What is drilling machine ?

A drilling machine, also known as a drill press, is a versatile tool used to create holes in various materials such as wood, metal, plastic, and more. It is commonly used in construction, manufacturing, woodworking, metalworking, and DIY projects.

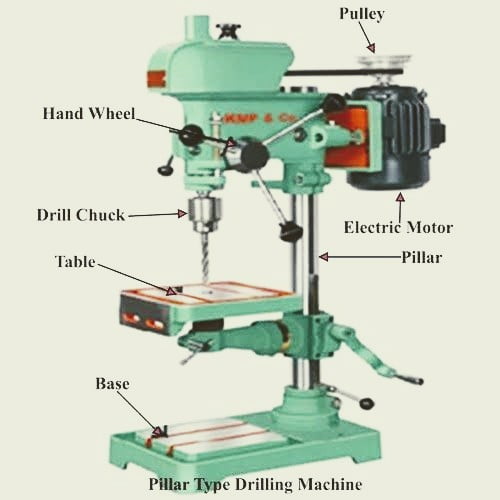

drilling machine parts

A drilling machine is a complex piece of equipment composed of several main parts that work together to perform efficient and accurate drilling operations. These parts include the bed, pillar, swivel table, motor, stepped pulley, spindle, chuck, drill bit, and hand-wheel. Let’s explore each of these components in more detail:

- Bed: The bed serves as the robust and sturdy foundation of the drilling machine, providing exceptional stability and unwavering support to ensure smooth and precise drilling operations. Its solid construction and ample size offer a reliable platform for the other components, promoting a secure and vibration-free drilling environment.

- Pillar: The pillar, also referred to as the column or upright, represents the vertically oriented structure firmly attached to the bed. This integral component plays a pivotal role in supporting and aligning various parts of the drilling machine. With its substantial height and resilient build, the pillar enables effortless adjustment of drilling height, accommodating a wide range of workpiece sizes and drilling depths.

- Swivel Table: The swivel table, an indispensable component, exhibits a flat and versatile surface that can be conveniently tilted or rotated. Designed to augment flexibility, it empowers operators to position the workpiece at multiple angles, facilitating drilling operations from diverse orientations. By offering this adjustability, the swivel table enhances accessibility and enables precise drilling in materials requiring specific hole orientations.

- Motor: As the prime source of power, the motor epitomizes the dynamic heart of the drilling machine. It effectively converts electrical energy into mechanical power, propelling the drilling operation with utmost efficiency and vigor. With its robust construction and potent performance, the motor exhibits remarkable reliability, ensuring consistent and smooth rotation of the spindle for precise hole creation.

- Stepped Pulley: The stepped pulley system, a remarkable mechanical marvel interposed between the motor and the spindle, encompasses an array of pulleys with distinct sizes and diameters. This ingenious mechanism empowers operators to effortlessly adjust or interchange the pulleys, thereby modifying the rotational speed of the drilling operation. By enabling versatile speed control, the stepped pulley system allows the drilling machine to adapt to diverse materials and drilling requirements.

- Spindle: The spindle, an integral vertical shaft affixed to the motor, embodies the essence of rotational power and precision. It acts as the conduit, effectively transmitting the motor’s rotational motion to the drill bit. The spindle’s impeccable alignment, meticulous engineering, and seamless operation ensure seamless power transmission, resulting in accurate and efficient drilling.

- Chuck: The chuck, positioned securely at the end of the spindle, serves as the indispensable clamping mechanism for the drill bit. With its reliable grip and steadfast holding capability, the chuck effectively secures the drill bit during the drilling process, guaranteeing stability and precision. Whether utilizing keyless chucks for rapid and tool-less bit changes or keyed chucks that necessitate a key for bit adjustment, this component plays a pivotal role in the drilling machine’s versatility and functionality.

- Drill Bit: The drill bit, the star cutting tool in the drilling machine arsenal, exemplifies precision craftsmanship and cutting-edge engineering. Comprising a pointed tip and spiraling flutes, the drill bit adeptly removes material during the drilling process. Available in an array of sizes and types, these versatile bits enable operators to tackle various drilling tasks with finesse, catering to different hole diameters and materials with optimal efficiency.

- Hand-wheel: The hand-wheel, an ergonomic and user-friendly manual control mechanism, facilitates convenient and intuitive adjustment of the drill bit’s vertical movement. By rotating the hand-wheel, operators can effortlessly raise or lower the drill bit, ensuring precise drilling depths tailored to specific requirements. This tactile and responsive control element enhances operator control and accuracy, enabling meticulous drilling results.

