Heat Exchanger

In todays article we are going to discuss about the Heat Exchanger. By the end of this article a lot of questions and concepts regarding it. It is one of the most used type of pump for various kinds of work. We will discuss the types of heat exchangers i.e. Shell and Tube Heat Exchanger and Plate Heat Exchanger.

It is an equipment which reduces the temperature of a medium by transferring it’s heat to another medium where both the mediums are separated by a solid membrane or wall like structure. In other words we can say that It is an equipment which is used for transferring the thermal energy of one fluid into the another fluid with having a medium of separation in between them.

Types of Heat Exchanger

There are two bases to determine its Type:

- On the basis on flow

- On the basis of design

We will be discussing both the classification of heat exchanger on the basis of flow and on the basis of design as well in detail in a sequential manner.

On the basis of flow

On the note of the flowing arrangement there are 3 Types of heat exchanger.

- Cross flow – In cross flow heat exchanger the flow of one of the fluid is perpendicular to the flow of the second fluid.

- Parallel flow – In parallel flow the direction of both the fluid is same. Both of them enter the exchanger from same side and exit from the same side.

- Opposite flow – In opposite flow the direction of both the fluid are in opposite direction. The entering side of one fluid is the exit side of the second medium.

On the basis of design

There are two types of heat exchanger according to their design

- Shell and Tube Heat Exchanger

- Plate Heat Exchanger

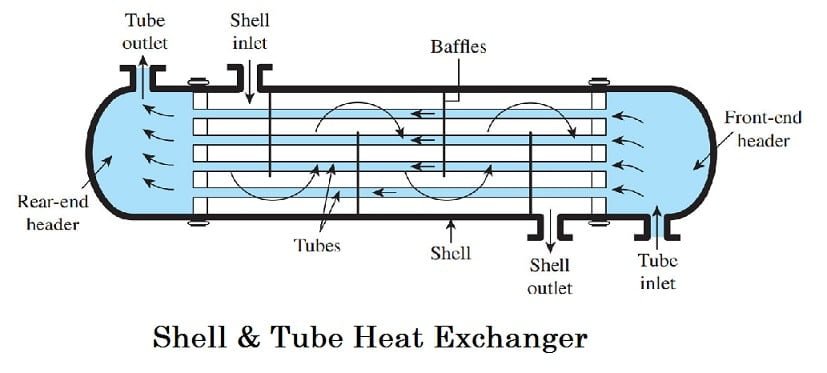

Shell and Tube Heat Exchanger

It is a type of heat exchanging Device consisting of tubes and shell in which the water or the fluid which needs to be cooled flows inside the shell and the cooling media flows inside the tube. It is very economical to install and easy to clean. Shell and tube type has baffle plates fitted across the tube which guide the liquid through the tube. It is also fitted with Sacrificial Anode to prevent corrosive effect.

Function of Baffle Plates :

- Guide the liquid through the tube.

- Provide Support for the tubes

- Prevent any vibration

- Maintains the spacing between the tubes

- Helps in efficient cooling

Plate Heat Exchanger

Plate heat Exchangers are made up of assembly of identical plates pressed together. The plates have horizontal or Chevron corrugations. The corrugations provide stiffness to the plate thus permitting the use of thinner material in the making. Moreover, it also increases the surface area and Aids in cooling. The working space of the plates are sealed by nitrile rubber. The sealings are provided in such a manner that one type of fluid flows in every alternate plates and the other fluid in other alternate plates.

Heat exchangers have applications in many products such as area heating, air-conditioning, chemical processing or waste heat recovery.

Now that we understand what is a heat exchanger the next thing we should know is What does a heat exchanger do ?

What does a heat exchanger do?

These are basically used to exchange or transfer heat between the fluids used. The function of heat Exchanging device depends on its purpose of use. It can be used either to heat a fluid or even to cool down a fluid.

