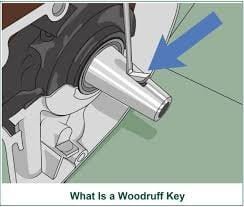

What is Woodruff Key ?

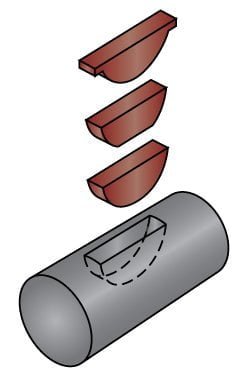

A Woodruff Key is a halfmoon shaped machine key that prevents gears, hubs, or other components from moving independently of a rotating shaft or spindle. They also serve as a failsafe, preventing expensive parts from shearing under extreme loads. The crescent profile of the key allows it to sit deeper in the shaft, reducing the likelihood of the key rolling laterally out of the groove.

The Woodruff Key is a semi-circular disc that fits into a circular recess in the shaft machined by the Woodruff keyway cutter. The shaft can be parallel or tapered, as shown by the method of dimensioning shafts for the Woodruff key, which includes the depths of the recess from the shaft’s outsides as well as the diameter of the recess.

Woodruff keys have the advantage of turning themselves into their circular recess to accommodate any tapers in the assembly’s mating hub; however, it cannot be used as a pawn key because it would jam.

Why use Woodruff Key ?

Woodruff is used preventing gear, hubs or other components from moving indepently of a rotating shaft or spindle.

HOW DOES A WOODRUFF KEY WORK?

When it is installed, the woodruff key’s long, flat face protrudes above the host shaft. The protruding section of the key locks components together when a mating hub, gear, or other component is pressed onto the shaft.

It is very important that the key is somewhat comfortable and stable on the main seat. The curved profile on the bottom can cause the key to slide out of the key seat if the key is not good/steady.

Because of the additional depth in the shaft, the strength capability is likely to be weakened. And, because of the increased depth of the key, it fits directly into the mating part, with no gap between them.

Installation of Woodruff Key

When you are installing a woodruff key

- First, align the key with the shaft’s pocket

- manually press the key into the shaft with force.

- If it doesn’t fit with the keyway, hammer the key with light force to fix it, being careful not to break it.

Once it’s in the shaft, align the top with the flat side of the key so that it’s parallel to the host shaft. To obtain the proper assembly, we can move the hub or shaft into each other with the key, depending on the condition.

Woodruff keys sometimes pop out of their grooves during installation as the mating component is pressed. This can make installing Woodruff keys difficult. So we can assemble the shaft and coupling by lightly striking it with a hammer.

How to keep Woodruff in a place ?

To keep a woodruff key in place while installing a mating component, make sure it is firmly seated in the key seat. Because woodruff keys are made to tight tolerances, they frequently require a press fit into their seat. This is accomplished by lightly tapping the flat, protruding face of the key with a hammer or mallet until the key is securely seated. The key will still extend above the surface of the mating shaft to lock the mating hub or gear in place. If the key still falls or slips out during component installation, it is most likely too small for the host groove.

Selection of Woodruff Key

Before selecting, It is very important to understand the different features of a woodruff key and it’s applications. Some considerations include

- Key types

- Key materials, and

- Key finish.

What Are The Different Types Of Woodruff Keys?

The two most common types of woodruff keys are full radius and flat bottom. Both perform the same function but may be better suited to different applications. It is important to note that both radius and flat bottom woodruff keys are standard, and either is shipped at the manufacturer’s discretion.

The following are the various types of woodruff keys:

- Full radius keys

- Flat bottom

- Hi-pro keys

1. Full radius

Full radius are half circles that make full contact with the groove seat. Full radius woodruff keys necessitate seat groove precision because contact between the woodruff key and the bottom of the seat can cause interference and the key to protrude from the groove higher than desired.

2. Flat bottom

Flat bottom have the same profile as standard woodruff keys, but the bottom of the key has been shaved flat. The flat bottom reduces the possibility of interference at the seat’s bottom, allowing the woodruff key to seat fully in the groove and alleviating potential clearance issues caused by excessive key height.

3. Hi-pro keys

HiPro keys are a type of woodruff key that has a full radius but also has feet. When it is installed in the shaft, the feet extend over the face of the host shaft, and did the work of preventing the key from rocking in its rounded seat.

High pro keys are a variation on Woodruff keys that have a full radius but also have two legs. The High Pro key has a full half-circular shape on the bottom and a slightly different profile on top.

The steps are on a flat part at the top for support while the parts are being assembled. The legs extend over the face of the host shaft when installed, preventing the key from moving in its round seat.

Woodruff key cutter

A key cutter is required to attach a part to a shaft. A key cutter, also known as a woodruff cutter, is a necessary tool for cutting keyways for woodruff keys. The teeth are not side cutting and the edges are slightly hollow for woodruff cutter relief.

A key is inserted into the seat after cutting the keyway into the shaft, and the two parts can now be joined together. This method is used for parts like gears, hubs, and pulleys.