By expanding on the descriptions of each part of a drilling machine, we provide a more comprehensive understanding of their functionality and significance, highlighting the intricacies and advantages of these components in facilitating efficient and precise drilling operations.

Drilling machine working

The working principle of a drilling machine involves a series of coordinated actions and mechanisms that enable the machine to create holes in various materials. Here is a simplified explanation of the typical working process of a drilling machine:

- Setup: The operator sets up the drilling machine by securing the workpiece to the swivel table or work surface. This ensures stability and proper alignment during the drilling process.

- Selection and Installation of Drill Bit: The operator selects the appropriate drill bit based on the desired hole size and the material being drilled. The chosen drill bit is securely installed in the chuck, either by using a key or through a keyless chuck system.

- Adjustments: The operator adjusts the drilling depth by using the hand-wheel or other depth control mechanisms available on the machine. This ensures that the drill bit penetrates the workpiece to the desired depth.

- Power On: The operator activates the drilling machine by turning on the power switch. This supplies power to the motor.

- Rotation: The motor transfers power to the spindle, causing it to rotate at a specific speed determined by the selected pulley position or other speed control mechanisms. The rotational motion is transmitted from the spindle to the drill bit.

- Drilling: The operator positions the drill bit above the desired drilling location on the workpiece. With the machine properly secured, the operator applies gentle pressure to engage the drill bit with the workpiece surface.

- Penetration: As the drill bit begins to penetrate the workpiece, the operator maintains a consistent pressure and guides the machine’s movement to ensure a straight and accurate hole. The spiral flutes on the drill bit help remove the material being drilled, allowing the drill bit to progress smoothly.

- Chip Removal: During the drilling process, chips or debris are generated. The drilling machine is equipped with chip evacuation mechanisms such as flutes on the drill bit or chip ejection systems to remove these chips and prevent clogging.

- Completion: Once the desired hole depth is reached, the operator reduces the pressure on the drill bit and gradually withdraws it from the workpiece. The drilling machine is then powered off, and the finished hole is inspected for accuracy and quality.

It’s important to note that the working process may vary depending on the specific type of drilling machine and the complexity of the drilling operation. However, the fundamental principles of securing the workpiece, selecting the appropriate drill bit, applying rotational motion, and controlling drilling depth remain consistent across most drilling machines.

types of drilling machine

There are several types of drilling machines, each designed for specific applications and requirements. Here are some common types of drilling machines:

- Benchtop Drill Press: Also known as a bench drill press or floor drill press, this type of drilling machine is mounted on a bench or floor and provides stability for drilling operations. It typically features a vertical spindle and a worktable that can be adjusted for height and tilt.

- Radial Arm Drill Press: A radial arm drill press has an extended arm that can rotate and move horizontally along a radial column. This design allows for greater flexibility and reach, making it suitable for drilling large workpieces or in locations that require extensive reach.

- Magnetic Drill Press: A magnetic drill press, also called a mag drill or electromagnetic drill press, is specifically designed for drilling holes in large, heavy, or vertically positioned metal workpieces. It utilizes a strong electromagnetic base to securely attach to the workpiece, providing stability and convenience during drilling.

- Portable Drill: Portable drills are handheld drilling machines that offer convenience and flexibility. They are lightweight and easy to maneuver, making them suitable for various drilling tasks, especially in areas with limited access or when working on smaller workpieces.

- Pillar Drill: A pillar drill, also known as a column drill or vertical drill, is similar to a benchtop drill press but typically larger and more robust. It features a sturdy column that provides stability and accurate drilling, making it suitable for professional workshops or industrial settings.

- CNC Drilling Machine: CNC (Computer Numerical Control) drilling machines are automated machines that are controlled by computer programs. They can perform precise and complex drilling operations with high accuracy, speed, and repeatability. CNC drilling machines are commonly used in industries such as aerospace, automotive, and manufacturing.

- Deep Hole Drilling Machine: Deep hole drilling machines are designed to create holes with a large depth-to-diameter ratio. They are used for drilling deep holes in components such as barrels, cylinders, and pipes. Deep hole drilling machines often incorporate specialized coolant systems to ensure efficient chip evacuation and cooling during the drilling process.

- Multiple Spindle Drill: Multiple spindle drills have two or more spindles that can operate simultaneously, allowing for multiple holes to be drilled in a single setup. These machines are ideal for high-volume production and applications that require drilling multiple holes with precise spacing.

