A Fusible plug is a type of warning device which operates as a safety valve when dangerous temperatures, rather than dangerous pressures, are reached in a closed vessel (Air compressor, Boiler ).

They are employed on compressed air system and steams systems,wellhead etc.

They are considered as a last line of defense and often are used to avert a catastrophic failure occurring , for example ,an explosion.

It is also called Last line of defense.

Note :- While safety valve did the work of protecting machinery and system from overpressure,while fusible plug protect machinery items and system from over temperature.

Application of fusible plug

Fusible plug has found widespread application in many industries because they have a

Very simple design,they are very effective and improvements to safety and they are also cheap.

They are normally installed

1.Within compressed air system

2.Coal fired boiler; Boiler burning light fuel oil (LFO ) or gas are not always equipped with fusible plugs.

Construction of fusible plugs

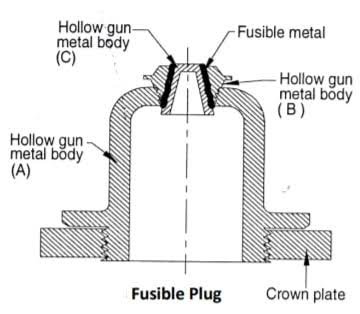

A fusible plug is a threaded metallic cylindrical object usually made up of bronze, brass or gunmetal, with a tapered hole drilled completely through its length.

This hole is sealed with a low melting point metal that flows away if a predetermined high temperature is reached.

Fusible plug parts

Fusible plug essentially consist of two parts

A) A body and B )fusible alloy channel running through the middle of the body.

It’s from the fusible alloy channel that the fusible plug gets its name.

Fusible plug materials

It contains a fusible alloy housed within a plug body.The plug body is usually manufactured from brass,bronze or gun metal.

The top of the body is called the head and below the head is the threaded section.

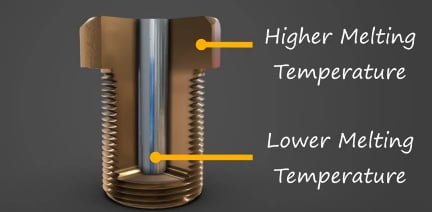

The material chosen for the fusible alloy has a predetermined melting point and this melting point is lower than the plug body’s melting point.

A common fusible alloy material is tin,which has a melting point of around 232 degree celcius orv450 degree Fahrenheit.

How fusible plug work

Now we know that fusible plug consists of two parts, the plug body and the fusible alloy channel,let’s have a look how it works;

The fusible allow within a fusible plug is designed to melt at a lower temperature than the surrounding plug body.

Fusible alloy melts before plug body.

If the plug is exposed to elevated temperatures, the fusible alloy will melt and a straight or tapered channel will be formed lengthwise through the plug body.

The now open channel allows the system pressure to vent direct to a predetermined location.

Location of fusible plugs is mentioned below,here I told how air or steam come out from system.

1.For compressed air system

Compressed air vent location :-

For compressed air system;this location is usually the space surrounding the plug, although we can also connect the space surrounding the plug, although we can also connect a pipe to the fusible plug and in this way we can went to a remote location.

2.For Boilers

Firefox or furnace;For boilers,it’s more likely to be the firebox or furnace .

Whistling noise;

The fusible plug body is often shaped so that a whistling noise is created as the system pressure vents.

This act as a local audible alarm to system operators.

Whistling noise = Audible alarm

The operator can take corrective action.So, we know how fusible plugs work.

Purpose of fusible plug

The function of fusible plug is that ,it act as a safety valve when dangerous temperatures, rather than dangerous pressures, are reached in a closed vessel. Let’s take a different examples;

One for compressed air systems,

And one for steam systems.

1.Compressed Air System

Compressed air High Temperature ;

Compressed air installations represent a considerable risk if exposed to fire.Thus, because the air within the system becomes heated and the system pressure rises until the pressure is too great for the system to hold( at constant volume: Temperature increase =pressure increase ).

The stored energy within the state is also quite large .

