The Ballast Water Treatment Systems (BWTS) is a system that removes and destroys/inactivates biological organisms (zooplankton, algae, bacteria) from ballast water.

Read :- Ballasting of ship

The Ballast Water Management Convention, abbreviated as the BWM Convention (International Convention for the Control and Management of Ships’ Ballast Water and Sediments, 2004), is a treaty adopted by the International Maritime Organization (IMO) to aid in the prevention of the spread of potentially harmful aquatic organisms and pathogens in ship ballast water.

Ships must manage their ballast water beginning on September 8, 2017, so that aquatic organisms and pathogens are removed or rendered harmless before the ballast water is released into a new location. This will aid in the prevention of the spread of invasive species as well as potentially dangerous pathogens. For

Ballast water treatment system IMO regulations includes

1.Ballast water exchange standard regulations DE

2.Ballast water performance standard regulations D -2

Regulations 1 :-

– The D-1 standard requires ships to exchange ballast water far enough away from the coast that at least 95 percent of the water by volume is exchanged.

D-2 standard – According to the D-2 standard, ships can only discharge ballast water that meets the following criteria:

Less than 10 viable organisms per cubic metre with a minimum dimension of 50 micrometres;

● less than 10 viable organisms per millilitre with a minimum dimension of 10 micrometres to 50 micrometres;

● less than one colony-forming unit (cfu) per 100 mililitres Toxicogenic Vibrio cholerae

● less than 250 cfu per 100 millilitres E. coli; and

● Intestinal Enterococci have less than 100 cfu per 100 milliliters.

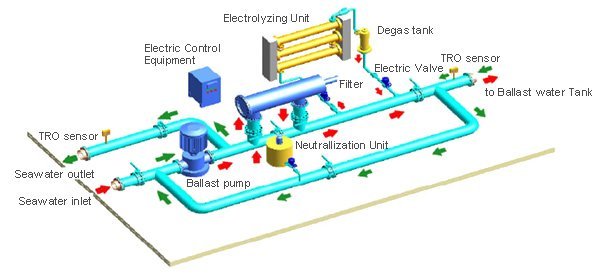

How Ballast water treatment system works ?

Ballast water treatment plant

The Ballast Water Treatment plant is a plant for removing and destroying biological organisms (zooplankton, algae, and bacteria) from ballast water.

Ballast water treatment is a unique technology offering the least diruptive option for ships to treat the ballast water as one of very few in tanks solutions on the market the unique circulation process treats the ballast water during a voyage rather than palestine this means that the powered system doesn’t delay the ship or interfare with cargo operations.

Ballast water treatment plant block diagram

Ballast water treatment methods

Ballast water treatment methods have ranged from simply exchanging ballast water while at sea to on-board treatment methods that eradicate any living invasive species, thus carrying and discharging non-threatening water regardless of the region where discharge is required. When a ship is in high seas and dropping ballast water would jeopardize the ship’s and crew’s safety, exchanging ballast water at sea is not always an option for the captain. Ships must be equipped with a comprehensive and effective solution under the new regulations.

Ballast water can be treated in three ways: 1.mechanically, 2.physically, or 3.chemically. Separation and filtration are mechanical methods; ozone, electrical currents, or UV radiation are physical methods; and biocides or a form of chlorination are chemical solutions.

Types of ballast water treatment systems

The main types of ballast water treatment systems used on ship are :-

1.physical separations

2.Ultravoilet system

3.Chemical treatment (oxidising or non oxidising biocides )

4.Deoxygeneration

5.Heat treatment

6.Electric pulse and pulse plasma treatment

7.Ultrasonic or cavitations treatment

8.Magnetic Field treatment

On vessel,two or more ballast water treatment system used together to ensure treated water meets IMO regulations.

1.Physical Separation/ Filtration Systems Ballast Water Treatments

These devices extract microscopic and other sea life, as well as solids, from either the sediment or the water’s surface. The backwash containing the unwanted material is then either discharged into the ocean from which the water was taken, or it is held and treated on board for use as ballast in the tanks, from which it can be discharged in a different location when the need arises (without any marine life left in it).

Equipments used for ballast water filter are :-

1.Filter/ Discs: With automatic backwashing, screens (fixed or movable) or discs are used to effectively remove suspended solid particles from ballast water. These are particularly environmentally friendly because no hazardous chemicals are used in the ballast water. Screen filtration is excellent for eliminating larger suspended solid particles, but it is ineffective for removing tiny particles and organisms.

2.Hydrocyclone: A hydrocyclone is a useful piece of equipment for removing suspended solids from ballast water. To separate solids, high velocity centrifugal force is used to rotate the water. Because hydrocyclones do not have moving parts, they are simple to install, operate, and maintain on board ships.

3.Coagulation: Because most physical filtration methods cannot remove smaller solid particles, coagulation is used prior to filtration to join smaller particles together to increase their size. The efficiency of the above-mentioned filtration processes increases as particle size increases. The process of coagulating smaller particles into small flocs is known as flocculation. The flocs settle faster and are easier to remove.

2.Ultraviolet system

The UV ballast water treatment method consists of UV lamps encircling a chamber through which ballast water is allowed to pass. UV lamps (Amalgam lamps) emit ultraviolet rays that act on the DNA of organisms, making them harmless and preventing their reproduction. This method has been used successfully around the world for water filtration and is effective against a wide variety of organisms.

