A globe valve is a linear motion valve which is used to start, stop and regulate the flow of liquid in the pipeline.

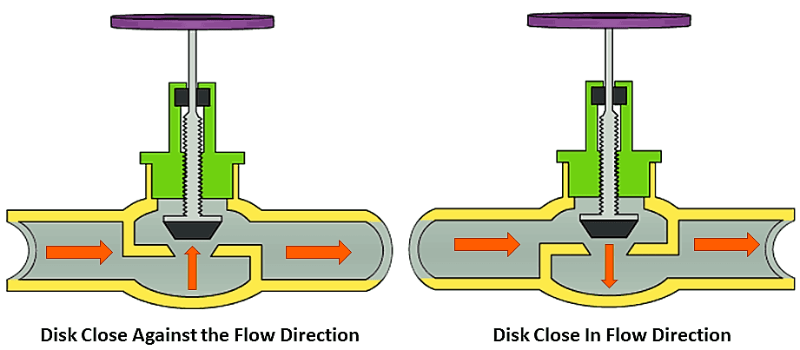

It is not bidirectional valve. It is not used in either direction.

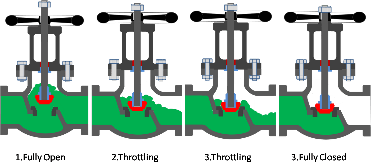

The disk did the work of starting, topping and regulating the flow of liquid. The disk has three positions :-

It can completely close the path

It can removed entirely from the path of flow.

In between valve seat and back seat for regulating the flow of liquid.

The disc of valve moves perpendicular to the seat as the valve opens and closes.

Must read :- Centrifugal pump

Globe valve working principle

The working principle of globe valve is that restricting the flow of liquid in pipeline by any obstruction material called disk.

When the handle wheel is rotated clockwise, stem and the valve plug move downward across the fluid flow line, and the valve plug is tightly located between the two valve seats. As a result, once the valve is completely closed, there will be no leakage of fluid through it.

When the handle wheel is turned anticlockwise, steam and the valve plug move upward across the fluid flow line, and the valve opens from its closed position, allowing fluid to flow through the globe valve.

How does a globe valve work ?

As we know that valve is used to regulate or shut off the fluid. As the seat of the valve is in the middle of and parallel to the pipe, and the opening in the seat is closed off with the disk. When the handle is turned, manually or through an actuator, a disc is lowered or raised by means of the valve stem. The fluid flow is turned off when the disc is fully lowered

Globe valve parts

Globe valve parts list are following :-

1.Handwheel and nut :-Handwheel is fitted with threaded stem on top by a nut.The operation of valve is done by rotating handwheel clockwise or anti-clockwise.

2.Bonnet :-One of the outer globe valve parts that is connected to the body to provide a leak-proof closure is the bonnet. In different globe valves, different bonnet types such as bolted, screw-in, or union bonnet are used.

Each of these bonnet styles has its own set of benefits. The union bonnet, for example, not only adds strength to the body but is also ideal for applications that require regular cleaning or inspection. With its simple design, the screw-in bonnet provides a pressure-tight seal. The last type of bonnet is bolted bonnets, which are attached with bolts and are ideal for higher pressures.

3.Gland packing :-

Valve packing is a gasket that forms a tight seal between the valve stem and the bonnet. It’s used to keep liquids from leaking out of valve stems and stuffing boxes. The gland followers on most valves are tightened until the valve is leak-proof. Leakage occurs with loose packing; tight packing impairs valve movement and may cause stem damage.

Packing is available in a variety of materials, including PTFE, elastomers, fibrous material, and others. The valve packaging must be properly designed and manufactured in order to reduce the risk of stem damage and fluid leakage. On the other hand, it is important to keep in mind that over-tight packing can harm the stem.

A gasket is required for a reliable seal between the stem and the bonnet. This is known as packing. This consist of following components

1.Gland follower, a sleeve that compresses the packing after it has been compressed by a gland into the so-called stuffing box.

2.Gland was a type of bushing that compressed the packing into the stuffing box.

3.A stuffing box is a chamber that compresses the packing.

4.Packing is available in a variety of materials, including Teflon®, elastomeric material, fibrous material, and others.

