what is cyclone separator

A cyclone separator is a type of industrial equipment used to separate solid particles or droplets from a gas or liquid stream. It utilizes the principles of centrifugal force and gravity to achieve separation. Cyclone separators are commonly employed in various industries such as manufacturing, power generation, agriculture, and more, to remove particulate matter or impurities from air, gas, or liquid flows.

Must read : Oily Water Separator

cyclone separator construction

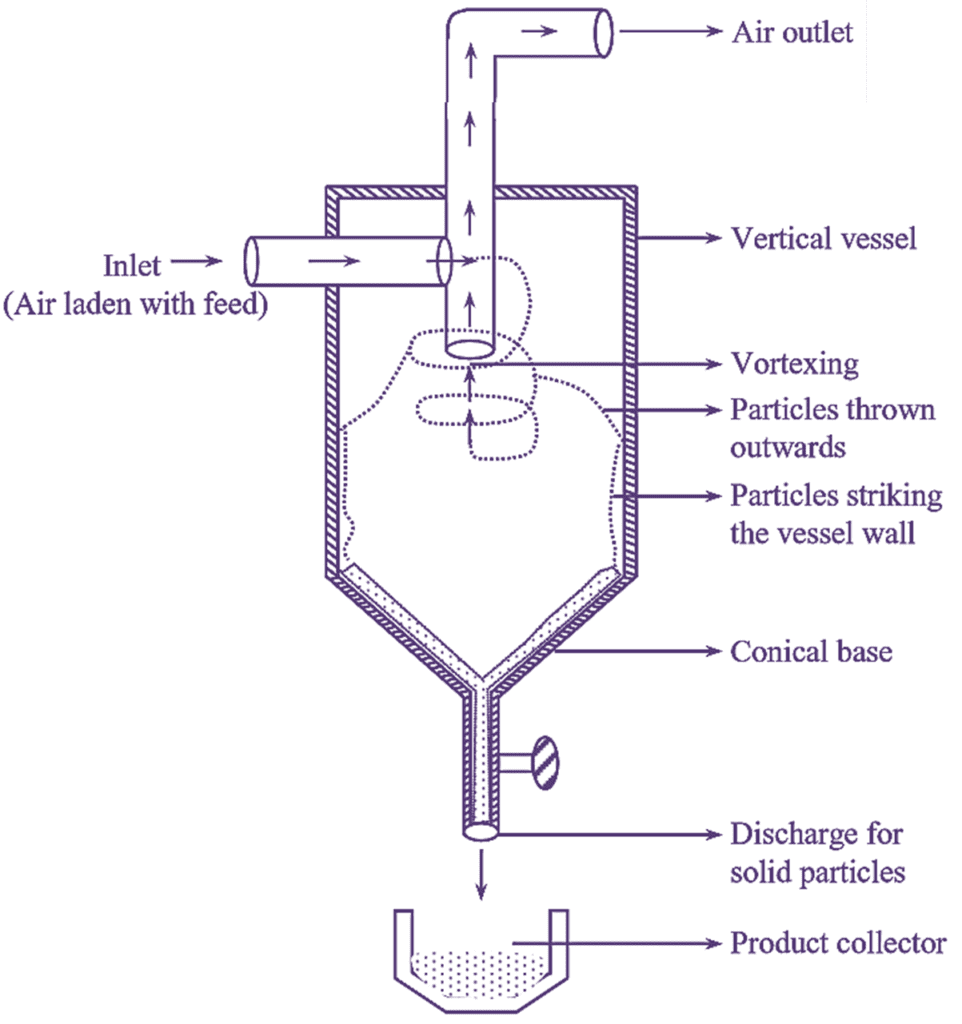

A cyclone separator typically consists of several key components that work together to achieve efficient particle separation. Here’s an overview of the construction of a cyclone separator:

- Inlet: The inlet is the entry point through which the gas or liquid mixture containing particles or droplets enters the cyclone separator. It is usually located at the top of the separator and is designed to introduce the mixture tangentially to initiate the swirling motion.