3.Chemical Treatment

Ballast water contains oxidizing and non-oxidizing biocides that have been shown to be effective in combating marine organisms. These biocides were chosen for their effectiveness as well as their ability to biodegrade or be easily removed in order to prevent toxins from contaminating ballast water.

Oxidizing biocides are general disinfectants such as chlorine, bromine, and iodine that are used to inactivate organisms in ballast water. Disinfectants of this type work by destroying organic structures of microorganisms, such as cell membranes or nucleic acids.

Non-oxidizing biocides are disinfectants that, when used, interfere with the reproductive, neural, or metabolic functions of organisms.

4.Deoxygeneration /Gas treatment method:-

As the name implies,The deoxygenation ballast treatment process involves eliminating oxygen from the ballast water tanks to make the organisms asphyxiated.

Nitrogen or another inert gas is introduced into the space above the water level in the ballast tanks. As a result, the oxygen in the water is removed. The marine organisms become asphyxiated and die in the absence of oxygen. It takes two to four days to complete the process. The ballast tanks must be completely airtight for the deoxygenation to be successful.

5.Heat treatment

The ballast water is heated to a temperature that kills the organisms in this treatment. A separate heating system can be used to heat the ballast water in the tanks, or the ballast water can be used to cool the ship’s engine, thus disinfecting the organisms from engine heat. However, such treatment may take a long time before the organisms become inactive, and it may also increase corrosion in the tanks.

6.Electric pulse and pulse plasma treatment

The electric pulse/plasma for ballast water treatment is still in the development stage. Short bursts of energy are used in this system to kill the organisms in ballast water.

Two metal electrodes are used in pulse electric field technology to generate energy pulses in ballast water at very high power density and pressure. The organisms in the water are killed by this energy.

In electric plasma technology, a high energy pulse is delivered to a mechanism placed in the ballast water, resulting in the formation of a plasma arc and the death of the organisms.

Both methods are said to have nearly the same effect on organisms.

7.Ultrasonic or cavitations treatment

In this treatment, ultrasonic energy generates high energy ultrasound in the ballast water, and the impact kills the cells of the suspended organisms. Ultrasonic or cavitation techniques are frequently used in conjunction with other systems.

8.Magnetic Field Treatment

This is a flocculation treatment method. Magnetic powder is combined with coagulants and added to the tank’s ballast water. Magnetic flocs or flakes form as a result of this process. These can hold a large number of marine organisms. Magnetic discs are used to remove the flocks from the water, and the contents are safely disposed of.

Headway ballast water treatment system

Headway ballast water treatment system is actually Ocean guard BWMS.It is developed by headway technology Co. Ltd. Together with leading universities in China.

Ocean guard BWMS is comprises of two parts Electrolysis unit and ultrasonic unit.

The Electrocatalysis Unit can generate enough hydroxyl radicals and other highly active oxidizing substances to kill all organisms in ballast water in a matter of nanoseconds. The entire sterilization procedure is carried out within the EUT Unit. During the treatment process, the Ultrasound Unit can clean the surface of the Electrocatalysis Unit on a regular basis to maintain the electrocatalysis material’s long-term treatment effectiveness.

Advantages

1.Use advanced electrocatalysis

Hydroxyl radicals produced during the Management process by AEOP technology will vanish after a few nanoseconds. These radicals have a high sterilization efficiency and can effectively kill various bacteria, viruses, algae, and dormant ovum in ballast water (broad spectrum sterilization) in a chained mode. Sterilization can be completed within the EUT Unit. The TRO (total residual oxidation) concentration can be controlled to within 2ppm, allowing the TRO to perform advanced management on the water in ballast tanks.

2.No corrosion

OceanGuard® Ballast Water Management System-generated hydroxyl radicals will dissipate after a few nanoseconds. The entire sterilization management process is completed within the EUT Unit. The TRO concentration is kept within 2ppm by the management. According to long-term operation results, the system is safe and reliable, and water treated by OceanGuardTM causes no corrosion to the hull.

3.Satisfy the requirements

Completely comply with IMO regulations and California requirements.

Compact design, small footprint, simple installation, and no maintenance. OceanGuard® BWMS can be installed on a variety of vessels with varying internal structures. All of the components are made of high-quality materials and have long-lasting spare parts.

4. A broad range of applications

OceanGuard® BWMS performs admirably in both fresh and salt water. The environment in the surrounding waters is not harmed by the discharged treated ballast water.

5.Energy Savings

Low operating expenses. For the treatment of 1000 m3 of ballast water, the energy consumption is only about 17KW.

6.Explosion proof

OceanGuard® obtained an Explosion-proof Certificate, allowing it to be installed in the pump room of an oil tanker, liquid gas carrier, or other vessel.

7.Single treatment

‘Single Treatment’ ;The entire process only requires inflow treatment rather than discharge treatment, making it suitable for all vessel ballast water discharge systems.

Check Out Other Important Topics

Home IC Engine Electrical Important PDFs Boilers Synergy Maritime Exam Naval Arch Interview Questions Difference Between Types of Pumps Types of Valves MEO Class 4 Auxiliary Machines