the liner allows for more efficient heat dissipation, which reduces the risk of hot spots and thermal stress.

However, one disadvantage of finned liners is that they can be more difficult to manufacture than other types of liners, due to the additional machining or casting required to create the fins. They can also be more expensive to produce than other types of liners, which can make them less practical for certain applications.

Materials Used for Cylinder Liners

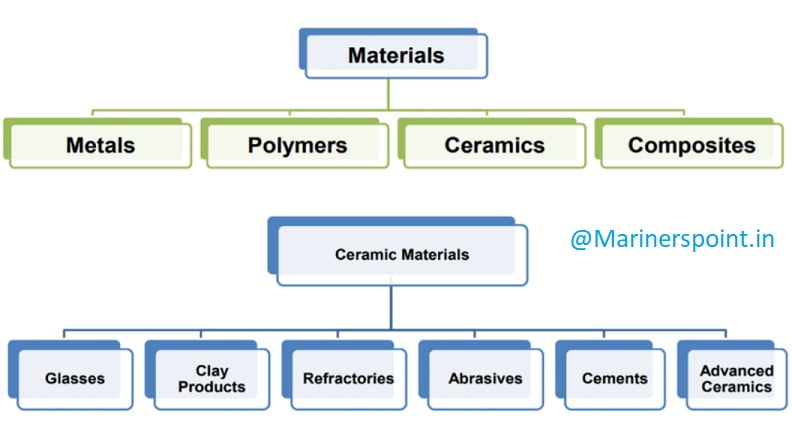

Cylinder liners are typically made from one of four materials: cast iron, aluminum, steel, or ceramic.

Cast Iron

Cast iron is the most common material used for cylinder liners. It is durable, wear-resistant, and can withstand high temperatures without deforming. Cast iron liners are also relatively inexpensive to manufacture.

Aluminum

Aluminum cylinder liners are lighter than cast iron liners, making them popular in high-performance engines. They are also more thermally conductive, which allows them to dissipate heat more efficiently. However, aluminum liners are more expensive to manufacture than cast iron liners.

Steel

Steel cylinder liners are strong and wear-resistant, making them a popular choice in heavy-duty engines. They are also relatively lightweight and can dissipate heat well. However, steel liners are more expensive to manufacture than cast iron liners.

Ceramic

Ceramic cylinder liners are the most expensive and least common type of liner. They are extremely wear-resistant and can withstand very high temperatures without deforming. Ceramic liners are also very lightweight, which can improve the performance of the engine. However, they are brittle and can crack or shatter if subjected to extreme stress.

Difference between Dry liner and Wet liner

| Feature | Dry Liner | Wet Liner |

|---|---|---|

| Cooling Method | Air-cooled | Water-cooled |

| Material | Made of harder materials | Made of softer materials |

| Installation | Press-fitted into the block | Fixed into the block with adhesive |

| Ease of Replacement | Easy to replace | Difficult to replace |

| Sealant | No need for sealant | Requires sealant |

| Cylinder Wall Thickness | Thick cylinder wall | Thin cylinder wall |

| Heat Dissipation | Lower heat dissipation | Higher heat dissipation |

| Suitability for High-Performance Engines | Suitable for high-performance engines | More suitable for low to medium-performance engines |

What are the cracked cylinder liner symptoms?

A cracked cylinder liner can cause a number of symptoms in an engine, including:

- Loss of Compression: A cracked cylinder liner can cause a loss of compression in the affected cylinder, which can result in a decrease in engine power and performance. The engine may also produce a noticeable decrease in exhaust noise.

- Coolant Loss: If the crack in the cylinder liner allows coolant to leak into the cylinder, the engine may experience a loss of coolant. This can lead to overheating and potential engine damage if the issue is not addressed promptly.

- Oil Contamination: A cracked cylinder liner can allow coolant to mix with the engine oil, resulting in oil contamination. This can cause the oil to lose its lubricating properties, which can lead to premature wear of engine components.

- Smoke and/or Steam from Exhaust: If coolant is leaking into the cylinder, it can cause smoke and/or steam to be emitted from the exhaust. This can be particularly noticeable during startup or acceleration.

- Rough Idling: A cracked cylinder liner can cause the engine to run rough or have a misfire. This can be caused by the loss of compression in the affected cylinder.

- Engine Overheating: If coolant is leaking into the cylinder, it can cause the engine to overheat. This can be particularly noticeable during heavy engine loads or when driving in hot weather.

- Engine Failure: If left unaddressed, a cracked cylinder liner can eventually cause engine failure. This can be a costly and time-consuming repair, and may even require an engine replacement in severe cases.

Marine cylinder liner removal Process

Marine cylinder liner removal is a specialized process used to remove the cylinder liner from a marine diesel engine. The process is necessary when the liner needs to be replaced or serviced due to wear or damage. Removing a cylinder liner from a marine engine can be challenging, and it requires specialized tools and expertise.

