What is Caustic Embrittlement ?

Caustic Embrittlement is a form of corrosion caused by a high concentration of sodium hydroxide (Na(OH)).

It is characterized by the formation of irregular intergranular cracks on the metal. particularly at places of high local bends such as bends and joints causes caustic embrittlement.

Caustic Stress Corrosion Cracking, also referred to as Caustic Embrittlement

It is one of the most prevalent conditions in the industry and one of the many environmental cracking mechanisms that usually occur in carbon steel equipment, but can also affect low alloy and austenitic stainless steel equipment.

Caustic environments (those containing high concentrations of NaOH & KOH) cause cracking most often in welding due to high residual stress, but can also impact base metal with high residual stress.

Or,

Caustic Embrittlement is inter crystalline fracture. It is cause by high concentration of caustic soda and the material under stress. The stress corrosion cracks follow the grain or crystal boundaries of the material and failure. Sodium sulphate or sodium nitrate is used for the prevention of caustic embrittlement.

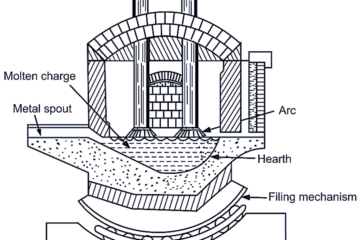

It can be found in highly stress area in boiler. Such as tube and tube plate connection, riveted head, seam and boiler mountings.

Caustic embrittlement in boiler

Caustic embrittlement in a boiler is a process in which the boiler material becomes brittle due to the accumulation of caustic substances.

Or,

It is a phenomenon that occurs in boilers where caustic substances accumulate in materials of boiler.

Or,

It is a form of corrosion caused by a high concentration of sodium hydroxide (Na(OH)) in the boiler feed water. It is characterized by the formation of irregular intergranular cracks on the boiler metal. particularly at places of high local bends such as bends and joints causes caustic embrittlement.

Causes of Caustic Embrittlement

It results from the conjoint action of three components:

a susceptible material (carbon steel)

a specific chemical species (concentrated hydroxide) and

tensile stress (around the riveted holes)

Caustic Embrittlement in Boiler Corrosion

When the water evaporates in the boiler, the concentration of sodium carbonate in the boiler increases. In high-pressure boilers, sodium carbonate is used in the softening of lime soda water due to the fact that some sodium carbonate might have been left in the water. If the concentration of sodium carbonate increases, it undergoes hydrolysis to form sodium hydroxide.

The presence of sodium hydroxide produces alkaline water.. This alkaline water enters minute cracks present in the inner walls of the boiler by capillary action.

Inside cracks, the water evaporates and the volume of hydroxide keeps rising. The concentrated area with high stress works as an anode and the diluted area works as a cathode. At anodine, sodium hydroxide attacks the surrounding material and dissolves the boiler iron as sodium ferrate forming rust. This causes boiler parts to break, such as rivets, bends and joints, which are under stress.

Or ,in simple language you can understand below

In boiler sodium bicarbonate is used for softening of water and thus a small amount of it is present in the boiler water which on hydrolysis forms sodium hydroxide.

This Sodium hydroxide makes the water saline and gets into the minute cracks. With time the water is evaporated and online salt remains in the cracks. This reacts with the surrounding metal and forms Rust, thus making the material brittle.

Prevention

Caustic Embrittlement can be prevented by several Method, these are

- By Controlling temperature or Potential.

- By Controlling Stress Level ( Residual or Load ) and Hardness.

- By avoiding Alkalis where it required.

- By Using such materials that do not crack when used in given environments.

- By the use of Sodium Phosphate in place of sodium bicarbonate as softening agent to the boiler water.

- By Adding lignin, tannin to the boiler water helps in blocking the hair line cracks thus preventing the accumulation of Sodium hydroxide in these places.

- Adding Na2SO4 to boiler water also blocks the hair-line cracks

Caustic Embrittlement Reactions

Na2CO3 + H2O → 2NaOH + CO2

Read More : Boiler Mountings

Also Read : Oily Water Separator

FAQ ( Frequently Asked Questions )

What is caustic embrittlement explain?

Caustic embrittlement is a form of degradation that occurs when a component operates in a caustic environment.

What are the causes of caustic embrittlement?

This caused because of high concentration of sodium hydroxide (NaOH).

Check Out Other Important Topics

Excellent site