Types of chisel :- Chisel tools Images, Uses, Applications, Precautions

What is a chisel ?

A chisel is a tool with a distinctively shaped cutting edge of blade on one end that is used to carve or cut a hard material such as wood, stone, or metal by hand, mallet, or mechanical power. The handle and blade of some chisels are made of metal or wood with a sharp edge.

Classification of chiesel tools

Chisels are used on both hot and cold metals. As a result, chisels have been classified into two types. Types of Chisel are following :-

Hot chisel

In a blacksmith’s workshop, a hot chisel is used to cut hot metals. A chisel has a hole in it where a wooden handle is attached. Their cutting edge is formed at a 30° angle. This part is frequently dipped into water to make it cold so that its edges remain intact while being used.

Read :- 33 Different types of pliers

Cold chisel

Cold chisels are commonly used in sheet metal and fitter trade workshops. When metals are cold, they can be cut or chipped with a cold chisel.

This is available in four, six, or eight sides. These are made of high carbon steel, which contains 0.75 percent to 1.00 percent carbon. In most cases, a chisel with a length of 150 mm is used. In practice, chisels are measured by the width of the cutting edge.

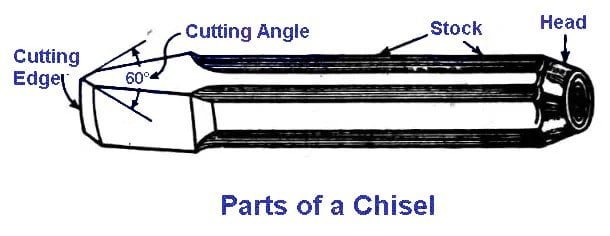

Parts of a chisel

Different parts of a chisel are following

- Head

- Body

- Forging angle

- Cutting edge

- Cutting angle

1.Head

The topmost part of a chisel is referred to as the “Head.” It’s a little suck in the middle, so the hammer blow hits the center of the chisel. As a result of repeated blows, its head transforms into a mushroom, as shown in fig.

In this case, the chisel’s head should be ground straight. The upper part of the body should be 10° to 20° when making the head.

2.Body :-

The body or stock of a chisel is the part of it from which we hold it. It has four, six, or eight sides and is designed to be easily held. From the bottom, the body is somewhat flat.

3.Forging angle

Some of the flat position beneath the body of a chisel is tapered. This taper angle is known as the forging angle. It is also referred to as the Draw Angle.

4.Cutting edge

It is the part of the chisel which performs the function of cutting is called the cutting edge. Its width is taken as the chisels measurement.

5.Cutting angle

The cutting angle of a chisel is the angle at which its cutting edge is ground. The cutting angle is greater when cutting hard metal and less when cutting soft metal. When grinding chisels for cutting various metals, their angles should be as follows:

- Mild steel – 55 °

- Cast iron – 60 °

- Tool steel – 65 ° to 70 °

- Copper – 45 °

- Aluminum – 30 °

- Brass – 50 °

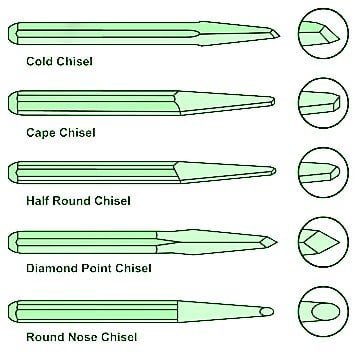

Types of Chisel with Diagram

Types of Chisel with diagram on basis of applications are following :-

Flat chisel

The flat chisel as shown in fig is the most common of all the chisels used in engineering. It is the chisel which is used for most of the general chipping operations. It may be used for removing surplus metal from surfaces of jobs.

The flat chisel should be drawn down to the shape shown in the diagram. The cutting edge should be slightly curved as shown as this will prevent corners digging in when it is being used. The length of a flat chisel varies from 100 to 400 mm, while the width of the cutting edge varies from 16 to 32 mm (IS : 402-1964).