5.A backseat is a seating arrangement located inside the engine compartment. When the valve is fully open, it creates a seal between the stem and bonnet and prevents system pressure from building up against the valve pakking. In gate and globe valves, back seats are frequently used

5.Seat ring :-The seat is one of components of globe valve that seal the space between the disk/stem and bonnet. The seat ring can be screwed into the valve or torqued. The seat, also known as a seat ring, offers a stable and replaceable shutoff surface. Seat rings can firmly secure the cage to the valve’s body.

6.Stem:-The valve stem is responsible for the proper positioning of the disk and provides the necessary movement to the disc, plug, or ball for opening or closing the valve.

The stem is a component of the globe valve that connects the disk to the handwheel or valve actuator in order to transmit the actuation force. It is one of the critical globe valve parts because it connects the actuator to the parts inside the globe valve. The stem of an actuator-controlled valve is smooth, whereas the stem of a manual valve is threaded.

The threaded ends of the smooth steam allow connection to the actuator and the plug. To prevent material from leaking from the valve, a wearable packing surrounds the smooth stem. As a result, during the maintenance period, the packing should be replaced on a regular basis. In the closure state, the stem can withstand a significant amount of compression force.

7.Disk:-One of the most important globe valve components is the plug or disk. It moves perpendicular to the seat and can either block or free the flow because it functions as a moveable physical barrier. When the valve is closed, the plug sits against the seat, blocking the flow, and when it sits above the seats, it allows the material to flow.

For globe valves, various disk arrangements have been designed, including composite type, ball type, and needle type. The composite disk has a better shut-off, whereas the ball type is used in low-temperature and low-pressure systems. When compared to the other two, the needle disk provides better throttling.

8.Body:-The valve’s body is the main structure that holds everything together. This section contains all of the internal parts of the globe valve that allow control of the substance that needs to be regulated. The body’s opening contains ports (usually two or three ports) that allow fluid to flow to the inside or outside of the globe valve.

9.Cage :-This cage is intended to encircle the stem and plug within the globe valve. The cage is one of the components that govern the flow within the globe valve. The flow can increase or decrease as the plug moves. The flow of the material inside the valve varies depending on the layout and design of the openings.

Cages are also responsible for guiding the plug to the seat to ensure a good shutoff.

What is a globe valve used for ?

globe valve used for regulation flow or pressures as well as complete shutoff of flow required.

Functions Of globe valve

A globe valve’s primary function is to start, stop, or regulate the flow. As the globe valve opens, the disk moves upward, allowing the fluid to flow proportionally. In an open position, the valve stem rises and pops out at the top. Globe valves are typically used in smaller sizes, usually 12 inches or less. The power required to operate a globe valve grows in proportion to its size. A globe valve is typically used as an on/off valve, but it can also be used for throttling.

Applications of globe valve

Globe valves are useful in a variety of applications where flow must be regulated but a constant flow of fluid is not required. Here are a few examples of common applications for globe valves:

1.Cooling water systems in which the flow must be regulated

2.A fuel oil system in which the flow is regulated and leaktightness is critical.

3.When leaktightness and safety are important considerations, use high-point vents and low-point drains.

4.Systems for feedwater, chemical feed, condenser air extraction, and extraction drain

5.Boiler vents and drains, as well as main steam vents and drains and heater drains

6.Seals and drains for turbines

7.Turbine lube oil system, among other things

Advantages and Disadvantages of globe valve

Advantages of globe valve

1.Shutoff capability is good.

2.Moderate to good throttling capability

Shorter stroke (compared to a gate valve)

3.Available in tee, wye, and angle patterns, each offering unique capabilities

4.Easy to machine or resurface the valve seats

5.With disc not attached to the stem, valve can be used as a stop-check valve

Disadvantage of globe valve

1.a greater pressure drop (compared to a gate valve)

2.To seat the valve, more force or a larger actuator is required (with pressure under the seat)

3.Throttling flow beneath the seat and shutoff flow above the seat

How does a globe valve work?

What is the difference between a globe valve and a gate valve?

One significant distinction between a gate valve and a globe valve is that a gate valve can be installed in multiple directions, whereas a globe v/v can only be installed in one direction.

A gate valve should only be installed where it can be fully opened and shut, and it should not be overtightened as this may cause the gate to distort.

A gate valve can be used to start and stop flow, but it cannot regulate the flow level.

Check Out Other Important Topics

Home IC Engine Electrical Important PDFs Boilers Synergy Maritime Exam Naval Arch Interview Questions Difference Between Types of Pumps Types of Valves MEO Class 4 Auxiliary Machines

Source :-Wikipedia