What Is Cooling Tower ?

A cooling tower is a specialised structure or device used to remove excess heat from industrial processes or building systems. It is primarily employed to dissipate heat from water-cooling systems by transferring it to the atmosphere through evaporation.

It’s working principle involves the circulation of water through the tower while utilising a combination of air and water to cool it down. The hot water from the industrial process or equipment is directed to the top of the cooling towers and distributed over a series of fill media or packing. As the water cascades down through the fill media, it is exposed to air that is drawn in through the tower.

Through the process of evaporation and direct contact with the air, the heat from the water is transferred to the air, causing the water to cool down. The cooled water collects in a basin at the bottom of the tower and is recirculated back to the industrial process or equipment to absorb more heat.

It often equipped with fans or blowers that induce airflow and enhance the evaporation process. These fans help to draw in ambient air, which further aids in removing heat from the water. Some cooling towers may also incorporate additional components such as drift eliminators to minimize the loss of water due to evaporation.

It is widely used in various industries, including power plants, chemical plants, oil refineries, HVAC systems, and manufacturing facilities. They provide an efficient and cost-effective method for dissipating heat generated during industrial processes, helping to maintain equipment performance, prevent overheating, and ensure the safe operation of machinery and systems.

cooling towers diagram

types of cooling tower

Cooling towers are essential components in industrial and commercial systems where the dissipation of excess heat is crucial. They come in various types, each designed to suit different applications and operating conditions. Below, I will provide an expanded overview of the commonly encountered types of cooling towers:

1. Crossflow Cooling Tower: In this Type, air moves horizontally across the falling water. As the water descends, heat transfer occurs through a combination of evaporation and direct contact with the air. This design promotes efficient cooling and is often preferred for its compact footprint and ease of maintenance.

2. Counterflow Cooling Tower: The counterflow cooling towers operates on the principle of air and water flowing in opposite directions. Air ascends vertically while water descends vertically, allowing for effective heat exchange between the two. This configuration provides a larger surface area for heat transfer and is known for its high efficiency.

3. Natural Draft Cooling Tower: Natural draft cooling towers rely on the natural buoyancy of warm air to create airflow. These towers are typically tall structures with a chimney-like design. As the warm air rises, it is replaced by cooler air from the surroundings, resulting in a continuous flow of air through the tower. Natural draft towers are often utilized in large-scale applications where their ability to handle high heat loads is advantageous.

4. Mechanical Draft Cooling Tower: Mechanical draft cooling towers employ fans or blowers to create airflow. They are further classified into two types: a. Induced Draft Cooling Tower: In an induced draft cooling tower, an external fan is positioned at the top of the tower, drawing air upwards. This configuration ensures consistent airflow, reduces the risk of hot air recirculation, and allows for greater control over the cooling process. b. Forced Draft Cooling Tower: In a forced draft cooling tower, fans or blowers are situated at the base of the tower, forcing air into the tower. This arrangement provides enhanced control over the direction and velocity of the airflow, making it suitable for applications with high ambient temperatures or when a greater degree of control is required.

5. Closed Circuit Cooling Tower: Closed circuit cooling towers, also known as fluid coolers, use a heat exchanger to separate the cooling water from the air stream. The process water circulates through the heat exchanger while the air stream cools a separate fluid, indirectly transferring heat from the process water. This design offers advantages such as minimising water loss through evaporation and providing a more controlled environment for heat exchange.

6. Hybrid Cooling Tower: Hybrid cooling towers combine the features of both dry coolers and traditional cooling towers. They utilise both air and water to cool the process fluid, providing flexibility in various environmental conditions. By employing a combination of dry and wet cooling methods, hybrid towers offer improved energy efficiency and reduced water consumption.

When selecting a cooling tower, factors such as cooling requirements, available space, environmental conditions, and budget considerations should be taken into account. Properly choosing the appropriate cooling tower type ensures efficient heat dissipation and optimal system performance in a given application.

Must Read : Heat Exchanger

cooling towers working principle

The working principle of a cooling tower, which is based on evaporative cooling, involves the transfer of heat through the process of water evaporation.

Evaporative cooling is a process used in cooling towers to remove heat from water or other fluids by utilizing the natural phenomenon of evaporation. It is based on the principle that when water evaporates, it absorbs heat from the surrounding environment, thereby reducing the temperature of the remaining water.

how cooling tower work ?

