Bearing Temperature Chart

Bearing Temperature chart in which Show the Temperature range of bearing for Different running conditions.

Or,

Bearing Temperature Chart basically gives us the information about the ideal working temperature of the bearing with optimum lubrication.

The diagram below illustrates how the maximum temperature for a specific lubricant (viscosity index) and bearing type may be limited to the maximum operating temperature.

Must read :-Bearing Temperature Sensor

Green Area in Above figure showing ideal operating Temperature of bearing.

This green area is stabilized operating temperature for Bearing.

Bearing Temperature Chart explanation

There is always fluctuations in the operating temperature of bearing.It depends on so many Factors ,I discussed it below.

However,as a reference, 180°F or 90°C should be considered as Normal.

As temperature increases from this point onwards, so does the risk of serious failure and engine damage.

We understand Range of bearing temperature in different conditions

Caution

The bearing temperature may be between 180 and 200 degrees F in a cautionary state. While this is slightly higher than desired, for certain applications, it could be a normal operating temperature. Therefore to determine whether the temperature is normal, it is important to have an operating temperature record for equipment in this range.

Alert Conditions

Temperature alarms should be set at 190°F or 90°C. It is necessary not to ignore them and to take immediate steps to find and resolve the cause of the rise in temperature. Stopped at this point, the damage is minimal and a total breakdown can be prevented.

Alarm

In an alarm condition, the range of bearing temperature may be between 250 and 300 degrees F. These elevated temperatures may be due to a heated application, a newly greased bearing, problems with the oil level, early bearing failure stages, etc.

Shutdown Conditions

The bearing temperature can be more than 300 degrees F in an equipment trip/shutdown state. In the final stages of failure, bearings at this temperature are probable. Failure can be rapid and devastating, depending on the equipment configuration. Just hours could be the time to respond, not days.

At this stage, the bearing is gone, so your actions should concentrate on minimising the remaining components’ secondary failure (shaft, housing, etc.). In order to avoid catastrophic failure and additional damage, an instant equipment trip/shutdown may be recommended.

Factor affecting operating temperature if bearing

As we know that bearings are used to reduce friction, it is important to properly lubricate them.Lubrication will cool the bearings ,also it will clean the bearings of fine wear particles if any and will reduce the friction.

In order to maintain proper lubrication, the temperature needs to checked regularly. As higher working temperature will lead to vaporization of the lube oil and hence the metal contact can occur.

To prevent such mis happenings it is important to know how much lubrication is needed at what temperature. Which will be ideal for longer working life of the surfaces.

The stabilized operating temperature for any bearing depend on many factors.

The Key Factors for operational temperature of bearing are :-

1.Bearing Style

2.Lubrication types

3.Shaft Mountings Style

4.Operational factors

5.Environmental Conditions

6.level of maintenance and

7.Auxilliary Items

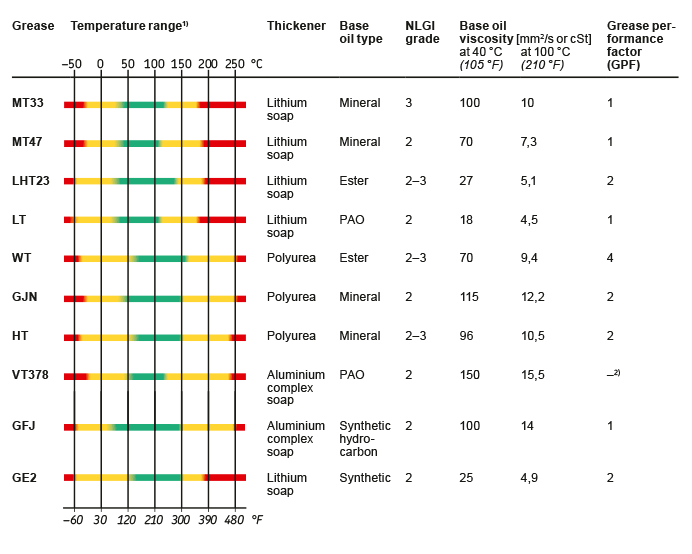

Skf Bearing Temperature Chart

SKF Bearing Temperature Chart is Shown Below

Green area showing ideal operating temperature of bearings.

For general use like motor, the operating temperature is upto 90 degree celcius but it can increase depending upon the materials, lubrication and types of bearings.

The acceptable operating temperature for hybrid bearings can be limited by:

1.the dimensional stability of the bearing rings

2.Cage

3.Sealing

4.Lubricant

When temperature go beyond permissible or operating range ,we should take immediate action.

1.Bearing Rings

The SKF hybrid bearings’ rings are heat stabilised up to atleast :

A)For basic and simple hybrid deep groove ball bearings,temp 120 ℃ ( 250 ° F )

B)For hybrid cylindrical roller bearings and XL hybrid deep groove ball bearings temp.upto 150℃ (300° F )

On request,SKF will supply hybrid bearings with rings stabilised at operating temperatures of up to 300 C (570 °F).

2.Cages

At the same operating temperature as the bearing rings of standard hybrid bearings, steel, brass or PEEK cages may be used. See Polymer Cages for the temperature limits of other polymer cages.

3.Seals

- NBR: –40 to +100 °C (–40 to +210 °F)

Temperatures up to 120 °C (250 °F) can be tolerated for short periods. - FKM: –30 to +200 °C (–20 to +390 °F) Temperatures up to 230 °C (445 °F) can be tolerated for short periods.

4.Figure below provides the temperature limits for the grease used in sealed SKF hybrid deep groove ball bearings.

For the temperature limits of other SKF greases, refer to Selecting the appropriate SKF grease.

The temperature limits should be assessed according to the SKF traffic light concept when using lubricants not supplied by SKF.

Check Out Other Important Topics

Home IC Engine Electrical Important PDFs Boilers Synergy Maritime Exam Naval Arch Interview Questions Difference Between Types of Pumps Types of Valves MEO Class 4 Auxiliary Machines