- Gun Drilling Machine: Gun drilling machines are designed for drilling deep and straight holes with a high degree of precision. They utilize specialized tools and coolant systems to achieve accurate results in applications such as firearm barrels, fuel injection components, and medical implants.

These are just a few examples of the different types of drilling machines available. Each type offers specific features and advantages tailored to different drilling needs, materials, and industries.

drilling machine operation

Drilling machines are versatile tools capable of performing various operations beyond simple hole drilling. Here are some of the common operations that can be performed using a drilling machine:

- Drilling Operation: The primary function of a drilling machine is to create holes in a workpiece. Drilling involves using a rotating drill bit to penetrate the material and form a hole with the desired diameter and depth.

- Boring Operation: Boring is a process of enlarging an existing hole in a workpiece. It is typically performed after drilling to achieve precise dimensions or improve the surface finish of the hole. Boring operations involve using specialized boring tools or attachments to remove material and enlarge the hole.

- Reaming Operation: Reaming is a process used to refine and improve the accuracy of a drilled hole. It involves using a reamer, a cutting tool with multiple flutes, to remove a small amount of material and achieve a smooth and precise hole with tighter tolerances.

- Counterboring Operation: Counterboring is a process of creating a flat-bottomed recess around a drilled hole. This operation is often performed to accommodate screw heads or other fasteners that need to be flush with or below the surface of the workpiece.

- Countersinking Operation: Countersinking is similar to counterboring, but it involves creating a conical recess at the top of a drilled hole. This allows the screw head to sit flush with the surface, ensuring a neat and streamlined appearance.

- Tapping Operation: Tapping is a process of creating internal threads in a drilled hole. A tapping tool, such as a tap, is used to cut threads into the hole walls, enabling the insertion of screws, bolts, or other threaded fasteners.

- Spot Facing Operation: Spot facing involves machining a flat surface around a drilled hole to provide a precise and smooth seating area for a washer or a mating component. It helps ensure proper contact and alignment between components.

- Trepanning Operation: Trepanning is a specialized drilling operation used to create large-diameter holes or cylindrical cavities in workpieces. It involves removing a central core from the material, leaving behind the desired hole or cavity.

- Honing Operation: Honing is a finishing process performed after drilling to improve the surface finish and dimensional accuracy of the hole. It involves using a hone, which is a fine-grit abrasive tool, to remove any residual material and achieve a smooth and precisely sized hole.

These various operations expand the capabilities of a drilling machine, allowing it to perform a wide range of tasks in industries such as manufacturing, construction, metalworking, and more. Each operation serves a specific purpose and helps achieve desired results in terms of hole size, accuracy, surface finish, or compatibility with fasteners and components.

Cutting Speed, Feed, and Machining Time of Drilling Machine

Cutting Speed, Feed, and Machining Time are key parameters to consider when working with a drilling machine. Let’s explore each of these parameters:

- Cutting Speed: Cutting speed refers to the speed at which the drill bit rotates during drilling operations. It is typically measured in surface feet per minute (SFPM) or meters per minute (m/min). The cutting speed is determined by the rotational speed of the spindle and the diameter of the drill bit. Higher cutting speeds are generally preferred for drilling softer materials, while lower cutting speeds are suitable for harder materials. The appropriate cutting speed helps optimize tool life, chip removal, and hole quality.

- Feed: Feed refers to the rate at which the drill bit advances into the workpiece during drilling. It is typically measured in inches per revolution (IPR) or millimeters per revolution (mm/rev). The feed rate affects the chip formation, hole accuracy, and tool life. It is important to select the appropriate feed rate based on the material being drilled, the drill bit geometry, and the desired hole quality. In general, a higher feed rate is preferred for softer materials, while a lower feed rate is used for harder materials.

- Machining Time: Machining time refers to the duration required to complete a drilling operation. It depends on factors such as the desired hole depth, the cutting speed, and the feed rate. Machining time can be calculated using the formula: Machining Time = (Hole Depth) / (Feed Rate x Spindle Speed). This calculation provides an estimate of the time needed to drill a hole based on the selected feed and spindle speed.

It’s important to note that the cutting speed, feed, and machining time are interrelated parameters. Optimal values for these parameters depend on the specific material being drilled, the drill bit type, the machine’s capabilities, and the desired hole quality. It is recommended to refer to cutting speed and feed rate charts provided by tool manufacturers or consult machining guidelines specific to the material being drilled to determine appropriate values.

