what is pressure reducing valve

A pressure reducing valve (PRV), also known as a pressure regulator, is a mechanical device used to control and reduce the pressure of a fluid, typically a liquid or gas, as it flows through a pipeline or system. The primary purpose of a pressure reducing valve is to maintain a consistent and predetermined lower pressure downstream of the valve, regardless of fluctuations or variations in the incoming pressure.

Pressure Reducing Valve working principle

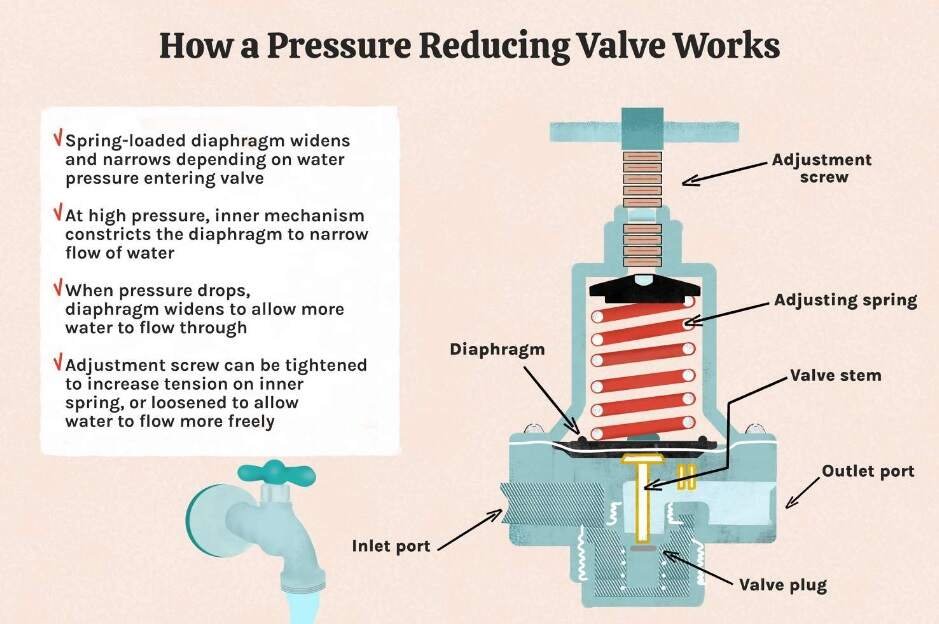

The working principle of a pressure reducing valve (PRV) is based on the balance between the force exerted by the inlet pressure and the force exerted by a controlled spring mechanism. The PRV maintains a consistent downstream pressure by adjusting the valve’s opening based on changes in the inlet pressure. Here’s how a typical pressure reducing valve works:

Inlet Pressure Adjustment: The PRV is installed in a pipeline or system where the inlet pressure (higher pressure) is greater than the desired downstream pressure (lower pressure).

Spring Mechanism: Inside the PRV, there’s a spring-loaded diaphragm, piston, or other mechanism that responds to pressure differentials. The spring is preloaded based on the desired downstream pressure.

Balancing Forces: The force exerted by the spring opposes the force created by the inlet pressure acting on a valve mechanism. The valve is held closed by the spring force. As the inlet pressure increases, it tries to push the valve open.

Adjustment Screw or Knob: Many PRVs have an adjustment screw or knob that allows users to set the desired downstream pressure. Turning the adjustment screw changes the tension of the spring, thus altering the balance between the spring force and the inlet pressure force.

Opening and Closing: When the inlet pressure exceeds the tension set by the spring force, the valve starts to open, allowing fluid to pass through. As the fluid flows through the valve, the pressure downstream of the valve decreases.

Pressure Equilibrium: As the downstream pressure approaches the setpoint, the spring force and the force exerted by the inlet pressure reach a balance. The valve modulates its opening to maintain this equilibrium and stabilize the downstream pressure.

Steady-State Operation: Once the pressure downstream of the valve reaches the setpoint, the valve remains in a partially open state to regulate the flow and maintain a consistent pressure level, even if the inlet pressure fluctuates.

