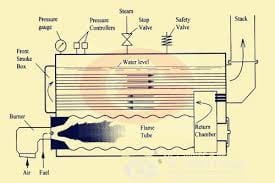

Fire Tube Boiler

Fire tube boiler is a type of boiler in which hot flue gas passing through tubes which surrounded The heat of the gasses is transmitted through the walls of the tubes by thermal conduction, the water is heated and, eventually, the steam is generated.

Or,

A fire-tube boiler is a type of boiler in which hot gases flow from a fire through one or many more tubes running through a sealed container of water. The heat of the gases is transmitted through the walls of the tubes by thermal conduction, heating the water and eventually producing steam.

Constructions of Fire Tube Boiler

◆Fire tube boiler consists of a vertical, cylindrical shell, fitted with a firebox in the bottom, water space in the middle portion and steam space in the upper portion.

The fire grate is positioned at the bottom of the firebox and coal is fired at the firebox. The ash pit is located at the bottom of the grate to collect the ash of the coal that has been burned, and is regularly removed.

◆One or more cross tubes are either flanged or riveted to the water area in the firebox to increase the heating surface area in order to enhance the flow of water.

At the top of the firebox, a short chimney is attached to discharge the waste flue exhaust gases at a higher height. Manhole and hand holes are provided for cleaning the inside of the boiler shell and the cross tubes.

◆The boiler consists of a pressure gauge, a water level indicator, a safety valve, a steam stop valve and a manhole to provide safety and ease of operation.

Fire Tube Boiler Parts

- Smoke outlet

- Reversing Chamber

- Boiler body

- Boiler frame

- Furnace

- Smoke tube

- Burner

- Flame detector

- Reversing chamber

- Feed water control switch

- Steam pressure switch

- Main stop valve

- Manhole

- Feed water valve

- Safety valve

- Blow Down valve

- Water gauge glass

- Lower water level cut off and alarm devices

- Pressure gauges

Operations of Fire Tube Boiler

The fuel burns in a firebox on the grate.The hot gas of burnt fuel is allowed to pass around the cross tubes.

The water surrounding the cylindrical firebox also receives heat through convection and radiation. That’s how steam is produced. The circulation of water in the boiler depends on the difference in water density caused by the difference in water temperature.

Types of Fire Tube Boiler

The different Types of fire tube boiler are shown below :-

1.Cornish Type Fire Tube Boiler

The first High pressure Cornish type boiler used by Richard Trevithick.

This type of a boiler has a long horizontal cylinder with a single large flue containing the fire. The fire itself was on an iron grating placed across this flue, with a shallow ashpan beneath to collect the non-combustible residue.

As the furnace relied on natural draught (air flow), a high chimney at the far end of the flue was required to promote a good supply of air (oxygen) to the fire.

For efficiency, the boiler was normally enclosed underneath a brick-built chamber. Flue gases were directed through this outside the iron boiler casing, after flowing through the fire tube, and thus through the chimney that was now on the front side of the boiler.

2.Cochran Boiler

The Cochran is a typical tank boiler of vertical type suitable for producing relatively small amounts of low pressure steam for auxiliary purposes.

The Cochran Boiler is a modified version of a basic vertical boiler with different fire tubes that can exchange heat by convection to water.

The efficiency of this boiler is much higher than the efficiency of simple vertical boiler.

Flue gases will flow in the tubes that will be surrounded by water in this boiler and water will be heated from these tubes by convection.

In several fields, the Cochran boiler is used. In several power plants, it is used to generate electricity where a high volume of steam requires high pressure and temperature.

Working

The fuel may be Oil, gas or coal which is burnt in the firebox placed over the grate. The flue gases generated by the combustion of coal will be go to the flue tubes which are surrounded by water.

The heat of flue gases gets transfer to the water surrounded. The heated water gets evaporated and converted into steam which is collected in hemispherical shell

3.Lancashire Boiler

It was invented by William Fairbairn.

This boiler is similar to Cornish boiler but it has two flue tubes containing the fire.

Theoretically,this boiler is more efficient because of two large flue causes increase the furnace grate area relative to the volume of water.

Later development in boiler is Galloway tubes, crosswise flue water tubes, thereby increasing the heated surface area.

4.Scotch Marine Boiler

The Scotch Marine Boiler is a very common boiler used for high vapour capacity at high strength.

This type of boiler is different from other because of using a large number of small-diameter tubes The furnace remains a single large diameter tubes with a number of small tubes arranged above it.They are connected each other with a combustion chamber So the flow of flue gas into the pipes is from the back to the front. An enclosed smokebox covering the front of these tubes leads up to a chimney or a funnel.

