Drill : A drill is a fitted cutting tool used to originate or enlarge a hole in a solid material. Drills are manufactured in a wide variety of types and sizes. The types of drill bit commonly used are :

1. Flat or spade drill

2. Straight fluted drill

3. Two-lip twist drill

a. Parallel shank (short series or “Jobbers” twist drill)

b. Parallel shank (stub series) twist drill

c. Parallel shank (long series) twist drill

d. Taper shank twist drill4.Taper shank core drill (Three or four fluted)

4.Taper shank core drill (Three or four fluted)

5. Oil tube drill

6. Centre drill

1. Flat or spade drill

A flat drill is sometimes used when a same sized , drill is not available. It is usually made from a piece of round tool steel which is forged to shape and ground to size, then hardened and tempered. The cutting angle varies from 90° to 120° and the relief or clearance at the cutting edge is 3° to 8°.

The disadvantage of this type is drill is that each time the drill is ground the diameter is reduced. Further, it cannot be relied upon to drill a true straight hole, since the point of the drill has a tendency to run out of centre.

Another difficulty of using this type of drill is that the chips do not come out from the hole automatically, but tends to pack more or less tightly, if deep holes are to be drilled.

2. Straight fluted drill

A straight fluted drill has grooves or flutes running parallel to the drill axis. A straight fluted drill may be considered as a cutting tool having zero rake. This type of drill is inconvenient in standard practice as the chips do not come out from the whole automatically.

It is mainly used in drilling brass, copper or other softer materials. In drilling brass, the twist drill tends to advance faster than the rate of feed and the drill digs into the metal.

No such difficulty occurs in the use of straight fluted drill when drilling sheet metal. The straight fluted drill does not tend to lift the feet as does the twist drill. fig

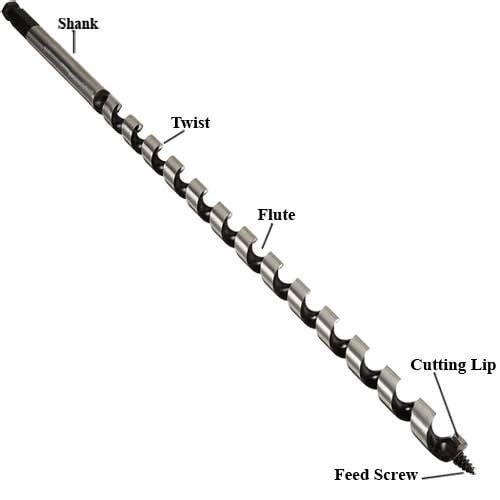

3. Twist drills

The most common types of drill bit in use today is the twist drill. It was originally manufactured by twisting a flat piece of tool steel longitudinally for several revolutions, then grinding the diameter and the point. The present a twist drills are made by machining two spiral flutes or grooves that run lengthwise around the body of the drill.

Twist drill is an end cutting tool. Different types of twist drills are classified by Indian standard institution according to the type of the shank, length of the flute and overall length of the drill.

A. Parallel shank (short series or “Jobbers”) twist drill

The drill has two helical flutes with parallel shank of approximately the same diameter as the cutting end. The diameter of the drill range from 0.2 to 16 mm increasing by 0.02 to 0.03 mm in lower series to 0.25 mm in higher series.

B. Parallel shank (stub series) twist drill

The drill is a shortened form of the parallel shank twist drill, the shortening being on the flute length. The diameter of the drill ranges from 0.5 to 40 mm increasing by 0.3 mm in lower series to 0.25 to 0.5 mm in higher series.

C. Parallel shank (long series) twist drill

The drill have two helical flutes with a parallel shank of approximately the same diameter as the cutting end, which however does not exceed the diameter at the drill point. The overall length of this drill is the same as that of a taper shank twist drill of corresponding diameter. The diameter varies from 1.5 to 26 mm increasing by 0.3 mm in lower series to 0.25 mm in higher series.

D. Taper shank twist drill

The drill have two helical flutes with a taper shank for holding and driving the drill. The shank for these drills conform to morse tapers. The diameter ranges from 3 to 100 mm.

