Diesel generators are extremely helpful equipment that provide electrical power in the event of a power outage. So lets have a quick view on Diesel Generator Working Principle.

A silent diesel generator is a combination of a diesel engine and an electric generator that is often used as a secondary source of electrical power in industrial and residential units. It is available in a variety of physical and electrical configurations.

Before understanding the principle of diesel engine generators we need to have an understanding of its working parts and how they help in generating the electricity.

What are the main parts of diesel generator?

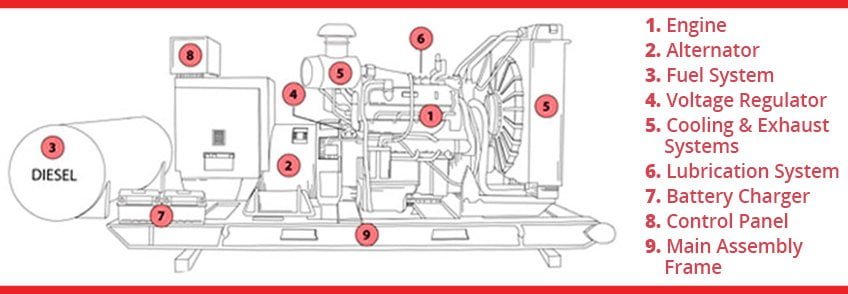

A diesel generator is a device that converts mechanical energy (from an internal combustion engine) into electrical energy. The diesel generator has several components that work together to generate electricity. The following are some of the essential components of a power diesel generator:

Diesel Generator Parts and Functions

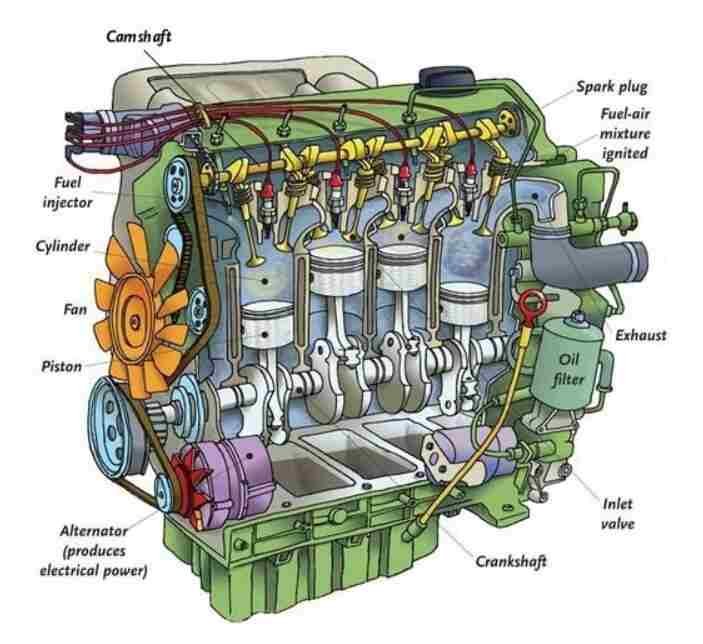

IC Engine – The engine is the principal component of a diesel generator set, supplying mechanical energy that is then converted to electrical power. In reality, the power output of these diesel generators is proportional to the size of the engine. The more powerful the engine is, more output we get as electricity.

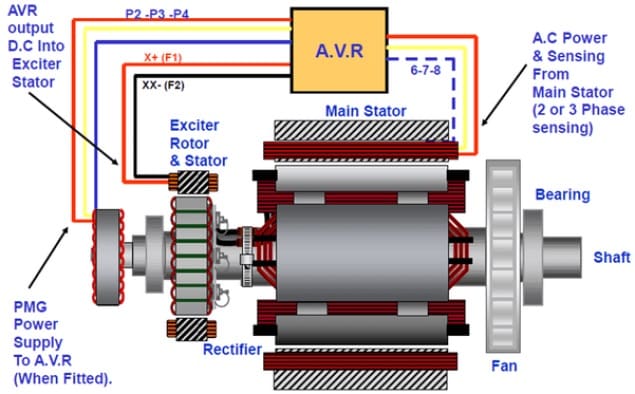

Alternator – Another important component of a diesel generator is the alternator. It turns the mechanical input from the engine into electrical output. An alternator is made out of a rotor that generates a magnetic field in order to generate alternating electricity. This is why the rotor is referred regarded as the alternator’s major component.

Fuel System — This component stores and distributes the generator’s fuel. Fuel is the most important thing to make the engine run. The engine converts the Chemical energy of the fuel into mechanical energy, and then this mechanical energy is converted to electrical energy.

Lubricating System – This component guarantees that the various components of a diesel generator run smoothly. As a result, it’s important to keep a close eye on the generator’s lubrication system to avoid any problems. Since there are many rotating parts being working inside a generator, it is highly important to have a proper lubrication system which not only protects from friction but also aids in cooling of the moving parts.

Control Panel – The Start/Stop button is located on the Control Panel, which also features indicators for other parameters such as current, voltage, and frequency. While operating a generator it is important to keep an eye on these parameters for its smooth functioning, otherwise the whole generator system may fail.