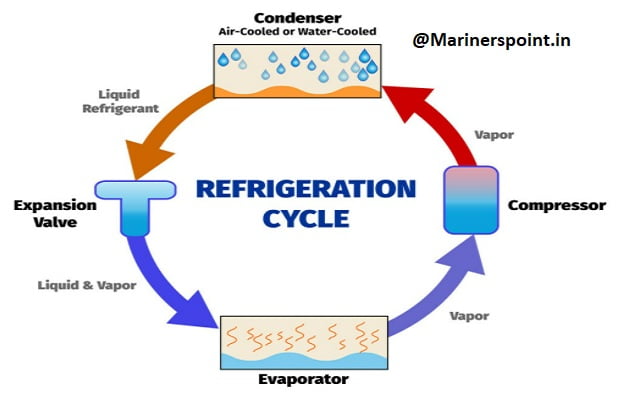

In our day to day life we encounter many such situations where we use this equipment. You can see it’s use in cooling of engines, in refrigerator, in AC, in power plants, radiator in cars etc. Somewhere they are used for cooling while in other situation to raise the temperature.

Let’s take an example to understand what does it actually do. We will take an example of shell and tube heat exchanger which is used to cool the jacket cooling water of an engine. So when the jacket cooling water takes away the heat of engine parts it becomes hot. The hot water is fed into the heat exchanging device in which another fluid which is at lower temperature is there which absorbs the heat of the hot water and brings down the temperature making it reusable. Referring to the section of What is a heat exchanger it is clear that there is transfer of thermal energy in between the two fluids.

These are also used onboard the ship which are generally known as Marine heat exchanger.

Use of Marine Heat Exchanger Onboard

- To run the main Engine properly. We need lube oil and fuel oil to have an adequate and desired viscosity which is maintained by passing it through the heat exchanger.

- For cooling the running engine parts we circulate the jacket cooling water which after taking heat from the engine is passed through heat exchanger to get it cooled again for recirculating.

- In Air Starting System the high pressure air is passed through an inter-cooler which is also a type of heat exchanger.

- In refrigeration System, the evaporator is also a phase changing heat exchanger.

Component of heat exchanger

So far we have learned Definition of heat exchanger, type of heat exchanger and also about Marine heat exchanger uses. Now let’s discuss about the construction and component of heat exchanger.

As we know there are two type of heat exchanging Device one is shell and tube type and other is plate type. Both of them have different appearance and components used in their construction.

Component of Shell and Tube Heat Exchanger

It has two main components that is the shell and the tube and all others are helping components for support or for it’s smooth functioning.

The shell which is cylindrical in shape can be constructed from rolled piping or plate with required diameter. Tubes are thin walled tubings which are manufactured specifically for the use of heat exchangers. Tube can be made in two ways . One is seamless tube which are produced in an extrusion process. And the other is welded tube constructed by rolling a strip into a cylinder and welding the seam.

Other components of shell and tube type are tubesheets, baffles, Tie rods and spacers, channels/heads.

Tubesheets – These are the base plate or forgings which are having the holes drilled into them to fit the tubes perfectly and tightly this preventing the fluid from shell to mix with the fluid in tube.

Baffles – Baffles plays an important role in proper Functioning of this equipment. It supports the tube, helps in maintaining the spaces between the tubes and also directs the flow of the fluid inside the shell.

Tie rods and spacers – These are used to serve two functions .To maintain a proper spacing of baffle plates and to hold the baffle assembly together.

Channels/ Heads – These are required to channelize the flow of fluid inside the shell .

Component of Plate Heat Exchanger

Plate Heat exchanger requires relatively less parts as compared to shell and tube type. The various components of the plate type of exchanger are Plates, fixed frame, tie rods, carrying bar, gasket, flow plate, end plate, Movable frame.

Component in a sequence :

- Front frame – The inlet and outlet connections are made on it. Also known as pressure plate

- Two shafts – Present at the top and bottom of it. Used for fixing and supporting the plates.

- Start plate – It prevents liquid from contacting the frame.

- Flow plates – These are the intermittent plates in which the liquid flows and the heat transfer takes place

- Last plate– It is fully closed at the last to prevent the fluid contacting the frame.

- Movable frame– Also known as frame plate or back frame. It is movable and contains the maintenance instructions on it.

