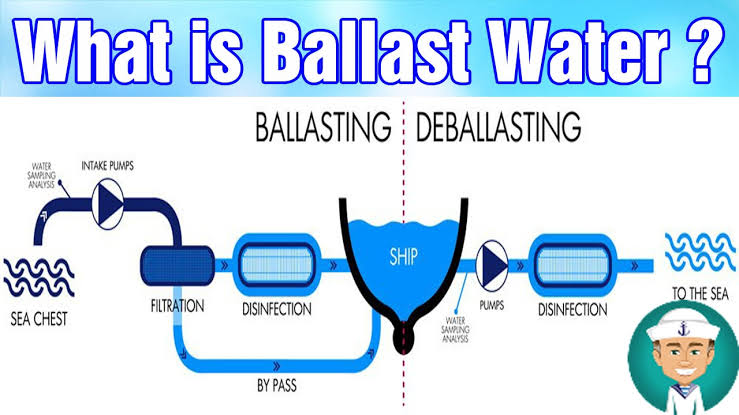

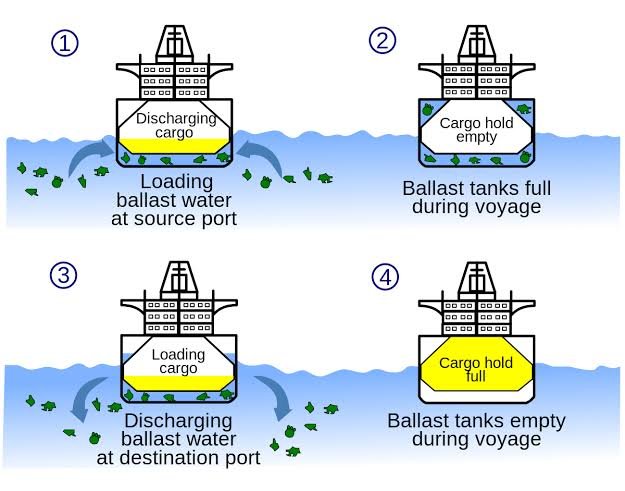

Ballasting of ship is a process by which sea water is taken on ship in a dedicated ballast water tank while cargo is discharging.

Deballasting is a process by which sea water is carried out in sea from ballast tank when the ship loading cargo.

Simply,Ballasting or de ballasting is a process in which sea water is taken in and out from the ship for its stability when it at port or at the sea.

The sea water which is carried by a ship is called as ballast water.

What is the purpose of ballasting ?

The main purpose of ballasting a vessel for a voyage are to increase its manageability (and safety), especially in rough weather; control its draft and trim for maximum efficiency; and control its stability to ensure safe passage.

Must read :- Centrifugal pump

When ballasting or Deballasting required ?

It is required when the ship is

1.During Loading or unloading of cargo

2.to enter a channel

3.cross any canal like panama canal and Suez canal and

4 when ship is going for berthing.

Why sea water is used for ballasting ?

For ballasting vessel ,ballast water is sea water carried by a vessel in its ballast tanks to maintain the vessel’s trim, stability, and structural integrity. Ballast tanks on ships are outfitted with a piping system and high-capacity ballast pumps to carry out the operation.

As we know that for stability of ship, ballasting is done.In ancient time,Ship did the work of carrying hard weights/solid weights in form of rocks and sand bags for stability when there was minimum cargo or no cargo being carried.

However, as time passed, difficulties arose during the loading and unloading of solid cargo. Because the process of transferring solid cargo was time-consuming, solid ballast was replaced by water ballast. Because sea water was readily available in large quantities, it was used in the ballasting and de-ballasting processes.

Why is ballasting of ship done ?

Ballast water is carried on board vessels in order to maintain safe operating conditions during a specific voyage or portion of a voyage. Proper ballasting (in terms of the amount and distribution of water taken aboard) performs the following functions:

1.reduces stresses on the ship’s hull

2.ensures transverse stability

3.controls the propeller’s submergence, which aids propulsion.

4 improves maneuverability by submerging the rudder and reducing exposed hull surface (freeboard or windage)

5.compensates for the weight lost as a result of fuel and water consumption

Ballast condition, including when and how much water is loaded, determined by ship’s officees.It is determined on basis of the specific vessel’s operating needs and national and international requirements for proper vessel trim and stability at sea.

Ballast conditions at sea

The main purpose of ballasting a vessel for a voyage are to increase its manageability (and safety), especially in rough weather; control its draft and trim for maximum efficiency; and control its stability to ensure safe passage. The following list summarizes the factors that influence ballast conditions at sea.

