In this article I am going to explain piston cooling in 2 stroke marine diesel in details.

Cooling of piston is done to to prevent stresses in the piston crown due to temperatures induced by combustion.

Piston cooling in 2 stroke marine diesel engine (The maine engine piston cooling ) is done by one of the cooling medium –

1. Water and

2.oil

Note :- Water-cooled pistons were mainly used in old MAN engines and Sulzer RND ,RLA and RLB engines.

Nowadays both MAN B & W and Sulzer engines prefer oil cooling to conventional water cooling piston.

Why Oil Cooling is preferred to conventional water cooling piston ?

Ans :- as the former reduces the risk of lube oil contamination in case of leakage.

Difference in piston cooling of sulzer and B & W Engines

In Wartsila engine , an articulated or swinging arm is attached to the crosshead which supplies the inlet oil.

In B&W Engines Telescopic pipe is used for supplying oil to the crosshead which supplies oil to the inlet pipe of piston rod.

MAN B & W

A branch of lube oil goes to crosshead.In MAN engine the lube oil is connected to inlet in the crosshead using a telescopic pipe,it moves up and down along with the crosshead and oil is supplied to it from the top .

Once the oil reaches the engine inlet it does three functions

A.Some oil travel up the piston rod to cool the piston and then comes down.

B.Some oil lubricates the crosshead bearing and the shoe guides.

C.the remaining oil passes through a hole drilled in the connecting rod to the bottom end bearings.

And finally all oil comes to the sump.

How oil branching taking place

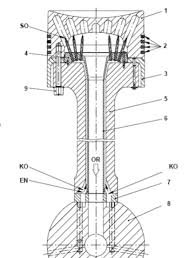

For understanding, How oil passes through piston rod to piston see the below figure :-

There is 3 hole showing in bottom of piston rod ( This bottom will sit on crosshead ) for flow of oil.One is in centre and other 2 is in the side.

Actually,The piston rod is utilised to carry the oil to and from the piston.The rod is hollow, and has a tube running up its centre. This gives an annular space which, with the central bore, allows a supply and return.

Flow pattern of oil

The cooling oil is delivered to the piston crown, through the centre of the hollow piston rod, circulating through the cooling channels in the crown. The oil returns through the piston rod via small holes drilled into the piston rod where it is collected in a tray at the cross head bearing. here the oil temperature and viscosity is monitored before spilling over the tray; cascading down into the main lube-oil sump.

MAN B&W Piston:

The new MAN engine uses simple bore cooling piston and jet nozzels, which comprises of oil passage within the piston crown for uniform cooling. The MAN engine also uses a top layer thermal coating over the crown, known as INCONEL 625 coat, which is 8mm thick and protects the crown surface from overheating.

Sulzer Engine

The oil in sulzer engine provided through articulate pipe.Two pipe is provided in articulate pipe.

One pipe go for crosshead lubrication (and after xhead it goes for bottom end bearing lubrication ) and second pipe for piston cooling.

Actually,The rod is hollow, and has a tube running up its centre. This gives an annular space which, with the central bore, allows a supply and return.

There is 3 hole showing in bottom of piston rod ( This bottom will sit on crosshead ) for flow of oil.One is in centre for return oil and other 2 is in the side for cooling piston.

Flow pattern of oil coolant

The Cooling oil Is delivered to the piston crown in sulzer engine is through the two outside holes in the piston rod.The larger bore being used for return oil after cooling.

This allows oil delivery at a higher pressure to the nozzles; causing it be injected as a mist against the inside surfaces of the crown and providing a more efficient cooling system.

SULZER Piston:

The new SULZER piston with concave crown comes with Jet-Shaker cooling design, wherein the jet nozzles are attached to the cooling passage of piston rod.

The piston crown design which comprises of bores and nozzles ( for supplying cooling oil with high pressure), provides better uniform cooling and reduces crown thickness and overall piston weight. This is known as jet shaker method as during downward movement of piston, the nozzle sprays the oil jet inside the bore and when the piston moves upward, the oil inside the piston crown shakes for efficient cooling.

Water Cooled Piston of Marine Diesel Engine

The diagrammatic sketch shows the general arangement for the main engine piston cooling

water system for Sulzer RD type engines.

Note:-This is line diagram of sulzer RD types engine in which one figure cooler is between sight glass and tank and in other figure cooler is after pump.I have also seen cooler is after pump in sulzer RLA and RLB engines.

The piston cooling water tank is located at lower level to allow the return cooling water to flow easily into the tank. A piston cooling pump draws the water from the tank and pumps it through the cooler into the piston through telescopic pipe arrangement.

The cooling water returns via a second telescopic pipe to the tank. Each return line has a thermometer, a flow sensor with ‘no flow’ alarm and a sight glass to observe the flow of water.

A connection is provided in the piston cooling tank as shown for the replenishment of water

as and when necessary.

A centrifugal pump supplies the cooling water under pressure to the piston crown; where it is circulated through water channels that have been cast into the piston crown.

These channels are positioned close to the walls and top of the crown, also behind the piston ring grooves to promote optimum cooling of the surfaces of the crown subjected to the high temperatures of combustion.

The water enters and leaves the piston through telescopic pipes that slide up and down on stand pipes as the piston reciprocates. These pipes have rubber water seals between them to prevent leakage of cooling medium into the crankcase lube-oil. There can also be enclosures around the seals that incorporate tell-tale leak pipes that eject water if a seal begins to leak. The pipes are located at convenient locations outside the engine enclosure, usually at control platform level.

The water temperature is maintained by a dedicated seawater cooler, and a header tank allows the system water and additive to be topped up.

Advancement of piston chamber

In water cooled piston,ribs is removed and made a bore inside which provide jet cooling.

Check Out Other Important Topics

Home IC Engine Electrical Important PDFs Boilers Synergy Maritime Exam Naval Arch Interview Questions Difference Between Types of Pumps Types of Valves MEO Class 4 Auxiliary Machines

Great article 👏👏👏