The process of marine cylinder liner removal typically involves disassembling the engine to expose the liner, removing the piston from the cylinder, and then using a specialized liner removal tool to extract the liner from the engine block. The removal tool is often hydraulically operated and is designed to exert a controlled amount of force on the liner, allowing it to be removed without damaging the engine block.

There are several factors that must be considered when performing marine cylinder liner removal. These include the type and size of the engine, the condition of the liner, and the accessibility of the engine components. In addition, it is essential to follow proper safety protocols, including wearing appropriate protective equipment and ensuring that the engine is properly secured during the removal process.

What is cylinder liner wear ?

Cylinder liner wear is a common problem that occurs in internal combustion engines. It refers to the gradual wearing away of the cylinder liner over time due to the constant friction between the piston rings and the liner during the combustion process.

The wear of cylinder liner can cause a number of problems such as reduced engine efficiency, decreased power output, and increased fuel consumption. It can also lead to oil consumption, which can result in engine damage if not addressed in a timely manner.

Cylinder liner wear is caused by several factors, including inadequate lubrication, high engine temperatures, and poor fuel quality. Over time, the piston rings can wear down the liner, causing it to become rough and uneven. This can lead to increased friction and heat, further exacerbating the problem.

To prevent cylinder liner wear, it is important to maintain the engine properly. Regular oil changes, proper lubrication, and use of high-quality fuel can help minimize wear and prolong the life of the liner. Additionally, using appropriate engine cooling and maintaining proper operating temperatures can also help reduce wear.

It is important to regularly inspect and measure the liner to monitor wear and prevent damage to the engine. Gauging can help determine the amount of wear and provide insight into the engine’s overall condition. If excessive wear is found, the liner may need to be replaced to avoid further damage to the engine.

Construction of Cylinder Liner Used on Ships

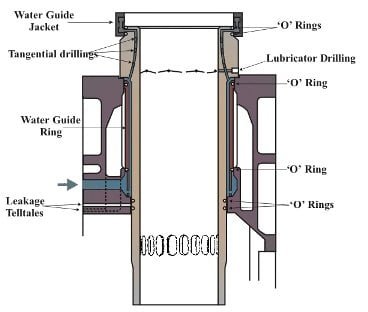

The upper end of the liners forms a flange of sufficient strength to support it. This flange is secured between the cylinder cover and the jacket or engine entablature, leaving the lower end of the liner free for thermal expansion.

The liner thickness must give adequate strength to resist the internal gas load but is limited by necessary to transfer heat rapidly to reduce the thermal stress. Thickness may be reduced towards the lower end where pressure and temperature are less, but External Flanges and bossing may be added to accommodate seal rings, lubricator connection etc.

In large two stroke engine liners, Scavenge air ports will be cut or cast in near the lower end. Engines using loop or Cross scavenge system will also need exhaust ports. All port edge are shaped to direct the flow. Cylinder liners in four stroke engine requires no ports and are of more simple shape.

To remove excess heat, limit thermal stress and maintain a surface temperature at which an oil lubrication film can be retained, liners require an external cooling system.

Cylinder Liner – FAQs

What is the difference between wet and dry cylinder liners?

Wet liners are removable and have coolant flowing around them, while dry liners are non-removable and do not have coolant flowing around them.

What is the purpose of a cylinder liner?

The primary purpose of a cylinder liner is to provide a wear-resistant surface for the piston to move against and to dissipate heat generated during combustion.

Can cylinder liners be replaced?

Yes, in the case of wet liners, they can be easily replaced. However, dry liners are cast into the engine block and cannot be replaced without damaging the block.

Which material is most commonly used for cylinder liners?

Cast iron is the most common material used for cylinder liners due to its durability, wear-resistance, and relatively low cost.

What factors should be considered when selecting a cylinder liner?

Factors such as the engine’s intended use, operating conditions, and budget should be considered when selecting a cylinder liner, as different types and materials offer unique advantages and drawbacks.

Cylinder liner, in which the compression of air and the combustion of fuel/air mixture takes place inside the cylinder liner, so it forms part of the combustion chamber.

Material

It must provide adequate strength and fatigue life,

Function :-

readily transfer heat,

resist abrasion and corrosion,be able to retain a film of lubricating oil on working surfaces, and have rate of thermal expansion compatible with adjacent parts.

It must maintain low wear rates and friction losses from the sliding motion of piston rings under fluctuating pressure and temperature.

To meet these requirements for Limited intial cost, liners are cast in pearlitic grey cast iron to which alloying elements such as vanadium and Titanium are added to enhance strength,wear and corrosion Resistance.

Chromium plating of internal surface can be carried out to reduce urea and corrosion further. The Chrome must either be deposited as a porous structure or else be etched to retain lubrication. Chrome plated liners have extended life but initial cost is Greater.

chromium plated piston ring must not used with plated Liners.

Co

[…] lube oil,un burnt fuel oil and carbon from the residual products of combustion spaces (cylinder liner ) are accumulated in the scavenge spaces with the running of the […]