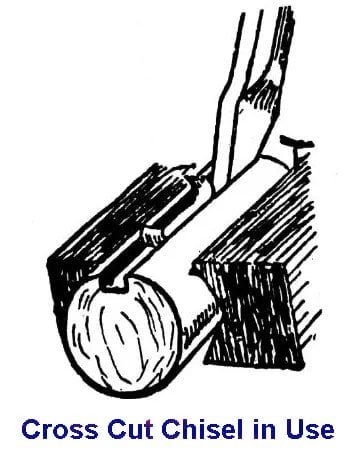

Cross-cut chisel

The cross cut chisel is a types of chisel as it is sometimes called, is used for cutting groves in large surfaces previous to using the flat chisel, and is also used in cutting key ways in wheels and shafts.

It is also known as Cape chisel

The cutting edge is slightly wider than the supporting metal to provide clearance. Length of this Caesar varies from 100 to 400 mm , and width of the edge varies from about 4 to 12 mm (IS : 402-1964).

Half-round chisel

A half-round chisel tools is shown in fig and is particularly used for cutting oil-ways or grooves in bearing, bosses and pulleys, etc. They are also used for setting-over pilot holes.When a hole is to be drilled a smaller or pilot hole is drilled first.

The shank is reduced to a half-round taper which is bevelled at the end to give a circular edge. Length varies from 150 to 250 mm and width of the cutting edge from 2 to 16 mm (IS : 402-1964).

Diamond-point chisel

The diamond-point chisel is a types of chisel as shown in the figure used for cutting vee grooves, cleaning corners and a squaring small holes.

The chisel is drawn to a square section. The end is ground off at an angle producing the “diamond” shape. Length of this chisel varies from 100 to 400 mm and width of the cutting edge from 6 to 16 mm (IS : 402-1964).

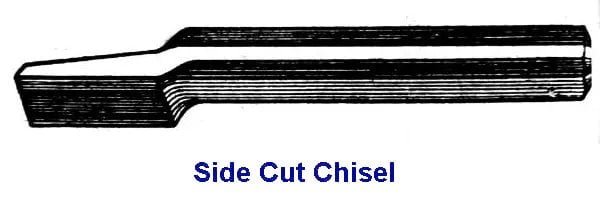

Side chisel

A side chisel tools is shown in fig. This is particularly useful in chipping and removing the surplus metal in cotter ways and slots, which may have to be cut by hand after being drilled.

The shank of this chisel is bent out a little sideway, and then vertically down again.

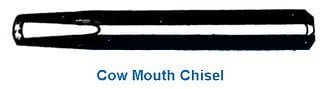

Cow mouth chisel

Its shape is similar to that of a cow’s broad mouth in these types of chisels. That is why it is known as a cow mouth chisel. It is used to make the edges of protruding plain metal parts, rivet heads, and large round holes. Its forging angle is at an angle.

Masonary chisel

The masonry chisel is a types of chisel , also known as the mason’s chisel, is capable of cutting through hard materials such as brick, concrete, and stone. It can also be used to remove excess mortar due to its wide and flat blade. Those with wider cutting edges are also referred to as ‘mason’s bolster.’

This type of chisel is relatively heavy and often has a handle to protect the user. For demolition purposes, it is frequently attached to jackhammers and hammer drills.

Cutting through a material with a mason’s chisel is simple, even for inexperienced DIYers. First, you must draw the lines. Mark two parallel lines on each side of the stone or material to be cut to accomplish this.

Using the lines as a guide, carve a deep and pointed channel (often in the shape of a “V”). Drill the blade into the material with a hammer. This allows the chisel to weaken the structure and then cut through it.

Bevel edge chisel

If there is a workhorse in the chisel tools family, it has to be the bevel edge chisel. This hand tool is also acknowledged as the most common chisel found in stores. And part of this trait can be attributed to its versatility.