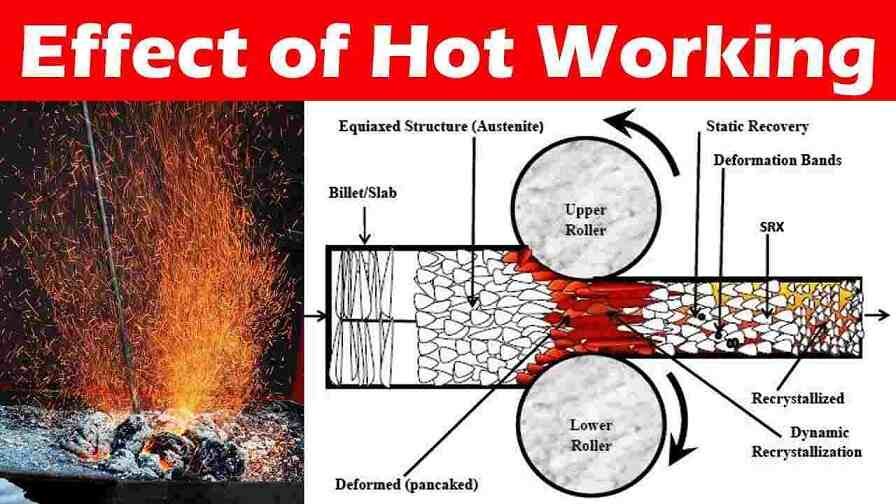

A cooling tower operates by employing the principles of heat transfer and evaporation to remove heat from industrial processes. Hot water, generated from the industrial equipment or processes, enters the cooling tower through an inlet pipe. Inside the cooling tower, the hot water is evenly distributed over the fill material or packing, which provides a larger surface area for efficient contact with the air.

Simultaneously, airflow is induced through the tower either by fans or natural draft. As the hot water flows over the fill material, it comes into contact with the moving air, facilitating heat transfer through convection and evaporation. Some of the water evaporates, absorbing heat from the remaining water and lowering its temperature. The airflow carries away the heat absorbed by the water vapor.

The heated air, now carrying the absorbed heat, is expelled from the cooling tower through openings or louvers at the top. This allows fresh air to enter the tower, continuing the cooling cycle. The cooled water collects at the bottom of the cooling tower and can be recirculated back to the industrial processes, completing the cooling loop. Overall, a cooling tower efficiently dissipates heat, preventing equipment overheating and maintaining optimal operating conditions.

cooling tower working step by step

It work by utilizing the principles of heat transfer and evaporation to remove heat from industrial processes and equipment. Here’s a step-by-step explanation of how a cooling tower operates:

- Hot Water Entry: Hot water generated from industrial processes enters the cooling towers through an inlet pipe.

- Water Distribution: The hot water is evenly distributed over the fill material or packing within the cooling tower. The fill material increases the surface area, allowing for efficient contact between the water and the air.

- Airflow: It employs fans or natural draft to induce a flow of air through the tower. This airflow can be either forced draft (fans at the bottom) or induced draft (fans at the top), depending on the cooling tower design.

- Heat Transfer: As the hot water flows over the fill material, it comes into contact with the air stream. Heat from the water is transferred to the air through a combination of convection and evaporation. The air absorbs the heat from the water, causing the water to cool down.

- Evaporation: A portion of the water evaporates into the air as it passes through the fill material. This evaporation process extracts heat from the remaining water, further reducing its temperature. Evaporation is a crucial mechanism for efficient heat removal in cooling towers.

- Air-Water Separation: As the air rises through the cooling tower, it carries the evaporated moisture with it. At the top of the tower, there is typically a demister or drift eliminator that helps separate the water droplets from the air, preventing water loss and ensuring efficient operation.

- Exhaust of Heated Air: The heated air, now carrying the absorbed heat, exits the cooling tower through openings or louvers at the top. This allows fresh, cooler air to enter the tower and continue the cooling cycle.

- Cooled Water Exit: The cooled water collects at the bottom of the cooling tower and is discharged through an outlet pipe. It can then be recirculated back to the industrial processes or used for other cooling purposes.

