In this article we will learn about Inverse Rate Curves For Steel.

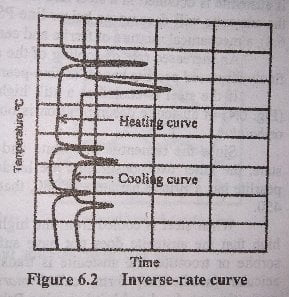

If a piece of steel is slowly and uniformly heated and its temperature recorded at definite intervals of time a curve may be obtained. Such a curve is called an inverse-rate curve, the temperature as ordinate and time increments as abscissa. This is shown in Fig. 6.2

The curve is a vertical line except at those points where the heating and cooling rates show marked change.

It will be found that at certain points the temperature will tend to remain stationary, although the rate of heat input to the steel specimen has not been altered. During heating, these points are known as decalescence points which imply that the heat is being absorbed by the specimen.

During cooling, however, these points are known as recalescence points where the steel is seen to take an extra glow as though heat has been imparted to it. Moreover, on heating a steel of specific composition, the temperature is arrested at always the same temperature points and the arrest at each point is apparent for constant time increment, within very fine margins of error for that point.

It can, therefore, be concluded that structural change takes place at these “arrest points” which are called critical points. The arrests that occur during cooling are denoted by the symbol Ar, ‘A’ standing for arrest and ‘r’ for refroidissement or cooling ; while arrests that occur during heating are denoted by Ac, “c’ being for chauffage or heating.

The arrest points in the order in which they occur during heating or cooling are given numerals 1, 2, 3 and 4 such as such as Ac1, Ar1, etc. The arrest points are seen to take place about 20° to 30°C above or below each other during heating and cooling respectively. The range or temperature between two arrest or critical points is known as thermal critical range.

Check Out Other Important Topics

Different Types of Steel & Constituents of Steel

Steel Making Process – Complete Overview with Flowchart

Cast Iron – Properties, Types & Uses

Recovery Recrystallization and Grain Growth – Working Process

Constrained Motion – Definition, Types, Examples, Images

| IC Engine | Important PDFs | Boilers | Synergy Maritime Exam | Naval Arch | MEO Class 4 |

| Interview Questions | Difference Between | Types of Pumps | Auxiliary Machines | Types of Valves | Home |