- Cyclone Chamber: The cyclone chamber is the main body of the separator, often cylindrical or conical in shape. It houses the swirling flow and is where the separation process takes place. The chamber’s design, dimensions, and shape influence the efficiency of the separator.

- Tangential Entry: The tangential entry point is where the mixture enters the cyclone chamber tangentially, inducing the swirling motion necessary for particle separation.

- Vortex Finder: Located at the center of the cyclone chamber, the vortex finder is a tubular extension that extends into the chamber and protrudes from the top. It helps guide the inner stream of cleaner gas or liquid upward while ensuring that separated particles are not carried into the outlet.

- Outlet: The outlet is positioned at the top of the cyclone chamber and serves as the exit point for the clean gas or liquid. It is designed to allow the separated gas or liquid to leave the separator while minimizing the re-entrainment of particles.

- Particle Collection Area: At the bottom of the cyclone chamber, there is a particle collection area. This is where the separated particles or droplets settle due to gravity and are collected. The bottom of the cyclone often features a conical shape that aids in directing the collected particles toward a discharge mechanism.

- Discharge Mechanism: A discharge mechanism is used to remove the collected particles from the particle collection area at the bottom of the cyclone. This can be in the form of a valve, slide, or other mechanical means.

- Support Structure: The entire cyclone separator is often mounted on a support structure to ensure stability and proper alignment within the industrial process.

- Material and Coatings: Cyclone separators are typically constructed from materials that are suitable for the specific application, considering factors like temperature, pressure, and chemical compatibility. Depending on the application, coatings or linings might be applied to the interior surfaces of the cyclone to protect against abrasion, corrosion, or erosion.

The construction of cyclone separators can vary based on the intended application and the requirements of the industrial process. Designs might include variations in chamber geometry, entry configurations, and materials to optimize performance and durability for specific situations.

cyclone separator working principle

A cyclone separator Works on the principle of centrifugal force, effectively pushing particles towards the outer edges due to their mass. As air enters the cyclone, it undergoes an automatic transformation into a rapidly revolving spiral motion, known as a “double vortex.” This intriguing motion comprises two distinct streams: an outer spiral that descends and an inner spiral that ascends. The point where these streams interact facilitates the transition of air from one to the other.

During this process, particles suspended within the air are compelled towards the periphery of the cyclone due to the influence of centrifugal force. Ultimately, these particles exit the separator by means of a collection mechanism situated at the separator’s base.

For optimal performance, the air velocity within a cyclone typically ranges between 10 and 20 meters per second, with around 16 meters per second being the most common speed. It’s worth noting that deviations from this optimal velocity, particularly if the speed is lowered, can lead to a significant decrease in the effectiveness of particle separation.

Cyclone separator working

Certainly, let’s break down the working principle of a cyclone separator in more detail:

- Inlet: The process begins with the introduction of a gas-liquid mixture containing particles or droplets into the cyclone separator. This mixture enters the separator through an inlet located at the top.

- Tangential Entry and Swirling Motion: As the mixture enters the cyclone chamber, it encounters a tangential entry point or a set of tangential nozzles. This arrangement causes the incoming flow to enter the chamber with a spinning or swirling motion around the center axis of the cyclone. This swirling motion is crucial to the separator’s operation as it sets up the conditions for separation.

- Centrifugal Force Generation: Due to the swirling motion, a centrifugal force is generated within the cyclone chamber. This force is directed outward, perpendicular to the axis of rotation. It causes all the particles or droplets present in the mixture to experience an outward force proportional to their mass.

- Particle-Droplet Separation: The heavier particles or droplets in the mixture, being more resistant to changes in motion due to their inertia, tend to move toward the outer walls of the cyclone chamber. This is because the outward centrifugal force acts as a virtual “wall” pushing these heavier components away from the center of rotation.

