What is a Flame Arrester ?

A flame arrester (or Arrestor) is a safety device fitted on the opening of an enclosure or to the connecting pipe work in a system of enclosure and which allow only gases and liquid etc. to pass through it but prevent the transmission of a flame in order to prevent a larger fire or explosion.

In simple language , it is a device which only allows gas to pass through it but stops the propagation of a flame.

Note :- It is also known as speller arrester, deflagration arrester, or flame trap.

Must read :-Fusible Plug

Purpose of Flame Arrester ?

The main purpose of flame arrestor is to prevent a larger fire or explosion or can be said to stop fuel combustion by extinguishing the flame.

Parts of Flame Arrestor

The main parts of flame Arrester are

1.Flame front

2.Housing

3.Flame arrester element absorbs and quenches the flame front.

4.Flange or connector for the pipe

5.Unprotected side

6.Protected side

Flame Arrester Working Principle

A flame arrestor operates on the principle of quenching and removing the heat from a flame front moving at subsonic speeds (through narrow passages with walls of metal or other conductive materials), thus dropping the temperature of the burning gas/air mixture below its auto-ignition temperature, consequently preventing the flame from continuing to burn.

The heat is absorbed through channels (passages) designed into an element. These channels are chosen and measured as the MESG (maximum experimental safe gap) of the gas for a particular installation.

These passages can be regular, like crimped metal ribbon, wire mesh, or a sheet metal plate with punched holes, or irregular, such as those in random packing.

How a Flame Arrester Works ? How it Extinguishes the flame ?

Flame arrester are designed to allow flow of gases or liquid etc and to prevent transmission of flame.

It consists of Flame filter (Flame arrester disc ) Spacers, and a Casing.

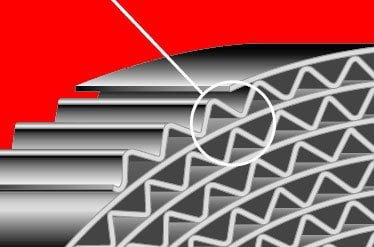

The flame filter is made up of wound crimped metal ribbon type flame cell element.

As combustion of fuel and air takes place ,the flame spreads towards the non combustible mixture.The expansion volume of the combustion mixture pre compresses the non combustible mixtures and accelerates the flame.

As flame filter is wound crimped metal like s structure creating narrow passage.

As the flame pass through arrester ,heat dissipation takes places in the boundary layer “s” transferring into to the larger surface of the gap length compared to the gap width “D” and by cooling down below it’s ignition temperature,the flame is extinguished.

The flame arrester disc’s extinguishing ability is determined by the gap width and gap length. The greater the extinguishing effectiveness, the narrower and longer the gap. The lower the pressure loss, the wider and shorter the gap. Experiments can be used to determine the best solution between the two conditions.

Types of Flame arrester

A flame arrester is best classified based on its installation or application, such as boats, tanks, vent stacks, and so on.

A flame arrester is classified into three types based on its installation:

1.End of line, vent to atmosphere arresters – to prevent an atmospheric fire or explosion from entering an enclosure.

2.In-Line – to prevent the propagation of an explosion within a pipeline.

3. Pre volume type

1. End of Line type

An end of line type flame arrester is used in deflagration type of fire or explosion in which combustion propagates through a gas or across the surface of an explosive at subsonic speeds, driven by the transfer of heat.

Most of the designs uses a single elements of crimped wound ribbon metals which provide the heat transfer needed to quench the flame.

End-of-line flame arrestors are fitted to the end of a pipe line or vessel exit to prevent flames from entering, not, as is sometimes mistaken, to prevent flames from exiting the pipe or vessel. They can be mounted in almost any orientation without a weather-hood, but inverted mounting is not recommended because it increases the risk of heat being trapped and causing a flash back.They should be used outside, exposed to rain and snow, with a weather-hood attached and in a conventional vertical orientation.

Note :-These arrestors can be mounted in any required direction. Although, inverted mounting is not recommended as the risk for blowback.

Where it is used :- It is used where the potential ignition source is located outside the vessel.These types of flame arrestors are mainly used in the venting system of tanks. It allows free venting operation in combination with fire prevention.

Conventionally these arrester types prevent the fuel oil tanks to explode; in the event, its vent is stuck by a lightning strike.

On a ship for storage tank ,this type of arrester is used.

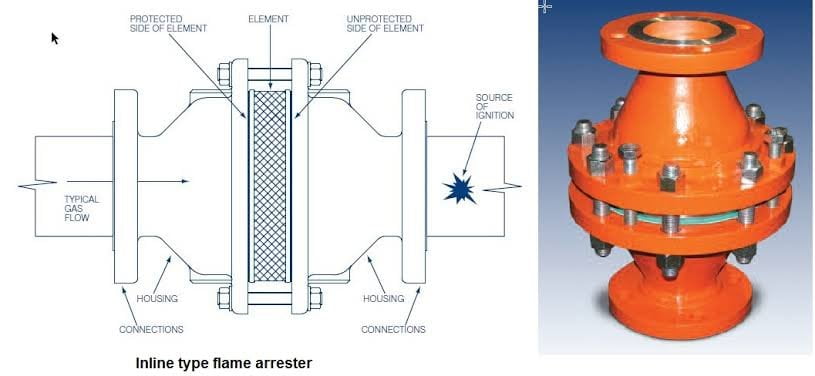

2. In Line Type

In-line flame arrestors are installed in piping systems to protect downstream equipment. Although the layout shown below is typical, it is possible that the source of ignition could cause the flame to travel with the gas flow. If the flame can come from either direction, a bi-directional flame arrestor is required.