Because of the bevel edges on its blade, the bevel edge chisel can get into acute angles, allowing it to get into tight corners and areas that other types of chisels cannot.

Consider the back of the tool when selecting a bevel edge chisel. It should be flat or slightly hollow to facilitate sharpening.

Aside from having a good edge, it must also be comfortable in the hand. The handle should also be impact resistant, able to withstand repeated blows from a hammer or mallet.

Uses :-

- It is comfortable to hold with hardened butts that are meant for hitting with a mallet so you can shape wood.

- It can also used by hand for fine Paring.

- We can do everything I.e from rough work to fine work.

Bench chisel

It is shorter than bevel edge generally, its handle and blade are both 5 inch long.Thus is idle choice for the cabinet and furniture’s makers.

It is used for pairing, trimming and chopping.

Because a bench chisel tools is shorter than other types of chisels, it is easier to handle and control. It can also be beveled on the sides to accommodate dovetails.

Straight-edged bench chisels, on the other hand, are thicker and heavier. These are ideal for carving large sections of hard material. Whether you want a straight or beveled-edge bench chisel, they come in sizes ranging from 1/16 to 3 inches.

Brick chisel

Brick chisels, as the name implies, are used to make smooth cracks and cuts in bricks. Bolster chisels are another name for brick chisels. Its wide blade can cut through items such as masonry blocks.

It can also be used to clean mortar and concrete surfaces. However, because it is not made of hardened steel, it cannot cut through metal such as reinforced bars. It is typically used in conjunction with a lump hammer to improve the efficiency of cracking bricks, blocks, and stone.

When purchasing a brick chisel, look for one with a heavy-duty hand guard to protect your hand while using the tool. It’s also a good idea to buy a chisel with all of its parts (head, edge, and handle) forged together to form one sturdy tool.

This way, you can be certain of the tool’s toughness or durability. When it comes to the head, it should be domed to prevent mushrooming and to ensure that it lasts for many years.

Concrete chisel

A concrete chisel is a types of chisel can be used to break up sidewalks, concrete floors, and other similar surfaces in situations where an air hammer would be impractical. A concrete chisel, unlike other types of chisels with a sharp edge, has a sharp and pointed tip. This enables it to break apart concrete rather than reshaping or sharpening it.

A concrete chisel can also be used to remove small amounts of concrete. A concrete chisel can also be useful during demolition, especially when inserted into a rotary hammer. This type of chisel may also be useful for sculpting and rockhounding.

Stone chisel

This type of chisel tools is designed for use in stone, as the name suggests. Because granite and other hard stones are extremely hard, stone chisels are made of hardened steel that can withstand abuse. They are, however, more than just a blunt force tool. Quite the contrary. This is the type of chisel used to create fine art sculptures. It all depends on the user’s skill.

Butt chisel

Butt chisel are types of chisel which get their name from the fact that they’re used to install butts and hinges. But, make no mistake, butt chisels are also widely used for cleaning joints on cabinets, desks, wardrobes, and other similar furniture.

They can also be used to trim small edges on intricate woodwork. A butt chisel’s compact shape allows you to gain more leverage in tight quarters.

Butt chisels are recommended for beginning cabinet makers because they are easy to control. Furthermore, the butt chisel’s short blade is sturdy enough for most applications. Butt chisel blades can be straight-edged or bevel-edged.

The blade of this chisel is 2.5 to 3 inches long on average. Its handles are usually elliptical, with rounded ends. This way, the ends fit snugly in the palm of a worker’s cupped hand. The width of the blade can range from a quarter of an inch to a full inch.

Corner chisel

A corner chisel is a types of chisel named as such because of the way its blade is designed. Its blade is angled at 90 degrees, allowing users to cut a perfect corner in wood.

You won’t need to use measuring tools to make a perfect corner with a corner chisel. Predictably, this chisel is very popular among carpenters, particularly those who make cabinets.