- Spiraling Downward: As the particles or droplets move toward the outer walls, they continue to spiral downward along the walls due to the combined effects of the swirling motion and the pull of gravity. This downward spiraling motion is a result of the balance between centrifugal force and gravitational force.

- Inner Core and Clean Gas/Liquid: In contrast, the inner core of the swirling flow remains relatively empty of particles or droplets. The clean gas or liquid, which is now mostly free of the separated particles, occupies this central region and continues its upward movement along the center axis of the cyclone chamber.

- Separation and Collection: The particles or droplets that have been pushed against the walls of the chamber eventually lose their momentum due to friction and gravitational settling. They accumulate at the bottom of the cyclone chamber, forming a conical-shaped collection area known as the “cone.”

- Outlet: At the top of the cyclone chamber, there is an outlet through which the clean gas or liquid exits the separator. This gas or liquid has undergone separation from the heavier particles or droplets.

- Particle Removal: Depending on the specific design and application, the collected particles or droplets at the bottom of the cyclone can be periodically removed through a valve or other means.

In summary, the cyclone separator’s working principle revolves around creating a swirling motion within the chamber, which generates centrifugal forces that push the heavier particles or droplets outward against the walls. The combined effects of the swirling motion and gravity cause the separated particles to spiral downward and collect at the bottom, while the clean gas or liquid continues its upward flow through the central axis.

cyclone separator design

The design of a cyclone separator involves several key considerations to ensure efficient particle separation and optimal performance. Here are the main factors that go into designing a cyclone separator:

- Cyclone Dimensions: The dimensions of the cyclone, including its diameter and length, play a significant role in determining its capacity and efficiency. Larger cyclones can handle higher flow rates and larger particles, while smaller cyclones are better suited for finer particle separation.

- Inlet Design: The design of the inlet affects how the gas or liquid mixture enters the cyclone chamber. A tangential inlet introduces the mixture in a swirling motion, which is crucial for establishing the cyclonic vortex. The angle of the tangential entry and the design of the entry nozzle impact the efficiency of particle separation.

- Vortex Finder Design: The height, diameter, and shape of the vortex finder can influence the separation efficiency. A well-designed vortex finder guides the clean gas or liquid stream upward while allowing particles to settle downward.

- Cone Angle: The angle of the cone at the bottom of the cyclone affects the downward movement of particles. Steeper cone angles can enhance particle settling, but there’s a trade-off with pressure drop. Shallower angles reduce pressure drop but might impact separation efficiency.

- Collection Mechanism: The design of the collection area, which gathers the separated particles or droplets, should facilitate easy removal and maintenance. This could involve using a hopper, bin, or similar structure.

- Outlet Design: The outlet for the clean gas or liquid should be properly sized and positioned to ensure smooth flow and prevent particle re-entrainment. The angle and position of the outlet affect the separation efficiency.

- Flow Velocity: The design should ensure that the gas or liquid flow velocity falls within an optimal range, typically between 10 and 20 m/s. This range promotes efficient particle separation without compromising performance.

- Material Selection: The materials used in the construction of the cyclone separator should be chosen based on factors such as chemical compatibility, temperature, and abrasion resistance. Some cyclones might also have wear-resistant coatings on internal surfaces.

- Pressure Drop: The pressure drop across the cyclone is a critical parameter. While some pressure drop is necessary for effective particle separation, excessively high pressure drop can impact overall system efficiency. Balancing pressure drop with separation efficiency is essential.

- Gas-Liquid Separation (If Applicable): In cases where both gas and liquid phases need to be separated, the design may include additional components, such as mist eliminators, to achieve effective separation.

- Multiphase Separation (If Applicable): For situations where multiple phases (e.g., solid particles, liquid droplets, and gas) need to be separated simultaneously, a more complex cyclone design may be required.

- Scale and Application: The cyclone design should match the scale of the operation and the specific application requirements. Industrial applications, laboratory-scale processes, and specialized industries might have distinct design considerations.