Pipe orientation is usually not an issue unless liquid is entrained in the gas flow and tends to collect in the arrestor. In such cases, an eccentric flame arrestor housing may be installed to allow liquid collection and drainage.

Note :- on ship,in air starting line this type of arrester is used

In such cases, an eccentric flame arrestor housing may be installed to allow liquid collection and drainage.

This flame arrester is designed for confined flame propagation at the sub and supersonic speed; it first reduces its speed and then quenches the fire.

Because the flame’s speed and heat are both high, it has either parallel plates or wire gauges in packs for faster heat transfer.

In a typical configuration, it has an exposed side, a protected side, and an arrester element to put out the fire.

The underlying process for this phenomenon can be either vapour destruction systems or vapour recovery systems.

Depending on the application under which they are used, in-line flame arrestors can be either deflagration or detonation arrestors.

It is of two types

2.1In-line Deflagration type

2.2In-line detonation type

The selection is done based on the distance between; the arrester and potential source of ignition.

Deflagration means rapid burning and detonation means explosion.

In-line Deflagration type

In line Deflagration type flame arrester are designed to use in confined flame propagation.

The distance between potential ignition source and the location of Deflagration flame arrester should not exceed the L/D ratio (pipe length /pipe diameter ) for which device was approved.

As per EN ISO 16852 L/D ratio shall be limited to less than or equal to 50 Deflagration flame arrester of explosion group 2A ans 2B 3 (hydrocarbon /air mixture ) and to less than or equal to 30 for explosion group 2c (hydrogen /air mixture).

In-line detonation type

A detonation is an explosion propagating at supersonic velocity. It entails increased compression of the gases by shock waves in front of the flame. Detonations require fuel-oxidant mixtures that are sufficiently reactive for the combustion zone to propagate at

supersonic speeds.

Detonations in pipes can develop from deflagrations, which after a flame path of about 100 D can undergo deflagration to detonation transition (DDT) and then form an overdriven detonation that eventually ends in a stable detonation. Detonation flame arrestors are used where the L/D ratio exceeds the values stated above or where the location of ignition source is not known.

3. Pre Volume Type

A pre-volume arrestor is used when the potential source of ignition is within the tank or a pipeline with a larger cross-section area.

Simply, these are much better arresters used to prevent fire from spreading from one system or tank to another.

Although the propagation speed is usually below subsonic, the pressure and heat generated are too great for a typical deflagration arrester to handle.

As a result, special care and consideration must be given to its design. As a result, it is slightly superior to normal fire arresters.

Normal inline or end of line arresters are designed to meet the expected conditions. A pre-volume in-line or end-of-line arrester must be twice as strong as the expected condition.

Flame Arrester Construction

A flame arrester typically consists of a housing, an element, and connection(s) to pipe work or equipment. The element is the device that extinguishes the flame, and the majority of constructions use a type of “filter” that provides small apertures through which the process gas can flow but prevents flame transmission.The flame front is broken down into smaller flamelets in the “filter,” which are cooled by the element’s large heat capacity,thus extinguishing the flame.

Crimped metal ribbons, woven wire gauze, sintered materials, and honey comb materials are among the materials used to make the filter element. Because of its design, the element will cause a pressure drop or an obstruction to process flow.In order To compensate for the increased resistance to flow, the element area is typically larger than the cross sectional area of the pipe work. Larger elements have a higher heat capacity as well.

The flame arrester housing can be integral to or separate from the element housing. In the latter case, fastenings are used to hold it together. To match the adjacent pipe work, the end connections are usually flanged or screwed fittings.

Other types of flame arresters include those with a small aperture that ensures the velocity of the gas being emitted exceeds the burning velocity of that gas, preventing the flame from being transmitted. Alternatively, the gas can be bubbled through a liquid or water to create a liquid barrier that prevents flame transmission.

Flame Arrester Design

The main parts of flame arrestor is flame arrester elements.

The elements of arrestor is made by Enardo employes layers of metal ribbons with crimped corrugation.

In the above figure circle mark is flame cell channel.

As we know that flame arrestor operates in the principle of quenching. The flame channel help in quenching the flame and dessipation of heat.

Flame Arrester for a Tank

Flame arresters on a fuel storage vent also serve a secondary purpose by allowing air pressure inside the tank to equalise when fuel is added or removed, as well as preventing insects from flying or crawling into the vent piping and fouling the fuel in the tanks and pipes.

A flame arrester can be used for a variety of purposes, including:

- Stopping the spread of an open fire

- Limiting the spread of an already occurred explosion

- Preventing potentially explosive mixtures from igniting

- Confining fire within a controlled location

- Stopping the propagation of a flame traveling at subsonic velocities

Applications of Flame Arrester

- On the vent of fuel storage tanks

- On the pipeline of fuel gas

- On the Safety storage cabinets for paint, aerosol cans, and other flammable mixtures

- On the exhaust system of internal combustion engines

- Portable plastic gasoline containers

- Overproof rums and other flammable liquids.

- Davy lamp in coal mines.

- The air intake of marine onboard engines (On pipe of air starting lines ).

FAQ ( Frequently Asked Questions )

Where are flame arrestors required?

Whenever there is a risk of an explosion caused by the mixing of combustible gas or vapour with air, flame arresters are frequently utilised. A flammable combination that accidentally ignites will produce a flame that will pass through the unburned mixture until the reaction has consumed all of the fuel.

Check Out Other Important Topics