Additionally, adjustments to cutting speed and feed rate may be necessary during drilling to achieve the desired results. Factors such as workpiece hardness, coolant usage, and the condition of the drilling machine can also influence the cutting speed, feed, and machining time. Regular monitoring and adjustments based on the drilling process’s performance are crucial to ensure efficient and accurate drilling operations.

Precautions which should be used in drilling Machine

When operating a drilling machine, it is essential to follow certain precautions to ensure safety and maintain efficient and accurate drilling operations. Here are some important precautions to consider:

- Read the Manual: Familiarize yourself with the drilling machine’s user manual and instructions provided by the manufacturer. Understand the machine’s features, limitations, and recommended operating procedures.

- Personal Protective Equipment (PPE): Always wear appropriate personal protective equipment, including safety goggles, hearing protection, and protective gloves. PPE helps safeguard against potential hazards such as flying debris, noise, and accidental contact with rotating parts.

- Machine Inspection: Before using the drilling machine, inspect it thoroughly for any damage, loose components, or signs of wear. Ensure all safety guards are in place and functioning correctly.

- Secure Workpiece: Ensure the workpiece is securely clamped or held in place to prevent movement during drilling. This helps maintain stability and prevents accidents caused by workpiece displacement.

- Drill Bit Selection: Choose the appropriate drill bit for the material being drilled and the desired hole size. Using the wrong drill bit can lead to inefficient drilling, poor hole quality, and potential tool breakage.

- Cutting Fluid/Coolant: When drilling metals or other materials that generate heat, consider using cutting fluid or coolant. These substances help lubricate the drill bit, reduce friction, and remove chips, resulting in improved cutting performance and prolonged tool life.

- Cutting Speed and Feed Rate: Adjust the cutting speed and feed rate based on the material being drilled, the drill bit size, and the desired hole quality. Operating within the recommended cutting parameters helps achieve optimal results and prevents excessive tool wear.

- Controlled Pressure: Apply controlled and consistent pressure when engaging the drill bit with the workpiece. Avoid excessive force or sudden pressure, as it can cause tool breakage, workpiece damage, or personal injury.

- Clear Work Area: Keep the work area clean and free from obstructions, tools, or other debris. This reduces the risk of accidents and allows for better visibility and maneuverability while operating the drilling machine.

- Emergency Stop and Power Disconnection: Familiarize yourself with the location and operation of the emergency stop button on the drilling machine. In case of any emergency or abnormal situations, immediately press the emergency stop button and disconnect the power supply to the machine.

- Operator Attention: Always remain focused and attentive while operating the drilling machine. Avoid distractions and do not leave the machine unattended during operation.

- Regular Maintenance: Follow the manufacturer’s recommended maintenance schedule to keep the drilling machine in optimal condition. Regularly inspect and clean the machine, lubricate moving parts, and replace worn-out components as necessary.

Adhering to these precautions helps minimize the risk of accidents, promotes safe operation, and ensures the longevity and performance of the drilling machine. Remember, safety should always be a top priority when working with any machinery.

Drilling Machine Specification

Drilling machine specifications can vary depending on the specific model and intended use. However, here are some common specifications to consider when evaluating a drilling machine:

- Power Rating: The power rating of a drilling machine refers to the electrical power it requires to operate effectively. It is typically measured in watts or horsepower (HP). Higher power ratings often indicate the ability to handle more demanding drilling tasks and work with tougher materials.

- Spindle Speed: The spindle speed indicates how fast the drill bit rotates during drilling operations. It is typically measured in rotations per minute (RPM). Different drilling machines offer varying speed ranges to accommodate different materials and drilling requirements. Machines with variable speed options provide greater versatility.

- Maximum Drilling Capacity: The maximum drilling capacity specifies the largest diameter of a hole that the machine can effectively drill in a specific material. It is typically measured in millimeters (mm) or inches (in). This specification determines the machine’s ability to handle different sizes of drill bits and work with various workpiece thicknesses.

- Spindle Taper: The spindle taper refers to the type and size of the connection between the spindle and the drill chuck or tool holder. Common spindle tapers include Morse Taper (MT) and R8. Matching the spindle taper with the appropriate tooling is crucial for secure and accurate drilling operations.

- Quill Travel: Quill travel refers to the vertical distance that the drill bit or spindle can be raised or lowered. It determines the maximum drilling depth achievable by the machine. Quill travel is typically measured in millimeters (mm) or inches (in).