The diameter increases by 0.3 mm in lowest series having morse taper shank No. 1, by 0.25 mm in Morse taper shank number 2 and 3, by 0.5 mm in Morse taper shank No. 4, and by 1 mm in Morse taper shank number 5 and 6. The use of Morse taper shank below 6mm size is not preferred. A drill gauge enables any drill to be readily selected by trying in the hole of the gauge.

4. Taper shank core drill (three or four fluted)

These drills are intended for enlarging cored, punched or drilled holes. These drills cannot originate a hole in solid material because the cutting edges do not extend to the center of the hill. The metal is removed by a chamfered edge at the end of each flute. Cored drills produce better finished holes than those cut why ordinary two fluted drills.

The cutting action of a core drill is similar to that of a rose reamer and it is often used as a roughing reamer. In some cases, a two fluted twist drill is chosen to originate a hole half the required size and the rest is finished by a three or four fluted drill.

5. Oil tube drill

The oil tube drills are used for drilling deep holes. Oil tubes run lengthwise spirally through the body to carry oil directly to the cutting edges. Cutting fluid or compressed air is forced through the holes to the cutting point of the drill to remove the chips, cool the cutting edge and lubricate the machined surface.

These are most useful for deep hole drilling.These are provided with two internal holes extending through the length of the drill through which the cutting fluid can be pumped under pressure. This keeps the cutting edge cool while flushing away the chips as well.

6. Center drill

The center drills are straight shank, two fluted twist drills used when center holes are drilled on the ends of a shaft. They are made in finer sizes.

7. Counter sinking drill

Countersinking drill a types of Drill which is used to drill a holes in the places where counter head screws are to be installed. In this way, the head job of the screw fits perfectly.

It is a multi-fluted drill in which four flutes are cut in it. Its cutting point is grinded at 60° or 82°.

8. Counter boring drill

The counterbore tool is typically a specialized drill bit that simultaneously creates the hole for the fastener’s body and the larger sized cavity for its head. Typically, a flat-bottomed screw, such as a round head or a pan head screw, is used.

It’s used to make a hole bigger. Boring in a hole is done from the upper side up to the screw head’s height.

A significant difference between countersinking and counterboring is that the hole in countersinking is cut slanting at 60° or 82° angle from the top, whereas the hole in counterboring is made deeper in the increased size up to the height of the screw head.

A counterboring drill is also known as a counterboring cutter. On its lower side, a pilot is constructed. This pilot is inserted into the hole to aid in straight counterboring.

9. Rivet drill

It is Specially designed for drilling holes for rivets. It is Ideal for drilling shallow holes through thin metal without pre-punching. 35% Shorter than standard drill bit.

Uses :- These drill bits are specifically designed for drilling tiny rivets into thin sheet metal.

10. Spirec Drill

These drills are extremely delicate. These are used to bore very small holes in spray pump nozzles, store nipples, and other similar items. They range in size from 0.0086′′ to 0.0984′′. There are a number of these available.

11. Core drill

These are special holes meant for enlarging already existing holes such as those in castings. These are either three-flute or four-flute type. The four-flute type is used for enlarging the drilled holes while the three-flute type is used for punched or cored holes. The three-flute type keeps the chatter to a minimum due to the fact that the cutting lips are not diametrically opposite.

12. Shell core drill

These are similar to the core drills, but do not have a normal shank for the purpose of holding and are for the large diameters. This needs to be mounted using a stub arbour similar to the shell end mills with the help of the central hole present.

13. Step drill

Step drill bits are commonly used on construction sites to enlarge holes in thin metals as well as other materials such as plywood, drywall, and particleboard.

Step drill bits are frequently used by electricians because they are ideal for drilling holes in the thin metal boxes that hold wiring.

Uses :- It is used to drill a hole in the metal sheet.

Advantages

The step bit’s design allows you to drill holes of various diameters firmly.

Another cool feature of these bits is that they create de-burr holes, allowing you to clean out the waste material.

14. Installer bit

An installer bit is a specialized twist bit which is used for installing wiring, such as that used in home for entertainment or security systems. The bit can drill through wood, plaster, and some masonry and can be up to 18 inches long.

The bit’s tip has a small hole. After drilling a hole in the surface, insert the wire into the tip’s hole and force it through. Pull it from the other side.