Pressure Reduction: The valve continues to adjust its opening based on changes in the inlet pressure. If the inlet pressure decreases, the valve closes slightly to maintain the desired downstream pressure. If the inlet pressure increases, the valve opens further to prevent pressure from rising above the setpoint.

By continuously adjusting its opening based on the inlet pressure changes, the PRV ensures that the downstream pressure remains within the specified range, providing a controlled and safe pressure for downstream equipment and processes. The ability to modulate its opening makes PRVs crucial for maintaining stable pressure levels in various fluid and gas systems.

Types of pressure reducing valve

There are several types of pressure reducing valves (PRVs), each designed to suit specific applications and requirements. Here’s an overview of some common types of PRVs along with their details:

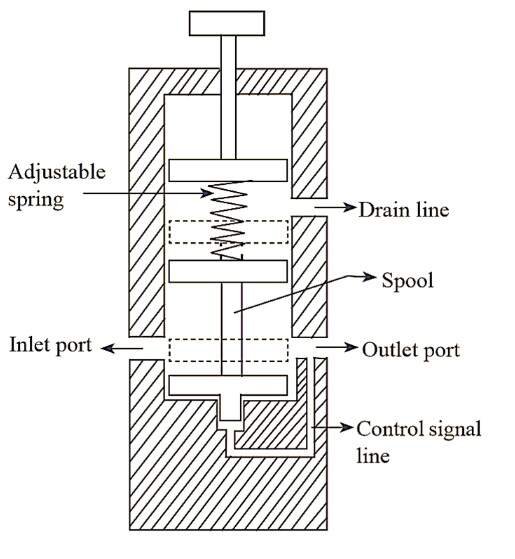

1.Direct Acting Pressure Reducing Valve:

- Working Principle: This is a basic type of PRV where the downstream pressure is sensed directly. As the downstream pressure increases, it pushes against a diaphragm or piston, compressing a spring and causing the valve to close.

- Advantages: Simple design, suitable for low to medium pressure applications, relatively inexpensive.

- Limitations: May not be suitable for high-pressure applications due to the limitations of the spring mechanism.

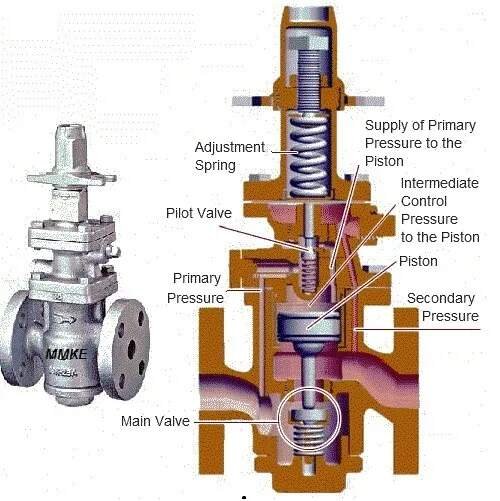

2.Pilot Operated Pressure Reducing Valve:

- Working Principle: In this type, a pilot valve controls the main valve. The pilot valve senses the downstream pressure and uses it to control the main valve’s opening and closing, often using a diaphragm and spring mechanism.

- Advantages: Suitable for a wide range of pressure levels, provides more precise control, can handle higher pressure differentials.

- Limitations: More complex design, may require additional maintenance due to pilot valve components.

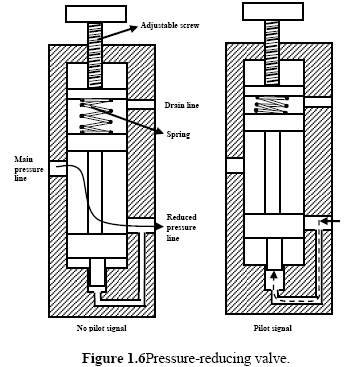

3.Externally Piloted Pressure Reducing Valve:

- Working Principle: Similar to the pilot-operated valve, but the pilot valve is located externally. This allows for remote control and adjustment of the valve’s operation.

- Advantages: Offers greater flexibility in control, particularly in situations where direct access to the valve might be challenging.

- Limitations: Similar to pilot-operated valves, with potential complexity and maintenance considerations.