Cyclone separator design involves a balance between various factors to achieve the desired level of separation efficiency while considering operational constraints. Computer simulations and modeling are often used to optimize cyclone designs before physical construction and testing.

application of cyclone separator

Cyclone separators find a wide range of applications across various industries due to their efficiency in separating solid particles or liquid droplets from gas or liquid streams. Some common applications of cyclone separators include:

- Industrial Dust Collection: Cyclone separators are extensively used in industries such as woodworking, metalworking, mining, and cement manufacturing to remove dust and particulate matter from air or gas streams. This helps improve air quality in workplaces and reduces the risk of dust-related health issues.

- Power Generation: In power plants, cyclone separators are used to capture fly ash from the flue gases produced during the combustion of coal or other fuels. This helps prevent pollution and environmental contamination.

- Chemical Processing: Cyclone separators are employed in chemical plants to separate solid particles from liquid suspensions. They are also used to recover or remove catalyst particles from various chemical reactions.

- Oil and Gas Industry: Cyclone separators are used to remove sand, particles, and water droplets from natural gas and crude oil streams. This enhances the quality of the extracted oil and gas and prevents equipment corrosion.

- Food Processing: Cyclone separators are used to separate food particles from air or liquid streams in the food processing industry. They can help maintain hygiene standards and ensure the purity of food products.

- Agriculture: Cyclone separators are used in grain handling and processing facilities to separate dust, chaff, and other impurities from grain and seed materials.

- Pharmaceutical Industry: Cyclone separators are employed to separate fine particles from air streams in pharmaceutical manufacturing processes. This helps maintain product quality and cleanliness.

- Pneumatic Conveying: Cyclone separators are often used in pneumatic conveying systems to separate solid particles from the conveying air, ensuring the efficient and clean transfer of materials.

- Waste Management: Cyclone separators are utilized in waste treatment facilities to separate solid particles from liquid effluents, aiding in waste management and environmental protection.

- Automotive Industry: In automotive paint shops, cyclone separators can be used to remove overspray particles from the paint booth exhaust, ensuring a cleaner environment and better paint application.

- Mining and Mineral Processing: Cyclone separators are employed in the mining industry to separate valuable minerals from ore slurry and to remove unwanted particles from mineral processing streams.

- Air Conditioning and Ventilation: In HVAC systems, cyclone separators can be used to remove larger particles from air streams before they reach filters, thus extending the lifespan of filters and improving system efficiency.

These are just a few examples of the many applications of cyclone separators in various industries. The versatility and efficiency of cyclone separators make them valuable tools for achieving particle separation and maintaining the cleanliness and quality of gas and liquid streams.

Advantages of cyclone separator

Cyclone separators offer several advantages that make them a popular choice for particle separation and removal in various industries. Some of the key advantages of cyclone separators include:

- Simple Design: Cyclone separators have a relatively simple design, which makes them easy to install, operate, and maintain. They consist of a few main components, such as an inlet, cyclonic chamber, and outlet, reducing the complexity of the equipment.

- Cost-Effectiveness: Due to their simple design and fewer components, cyclone separators are often more cost-effective than more complex separation systems. They can provide efficient particle separation without the need for extensive maintenance or specialized parts.

- High Particle Removal Efficiency: Cyclone separators are effective at removing larger and heavier particles from gas or liquid streams. They can achieve high separation efficiencies for particles within a certain size range.

- Low Maintenance Requirements: Cyclone separators have few moving parts and are less prone to mechanical failures. This results in lower maintenance requirements and reduced downtime compared to more intricate separation systems.

- Compact Size: Cyclone separators are relatively compact compared to some other types of particle separation equipment. This makes them suitable for installations where space is limited.

- No Consumables: Cyclone separators do not require filter media or consumables for operation. This eliminates the ongoing cost of replacing filters or other materials that might be needed in alternative separation methods.

