What is settling tank in ship ?

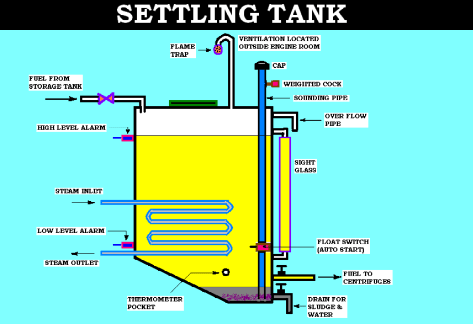

The settling tank in a ship is a deep tank in the engine room which is used for gravity-based pre-cleaning of fuel oils. A liquid mixture in the settling tank slowly seperate a heavier liquid and solids sink to the bottom.

What is the purpose of settling tank or uses ?

The purpose of settling tank is to separate heavy solids particles and liquid (water ) from fuel mixture by a gravity separations.

Or, The function of settling tank is to separate the sludge and water contained in the fuel oil,to act as a buffer tank and to provide a suitable constant fuel temperature of 50-70℃ .This can be improved by installing two settling tanks for alternate daily use.

What does a settling tank do or uses ?

A settling tank did the work of separating heavy solid particles and liquid ( water ) from fuel mixture.

How many settling tank in ship ?

There are usually two settling tanks, each with a capacity sufficient for full load operation of all customers for 24 hours.

Settling tank Design

Tanks should be designed in such a way so that separation of sludge and water is efficient. Baffles should be provided in each settling tank to reduce sludge-fuel mixing.

The tank’s bottom should slope toward the sludge drains, and the pump suction should not be near the sludge space.

An Ideal Settling Tank Should Have Inclined Bottom To Facilitate The Separation And Draining.

Why suction is above in settling tank ?

It is because it pump does not take suction of sludge and solid particles.

Temperature in the settling tank ?

The temperature in fuel settling tanks should be as high as possible to allow the dirt to settle. However, the temperature should be kept below 75°C to avoid the formation of asphaltenes and at least 7°C above the fuel’s pour point to ensure pumpability.

Why fuel oil is heated in the settling tank ?

Fuel Oil Is Heated In The Settling Tank For Faster Separation Of Impurities, For This Reason Settling Tanks Are Provided With Heating Arrangement.

What are the factors for the rate of seperation of impurities in the settling tank ?

The Rate Of Separation Of Impurities In Settling Tank Depends On Following Factors.

Higher The Density Difference Between Oil And Other Impurities, Greater Will Be The Rate Of Separation.

Bigger The Size Of The Impurity Particle Better Will Be The Rate Of Separation.

Lower The Viscosity Of Oil, Better Will Be The Rate Of Separation.

As Heating Results In Better Separation, The Fuel Is Generally Heated To A Minimum Temp., Of 50℃ Or To A Temp., About 70℃.

One Of The Solid Contaminats In The Fuel Oil Is A Cat (CATALYTIC) Fine, Having Density Of 2600 To 2800 Kg/M3 And Having Particle Size Of 10 To 50 Microns. These Compound Take Long Time To Settle Even When The Fuel Temp., Is Raised To 70℃.

An Ideal Settling Tank Should Have Inclined Bottom To Facilitate The Separation And Draining.

Mountings or safety devices fitted on settling tank

1.Fuel Outlet Valve: This Is Remotely Operated Quick Closing Valve Fitted On The Settling Tank. It Is Arranged To Operate From Outside The Engine Room In Case Of Emergency.

2.Air Pipe: This Pipe Is Led To Above The Upper Deck Level And External To The Deck House. The Outlet Of This Pipe Is Fitted With Metallic Wire Gauge Screen Called Flame Trap To Prevent Fire Hazards.

3.Thermometer:This Is Used For Measuring The Temp., Of Oil

Sludge Valve / Cock: This Is Used For Draining Water And Sludge Collected At The Bottom Of The Tank. This Valve Must Be Self-Closing Type.

4.Over Flow Pipe: It Is Fitted At The Top Of The Tank And Led To An Over Tank In The Double Bottom. An Alarm Activated By An Over Flow Condition Is Sometime Fitted To The Tank.

5.Alarms: These Are Fitted To Warn High Fuel Temp., And Low Fuel Level.

6.Dumping Valve: This Valve Is Used In The Event Of Fire, To Dump The Oil To The Double Bottom Tank.

7.Quick Closing Valve: In Case Of Emergency To Stop The Engine, This Valve Cuts The Supply Of Oil To The Engine. The Arrangement Provided Outside The Engine Room To Close This Valve.

8.Sounding Valve: This Pipe Is Provided To Take Sounding Of The Tank For Checking Fuel Level.

9.Steam trap :-

10.High and low level alarms are fitted in the tank.

Fuel In the settling tank

In settling tank main 4 pipe connection for fuel transfer and recirculation

1.filling line

2.Recirculation line near (filling line )

3.Suction to FO Transfer pump ( Valve is quick closing valve )

4.Suction to Fuel oil Purifier (Valve is quick closing valve )

The Fuel Is Transferred From Bunker Storage Tanks To The Settling Tanks Prior to Centrifuging, For Use In Diesel Engines And Also For Burning In Boilers.

The Fuel Is Heated In Settling Tank And Retained there for as Long as Possible.

The Settling Period Should Not Be Less Than 24 Hours For Optimum Separation Of Impurities.

While The Fuel Is In Settling Tank Some Of The Solids, Sludge And Water Separates Out And Settle Down At The Bottom Of The Tank From Where They Can Be Drained Off Through The Drain Connections Which Must Be Of Self Closing Type.

For Use In Diesel Engines, Only Purification By Settling Is Not Enough As Subsequent Centrifuging Is Carried Out To Separate The Impurities. Still Draining Of The Settling Tank Regularly Once In A Watch Is Recommended.

High And Low Level Alarms Are Fitted On The Tanks.

Check Out Other Important Topics

Home IC Engine Electrical Important PDFs Boilers Synergy Maritime Exam Naval Arch Interview Questions Difference Between Types of Pumps Types of Valves MEO Class 4 Auxiliary Machines