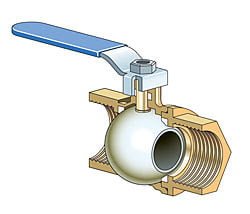

A ball valve is a type of valve which is used to start,stop and regulate the flow of liquid in the pipeline by controlling the movement of a rotary ball having a bore.

As we know that valve is a device which are designed to control or interrupt the flow of fluid in pipeline.This is done in valves by lowering,raising or rotating a disc in relation to a seating surface or by controlling the movement of a ball.

It is also called quarter turn valve.It is because, ball fitted or handle is turned only up to 90° For regulating the flow of liquid.

This valve uses hollow, perforated and pivoting ball to control flow of liquid or gas flow through it.

It is in the open conditions when the hole of ball is in line with the flow and closed when the ball’s hole came in the path of flow which is done by rotating or pivoting 90° by the handle of the valve.

Must Read :- Gate valve parts |Working principle |Types |

How do you know if a ball valve is open or closed ?

The handle fitted in the valve will make easy for visual confirmation of the valve status (open or close ).

When the handle of valve lies parallel the the valve then it is open and when handle is perpendicular to the valve then it is closed.

The shut position 1/4 turn or 90 °could be in either CW or CCW direction.

Ball valve working principle

The working principle of ball valve is that, it regulates, directs or controls the flow of a fluid (gases, liquids, fluidized solids, or slurries) by opening, closing, or partially obstructing various passageways by a controlling ball having hole inside.

Or we can say that it uses hollow, perforated and pivoting ball to control flow through it.

There is no any special law’s (Newton’s law or Bernoulli principle etc. ) On which valve work. It only control by putting obstructing material un passageways of fluid.

Suggested read :-Globe valve working principle |Parts and it’s function |Types |

How does a ball valve works ?

A ball valve works in any pipeline in regulating the flow of liquid by using rolling ball inside it.

There is a hole in the centre of the ball.

When the valve is opened, the bore aligns with the pipeline opening, allowing oil, gas, or other liquid to flow through. It can then be turned to the closed position, where the bore is perpendicular to the opening of the pipeline, preventing the contents from flowing through.

Ball valves typically only require a 90-degree rotation to operate, which makes them quick and easy to open and close.

Ball vale symbol

Ball valve parts and it’s functions

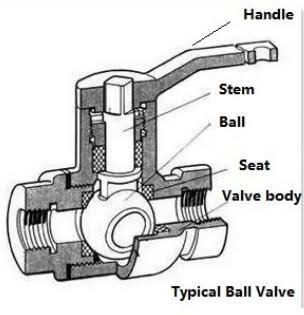

Parts of the ball valve are:-

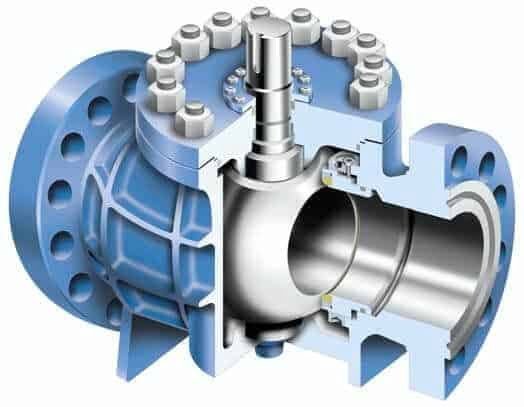

1.Body :-The body serves as the foundation for the entire ball v/v. It acts as a barrier to the media’s pressure load, preventing pressure transfer to the pipes. It holds all of the parts together. Threaded, bolted, or welded joints connect the body to the piping. Ball valves are classified by the type of body, which is usually cast or forged.

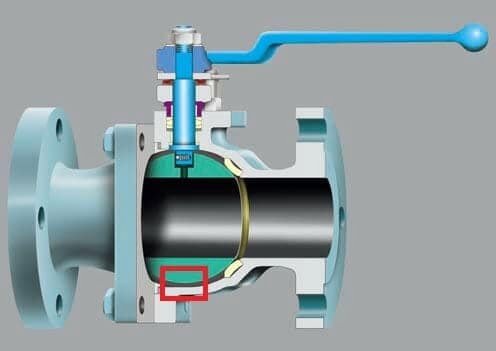

2.Stem :-The stem is responsible for opening and closing the valve. This also serves as the connector between the ball disc and the lever, handle, or actuator. The stem is the part of the ball disc that rotates to open or close it.