By continuously cycling hot water through the cooling tower, the heat generated in industrial processes is transferred to the surrounding air through evaporation and convection. This helps maintain optimal temperatures and prevents equipment from overheating, ensuring efficient and reliable operation.

induced draft cooling towers

Induced draft cooling towers are a type of cooling tower design that utilizes an external fan located at the top of the tower to draw air through the system. The fan creates a negative pressure or suction that induces airflow into the tower. The air is drawn in through the air-inlet louvers at the base of the tower and moves vertically upward, passing over the water or process fluid. This upward flow of air enhances heat transfer and evaporation, contributing to effective cooling. The induced draft design helps to maintain a uniform and controlled airflow, minimizing the potential for recirculation of hot air within the tower. Induced draft cooling towers are commonly used in various industries and applications where precise control over the cooling process is required.

cooling towers fans

A cooling tower fan plays a crucial role in the operation of a cooling tower. The fan is responsible for creating the airflow that facilitates the heat transfer process. It draws ambient air into the cooling tower, causing it to come into contact with the water or process fluid, allowing for evaporation and heat dissipation. The fan can be either induced draft, located at the top of the tower, or forced draft, situated at the bottom. It helps maintain proper airflow, enhances cooling efficiency, and ensures optimal performance of the cooling tower system.

application of cooling tower

Cooling towers find application in various industries and processes where the removal of excess heat is necessary. Some of the common applications of cooling towers include:

- Power Plants: It play a critical role in thermal power plants, where they cool the circulating water used to condense steam after it passes through the turbine. This allows the steam to be reused in the power generation process, improving overall efficiency.

- Industrial Processes: It is widely used in industrial processes such as chemical manufacturing, oil refineries, steel mills, petrochemical plants, and food processing. They remove heat generated by equipment, reactors, furnaces, and other machinery, ensuring stable operating temperatures and preserving equipment performance.

- HVAC Systems: It is essential components of large-scale HVAC (Heating, Ventilation, and Air Conditioning) systems in commercial buildings, hospitals, shopping malls, and hotels. They provide chilled water for air conditioning by removing heat from the building’s cooling loop.

- Data Centers: Data centers generate significant heat due to the high density of computer servers. Cooling towers are employed to dissipate this heat, maintaining optimal operating temperatures and preventing equipment failure.

- Refrigeration Systems: It is utilized in industrial refrigeration systems, including cold storage warehouses, food processing plants, and breweries. They remove heat from the refrigeration process to keep products and storage areas at the desired low temperatures.

- Chemical Plants: It is crucial in chemical plants to control the temperature of chemical reactions, condense vapors, and cool process fluids. They help maintain safe operating conditions and ensure efficient chemical processes.

- Manufacturing and Machinery: It is used in various manufacturing processes that generate heat, such as plastic extrusion, metal casting, and automotive production. They cool equipment, molds, and fluids, enhancing productivity and product quality.

- Natural Gas and Oil Refineries: It play a vital role in natural gas and oil refineries to cool and condense gases and vapors during processing, including fractional distillation and fractionation processes.

- Pharmaceutical Industry: It is employed in pharmaceutical manufacturing to maintain controlled temperatures during drug production and storage, ensuring product quality and compliance with regulations.

- Renewable Energy: It is used in renewable energy systems like solar thermal power plants, biomass plants, and geothermal power plants, where they assist in cooling processes and enhance overall energy efficiency.

These are just a few examples of the wide-ranging applications of cooling towers in diverse industries. The specific use of cooling towers depends on the cooling requirements and temperature control needs of the processes involved.

advantages of cooling tower

Cooling towers offer several advantages in industrial and commercial applications. Some of the key benefits of cooling towers include:

- Efficient Heat Dissipation: It efficiently remove excess heat from industrial processes, machinery, and equipment. By utilizing the principles of heat transfer and evaporation, they help maintain optimal operating temperatures, preventing equipment overheating and ensuring smooth operation.

- Energy Efficiency: It is energy-efficient cooling solutions compared to other methods. They utilize natural air circulation or fans to facilitate heat transfer, reducing the need for excessive energy consumption. By harnessing the cooling power of evaporation, cooling towers can achieve effective heat removal while minimizing energy usage.