- Gaskets – Gaskets are used as sealings to prevent the inter mixing of the fluids .

- Guide bar– It ensures the correct alignment and arrangements of the plates when they are opened or closed.

Also there are washers and pins which are used to hold the plates in their respective positions.

How does a Heat Exchanger work?

By this time we are familiar with the idea about what does a heat exchanger do. The basic function of it has been discussed in the above sections. Now we will look into more detailed explanation of how does a heat exchanger work and we will be discussing the way of working of both the types of the heat exchanging here individually.

How Shell and Tube Heat exchanger Work?

There are two things, the shell in which the fluid which needs to be cooled is placed and the tube in which the coolant or the cooling media is placed. The tubes are made of such materials which are having good thermal conductivity so that easy heat transfer can take place. With proper sealing arrangements it is made sure that the two fluids don’t mix with each other. Now when the coolant having lower temperature is passed in the tube though the another fluid filled in the shell , heat from the higher temperature flows to the lower temperature thus making the fluid in the shell colder an Aids in cooling. Same reverse thing can happen if we want to heat the medium we can proceed in the same manner as it can be used to cool and heat both.

How Plate Type exchanger works?

To understand how plate heat exchanger works we will take an example considering two fluids one is hot and the other one is cold. Now the fluid which is hot is fed into the hot fluid inlet and this then flows to the various plates, not in every plate, the because of the gasket arrangements it is such that the fluid passes in every alternate plates leaving one plate in between. Then the second fluid is fed into the cold fluid inlet and it also then travels to the remaining empty plates. Now the arrangement is successful with a pattern of hot, cold, hot, cold… and so on. Since the plates are packed very tightly and close to each other the heat transfer from hot medium to cold medium takes place via the plates thereby cooling the hot fluid. And then finally they exit out from their respective outlets.

Application of Heat Exchanger

These have a varied range of applications as we see there are many equipments which we use needs cooling or thermal assistance. In such cases either to increase temperature like increasing lube oil temperature to maintain it’s viscosity or to cool down the jacket cooling water , they can be used in both the cases.

Applications of Shell and Tube Type

The shell and tube type come in various configurations and types depending on the number of tubes and other arrangements present in them . Being easy to maintain and simple design it is easy to use in variety of places.

- Refrigeration

- Power Generations

- On Ships for cooling and heating both

- Pulp and paper industry

- Pharmaceuticals industries

- HVAC

- Air process and compressor cooling

- Metals extraction

- Mining

- Cooling of Engines

Applications of Plate Type Heat Exchanger

Plate heat exchangers are very compact in size and can fit in a small space. So it can be used in less space. The number of components are also less so less wear and tear.

- Refrigeration

- HVAC

- Chemical Industry – composite cooling

- Metallurgical Industry – quenching liquid cooling

- Machinery – Cooling Lube oil or Fuel oil

- Power Industry – High Voltage Transformer oil Cooling

- Marine Industry

- Textile Industry- alkaline cooling

- Food and Beverage Industry – sterilization cooling

- Paper Industry- Bleaching process heat recovery

Heat exchanger efficiency

Whenever we make a device or an equipment for doing or making our work easy we want the best result out of it i.e we want that it should have maximum efficiency. Heat exchanger efficiency depends on different Factors according to it’s type and usability.

The efficiency of shell and tube heat exchanger will depend upon the material used in making of the tubes, the type of fluid used, viscosity of fluids, alignment of Baffles in between, proper sealing, proper cleaning. In case of plate type the efficiency will depend upon the material used in making plates, design of the plate, condition of gaskets, the nature of fluid, the tightness of the plate stack and proper cleaning.

Conclusion

Heat Exchanger is used to transfer heat from one of the fluid to another fluid and both of them are separated using different medium as we have seen in two types of heat exchangers. In Shell and Tube Type, the heat is transferred across the tubes separating the two fluids. In Plate Heat Exchanger the heat is transferred through one fluid to another and they are separated by corrugated plates for maximum efficiency.

Check Out Other Important Topics

[…] Heat exchanger […]