Diesel Generator Working Principle

The basic principle of operation of a diesel generator is based on the thermodynamics law of energy conversion. According to this law, energy cannot be generated or destroyed, but only converted from one form to another.

How Electricity is Produced in Diesel Generator?

A diesel generator is made up of an engine that runs on diesel fuel. During the combustion process, the chemical energy of the fuel is now turned into mechanical energy. The mechanical energy created is then turned into electrical energy, which can be utilized in the event of a power outage.

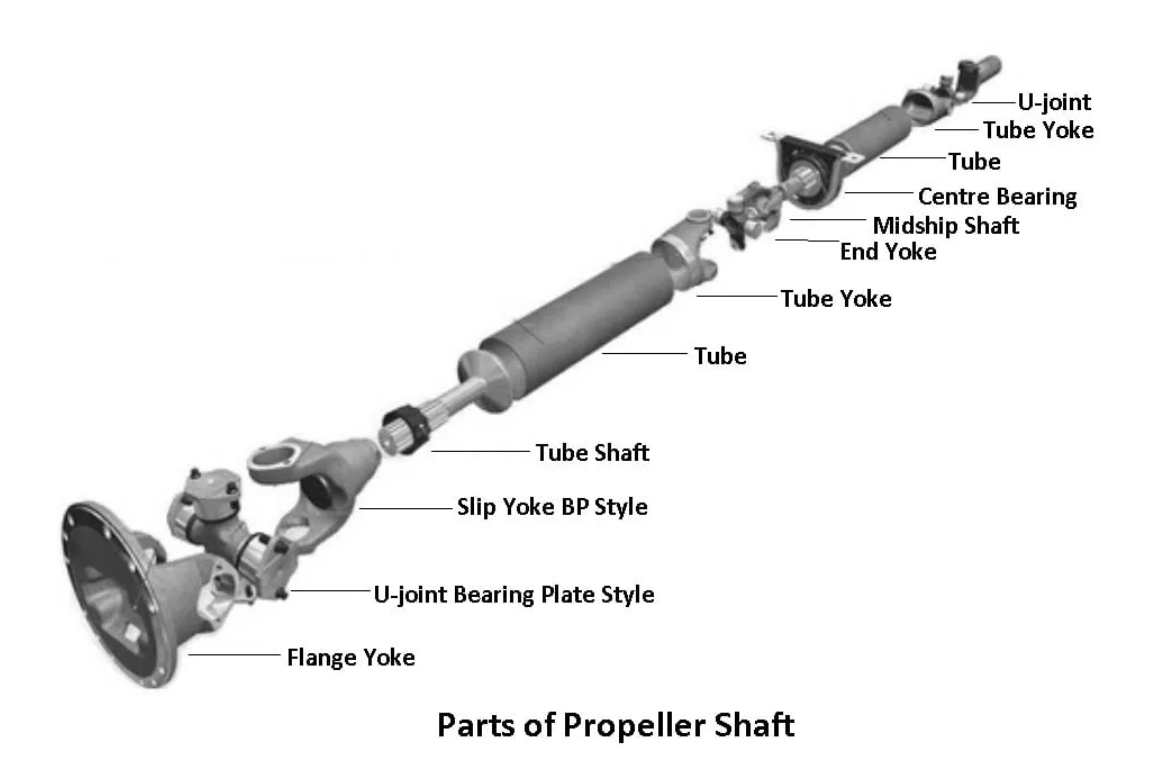

When the Diesel Generator is started, the engine goes through its four process of combustion, i.e Suction, Compression, Power and Exhaust. And as a result the chemical energy of fuel converts into mechanical energy, which we get as an output at the shaft of the engine.

Now this rotating shaft is used to rotate the Rotor of the alternator. An alternator’s rotor and stator are the components that generate energy.

The rotor, a cylindrical element encircled by magnets, revolves inside the stator, which has a fixed arrangement of conductive copper wiring. The movement of the magnets across the wiring is what produces electricity in the end.

As the rotor spins, electricity is generated. The magnets around the rotor are strategically arranged to create a magnetic field as they travel over the copper wiring in the stator. This magnetic field, in turn, generates voltage, which the stator captures. This power then travels to the voltage regulator, which distributes electricity to the required place controlling the voltage received. So, this is an how diesel generator works with the principle stated above.

Is diesel generator AC or DC?

The output produced by the alternator in Diesel generator is an AC current which is converted to DC with the help of a Rectifier.

Principle behind the rotor and stator generating electricity

When the rotor with magnets is rotated inside the stator consisting of copper wires , the magnetic field changes and this change is magnetic field is responsible for generating an induced EMF at the end thus providing the current to flow.

I hope this article has been able to make you understand about the diesel generator working principle with an overview of how diesel generators produce electricity.

Read More :

Piston : A Complete Overview with Diagrams

Ammeter : Working | Construction | Uses

Check Out Other Important Topics

Home IC Engine Electrical Important PDFs Boilers Synergy Maritime Exam Naval Arch Interview Questions Difference Between Types of Pumps Types of Valves MEO Class 4 Auxiliary Machines

[…] Read More : Diesel Generator Working Principle […]

[…] Suggested: Diesel Generator Working Principle | Parts And Functions […]