- Water Conservation: It enable water conservation by utilizing evaporative cooling. The evaporation process allows a portion of the water to be transformed into vapor, reducing the overall water consumption compared to other cooling methods. This can be advantageous in areas where water resources are limited or conservation is a priority.

- Cost-Effectiveness: It can provide cost savings in terms of both installation and operational expenses. They typically have lower initial costs compared to alternative cooling systems. Moreover, their energy-efficient operation can lead to reduced energy bills over time, contributing to long-term cost savings.

- Versatility: It is versatile and can be adapted to various applications and industries. They can handle a wide range of cooling loads, making them suitable for diverse processes and equipment. Cooling towers can also be customized based on specific requirements, such as size, capacity, and environmental conditions.

- Scalability: It offer scalability, allowing for easy expansion or modification of cooling capacity as needed. Additional cooling towers can be installed or existing ones can be upgraded to meet changing cooling requirements, ensuring flexibility in adapting to evolving operational needs.

- Environmental Impact: It has a relatively lower environmental impact compared to alternative cooling methods. They do not rely on harmful refrigerants or chemical agents and operate using natural air and water. Additionally, their water conservation capabilities contribute to sustainable water management practices.

- Reliability: It is known for their reliability and robust operation. They are designed to withstand demanding industrial environments and can effectively handle high heat loads. With proper maintenance and regular inspections, cooling towers can provide long-term, dependable cooling performance.

Overall, the advantages of cooling towers include efficient heat dissipation, energy efficiency, water conservation, cost-effectiveness, versatility, scalability, environmental friendliness, and reliability. These factors make cooling towers a popular choice for various cooling applications in diverse industries.

disadvantages of cooling tower

While cooling towers offer numerous benefits, there are also some disadvantages associated with their use. Here are some of the potential drawbacks of cooling towers:

- Water Consumption: It rely on water evaporation for heat removal, which results in water loss. This evaporation can lead to significant water consumption, especially in large-scale cooling systems. Consequently, cooling towers may contribute to increased water usage, which can be a concern in areas with water scarcity or where water conservation is a priority.

- Potential for Legionella Growth: It provide a favorable environment for the growth of microorganisms, including the bacteria responsible for Legionnaires’ disease, such as Legionella pneumophila. If not properly maintained and treated, cooling towers can become a source of bacterial contamination, posing health risks to workers and surrounding communities. Adequate water treatment and regular maintenance are essential to prevent the growth of harmful bacteria.

- Noise Generation: It often utilize fans or blowers to induce airflow, which can generate noise during operation. Depending on the size and design of the cooling tower, the noise level can vary. In some cases, noise generated by cooling towers may cause disturbances for nearby residents or work environments. Proper noise control measures, such as sound barriers or insulation, may be necessary to mitigate this issue.

- Visual Impact: It can be large structures, particularly in industrial settings, and their presence may have visual impacts on the surrounding landscape. In certain areas, the aesthetic aspect and visual disruption caused by cooling towers can be considered a disadvantage.

- Maintenance and Upkeep: It require regular maintenance and inspections to ensure proper functioning and prevent issues such as scale buildup, fouling, or corrosion. The maintenance tasks can include cleaning, water treatment, checking the condition of fans and motors, and maintaining proper airflow. Neglecting maintenance can lead to reduced efficiency, increased energy consumption, and potential equipment failure.

- Energy Consumption: Although These are generally energy-efficient compared to other cooling methods, they still require energy to operate fans or pumps. Depending on the size and configuration of the cooling tower, energy consumption for the equipment may contribute to overall energy usage.

- Risk of Freeze in Cold Climates: In regions with extremely low temperatures, It can be susceptible to freezing during winter months. If proper precautions are not taken, the water inside the tower and associated pipes can freeze, causing damage to the equipment. Implementing appropriate freeze protection measures is essential in cold climates to prevent such issues.