4.Self-Actuated Pressure Reducing Valve:

- Working Principle: These valves use the flow of fluid through the valve to control its operation. An increase in flow leads to the valve opening, reducing pressure.

- Advantages: No external power source needed, works well in applications with varying flow rates.

- Limitations: Flow-dependent operation might lead to less precise pressure control compared to pilot-operated valves.

5.Balanced Pressure Reducing Valve:

- Working Principle: These valves are designed to reduce the effects of variations in the inlet pressure on the valve’s operation. They maintain a more consistent downstream pressure regardless of fluctuations in the inlet pressure.

- Advantages: Effective in applications where the inlet pressure can vary widely, provides stable outlet pressure.

- Limitations: More complex design, might be larger and costlier than standard PRVs.

6.Pressure Reducing Valve with Integral Bypass:

- Working Principle: These valves include a built-in bypass that allows a controlled amount of fluid to bypass the valve. This can help maintain a minimum flow rate and prevent issues like cavitation.

- Advantages: Prevents damage from low flow conditions, suitable for applications with varying demand.

- Limitations: Adds complexity to the valve, might require additional maintenance.

These are just a few examples of the different types of pressure reducing valves available. The choice of PRV type depends on factors such as the required pressure range, flow rates, accuracy of control, system design, and specific application requirements.

application of pressure reducing valve

Pressure reducing valves (PRVs) have a wide range of applications across various industries. Their main purpose is to regulate and control fluid pressure, ensuring that downstream systems operate safely and efficiently. Here are some common applications of pressure reducing valves:

- Water Distribution: In municipal water supply systems, PRVs are used to maintain consistent and safe water pressure for residential, commercial, and industrial users. They ensure that water pressure remains within acceptable limits, preventing damage to pipes, appliances, and fixtures.

- Steam Systems: PRVs are crucial in steam distribution systems to control the pressure of steam supplied to various processes and equipment. This helps prevent equipment damage, steam leaks, and safety hazards associated with high-pressure steam.

- Gas Distribution: PRVs are used in natural gas and propane distribution systems to regulate gas pressure for residential and commercial appliances like stoves, heaters, and industrial burners. They ensure that gas is delivered at the appropriate pressure for safe and efficient combustion.

- Industrial Processes: Many industrial processes require specific pressure levels for optimal operation. PRVs are used in various applications such as chemical processing, food and beverage production, pharmaceutical manufacturing, and more.

- Fire Protection Systems: In fire sprinkler systems, PRVs maintain the required pressure to ensure effective operation in case of a fire. They help ensure that water is distributed evenly and at the correct pressure throughout the system.

- Boilers: PRVs are critical safety components in boilers. They release excess pressure to prevent explosions caused by the buildup of steam pressure beyond safe limits.

- HVAC Systems: Pressure reducing valves can be found in heating, ventilation, and air conditioning systems to regulate the pressure of refrigerants or other fluids, ensuring optimal system performance.

- Agriculture: In irrigation systems, PRVs are used to control water pressure in order to efficiently distribute water to crops and prevent damage to irrigation equipment.

- Automotive Industry: PRVs are used in automotive applications to regulate fuel pressure in fuel injection systems, ensuring the right fuel pressure for efficient combustion.

- Hydraulic Systems: PRVs are employed in hydraulic systems to control the pressure of hydraulic fluids, preventing damage to components and ensuring precise control in machinery and equipment.

- Pneumatics: In pneumatic systems that use compressed air, PRVs maintain consistent air pressure for various tools and equipment, ensuring their proper functioning.

- Diving and Subsea Applications: PRVs are used in diving equipment and subsea systems to regulate the pressure of breathing gases and other fluids, ensuring the safety of divers and the proper operation of equipment.

These are just a few examples of the many applications of pressure reducing valves. In each case, the PRV plays a critical role in maintaining safe and efficient operation by controlling fluid pressure according to specific requirements.

advantages of pressure reducing valve

Pressure reducing valves (PRVs) offer several advantages in various applications where pressure control is crucial. Here are some key advantages of using pressure reducing valves:

- Equipment Protection: PRVs prevent downstream equipment from being exposed to pressures that could cause damage or malfunction. By maintaining a controlled and safe pressure level, PRVs extend the lifespan of equipment, reducing maintenance and replacement costs.