3.Packing :- This is the gasket that keeps the bonnet and stem sealed together. Because many problems arise in this area, proper installation is critical. Leakage occurs when the seal is too loose. When the stem is too tight, it restricts movement.

4.Bonnet:-The valve opening is covered by the bonnet. This serves as a secondary pressure barrier. After all of the internal components have been inserted into the valve body, the bonnet is what holds everything together. The bonnet, which is often made of the same material as the valve body, can be forged or cast.

5.Ball :-This is the ball valve’s disc. When the disc is closed, the pressure of the media acts against it, making it the third most important pressure boundary. Ball discs are frequently made of forged steel or other tough materials. The ball disc can be suspended, as in the case of a floating ball valve, or mounted, as in the case of a trunnion-mounted ball valve.

6.Seat :-This is where the ball disc rests, and it’s also known as the seal rings. The seat is either attached to the ball or not, depending on the design of the ball disc.

7.Actuators:-Actuators are devices that cause the ball valve to rotate in order to open the disc. These frequently have a power source. Some actuators can be controlled remotely, allowing valves to function even if they are in remote or difficult-to-reach locations.

Actuators for manually operated ball valves can be handwheels. Solenoid actuators, pneumatic actuators, hydraulic actuators, and gear actuators are some of the other types of actuators.

Ball valve types

Types of ball valve on basis of different criteria :-

On the basis of different styles of body of the valve

A.single body,

B.three-piece body,

C.split body, top entry, and

D.welded

A.Single body :-The ball is inserted into the body through an opening in one of the pipe flanges and secured with a raised face gasket. This has inherent strength and reduces the number of leak paths.

B.Split body :-The body of this ball valve is split in one or two places in the same plane as the valve flanges, and it is also known as a two-piece or three-piece ball valve. Following that, the body is bolted to the ball. Due to lower manufacturing costs and component weight, 3 piece ball valves and trunnion mounted ball valves are popular among smaller sizes. The ease of maintenance is a major advantage of split body ball valves.

C.Top entry :-This is a more uncommon valve design in which the ball is inserted through a bonnet in the top of the valve. The main advantage of this is that the valve’s critical parts can be maintained while the valve is still in the pipeline. It is frequently used in welded pipe systems.

D.Welded :-This is where the valve’s body is entirely welded and completely unmaintainable. These are frequently used in gas pipelines.

On the basis of attachment and lateral movement of the ball

The ball type disc can be a free float or fixed in the valve body. A free-floating valve is known as a floating type whereas a fixed type valve is known as a trunnion mounted valve.

Trunnion, floating and actuated

1.Trunion :-The ball is supported by a trunnion rather than the valve seats in this design, allowing for much higher pressure and temperature ratings. The shaft and trunnion are designed to be one piece.

To prevent the ball from moving against the downstream seat, the shaft and trunnion are held in bearings. To facilitate loading, the upstream seat is designed to move forward against the ball, and thus the primary seat is formed on the upstream side of a trunnion mounted ball valve.

Behind both seats is a spring mechanism that ensures even seat loading even at low pressures and provides a secondary seat on the downstream side. Trunnion mounted ball valves, like floating ball valves, can be shut off in both directions. One of the primary advantages of trunnion mounted ball valves over floating ball valves is lower operating torque, which means lower actuation costs.

2.Floating :-The ball is held between two ball seats by the compression of the seats against it in this design. The ball is driven by a shaft that connects to a slot in the top of the ball to turn it 90° or quarter turn.

Because of the influence of upstream line pressure, the slot allows for some lateral movement of the ball. The floating ball valve design principle is that they are loaded by line pressure against the downstream seat, which is why this seat is always regarded as the primary seat. In some cases, the upstream seat can also provide a secondary seal if the design includes pre-loading or a spring.

3.Actuated :-Manually operated ball valves can close quickly, chance a risk of water hammer. Some ball valves include an actuator that can be pneumatic, hydraulic, or motor driven. These valves can be used for on/off control or flow control. A pneumatic flow control valve also has a positioner, which converts the control signal into actuator position and valve opening.

On the basis of arrangement/Size of port

1.Full port :-A full port ball valve, also known as a full bore ball valve, has an oversized ball with a hole the same size as the pipeline, resulting in lower friction loss. The flow is unrestricted, but the valve is larger and more expensive, so it is only used where free flow is required, such as in pipelines requiring pigging.

