Types of Lubrication :- Lubrication is used to reduce the friction in the sliding conditions. You will Know About What is Lubrication and different types of lubrication its uses Advantages and Disadvantages with example.

Friction :- Friction is the force that opposes the sliding motion of solid surfaces, fluid layers, and material elements.

| Types of Lubrication are following: |

|---|

| 1. Boundary Lubrication |

| 2. Hydrodynamics Lubrication |

| 3. Hydrostatics Lubrication |

| 4. Elastohydrodynamics Lubrication |

But The above types of lubrication comes under liquid fluid film lubrication

Broadly Types of Lubrication

- Solid

- Starved

- Grease

- Fluid film lubrication

What is Lubrication ?

Lubrication is basically a solutions to reduce the friction. Lubrication is the process or technique of reducing wear on one or both surfaces that are close to each other and moving relative to each other by interposing a substance called lubricant between the surfaces for carrying out the load between them.

Must read : Lubrication in Four Stroke Diesel engine

Types of Lubrication

1. Solid Lubrication

A solid lubricant is a material that is used in the form of powder or a thin film, reduces friction and wear on contacting surfaces in relative motion and protects them from damage.As a result, the asperities of these two materials will interact.

Some solids can provide very high friction while others can provide low friction. The pair of materials for sliding depends on the relative properties or interfacial friction of these two materials. So, it is a basically, material selection process to find a material with a low coefficient of friction for solid lubrication.

Graphite, for example, has traditionally been used as a solid lubricant. However, in modern times, we can use plastics such as PTFE and other plastic gear and bearings. PTFE has a low coefficient of friction, and the material is known as mos2 ( molybdenum disulphide)

2. Starved lubrication

Basically, this is a solid lubrication having some amount of lubricant used in it. Thus, only a small amount of lubricant in the form of vapor is used. Sometimes material in the form of foam or porous material, in which we have impregnated some amount of liquid lubricant. So this is referred to as starved lubrication because it is a combination of contact of solid-to-solid to each other with some lubricant works which significantly reduces friction.

3. Grease lubrication

Grease is a solid or semisolid lubricant that is formed as a thickening agent dispersion in a liquid lubricant. Grease is typically made up of soap emulsified with mineral or vegetable oil.

Grease has a high initial viscosity, which drops when shear is applied, giving the effect of an oil-lubricated bearing with approximately the same viscosity as the base oil used in the grease.

We have seen grease many times, and we are quite familiar with it. Basically, grease is a form of lubricant. But ,grease used here as lubricants provides thickner. And this thickner provides very high viscosity. Thus, grease is used in a situation where we required, lubrication for quite a long period of time andw working without any kind of Maintenance to it. Because do not have to regrease so often. So, grease in the system is always present.

Grease is frequently used for rolling element bearings because it provides a thick layer. As a result, the viscosity is high. As a result of its high viscosity, grease can provide lubrication as well as damping or cushioning. So, grease is a type of lubrication.

4. Fluid film lubrication

It is a types lubrication which occurs when opposing surfaces are completely separated by a lubricant film and there is no asperities are in contact between two surfaces. The load applied is carried by the pressure created within the fluid, and frictional resistance to motion is entirely due to the viscous fluid shearing.

Fluid film lubrication is a lubrication regime in which the load is fully supported by the lubricant within the space or gap between the moving parts relative to each other (the lubricated conjunction) and solid–solid contact is avoided.

In this type of lubrication, we use a liquid air a gas. It is because as we know fluid means both liquid and gas. So we can use either a liquid or a gas, and the liquid or gas which forms a kind of film layer between two surfaces, and thus lubrication is provided in fluid film lubrication.

Types of fluid film lubrication

- Liquid fluid film

- Gas lubrication

Both works on the same principles as fluid film lubrication but main difference is ,in liquid fluid type we use liquid and in another type gas is used. In gas type, generally we use air as gas.

There are some of advantage and disadvantage of this type of fluid film lubrication but one of the main important difference is, liquid is incomprehensible while gas is compressible. So, this property of fluid define main difference between both Type lubrication.

1. Liquid fluid film lubrication

It is type of lubrication in which two opposing surfaces are completely separate by a liquid lubricant and there is no asperity in contact. The applied load is carried by pressure generated within the liquid lubricant used , and frictional resistance to motion arises entirely from the shearing of the viscous liquid.

Types of liquid fluid film lubrication

1. Boundary lubrication

Boundary lubrication is a type of lubrication in which two surfaces are separated a thin fluid films.