- Safety: One of the primary functions of PRVs is to ensure the safety of systems and processes. They prevent overpressure situations that could lead to catastrophic failures, explosions, or other hazardous events.

- Energy Efficiency: PRVs help optimize energy consumption by maintaining the required pressure without excessive pressure buildup. This is particularly important in systems where excessive pressure could lead to energy wastage.

- Consistent Performance: In applications such as water distribution or industrial processes, maintaining a consistent pressure level is crucial for proper performance and product quality. PRVs ensure that pressure fluctuations are minimized.

- Regulatory Compliance: Many industries and applications have regulatory standards for pressure levels. PRVs assist in meeting these standards and ensuring compliance with safety and quality regulations.

- Preventing Water Hammer: In water supply systems, sudden changes in pressure can lead to water hammer, which is a rapid increase in pressure that can damage pipes and fittings. PRVs help prevent water hammer by maintaining a steady pressure.

- Appliance Protection: In residential and commercial settings, appliances such as water heaters, dishwashers, and washing machines have pressure limits. PRVs prevent these appliances from experiencing pressures beyond their design specifications.

- Reduced Noise: Fluctuations in pressure can lead to noise in pipelines and equipment. PRVs contribute to a quieter working environment by maintaining a steady pressure.

- Process Control: Many industrial processes require precise pressure levels for optimal performance. PRVs provide accurate pressure control, leading to consistent product quality and process efficiency.

- Emergency Pressure Relief: PRVs can also act as a form of emergency pressure relief in case of system malfunctions or unexpected pressure spikes. They help prevent system damage or accidents during such situations.

- Versatility: PRVs come in various sizes, materials, and designs to suit a wide range of applications and industries. This versatility allows them to be integrated into different systems effectively.

- Reduced Water and Resource Waste: In water supply systems, PRVs help regulate pressure, reducing the likelihood of leaks and water wastage. This is particularly important in regions with water scarcity.

- Customizable Pressure Settings: PRVs often have adjustable pressure settings, allowing users to set the desired downstream pressure according to specific requirements.

In summary, pressure reducing valves offer a combination of safety, efficiency, and equipment protection benefits, making them essential components in many fluid and gas systems.

disadvantages of pressure reducing valve

While pressure reducing valves (PRVs) offer numerous advantages, they also come with some potential disadvantages and limitations that need to be considered in various applications. Here are some disadvantages of pressure reducing valves:

- Pressure Drop: One of the primary disadvantages of PRVs is that they create a pressure drop across the valve. The valve restricts the flow of the fluid or gas, leading to a decrease in pressure downstream of the valve. This pressure drop could affect the efficiency of certain processes or systems that require higher pressures.

- Flow Limitations: PRVs have a specific flow capacity that they can handle. If the flow rate exceeds this capacity, the valve might not be able to maintain the desired downstream pressure effectively, leading to pressure fluctuations.

- Cavitation and Noise: Under certain conditions, pressure reducing valves can cause cavitation—a phenomenon where vapor bubbles form and collapse due to rapid pressure changes. This can create noise, vibrations, and damage to the valve and piping.

- Precision and Sensitivity: Some PRVs, especially those used in processes requiring precise pressure control, might be sensitive to changes in the upstream pressure. Variations in the inlet pressure could lead to inaccurate downstream pressure control.

- Maintenance: PRVs, like any mechanical devices, require regular maintenance to ensure they function correctly. Debris, sediment, or corrosion can affect the valve’s performance over time, leading to malfunctions.

- Selection Complexity: Choosing the right PRV for a specific application can be challenging. Factors such as flow rate, pressure range, material compatibility, and environmental conditions need to be carefully considered to ensure proper functioning.

- Temperature Sensitivity: Some pressure reducing valves might be sensitive to temperature changes, which can impact their accuracy and reliability in maintaining the desired downstream pressure.

- Installation Challenges: Incorrect installation or improper sizing of PRVs can lead to inefficiencies, pressure fluctuations, and even damage to the valve or the system.