A large number of small diameter provides a greater heating surface for volume and weight.

5.Immersion Fired Boiler

The immersion fired boiler was developed in the 1940s by Sellers Engineering as a single-pass fire-tube boiler. It has only fire tubes, which also act as a furnace and combustion chamber, with numerous burner nozzles under pressure injecting premixed air and natural gas.

It claims to minimise thermal stresses and, due to its structure, totally lacks refractory brickwork.

6.Locomotive Fire Tube Boiler

A locomotive boiler has three main components:

1.a double-walled firebox;

2.a horizontal, cylindrical “boiler barrel” containing a large number of small flue-tubes; and

3. a smokebox with chimney, for the exhaust gases.

The boiler barrel includes larger flue-tubes, where present, to hold the superheater elements. In the locomotive boiler, forced draught is given by injecting exhausted steam back into the exhaust through a blast pipe in the smokebox.

Uses

Locomotive-type boilers are also used in traction engines, steam rollers, portable engines and some other steam road vehicles.

The inherent strength of boiler means that it is used as the basis for the vehicle: all the other components are mounted on the brackets attached to the boiler, including the wheels. Superheaters designed for this type of boiler are rarely found, and they are generally much smaller and simpler) than types of railway locomotives.

The locomotive-type boiler is also a feature of the over-type steam wagon, the steam-powered forerunner of the truck.

7.Vertical Fire Tube Boiler

A vertical fire-tube boiler or a vertical multi-tube boiler is a vertical boiler where the heating surface consists of multiple small fire-tubes arranged vertically.

The vertical boiler is a simple boiler which consists of a cylindrical shell enclosed with a larger portion of water and the rest of the section is filled with steam.

It comprises a cross tube and a furnace at the bottom of the boiler. After heating the water, the combustion gases are allowed to escape into the atmosphere.

Due to drawbacks with excessive wear in service, these boilers were not common. A more common form of vertical boiler,which was very similar in exterior appearance, used a single flue and a water-filled cross-tube instead. Another form used horizontal fire tubes, even where this added complexity, such as the Cochran boiler.

Vertical tubes were used where a sustained high evaporative capacity (i.e. power) was needed, but rarely. These cases were mostly for locomotives, either rail locomotives or road steam waggons.

8.Horizontal Return Tubular boiler

Horizontal Tubular Return Boiler (HRT) has a horizontal cylindrical shell, containing several horizontal flue tubes, with a fire located directly below the boiler shell, typically within a brickwork framework.

Water tube vs Fire tube boiler

The comparison between the two boilers, namely the water tube and the fire tube, mainly includes working pressure, material type, steam production rate, floor area requirements, efficiency, load handling variance, design, operator skills, maintenance costs are discussed below.

1. In a fire tube, the flow of hot flue gas will be through pipes and enclosed with water, while in a water tube, the flow of water will be through pipes and enclosed with hot flue gas.

2.The low-pressure range of the fire tube is up to 20 bar while it is up to 250 bar in the water tube.

3.Load fluctuations in the fire tube cannot be handled although it can be handled easily in the water tube.

4.This boiler occupies more floor space for output, while in water tube boiler,require less floor area.

5.Fire tubes are wide and large and so not easy to carry, while for a water tube boiler it is not a matter of concern.

6.The efficiency of fire tube is up to 75 per cent, while the water tube boiler is up to 90 per cent.

7.The direction flow in the fire tube is not in the same direction, although the direction flow in the water tube is in the same direction.

8.The size of the drum in the fire tube is big, as well as the damage caused by the burst is also large, while in the water tube, if any water tube is damaged, we can easily replace it.

9.The design of the fire tube is simple, easy to install, and the maintenance price is low, while the design of the water tube is complicated, not easy to instal, and the maintenance price is high.

10.Fire tubes need little experts for effective operation, whereas water tubes need experts for effective operation.

Advantage and Disadvantages of Fire tube boiler

Advantage

- The construction of this boiler is simple and the price of maintenance is lower.

- It refers to small-scale industries

- No require too much experts for operation of this boiler

- No fresh water is necessary.

- For this boiler,no need of treatment if feed water.

Disadvantage

- The efficiency of this boiler is up to 75%.

- The variance of the load is not possible

- It occupies most of the floor space

- The working pressure of this boiler is not more than 20 bar.

- The handling of variations in load is not easy.

Mountings fitted on Fire tube Boiler

1.Safety Valve :-

2.Relief valve :-

3.Fusible Plug :-

4.Feed check valve :-

5.Water level indicator :-

6.pressure gauge :-

7.Steam Stop valve :-

You can read it in Details all Boiler mountings

Check Out Other Important Topics