It’s important to note that many of these disadvantages can be mitigated or minimised through proper design, maintenance, and management practices. By implementing appropriate measures and adhering to best practices, the potential drawbacks of cooling towers can be effectively addressed.

water cooling tower

A water cooling tower is a type of cooling system that utilizes water as the primary medium for heat transfer and dissipation. It is designed to remove excess heat from industrial processes or equipment by circulating water through the tower. The hot water enters the tower, where it is distributed over the fill material or packing. As the water flows over the fill material, it is exposed to a stream of air, which facilitates heat transfer through evaporation and convection. The evaporated water carries away the heat, resulting in a cooling effect. The cooled water is then collected at the bottom of the tower and recirculated back to the process or equipment, completing the cooling cycle. Water cooling towers are commonly used in power plants, manufacturing facilities, and other industries where efficient heat dissipation is essential.

paharpur cooling towers

Paharpur Cooling Towers is a renowned global company specializing in the design, manufacturing, and installation of efficient and reliable cooling towers. Headquartered in Kolkata, India, they offer a wide range of cooling solutions for various industries. With a strong emphasis on sustainability, Paharpur Cooling Towers delivers high-quality products and services worldwide. Their commitment to engineering excellence and environmental responsibility has solidified their position as a trusted provider of cooling tower solutions.

What is a cooling tower used for?

A cooling tower is primarily used for the removal of excess heat from industrial processes, machinery, or equipment. It serves the purpose of dissipating heat generated during various operations to maintain optimal temperatures and prevent equipment overheating. Cooling towers are commonly employed in power plants, manufacturing facilities, refineries, chemical plants, data centers, and HVAC (Heating, Ventilation, and Air Conditioning) systems. By utilizing the principles of heat transfer and evaporation, cooling towers help regulate temperatures, improve equipment efficiency, prevent damage, and ensure smooth operation in a wide range of industries and applications.

What is cooling tower and how it works?

A cooling tower is a device that removes heat from industrial processes. It operates by transferring heat from hot water to the surrounding air through evaporation. Hot water enters the tower, flows over fill material, and comes into contact with air. Some water evaporates, absorbing heat and lowering the temperature. The heated air rises and is expelled, while fresh air enters to continue the cooling process. Cooled water collects and can be reused. Cooling towers maintain optimal temperatures, preventing equipment overheating and ensuring efficient operation.

3 types of cooling tower

The three main types of cooling towers are:

Crossflow Cooling Tower: Air flows horizontally, and heat transfer occurs through evaporation and direct contact between air and water.

Counterflow Cooling Tower: Air flows vertically upward, opposite to the downward flow of water, maximizing heat transfer efficiency.

Natural Draft Cooling Tower: Utilises warm air’s natural buoyancy to induce airflow, drawing in cooler air for heat dissipation.

What is the function of a cooling tower

The function of a cooling tower is to remove excess heat from industrial processes, machinery, or equipment. It accomplishes this by facilitating the transfer of heat from hot water or other process fluids to the surrounding air through evaporation and convection. By dissipating heat, cooling towers help maintain optimal operating temperatures, prevent equipment overheating, and ensure the efficient and reliable performance of industrial processes.

What is coming out of cooling towers

It emits water vapor and air as they remove heat.

What comes out of cooling towers

It primarily release water vapor into the atmosphere.

When are cooling towers used

Cooling towers are used when there is a need to remove excess heat from industrial processes, machinery, or equipment. They are employed in various industries such as power generation, manufacturing, chemical processing, data centers, and HVAC systems. Cooling towers are utilized whenever maintaining optimal operating temperatures and preventing equipment overheating is essential for efficient and reliable operation.

Where are cooling towers located

Cooling towers are typically located in close proximity to industrial facilities or commercial buildings where heat dissipation is necessary. The exact location of cooling towers within these facilities may vary, but they are often situated on the outskirts or rooftops to facilitate airflow and minimise the impact of heat on the surrounding environment.

cooling tower requirement

Cooling tower requirements: heat dissipation, proper water flow, airflow, water quality, maintenance, environmental compliance, safety.

How to treat cooling towers

Cooling tower treatment involves water testing, chemical treatment, regular cleaning, filtration, biocide application, pH balance, inspections, and compliance with regulations.

When are cooling towers most efficient

Cooling towers are most efficient when the ambient air temperature is lower. As the temperature difference between the hot water being cooled and the surrounding air increases, the rate of heat transfer and evaporation also increases. Therefore, during cooler weather or at night when the air temperature is lower, cooling towers can achieve higher efficiency in dissipating heat. Additionally, proper maintenance, water treatment, and design optimization contribute to the overall efficiency of cooling towers.