Scavenge fire,one of the most common causes for a fire in the engine room of ship.Scavenge fire has been the cause of several major ship accidents in the past, and it is for this reason that it is considered to be the most dangerous cause of ship accidents.

As we know that, prevention is better than cure,In this Article I am going to Discuss every aspect of scavenge fire- from causes to actions taken.

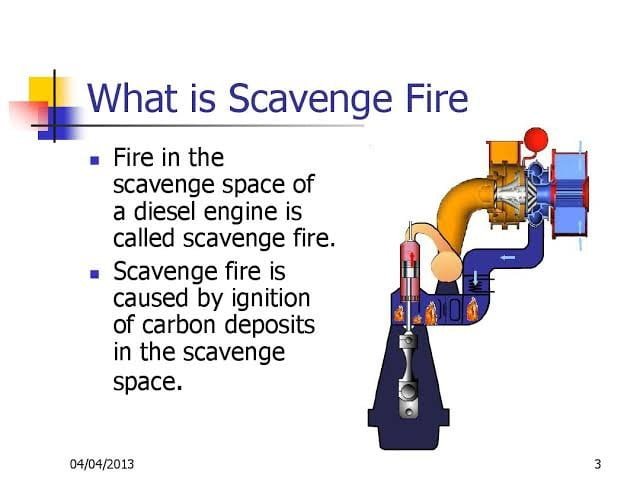

What is scavenge fire ?

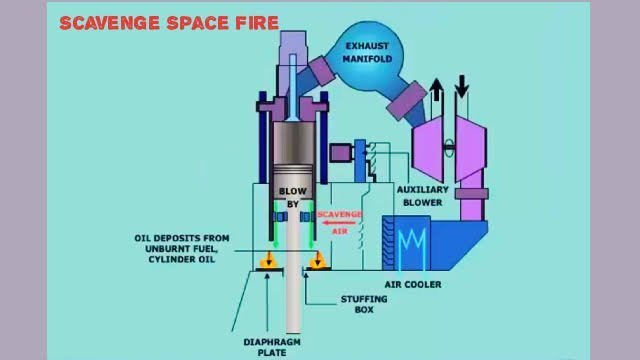

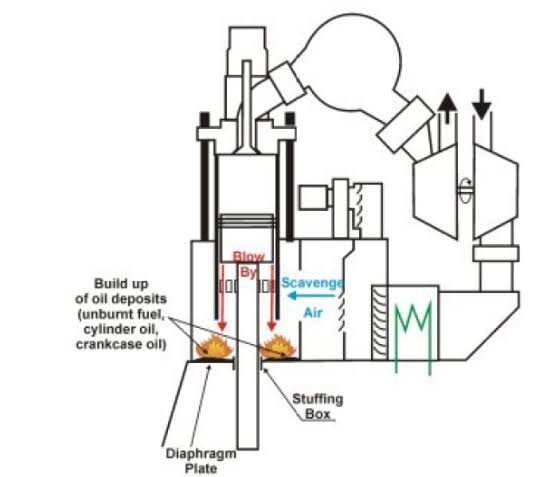

Carbonized lube oil,un burnt fuel oil and carbon from the residual products of combustion spaces (cylinder liner ) are accumulated in the scavenge spaces with the running of the engine.

Under Certain faulty running conditions of the marine diesel engine,these may ignite causing a fire in the enclosed scavenge spaces,known as scavenge fire.

Basic Elements Required

As we know that fire is continuous chemical reaction of fuel,02 and heat.To Occur any Fire, We required three elements which make the Fire Triangle .

The three elements required for fire in the engine scavenge spaces are :-

- Oxygen :-This is available in abundant anount.The oxygen needed for combustion is delivered by the scavenge air, which is in abundant supply for the operation of the engines.

- Heat Source :-The heat source for ignition of fire comes from piston blow-by I.e blowing of hot gases between piston rings and cylinder liner,afterburning,slow ignition or excessive back pressure and it causes a blowback through the scavenge ports.

- Fuel :-This may be from unburned fuel, carbon, cylinder lubricating oil that has leaked into space or crankcase oil which carried out upwards on the piston rod because of faulty or damage stuffing box.

To catch fire in scavenge spaces ,the basic three elements mentioned above must be present in proper ratio.

Note:- For occurring continuous fire 16 percent of oxygen is required.

Causes of Scavenge fire

1.Blow past :- From Combustion Chamber ( cylinder liner ), leakages of combustion products, residual fuel which is caused by damage

- Cylinder liner excessive wearing

- The piston rings of the engine might be worn out or have loose ring grooves

- Improper cylinder liner lubrication

- Insufficient axial clearance of piston rings.

2.Overheating of piston:-

- Due to failure of piston cooling oil flow .It causes piston overheating and dissipate heat to under piston area.