- Cost: High-quality pressure reducing valves can be relatively expensive, especially those designed for precise pressure control in critical applications. Additionally, the cost of installation, maintenance, and occasional replacement needs to be factored into the overall cost.

- Complex Systems: In some cases, pressure regulation might require more complex systems involving multiple PRVs, bypass lines, and control mechanisms. These systems can be intricate to design, install, and maintain.

- Limited Pressure Range: Some pressure reducing valves might have limitations in terms of the pressure range they can effectively control. Extremely high or low pressures might require specialized or custom solutions.

- Compatibility Issues: PRVs need to be compatible with the fluid or gas they are regulating. Corrosive or abrasive substances can damage the valve over time, affecting its performance.

It’s important to carefully assess the advantages and disadvantages of pressure reducing valves in the context of your specific application to determine whether they are the right choice for your system. Proper design, installation, and maintenance can help mitigate some of these disadvantages and ensure optimal performance.

pressure reducing valve Vs Pressure Relief Valves

Here’s a comparison of Pressure Reducing Valves (PRVs) and Pressure Relief Valves (PRVs) in table form:

| Aspect | Pressure Reducing Valve (PRV) | Pressure Relief Valve (PRV) |

|---|---|---|

| Purpose | Maintain a steady downstream pressure by regulating the flow to reduce the incoming pressure to the desired level. | Protect systems from overpressure situations by releasing excess pressure to prevent damage or catastrophic failure. |

| Operation | Modulates the valve opening based on the difference between inlet and desired outlet pressure. | Remains closed until the pressure exceeds a set threshold, then rapidly opens to release excess pressure. |

| Main Application | Fluid or gas systems where controlled downstream pressure is required for operational efficiency and equipment protection. | Systems where the pressure might unexpectedly rise due to equipment malfunction, thermal expansion, or other factors. |

| Setpoint | Adjustable by users to achieve the desired outlet pressure. | Set to a predetermined pressure threshold, typically based on system design and safety standards. |

| Valve Behavior | Reduces pressure gradually to maintain a controlled and steady outlet pressure. | Rapidly opens when the pressure exceeds the setpoint, then closes once pressure returns to normal. |

| Components | Diaphragm, piston, spring, and adjustment mechanism for pressure control. | Spring-loaded mechanism with a valve disc that opens against the spring force when pressure exceeds the setpoint. |

| Pressure Control Range | Suitable for regulating pressures within a specific range, providing a consistent outlet pressure. | Designed to respond to pressure spikes and prevent pressure from exceeding a certain level. |

| System Impact | Helps optimize system efficiency and equipment lifespan by maintaining a stable pressure. | Prevents system damage or failure by preventing overpressure events, but doesn’t contribute to efficiency. |

| Common Applications | Water distribution, steam systems, gas pipelines, industrial processes requiring controlled pressure. | Boiler systems, storage tanks, pipelines, where sudden pressure surges or overpressure events can occur. |

| Failure Response | Gradual adjustment to maintain pressure within the set range. | Rapid opening to release excess pressure, closing once pressure stabilizes. |

| Safety Aspect | Focuses on maintaining a safe operational pressure to protect equipment. | Focuses on preventing catastrophic failures and ensuring safety during pressure spikes. |

| Leakage | Designed to minimize leakage to maintain consistent pressure. | Typically discharges fluid or gas when pressure exceeds the setpoint. Leakage might be a concern. |

| Valve Types | Direct-acting, pilot-operated, balanced, etc. | Safety relief, pilot-operated relief, rupture disc (bursting disc), etc. |

Both Pressure Reducing Valves and Pressure Relief Valves serve critical roles in different aspects of fluid and gas systems. PRVs ensure steady and controlled operational pressure, while PRVs protect systems from dangerous pressure levels. The choice between them depends on the specific needs of the application.

Check Out Other Important Topics

| IC Engine | Important PDFs | Boilers | Synergy Maritime Exam | Naval Arch | MEO Class 4 |

| Interview Questions | Difference Between | Types of Pumps | Auxiliary Machines | Types of Valves | Home |