If this system is allowed to continue the system pressure could be released catastrophically.This catastrophically failure is likely to damage the immediate area surrounding the compressed air system as well as potentially leading to loss of life.

Compressor oil vapour ignition.

Piping oil carry-over ignition:

Other damages associated with high temperature in compressed air systems include ignition if oil vapour with in air compressors,and ignition of any oil carry-over that may be within compressed air system piping.

Steam System or Fusible plug in boiler

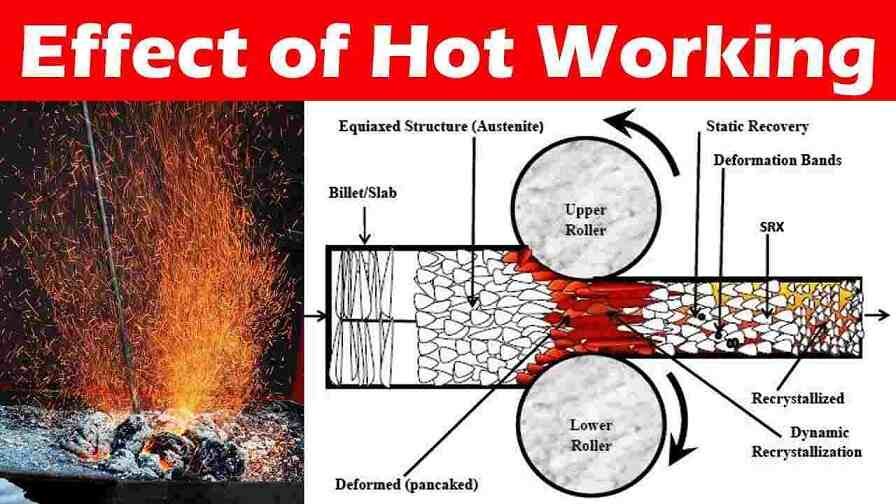

Boiler fusible plug is used for protection from low firing ;If we look at steam systems,fusible plugs are installed within boilers to reduce the risk of a boiler explosion as a result of low water firing. (Protect from low water firing )

A low water level scenario in a boiler would lead to overheating of the heat transfer surfaces and result in damage to the boiler would occur.

Low water firing of boilers has led to catastrophic failure in the past and continues to be a primary safety concern for boiler operators today.

Types of fusible plug a/c to actuation

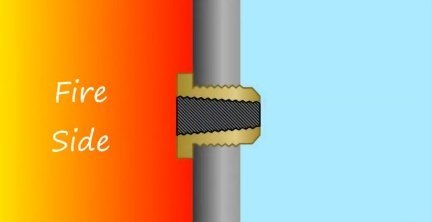

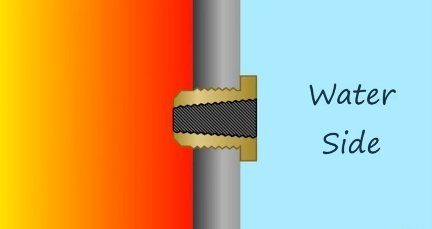

Boiler fusible plug are classifieds as a)steam -actuated or b)fire actuated and can be installed both on fire tube boilers and water tube boilers.

It is also possible to classify boiler fusible plugs as being either a)fire side or b)water side plugs.

a)Fire side plugs are are screwd from the fire side to the water side.

b)Water side plugs are screwd from the water side to the fire side.

Boiler fusible plug usually did the work of venting steam to the firebox which extinguishes the flame of boiler and thus reduce the temperature and pressure if the steam system.

Location of Fusible plug

1.Compressed air system

The location of fusible plug in air compressor system is anywhere in underside of the Pipe between relief valve and air bottle .or on air storage vessel when safety valve is not fitted directly on aur bottle.

2.Steam System or boiler fusible plug

The location of fusible plug depends upon the design of the boiler.