2.Reduced port or reduced bore:-

Reduced port (also known as reduced bore) ball valves have flow that is one pipe size smaller than the valve’s pipe size, resulting in a flow area that is smaller than the pipe. Because the flow discharge remains constant and is equal to the area of flow (A) times the velocity (V), A1V1 =A2V2, the velocity increases as the area of flow decreases.

3.V port :-A V port ball valve has either a ‘v’ shaped ball or a ‘v’ shaped seat. This enables linear and even equal percentage flow characteristics. When the valve is closed and the opening process begins, the small end of the ‘v’ is opened first, allowing for stable flow control during this stage. Because of the higher velocities of the fluids, which could damage a standard valve, this type of design necessitates a more robust construction. When machined correctly, these are excellent control valves with superior leakage performance.

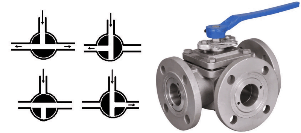

On the basis of no. of port

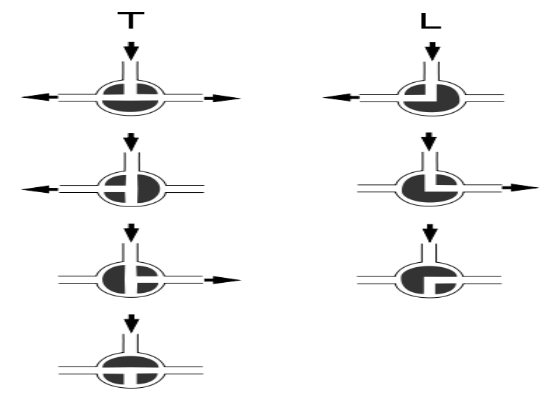

Depending on requirements, we can arrange the port of valve in the three-way.

A.One inlet and two distribute

B.One inlet and one outlet with diverting a flow

C.Stright pass the fluid without No inlet

3 way valve

3 Way valve :-Three-way and four-way have an L- or T-shaped hole in the center. The figure depicts the various flow combinations. It is obvious that a T valve can connect any pair of ports, or all three, but the 45 degree position, which may disconnect all three, leaves no room for error. The L valve can connect the center port to either side port or disconnect all three, but not all three at the same time.

Multi -ports

Multi-port ball valves with four or more ways are also available commercially, with the inlet way frequently being orthogonal to the plane of the outlets. The operation is performed by rotating a single lever four-way valve for special applications such as driving air-powered motors from forward to reverse. The 4-way ball valve has two L-shaped ports in the ball that do not interconnect, also known as a “X” port.

Applications of ball valve

1.Valves for shutting down and isolating liquid and gaseous services that require leaktight valves.

2.Valves for shutting down the system in the event of an emergency.

3 Control valves with a low differential pressure.

4.Steam service control and shut-off valves.

5.For liquid and gaseous services, there are vent and drain valves.

6.Surge control valves for pipelines.

Advantages and Disadvantages of a ball valve

Advantages of a ball valve

1.Efficiency :- Ball valves require no lubrication and provide a bubble-tight seal with very little torque.

2.Affordability: They can often be purchased at a considerably lower cost than comparable products for the same job.

3.Durability: They have a long service life and will provide many years of reliable service when used properly. Ball valves are less likely to be damaged than other valve types, and the plastic variety isn’t corrosive.

4.Easy to use :-It is simple to install and operate, and plastic ball valves are lightweight and easy to handle.

5.versatile :-They’re versatile enough to be used in a wide range of industrial applications where liquid or gas flow must be controlled.

6.Strong:-Ball valves are capable of maintaining and regulating high pressure, volume, and temperature flow.

7.Simple to repair :-When a valve needs to be repaired, the seats are easily accessible.

Disadvantages of a ball valve

1.Poor throttling characteristics: In a throttling position, high velocity flows may cause erosion of the partially exposed seat. As a result, they’re not recommended for long-term throttling.

2.Wear and tear :-Ball valves can stick in place and become jammed when used to regulate the wrong types of fluids, such as slurries, due to suspended particles being trapped. This can lead to the valve wearing out, becoming damaged, or becoming stuck.

Check Out Other Important Topics

Source :-wikipedia

You can also read :-