Another important function or application of corner chisels is the creation of mortise and tenon joints, which connect two pieces of wood. Mortise and tenon joints have been used in adjoining pieces of wood by woodworkers for many years.

Mortise chisel

This chisel tool is named after its main purpose, which is to cut mortise joints, as the name implies. It is far more durable than a bench chisel, which lacks the strength, length, and thickness to lever out stone or wood, as well as the crushing and continuous blows of a mallet.

To serve its purpose, the mortise chisel has a thick, heavy blade. It also has massive forged bolsters that can withstand a lot of pressure. It frequently has a capped handle to withstand being hammered. It has an angled edge of 30-40 degrees.

Sash mortise chisel

The sash mortise chisel tool is a lighter version of the mortise chisel that is also thinner than its larger brother. The word’sash’ in the name of this chisel implies that it is designed for furniture-scale mortising. As such, it is intended to work on shallow mortises found in window mullions.

For deep mortises, sash mortise chisels are ideal. It’s especially useful if you’re always frilling out the waste when mortising. The bad news is that sash mortise chisels are no longer available in a wide range of sizes, owing to the abundance of mortise chisels on the market.

Paring chisel

Paring chisels are types of chisel which are long and thin tools that are traditionally used to cut thin slivers of wood. These chisels frequently have bevelled sides. Paring chisels, on the other hand, aren’t meant to be hit with a mallet like mortise chisels.

A paring chisel is ideal for fine work because it is delicate yet flexible. It usually has a long handle attached to a tang and gives the worker complete control. The handle is thin and graceful, designed to be pushed rather than struck with a mallet. The thin handle also places the tool’s weight at the cutting edge, making the paring chisel easier to maneuver.

It has a long, flat, and thin blade. It tapers near the cutting edge, allowing the user to make fine cuts when cleaning out grooves. The length of the chisel also naturally reduces the impact of the hand’s side-to-side movement. It also allows the user to easily see if the chisel is at the proper working angle.

A low cutting angle is another important feature of a paring chisel. The cutting angle of a paring chisel is approximately 20 degrees. This is significantly lower than other chisel types such as bench chisels (25 degrees) and Japanese chisels (30 to 35 degrees).The low cutting angle produces a fragile edge with superior cutting ability, greater control, and less need for a mallet.

Slick chisel

Slick chisels are types of chisel are related to paring chisels because they are essentially larger versions of the latter. This chisel is ideal for removing extra thin pieces of wood from a workpiece. Slick chisels, like paring chisels, have a low cutting edge with a range of 20 to 30 degrees. The handle, on the other hand, is frequently shaped like a baseball bat. Despite its shape, it has a good grip.

Slick chisels are one of the largest chisel types, with a wide blade and a long flat back. This design enables the slick chisel to quickly work through large notches. A slick chisel’s long handle also gives you leverage when shearing curls of wood with a single motion of your arms. A slick chisel, like a paring chisel, should not be struck with a mallet.

By the name alone, you’ll know what a dovetail chisel is for. You can easily create a dovetail and finish its joints with a dovetail chisel.

Dovetail chisels are distinguished by their long, beveled blades. This tool’s long and thin blade makes it useful for cleaning out the joint. The triangular cross-section of the blade also allows the tool to fit into tight corners of dovetails. Meanwhile, the back of the blade is typically slightly hollow to reduce friction.

Framing chisel

Framing chisel tools are essential tools in the construction of wooden structures. They are widely used in timber framing, boat building, and construction. It is built to withstand repeated, crushing blows from a mallet or hammer. It’s used to make deep cuts in woodworking.

A framing chisel is wider, thicker, and longer as compare to a firmer chisel. Its blade can have a bevel or a straight edge. Because it is intended to be hit with a mallet, it usually has features such as capped handles and sockets.