Fire tube boiler fusible plug installed one to two inches above the highest row of tubes.Typical location for fusible plug include the crown sheet (top of the combustion chamber ) ,rear tube sheet (Scotch marine boiler ) and front tube sheet ( firefox boiler )

The water level in the boiler becomes too low ,the side of the fusible plug that’s exposed normally to water would then come into contact instead both steam.

This would cause the fusible alloy to melt and steam would then travel from the steam space.and into the furance,and then steam would then travel from the steam space and into the furnace.

Once this occurs, combustion within the furnace would no longer possible and the flame would be extinguished..

In this manner this possible to shut down the boiler before the top row of tubes are no longer covered by water and they vihin to overheat.(Boiler tubes not covered by water will overheat.)

Fusible plug maintenance

Fusible plugs require some firm of maintenance.If we look at compressed air system and steam system example again.

1.Compressed air system

● Compressed air system maintenance normally quite clean.compressed air system are normally maintained in a clean state.

● Oil carry -over :- Some oil carry-over may occur from the comoressors but this can be prevented by using oil free compressors or filters.

● Moisture carry over :Moisture carryover may also occur buy nowadays most installation utilize dryers of the desiccant or refrigeration type and these dryers remove any moisture from the system.

NOTE :-No oil and no moisture = clean oil syatem

Providing the oil and moisture are removed ,the compressed air system will remain clean and the fusible plug will remain in good condition,that is to say it would not be coated in an oil film or corroded by water.

> Fusible plug should be replaced periodically.

Despite this,periodic changing of the plug is still required and should definitely pe performed as part of any maintenance strategy.

>Not only that but sometimes it’s a legislative requirement to change the plug after a certain period of time,for example,after 12 months .

Steam System Maintenance

Maintenance associated with fusible plugs for steam system is slightly different.There are several factors that may influence a boiler fusible okug’s operation.

These relate to the plug being insulated and not functioning correctly as a result.

1.Thermal insulation affects water and fire side of plug :-

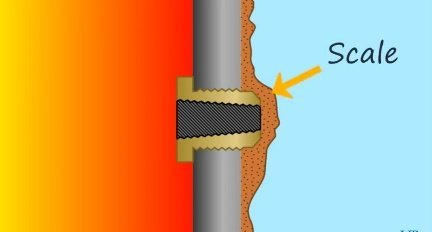

Insulating of the fusible plug is a problem that may occur on the water side,fire side,or both sides of the plug.

On the water side ,dissolved solid smay solidify on heat transfer surfaces and form an insulating barrier.This insulating barrier also known as scale.

Scale build up on the fusible plug may cause the fusible plug not to operate as designed because heat transfer may be inhibited.

If heat is not transfered to the plug ,then the fusible allow will not melt and the boiler will not be protected as designed.

On the fire side, soot from combustion may accumulate on the fusible plug surface and form an insulating barrier.

Because the soot forms an insulating barrier,heat transfer from the exhaust gas to the water side of the boiler is inhibited.

For the same reason,heat transfer to the fusible plug is also inhibited.

Soot is a thermal insulator (low heat transfer rate )

If this occurs,the fusible plug will not operate as intended.

Scale and soot should be removed during maintenance:

Whenever boilers are maintained,scale and soot is removed in order to restore the heat transfer surfaces back to their original condition or as close to it as possible.

Steam system maintenance

Dictated by governing bodies and legislation :-

A boiler’s inspection frequecy and the maintenance tasks that are performed are often dictated by governing bodies and legislative requirements.

Because of this ,even if a fusible plug appears to be in good condition ,some governing bodies will insist that the plug is replaced after a certain period of time.They are actually good reason for this.

Replacement of fusible plugs often a requirement.

Many materials degrade over time. And the properties of tin,which is the fusible alloy for many fusible plugs,will also degrade over time.

For this reason, annual replacement if fusible plugs is often considered good practice ,even it is not a legislative requirement.

Check Out Other Important Topics

Home IC Engine Electrical Important PDFs Boilers Synergy Maritime Exam Naval Arch Interview Questions Difference Between Types of Pumps Types of Valves MEO Class 4 Auxiliary Machines

[…] Must read :-Fusible Plug […]