Boundary lubrication, naturally forms a kind of film of some organic material on the both surfaces. It works on some biochemistry and it forms a kind of layer. This layer of organic materials which help to protect the two rubbing surfaces. These two surfaces can be steel . So, boundary lubrication , basically, helps to protect two rubbing surfaces.

In the boundary lubrication, the two opposing surfaces meet with little or no oil film separation. Damage of two surfaces are prevented in this regime by protective additives which helps in sliding rather than welding of the surface asperities. This is typically observed at low speeds of the two surfaces.

2. Hydrodynamic lubrication ( Types of Lubrication )

The term “hydrodynamic lubrication” refers to a situation in which two rubbing surfaces are separated by a thin film of lubricant. This situation is frequently advantageous, and lubrication is used to reduce friction and/or wear of rubbing solids using a liquid (or semi-solid) lubricant.

Hydrodynamic lubrication which occurs when the non-parallel rigid surfaces of bearing are lubricated by a film-fluid which slide over each other, and it forming a converging wedges of fluids and creating a lifting pressure.

Note : It is most effective lubrication in terms of reducing the coefficient of friction and finally increase the life and reduce the wear rate to zero.

How Does Hydrodynamics Lubrication Works ?

It works on the Principle , when two surfaces are relative motion in which one is stationary and there is some load here creating converging surface, causing built up of hydrodynamics pressures inside it and supporting the load.

The gap convergence and the relative speed between the two planes build up a hydrodynamic pressure in the region.

The load bearing depends on the relative velocity and the viscosity of fluid.

This types of lubrication mainly occur in journal bearing.

For Example :- The below figure showing a shaft and bearing. The shaft which is rotating in clockwise directions then fluid used is pushed towards the convergence surface and cause hydrodynamics pressure produced and this will act to take load of the shaft and this load is lifted and pressure supports the load.

3. Mixed Lubrication

Mixed lubrication is a types of lubrication Which consists of mixture of hydrodynamic and boundary lubrication.

For Example : It will happen in the two surfaces where there is roughness and the lubricant is present at the contact point of the surfaces. so, at the contact points of the surfaces , the lubricant action is taking place but at the surface is not in contact at there , lubricant action is mot taking place & at the some point of surfaces there is solid to solid contact. This is called mixed lubrication.

4. Elastohydrodynamic lubrication ( Types Of Lubrication )

(EHL ) Elastohydrodynamic Lubrication is a type of fluid film lubrication in which extremely high contacts pressure causes elastic deformations of the contacting surfaces of at least the same order of magnitude as the thickness of the film which separating them.

We can say, Elasto hydydynamics lubrication is basically a hydrodynamic lubrication in which load is extremely high and there is some amount of elastic deformation of any of the two surfaces.

For Example : – Gear Pump

5. Squeeze Film Lubrication

Squeeze film lubrication is a types of liquid full film lubrication which occurs when two lubricating surfaces move in the same direction in the normal direction, generating positive pressure and thus supporting a load.

Squeeze film lubrication occur when two lubricating surface approaching at very high rate.

How Squeeze Film Lubrication Occur ?

When two surface approaching at very high rate then in this situations , liquids is available between the surfaces , when two surfaces approaches at high rate then liquid will made to flow or it will squeeze out.

Because of rate of approaches is very high and because of the viscosity of liquid , not all liquids will squeeze out, and a thin a layers of liquids is still present between the two surfaces and this liquid will provide lubrication to the two surfaces.

Note: – The squeeze filmed formed prevents direct contact surfaces and provide cushioning effect against vibrations and impact loads.

For Example :- Ball bearing Gudgeon pin lubrication.

6. Hydrostatic Lubrication

Hydrostatic lubrication is a types of lubrication Which is a form of hydrodynamic lubrication in which a complete film of oil separates the metal surfaces, but the separating pressure is supplied by an external oil pump rather than being self-generated.

Hydrostatic lubrication is defined as the complete separation of a kinematic pair’s conjugated surfaces using a film of fluid pressurised by an external piece of equipment.

How does it Works ?

It is achieved by when we have two surfaces and and We pump liquid in it. So, how can pump the liquid to it. for this we make surface porous or holes on it. Through this holes , we pump or supply the liquid and lubricate. Liquid supply with some pressure and due to this pressure the load of bearing lifted or will be taken. This is called Hydrostatic Lubrication.

It is called hydrostatic lubrication because we are creating hydrostatic pressure and this pressure is built up pumping action ( pump ). Here, we take help of external pump to generated hydrostatic pressure for lubrication of the two surfaces,

Note : – Air hocky works on the same principle of hydrostatic lubrication but uses air, hence, it is aerostatic lubrication.