- Table Size and Adjustability: The table size indicates the dimensions of the work surface on which the workpiece is placed during drilling. A larger table provides more space for accommodating larger workpieces. Additionally, the adjustability of the table, including height, tilt, and rotation, allows for versatile positioning and drilling angles.

- Chuck Type and Capacity: The chuck type specifies the mechanism used to hold the drill bit in place. Common types include keyless chucks and keyed chucks. The chuck capacity indicates the maximum diameter of drill bits that can be securely held by the chuck. It is typically measured in millimeters (mm) or inches (in).

- Motor Type and Voltage: The motor type and voltage refer to the electrical characteristics of the motor that drives the drilling machine. Common motor types include induction motors and brushless motors. The motor voltage indicates the electrical power supply required for the machine to operate effectively.

- Machine Dimensions and Weight: The machine dimensions and weight provide information about the physical size and portability of the drilling machine. This specification is important to consider, especially if the machine needs to be transported or if space is limited in the workshop.

- Safety Features: Safety features vary among drilling machines but can include features such as safety guards, emergency stop buttons, and overload protection mechanisms. These features are crucial for operator safety and should be evaluated when selecting a drilling machine.

These specifications can help determine the suitability of a drilling machine for specific drilling tasks, materials, and operational requirements. It is important to review the manufacturer’s specifications and guidelines for accurate and detailed information regarding a specific drilling machine.

application of drilling machine

Drilling machines are versatile tools that are widely used in various industries for different applications. Here are some common applications of drilling machines:

- Metalworking: Drilling machines are extensively used in metalworking industries for creating holes in metal components. These holes can be used for various purposes such as assembly, fastening, threading, or creating openings for pipes and wires.

- Woodworking: In woodworking industries, drilling machines are employed for tasks like creating holes for dowels, screws, or nails, as well as for precise drilling operations such as making mortises and drilling pocket holes.

- Construction: Drilling machines are essential in construction projects for tasks like creating holes for anchors, bolts, or screws in concrete, masonry, or other building materials. They are also used for drilling holes in wood or metal frames during construction or remodeling.

- Mining and Exploration: Drilling machines play a crucial role in mining and exploration activities. They are used to extract core samples from the earth’s crust to determine the presence of minerals, assess geological formations, and locate potential mining sites.

- Oil and Gas Industry: In the oil and gas industry, drilling machines are used for drilling wells to extract oil or natural gas. These drilling machines, known as drilling rigs, are complex and specialized equipment capable of drilling deep into the earth’s crust.

- Automotive Industry: Drilling machines find applications in the automotive industry for tasks like drilling holes in engine blocks, cylinder heads, or other components during manufacturing or repair processes.

- Electrical and Electronics: In the electrical and electronics industry, drilling machines are utilized for drilling holes in circuit boards, enclosures, or cabinets for mounting components, connectors, or wiring.

- Aerospace Industry: Drilling machines are used extensively in the aerospace industry for manufacturing aircraft components, such as drilling holes in airframes, wings, engine parts, or composite materials.

- Medical and Dental: In medical and dental fields, drilling machines, specifically designed for these purposes, are used for tasks like bone drilling in orthopedic surgeries, dental implant placement, or precision drilling in prosthetic devices.

- DIY and Home Improvement: Drilling machines are commonly used by DIY enthusiasts and homeowners for various home improvement projects, such as hanging shelves, installing fixtures, or assembling furniture.

These are just a few examples of the many applications of drilling machines. The versatility and precision of these machines make them indispensable in various industries, enabling efficient and accurate drilling operations.

advantages of drilling machine

Drilling machines offer several advantages that make them valuable tools in various industries and applications. Here are some key advantages of drilling machines:

- Versatility: Drilling machines are highly versatile and can be used for a wide range of drilling operations, including creating holes of different sizes and depths in various materials such as metal, wood, plastic, and concrete. They can also perform other operations like tapping, reaming, countersinking, and counterboring.

- Efficiency: Drilling machines are designed to efficiently and quickly create holes. They can drill holes with precision and repeatability, allowing for consistent results. This efficiency helps save time and increases productivity in manufacturing processes or construction projects.

- Accuracy: Drilling machines are equipped with features that enable precise hole drilling. They have adjustable depth stops, laser guides, digital readouts, or templates to ensure accurate hole placement and depth. This accuracy is crucial in industries where precise measurements are essential.