A framing chisel’s cutting edge is 25 to 30 degrees. Most framing chisels are hand-forged from a single piece of steel, making them extremely durable due to the reduced likelihood of parts breaking.

Lathe chisel

A lathe chisel is a type of woodworking machine that spins the wood you’re working on. By holding the chisel against the wood and removing material with each pass, lathe chisels allow you to shape the wood while it spins.

Skew chisel

Skew chisel are types of chisel which are one of the most important tools for woodworkers because they are unrivaled when it comes to smoothing a spindle. For example, suppose you’ve just rounded out a square piece of stock into a smooth round spindle. With a skew chisel, you can fine-tune that spindle for a smooth finish. You can also use a skew chisel to make V-cuts, beading, and tapering.

It has a long, beveled-edged blade with an angled tip. The long point of the edge is known as the toe, while the shortest point is known as the heel. DIY woodworkers, on the other hand, should be cautious when using this chisel. Many woodworkers, especially beginners, find it difficult to use the skew chisel. It takes a certain amount of pressure and digging to get it to work.

Furthermore, even the smallest error in using a skew chisel can result in a dig-in or gouge of the wood. Poor dig-ins can even result in the worker’s tool being yanked from his or her hands. This is not to say that the skew chisel is the most difficult tool to master. You can easily avoid these mishaps by using proper techniques and cautious actions.

Japanese chisel

The Japanese chisel, or nomi , is made in the same way as the Japanese plane. A hard blade known as the hagane is attached to a softer piece of metal known as the jigane.

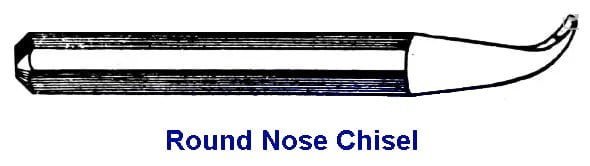

Gouge chisel

A gouge (a type of chisel) is used to carve small pieces from material, especially in woodworking, woodturning, and sculpture. Concave surfaces are most frequently produced by gouges. A gouge’s cross-section is typically shaped like a letter ‘U.’

Uses :- This chisel has a half-moon-shaped curved blade. They are designed to cut round or semi-circular grooves in metal.

Cape chisel

Cape chisels have a long, tapered blade and are a type of cold chisel. They’re ideal for carving tiny grooves into the surface of metals to create details and art.

It is Also known as a slot chisel.

Uses :- To cut a flat grooves for keyways or slots. Narrows to a flat cutting end for precision

Power chisel

Until now, all of the types of chisels on this list resembled the basic chisel that we are all familiar with. However, power chisels are a purely modern invention. These chisels are powered by a motor, giving them far more power and accuracy than hitting a hand tool with a hammer. When you need some serious power behind your chisel, the power chisel is here to help.Efficiency is also better compared to other traditional chisel types.

Process of using chisel

A chisel is used to cut and chip thin metal sheets, plates, round rods, and other materials. Figure depicts the cutting of a metal plate. When using a chisel, keep the following points in mind:

- The metal to be cut should be accurately marked.

- Always use your left hand to hold the chisel and your right hand to hold the hammer.

- Properly position the chisel on the marked line, then strike the hammer on its head. It should be reset before striking the second blow with the chisel.

- When using a chisel, we should focus on the cutting edge.

- Make a hammer blow to the center of the chisel’s head.

Precautions during using chisel tools

- We must always wear safety goggles when chipping.

- While chipping, keep your face to the wall.

- If you have someone working in your front, you should install a chipping guard at the back of the vice to prevent chips from hitting him.

- Never use the mushroom head chisel for chipping.

- There should be no greasy substance on the chisel head or the face of the chipping hammer.

- A very long chisel should not be used for chipping.

- While chipping, keep the chisel’s edge lubricated with grease.

Conclusion :- In this article , I have written all the types of chisel with diagram in details. If forget to mention anyone chisel tools please comment.