- Versatility: Cyclone separators can handle a wide range of particle sizes and types. While they are more efficient at removing larger particles, they can still provide some level of separation for smaller particles.

- High-Temperature Applications: Cyclone separators can be designed to handle high-temperature gas streams, making them suitable for applications in industries like power generation and metallurgy.

- Low Energy Consumption: Cyclone separators typically have low energy requirements. They rely on the natural swirling motion of the gas or liquid stream to achieve separation, which reduces the need for additional energy input.

- Robustness: Cyclone separators can handle abrasive and erosive particles without significant wear. This makes them suitable for applications where the separated particles might be abrasive to other equipment.

- Prevention of Filter Clogging: When used as a pre-filtering step, cyclone separators can prevent larger particles from reaching downstream filters, thus extending the lifespan of those filters and reducing maintenance needs.

- Environmental Benefits: Cyclone separators can be used as a part of pollution control systems to reduce emissions and improve air quality. They help industries comply with environmental regulations by removing particulate matter from exhaust gases.

Overall, the advantages of cyclone separators make them a reliable and efficient choice for particle separation needs in various industries, particularly where simple, cost-effective, and low-maintenance solutions are desired.

Disadvantages of cyclone separator

While cyclone separators offer several advantages, they also have some limitations and disadvantages that should be considered when selecting them for specific applications. Here are some of the disadvantages of cyclone separators:

- Limited Efficiency for Small Particles: Cyclone separators are more efficient at removing larger particles due to their reliance on centrifugal force. They may struggle to effectively separate very fine particles from gas or liquid streams.

- Particle Loading: If the particle loading is too high, a cyclone separator’s efficiency can decrease. This might lead to particles escaping with the clean gas or liquid stream, reducing the desired separation quality.

- Inlet Flow Variations: Cyclone separators can be sensitive to variations in inlet flow rates and conditions. Sudden changes in flow can impact the separation efficiency and cause particles to escape.

- Space Requirements: While cyclone separators are generally compact, multiple cyclones might be needed for efficient separation of particles across a wide range of sizes. This could require additional space.

- Pressure Drop: Cyclone separators can cause a pressure drop in the system due to the swirling motion and the change in flow direction. This pressure drop might affect the overall system efficiency.

- High-Speed Particles: If the incoming particles have high velocities, they might not follow the expected cyclonic flow pattern, reducing the separation efficiency.

- Limited Liquid Removal: Cyclone separators are more efficient at separating solid particles from gas streams. While they can separate liquid droplets to some extent, they might not be suitable for applications requiring high-efficiency liquid removal.

- Abrasion and Wear: In applications involving abrasive particles, the inner surfaces of the cyclone chamber can experience wear over time, potentially leading to reduced efficiency or the need for more frequent maintenance.

- Complex Particle Mixtures: If the particle mixture contains a wide range of sizes, densities, or shapes, achieving consistent and efficient separation in a cyclone separator can be challenging.

- Requirement for Precise Design: The design of a cyclone separator needs to be tailored to the specific application and particle characteristics to achieve optimal performance. Poor design can lead to reduced efficiency.

- Collection of Separated Particles: Depending on the application, collecting the separated particles from the bottom of the cyclone chamber can require manual intervention or additional equipment.

- Combining with Other Technologies: In some cases, a cyclone separator might need to be combined with additional separation technologies, such as filters or scrubbers, to achieve the desired level of particle removal.

- Gas Turndown Ratio: Cyclone separators might not work efficiently across a wide range of gas flow rates. They often have a limited turndown ratio, meaning they work best within a certain flow range.

Despite these disadvantages, cyclone separators remain a valuable tool in various industries for achieving particle separation and removal. It’s essential to carefully evaluate the specific application’s requirements and characteristics to determine if a cyclone separator is the most suitable choice or if a different separation method should be considered.

Reference : https://en.wikipedia.org/wiki/Cyclonic_separation