15. Masonry bit

Masonry bits are drill bits that can drill through concrete. They can also be used to drill through brick and stone. Masonry bits drill holes in concrete in two steps. The drill bit’s tip is larger in diameter than the shaft below, so when the shaft reaches the hole, it fits perfectly.

Because these bits are so tough, they must be replaced almost on a regular basis as they wear out.

Precautions :- If you drill into the concrete for a long period of time, the tip will melt. You can alleviate this problem by changing the drill out of the concrete on a regular basis.

How to identify a masonry drill bit ?

Masonry bits look similar larger twist drills with a slightly tighter corkscrew shape. They are distinguished by their broad arrow-shaped heads. They’re commonly used in hammer drills to grind down masonry as they cut through it. They can be used on brickwork, stone, breeze blocks, and other hard stone surfaces.

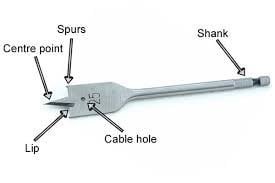

16. Augur bit

Auger, a tool (or bit) used to drill holes in wood with a carpenter’s brace. It resembles a corkscrew and is made up of six parts: screw, spurs, cutting edges, twist, shank, and tang. The screw resembles a tapered wood screw and is short and small in diameter; it centers the bit and draws it into the work.

It is used to drill a hole in the thick and dry wood. It easily makes a hole in the woods, so you don’t have to exert as much force. These have a screw tip that creates the hole and assists in pulling the bit out, resulting in a clean hole.

We can us it on thicker wood also ,it is Because many of these bits are up to 18 inches in length. The large flute’s shape helps to support the channel by allowing dust to enter the hole. Some are hollow in the center, allowing for even more chip removal.

17. Tile bit

Tile bit is consists of a carbide tip which used to drill in a certain tile and reduces the chance of chips and cracks. The various types of tile bits are intended for the various types of tiles.

Ceramic tiles are easily broken, and drilling a hole in them is difficult. For this purpose, tile bits with ground tungsten carbide or diamond tips are ideal. They are both designed to drill into hard surfaces and leave a cone-shaped hole in the tile.

18. Hammer bit

A hammer drill is used to make holes in brick, concrete, masonry, and even rock. A hammer drill uses a specific type of drill bit designed specifically for these tough materials….

The most powerful of this type, SDS hammer drills, can only be used in hammer mode, with no rotation.

19. Glass bit

A glass drill bit is used to drill through glass, plastic, composite, brick, marble, and hollow brick. It is more resistant to high temperatures, is ideal for drilling into dense material, and speeds up dust removal.

20. Forstner bit

Forstner bits are unique in their ability to drill overlapping holes, notches on the edges of a workpiece, and angled holes on the face of a workpiece (pocket holes, for example). The bit will cut whether or not the center spur is engaged with the workpiece. This feature is unique to the Forstner bit.

For making clean and smooth hole in the wood ,this type of drill bit is right choice to use.

This bit allows for precise hole cutting. It has a pointed tip which assists in keeping the bit precisely where you need it.

Forstner bit has no flute and must be removed on a regular basis for cleaning of chips and dust. A drill press with this type of drill bit is required for a variety of applications.

21. Hole saw

Hole saw, also known as a hole cutter, is a saw blade with an annular kerf that cuts a hole in the workpiece without removing the core material.

It is used fot drilling. Hole saws typically have a pilot drill bit at their center for keeping the saw teeth from walking.

This type of drill bit is useful for installing door hardware or creating a wiring pass-through. The hole saw creates a useless plug, which is pushed out by a side cut-out in the saw cylinder.

You can also use an attachment to center the hole and a pilot bit to stabilize the blade. Instead of a pilot bit, small hole saws have a built-in shank. You can make holes in both wood and metal with a bi-metal hole saw.

22. Plug cutter

Plug cutter is a drill bit used for covering up any unwanted holes created when making screw holes.

One of the most common applications for a wood plug cutter is to make plugs to cover up and conceal screw heads. Drilling screw holes with carbide tipped countersink bits creates a deeper hole, allowing the screw head to be inserted below the surface.

Uses :- these plug cutters are used to cover up any unwanted holes created when making screw holes In wood carvings, and any wood carpentry shops. Expert wood workers also utilize plug cutters for decorative works.

Check Out Other Important Topics