For woodruff keys, a woodruff key slot milling cutter is typically used. These instruments are made from high-quality raw materials that are regarded as having world-class quality and performance. A 5 % percent cobalt high-speed steel tool suitable for general cutting on all materials.

Why do Woodruff keys use?

Because it is easily fixed in the shaft’s circular opening or recess, it can be adjusted to taper into the mating hub. As a result of the elimination of milling near the shaft shoulder, it reduces stress concentration in that area.

When it is half semi-circular in shape, it is easily removed by applying moderate pressure to the edge with a hammer. As a result, the circular slot forces the key out of the slot. Standard keys, on the other hand, require axial force to deflect.

Woodruff keys are also nearly as small as heavier keys and may not withstand the same amount of weight. They’re used for light-duty applications like mounting taper-bore components on tapered shaft ends.

Woodruff key materials

Woodruff keys are crafted in carbon, alloy, and stainless steel.

- Carbon

- Alloy and

- Stainless steel

Both carbon and alloy steel are strong, but they must be plated or coated to prevent corrosion. In terms of corrosion resistance, stainless steel outperforms carbon and alloy steel, but it is not so strong.

Woodruff key finishes

Woodruff keys are available in a variety of finishes. Finishes contains Plain, clear, yellow zinc, and passivated.Plain finish :- Plain finish is available on carbon steel and alloy steel woodruff keys. This finish is an economical solution for keys. This will not be subjected to corrosive elements.

1. Plain finish :- Plain finish is available on carbon steel and alloy steel woodruff keys. This finish is an economical solution for keys. This will not be subjected to corrosive elements.

2. Zinc plated woodruff keys :- zinc plated woodruff keys are carbon steel keys that have been plated in either yellow or clear zinc.The zinc plating offers an increased level of the corrosion resistance as compared to plain parts.

Passivated finish :- Passivated finish is a type of oxidation process used on stainless steel parts. This microfilm is added to the already resilient material to provide additional corrosion resistance.

HOW ARE WOODRUFF KEYS MEASURED?

Woodruff keys, particularly inch woodruff keys, can be difficult to measure. Use the infographic below to learn which measurements are required to order the correct woodruff key.

Advantages of Woodruff key

- Easily adjustable :- You can easily adjust them with these keys, which are also quite simple. They are also simple and easy to remove.

- There is no gap between the shaft and the key because it is properly fitted. As a result, the stress concentration is reduced, and the shaft’s safety is improved.

- These keys are ideal for high-speed operating systems.

- They can lean into the main seat or keyway and it is able to adjust the taper in the hub keyway.

- They can offer a more precise fit while also reducing movement in the key seat.

- The deep seat in the shaft reduces the possibility of the main seat rolling over.

Disadvantages of Woodruff Key

- It is not used where there is a high load carrying capacity.

- If the keys have an extra depth of keyway into shaft, this may cause increase of the stress concentration and reduce its strength.

- Because of its groove design, the Woodruff key is quite difficult to install.

- The key does not allow axial motion between the shaft and the hub.

- They are not used for transmitting high torque, as multi-groove and V belt pulleys are.

Frequently Asked Questions

What is the purpose of a Woodruff Key?

The purpose of woodruff key is used to prevents gear gears, hubs, or other components from moving independently of a rotating shaft or spindle.

They also serve as a failsafe, preventing expensive parts from shearing under high loads.

Why is it called a woodruff key?

Named after the Woodruff Manufacturing Co, in Hartford, Connecticut, who first manufactured it in 1892.

What is a woodruff key slot?

Metric Woodruff Keys are semicircular keyways that are used to secure rotating elements to shafts. Woodruff Keys fit into a rounded slot cut into a shaft, and when a pulley or sprocket with a slot cut into it is installed onto the shaft, the slot slides over the woodruff key, resulting in an assembly that rotates as a single unit.

Can Woodruff key be used as feather?

The disadvantages or drawbacks of woodruff keys include the fact that the depth of the keyway weakens the shaft, that it cannot be used as a feather key, and that it is difficult and small to install. Installing two or more Woodruff keys to lift the majority of the load is costly and complicates installation.

How tight should a Woodruff key be?

It is important for key to be somewhat snug and stable in the key seat. If the key is not snug/stable, it can easily slide out of the key seat due to the curved profile on the bottom.

Who invented the Woodruff key

This types of key was developed by W.N. Woodruff, who was awarded the John Scott Medal by the Franklin Institute for his invention in 1888.

How do you remove a Woodruff key?

- Using a gear puller

- By using hand with the help of hammer

What does a Woodruff key look like?

Woodruff keys are semicircular in shape, with a protruding tab when installed. The keyway in the shaft is a semi-circular pocket, with a longitudinal slot as the mating part. They are used to increase the concentricity of the shaft and the mating part, which is essential for high-speed operation.

What is sunk key ?

In machinery, a key that fits into keyways in both the shaft and the secured member.

| IC Engine | Important PDFs | Boilers | Synergy Maritime Exam | Naval Arch | MEO Class 4 |

| Interview Questions | Difference Between | Types of Pumps | Auxiliary Machines | Types of Valves | Home |