In this article you will learn about Water Hammering, What are its types, Effects, what causes water hammering, how to stop it.

High temperature and medium pressure steam is used at ship for following purposes: Heating, Soot blowing, Evaporator, Steam driven pumps, Tanks etc. Steam is circulated through dedicated steam pipelines. And circulation/flow of steam is responsible for water hammering. Generally at ship, water hammering occurs in Steam line, Boiler feed water line, Hot water circulating line.

What is Water Hammering ?

- It’s a hydraulic phenomenon of fluid flow in pipes.

- It’s like surge/shock wave of steam flow due sudden change in the momentum of flow. (Later we’ll see how?)

- It’s an effect of collision between high speed flow of (steam + water) and obstructions.

- It makes sound of whopping/banging/thumping.

Remember: Water hammering sound is just an indication of water hammering, effects are different.

Types of Water Hammering

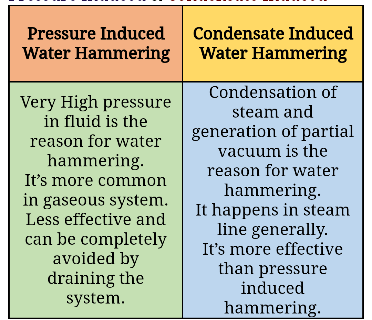

There are 2 types of water hammering according to process of hammering:

- Pressure Induced

- Condensate Induced

1. Pressure Induced Water Hammering

Pressure induced hammering occurs due to high pressure in the system. As pressure of steam used at ship is mild or moderate, so probability of pressure induced hammering is less. So here we’ll go in details of condensate induced water hammering.

2. Condensate Induced Water Hammering

Here we are talking about condensate of steam, that’s why you can also say it steam condensation induced water hammering or steam driven water hammering.

Condensate = Product of condensation (Condensate of steam is fresh water).

Generally, steam lines and valves are shut after requirement (for example, after heating bunker tanks and settling tank up to desired temperature and stopping purifier, we shut the respective steam valves).

As we shut the steam valves, steam is trapped in the pipeline. Now trapped steam starts condensing when pipeline becomes cold. And the condensation of steam is nothing but fresh water which remains in the pipeline.Be clear, condensed water remains in bottom of pipeline as it is a liquid.

Again, when we have to use steam, we open the valves and steam (high temperature steam) is passed through that pipeline. Note the point that steam passes over the water as it is in gas phase and water is in bottom. As this high temperature steam comes in contact with fresh water (condensed water), steam starts condensing suddenly.

As we know the specific volume of steam is approximately 1000 times more than that of condensed water. And sudden condensation of this steam reduces its volume drastically (i.e. approximately 1000 times less volume). During this sudden condensation process, space occupied by the steam i.e. bigger initially, becomes vacuum for short period.

This vacuum accelerates the steam flow which drags the condensate water (also termed as slug of water) with same speed (speed is very high i.e. sometimes 100 miles per hour also). In normal cases, Velocity of water = 2-5 m/sec and Velocity of steam = 20-40 m/sec in pipelines but due to vacuum, it increases very high.

And when this slug of water faces any obstructions (for example: bend, valve, joints etc.), then these obstructions act as sudden stoppage of flow. Due to high speed, flow hits the obstruction and causes banging sounds and various effects at obstructions. Actually, at this stage kinetic energy of flow is converted into pressure energy. And this is nothing but water hammering.

Effects of Water Hammering

- Noise: It causes loud and dreadful sounds. If you listen it first time, I’m sure that your heart beat will increase suddenly.

- Vibration: It generates vibration in the pipelines which can cause serious damages.

- Damaged pipes: It’s obvious that high vibration and sudden impact on certain portions of pipe will rupture the pipelines. Continuous impact on same portion of pipe leads to crack and holes at that portion.

- Injury: No doubt, continuous hammering, high impact and sudden crack in the lines can be fatal.

- Relax, we can minimize the chances of hammering by some proper installation and watchkeeping practices.

How can we prevent or minimize the Water Hammering ?

The whole process of hammering includes steam, pipe and condensed water (condensate). To prevent hammering, we have to care about these things (steam, pipe & water) properly. Here are some suggested practices for minimizing the chances of water hammering by controlling the above parameters:

- Drain: It is most common watchkeeping practice to minimize the chances of hammering. As we know, condensate water is the main reason for water hammering. Drain condensate water from the pipelines.

- Steam pressure: Do not open the main steam stop valve fully at one go. Just open it slowly slowly.

- Steam trap: It traps the condensed water and provide passage for steam. Use steam traps of correct type and capacity. Its regular maintenance is also essential for better operation.

- Piping: Avoid sharp bend in the pipeline. Always install pipelines with equal gradient to avoid sharp bends. Keep pipelines as straight as possible.

- Boiler operation: Operate boiler with proper knowledge of steam pipelines and operational skills.

Check Out Other Important Topics

Parallel operation of generators

Components of IC Engine With Functions & Images

TOP 50+ Frequently Asked IC Engine Interview Questions

Parallel operation of generators

Diesel Generator Working Principle | Parts And Functions

| IC Engine | Important PDFs | Boilers | Synergy Maritime Exam | Naval Arch | MEO Class 4 |

| Interview Questions | Difference Between | Types of Pumps | Auxiliary Machines | Types of Valves | Home |