Gas Lubrication

Gas Lubrication works on the same principle as Full fluid film lubrication but the only difference is instead of liquids , air is used.

There are two Types Of Gas Lubrication.

- Aerodynamics lubrication

- Aerostatic lubrication

1. Aerodynamics Lubrication

Aerodynamics Lubrication Based On the Same principle as hydrodynamics lubrication instead of liquid we use air. Both Hydrodynamics and aerodynamics use Reynolds Equations to provide a thin layers of Lubricant between the two lubricating surfaces, In this case we use air or any kinds of gases

2. Aerostatic lubrication

Aerostatic lubrication is a form of hydrostatic lubrication in which pumping air instead of liquid to lift the surfaces.

Types Of Lubrications In Main Engine

Different Types of Lubrication used in main Engines are following :-

- Boundary lubrication :- Thin film lubrication

- Hydrostatic Lubrication :- Thick film Lubrication

- Hydrodynamic Lubrication :- Full fluid Film Lubrication

- Elastohydrodynamics lubrication :- Thin film or squeeze film

1. Boundary Lubrication :-

Boundary Lubrication is a types of lubrication which occurs in between the two rubbing surfaces in which sliding surfaces are separated by a thin film.

It occurs at

- a shaft starts moving from rest

- when the load is very low

- the speed is very low

For example :-

- Guide and guide shoe in the two stroke engine.

- Lubrication of journal bearing during starting and the stopping of the engine.

- piston rings and liner.

2. Hydrostatic lubrication

Hydrostatic Lubrication is a types of lubrication which occur in pair of rotating objects by creating a thick film instead of self created, the external oil pipe supply a separating pressure.

It depends upon

- inlet pressure of lube oil supply.

- clearance between the two rotating objects or surfaces.

3. Hydrodynamic Lubrication

Hydrodynamic lubrication is a types of lubrication which occur in moving surfaces are separated completely by the full fluid film known as wedge created by motion of the rotating surfaces due to geometric conformity.

for example : – Journal bearing, bottom end bearing, thrust bearing/

4. Elastohydrodynamics lubrication

This is types of lubrication which occur when there is line contact or normal point between rolling sliding surfcaes.

For example :- Gear Pump.

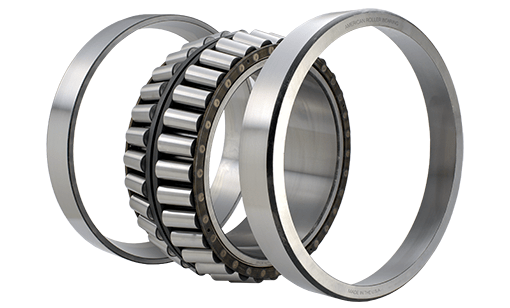

Note :- ball bearings and journal bearings are two important bearings used in engineering.

Bearings are simply a device which is used to reduce the friction in machine components with relative motion and load bearing. And the types of lubrication is mechanism that works on these bearings for reductions of bearings.

What’s the difference between boundary and hydrodynamic lubrication?

Friction force is independent of speed in boundary lubrication. The viscous friction force increases with increasing speed in hydrodynamic lubrication. The fluid pumping torque is usually proportional to the square of the speed.

What is the distinction between hydrostatic lubrication and hydrodynamic lubrication?

The inlet pressure of the lube oil and the clearance between the metal surfaces determine hydrostatic lubrication, whereas the relative speed or motion between surfaces, oil viscosity, load on the surfaces, and clearance between the moving surface.

What are the 5 types of lubricant?

1. Grease

2. Oil

3. Penetrating Lubricants

4. Dry Lubricants

5. Water ;- It is also used as lubricants.

What are the different methods of lubrication?

1. Drip oil feed lubrication.

2. Splash oil feed lubrication.

3. Force oil feed lubrication.

4. Grease lubrication.

What are the 7 purposes of lubrication?

1. To lubricate each bearing component and reduce friction and wear

2. To remove heat generated inside the bearing as a result of friction and other factors

3. To protect the rolling contact surface with an appropriate oil film in order to extend bearing fatigue life.

4. To avoid corrosion and dirt contamination

Check Out Other Important Topics

| IC Engine | Important PDFs | Boilers | Synergy Maritime Exam | Naval Arch | MEO Class 4 |

| Interview Questions | Difference Between | Types of Pumps | Auxiliary Machines | Types of Valves | Home |