- Increased Productivity: With their ability to automate drilling operations, drilling machines significantly enhance productivity. They can drill multiple holes in a single setup, reducing the need for manual labor and repetitive tasks. This automation also minimizes the chances of errors and increases the overall output.

- Cost-effectiveness: Using drilling machines can be cost-effective in the long run. While the initial investment may be higher, they offer durability and long-term performance, reducing the need for frequent replacements. Additionally, the efficiency and productivity gains provided by drilling machines can lead to cost savings in terms of labor and time.

- Safety: Modern drilling machines are equipped with safety features such as safety guards, emergency stop buttons, and automatic shut-off mechanisms. These features help prevent accidents and ensure operator safety during drilling operations.

- Flexibility: Drilling machines can be equipped with various types of drill bits and attachments, allowing them to perform different operations beyond simple hole drilling. They can be used for tasks like chamfering, counterboring, reaming, and tapping, providing versatility and flexibility in machining processes.

- Consistency: Drilling machines can achieve consistent results in terms of hole size, depth, and placement. This consistency is crucial in industries where precision and standardization are required, ensuring proper fitment of components and efficient assembly processes.

- Improved Surface Finish: Drilling machines, especially those with advanced features and high-speed capabilities, can produce smooth and clean holes with improved surface finish. This is beneficial in applications where aesthetics, precision, or smooth functioning are important.

- Automation and CNC Integration: Some drilling machines can be integrated with computer numerical control (CNC) systems, enabling automation and programmable drilling operations. CNC drilling machines offer high precision, repeatability, and the ability to execute complex drilling patterns or sequences.

These advantages make drilling machines indispensable in numerous industries, providing efficient, accurate, and cost-effective solutions for various drilling and machining requirements.

disadvantages of drilling machine

While drilling machines offer numerous advantages, there are also some disadvantages associated with their use. Here are some common disadvantages of drilling machines:

- Initial Cost: High-quality drilling machines can be expensive, especially those with advanced features, high precision, or specialized capabilities. The initial investment required to purchase a drilling machine may be a significant consideration for small businesses or individuals.

- Size and Portability: Some drilling machines, particularly larger ones, can be heavy and bulky, making them less portable and challenging to move around. This limitation can restrict their use in certain situations or locations where mobility is essential.

- Noise and Vibration: Drilling machines can generate significant noise and vibration during operation, especially when drilling hard materials or using high-speed settings. Prolonged exposure to such noise and vibrations can be uncomfortable for operators and may require the use of personal protective equipment.

- Skill and Training Requirement: Operating a drilling machine effectively and safely requires proper training and skill. Inaccurate use of the machine or failure to follow safety protocols can result in accidents, damage to the workpiece, or poor drilling results. Adequate training and experience are necessary for optimal performance.

- Limited Flexibility: While drilling machines are versatile tools, they have limitations in terms of the types of materials they can drill and the specific operations they can perform. Some drilling machines may not be suitable for certain materials, such as extremely hard metals or delicate materials, requiring alternative drilling methods or specialized equipment.

- Maintenance and Upkeep: Like any machinery, drilling machines require regular maintenance to ensure optimal performance and longevity. This maintenance includes tasks such as lubrication, cleaning, and occasional replacement of parts or components. Neglecting maintenance can lead to decreased efficiency, increased downtime, and potential breakdowns.

- Safety Risks: Despite safety features, drilling machines still pose certain risks. Operators must be cautious of rotating parts, sharp drill bits, and potential hazards associated with the workpiece or drilling environment. Failure to follow safety protocols can result in injuries to the operator or damage to the machine and surrounding equipment.

- Limited Precision in Some Cases: While drilling machines generally offer high precision, there may be limitations when drilling extremely small or intricate holes. Achieving tight tolerances or complex hole patterns may require specialized drilling techniques or additional equipment.

- Energy Consumption: Drilling machines typically require a power source to operate, which can lead to energy consumption and associated costs. Additionally, some drilling processes, such as deep drilling or drilling hard materials, may require higher power consumption, adding to the operational expenses.

- Environmental Impact: Some drilling operations, especially in industries like mining or oil and gas, can have environmental consequences. Extraction processes associated with drilling machines may contribute to soil erosion, water pollution, or air pollution if not properly managed and regulated.

It’s important to note that while these disadvantages exist, many of them can be mitigated or minimised with proper training, maintenance, and adherence to safety guidelines. Overall, drilling machines remain valuable tools in various industries, but it is crucial to consider these drawbacks when determining their suitability for specific applications.

Reference : https://en.wikipedia.org/wiki/Drill