Heavy weather conditions

Ships must be anchored deep enough in the water to ensure safe passage, especially in bad weather. If the bow of the ship is not deep enough, the ship’s forefoot will emerge from the water surface on a regular basis. This causes hull slamming (or heavy impact) when the bow hits the water with high velocity on re-entry.

Sailing with full tanks

Depending on the ship’s stability and strength requirements, ballast tanks used to control trim or heel, some fuel oil tanks, and tanks containing fresh water for domestic use may be partially full at sea. It is usually necessary to sail with as many of the tanks on board as possible, either completely full or completely empty. When a tank is not completely full (i.e., “slack”) and the ship heels, the free surface effect of the liquid in the tank moves the center of gravity of the liquid in the tank, reducing the ship’s transverse stability (see Appendix C).

Furthermore, fluid in a slack tank sloshes around during ship motion, which cause excessive loads on tank/hold bulkheads, frames, or underdeck structure. This could lead to structural failure in severe weather conditions. As a result, when changing ballast at sea, the ballast in a single tank or pair of tanks should be completely changed before moving on to the next tank or tanks.

Controlling trim during voyage

The draft and trim of the ship will change as fuel is consumed during a voyage. Thousands of tons of fuel may be consumed during a long voyage. As a result, in order to keep the hull immersed correctly for maximum efficiency, additional ballast is frequently required as the voyage progresses. Some ship designs position the fuel tanks so that the ship naturally trims by the stern as the fuel oil is consumed, but ballasting may still be necessary. Ballast capacity and location on a given voyage are determined by examining the estimated amount of fuel to be consumed, the expected weather conditions, and the required draft and trim for the arrival port (s).

Transverse stability considerations

A ship’s transverse stability is defined as its ability to sail upright and avoid capsizing. To achieve proper transverse stability, the ship’s righting moment must be carefully controlled (see Appendix C). The ship should ideally be loaded and/or ballasted in such a way that it has a smooth rolling period that is neither too fast nor too slow. A ship that rolls too fast has excessive stability (a stiff ship) and has a strong tendency to quickly return to its original upright position. This causes a very uncomfortable motion that can put a lot of strain on the ship’s structure and cargo lashings, as well as a lot of sloshing in the slack tanks.

A vessel that rolls too slowly has insufficient stability (it is a tender ship) and may capsize in bad weather. When ballast is moved, it causes slack ballast tanks to form. When the vessel heels, the associated free surface effect can cause a weight shift, which has a negative impact on the ship’s transverse stability.

Ballast conditions in port

Bulk oil carriers (tankers), dry bulk carriers, and the majority of other ships deballast during cargo loading and reballast during cargo discharge (see Table 2-1). A fleet of ships operates as float-on, float-off platforms, with the ship ballasted down to allow cargo to be floated on board and deballasted to lift the cargo for the journey. For unloading, the procedure is reversed.

Controlling draft and trim for port entry

Vessel must alter draft and trim to when entering to ports ,Berths,or both at loading or unloading.

Ballast may be discharged to reduce water drafts when entering certain ports or approaching specific terminals, and it may be added to reduce air draft when clearing bridges or approaching under loading heads at some bulk cargo terminals. These operational parameters can limit the timing and location of ballasting and deballasting.

Safe longitudinal loading consideration

The distribution along the hull of the difference between the light ship weight, including cargo, fuel, ballast, and other dead weight items, and the supporting buoyancy force determines the shear forces and bending moment on a ship’s hull. Buoyancy support forces change in a seaway as waves move along the hull and the hull moves relative to the sea surface. The ship operator must ensure that the ship’s in-service conditions are consistent with the ship’s structural design.

Summary of Ballasting or Deballasting

When the ship is not carrying cargo, it becomes light in weight, which can affect its stability. As a result, ballast water is stored in dedicated tanks on board the ship to stabilize it. Ballasting is the process of filling tanks with ballast water using large capacity ballast pumps.

When the ship is loaded with cargo, the weight of the cargo itself maintains the ship’s stability, and thus no ballast water is required. De-ballasting is the process of removing ballast water from ballast tanks in order to empty them.

Check Out Other Important Topics

Home IC Engine Electrical Important PDFs Boilers Synergy Maritime Exam Naval Arch Interview Questions Difference Between Types of Pumps Types of Valves MEO Class 4 Auxiliary Machines

Source :- https://en.m.wikipedia.org/wiki/Ballast