- Bad combustion , due to not proper atomisation,improper injection pressure,wrong fuel pump timing,loss of compression & overloading of the engine.

3.Presence of fuel oil :-Presence of un burnt fuel oil in the scavenge spaces because of

- Defective or Faulty fuel injectors

- Injectors pressure setting incorrect

- Fuel particles landing on cylinder liner due to excessive penetration.

4.Blowback of the exhaust gas :-It occurred due to high back pressure of the exhaust gas or deposits on exhaust port,fouling of grid before turbine inlet ,fouling of the blades of turbine,exhaust gas boiler chocked or economizer gas outlet.

Indications of Scavenge fire

You must aware of the below indication of the scavenge fire so that to identify and control the fire.

These are :-

1.Increase in scavenge temperature of one unit relative to the other.

2.The affected cylinder does not obtain fresh air leading to an rise in exhaust temperature.

3.The engine speed decrease due to power generation in the affected cylinder is reduced.

4.The exhaust smoke of engine is blacky due to incomplete combustion in that unit.

5.There is spark,flame or smokes at scavenge drain from scavenge air boxes.

6.The exhaust and scavenge system pressure and temperature increase.

7.Check visible evidence of fire through transparent windows fitted .

8.The outlet temperature of cooling water of affected cylinder is increased.

9.The operation of engine rough with slight drop in rpm and may cause surging of turbocharger.

10.loss of power , irregular running of the engine and reduction in rpm of the engine.

Actions to be taken

Action taken in the event of a scavenge fire.It depends on the type of fire, whether small or large.

For small fire

- Inform the bridge, and start to reduce the speed of the engine & reduce it to slow or dead slow.

- Cut off the fuel supply to the affected unit and shut off valves.

- Cylinder lubrication of affected unit should increased . ( Note:- In case of increase of fire,Do not increase lubrication. )

- Coolant flow through jacket and piston is maintained.

- Scavenge drains to be shut to prevent flow of spark and smoke in the engine room.

- Keep clear of scavenge space relief valve to prevent human injury.

Minor fire will burn out itself after sometimes.

For large fires

- Inform the bridge immediately,and stop the engine immediately.

- Stop fuel oil booster pump.

- Open indicators cock ,engage turning gear and turn the engine to prevent engine seizure.

- Normal engine cooling and lubrication are maintained.

- Scavenge air duct flap valve before engine to be shut.

- Extinguishing the fire with fixed fire fighting system for scavenge fire.This may be co2 system or a steam connection for smothering the fire.

- On very old ship,if there is not fixed system then external cooling is provided to prevent distortion due to heat.

- Before opening scavenge door, ventilate the space through if o2 is released.

Inspections after scavenge fire

After the scavenge fire is completely extinguished, we need to cool down and ventilate the room thoroughly. In addition, we need to check the area and component in order to prevent failure and to cause any breakdown of the components.

Note :-Component affected by scavenge fire involves piston rod, cylinder liner, stuffing box, piston and rod alignment, marking or cracking of the liner and tie rod. Inspect the affected area thoroughly for any damage and cause of scavange area.

- Piston misalignment :- Check for the binding occurrence at the part of stroke ,it indicates the piston misalignment.

- Check spring on scavenge space relief valve.

- Check piston rings and liner for any distortion or redfish burning mark on the surface.

- Check the crown of piston for any crack or any leakage from the fuel injector.

- Check diaphragm and frame near affected area.

- Tensions and tightness of tie bolts.

- Guide and guide shoe of affected area should be checked.

- Check the movement of piston in cylinder liner by turning the engine.Check binding at liner which shows indication of misalignment.

Preventions of scavenge fire:-

- Scavenge Spaces checked at regular intervals of time.It should be open always in running conditions.

- Clean scavenge space as per manuals or PMS.

- Excess cylinder lubrication will be avoided which cause accumulation and it act as fuel in scavenge fire.

- Engine piston rings must be maintained properly & lubricated adequately .If not then leakage of it cause blow past.

- The piston rod stuffing box must be properly maintained for preventing oil ingress on the scavenge spaces.

- Fuel injectors should be kept in good condition,timed correctly and load on each unit properly adjusted.

Scavenge spaces safety devices

1.Electrical temperature sensing system mounted within the trunk, which will automatically sound the alarm in the event of an excessive increase in local temperature.

2.Fixed fire extinguishing system .It may be co2,dry powder or steam.

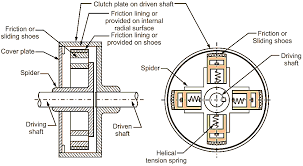

3.Pressure relief valves consisting of self-closing spring-loaded valves are installed and should be regularly inspected and tested.

For better understanding see the Scavenge fire Video

Check Out Other Important Topics

[…] Must Read :- Scavenge fire […]

[…] Suggest read :- Scavenge fire […]