In this article we will learn about different types of forging tools and equipment along with their images and their uses.

1. Furnace or Hearth

Blacksmiths use forging tools to heat metal pieces. They usually have four legs, a cast iron or steel body, an iron bottom, a chimney, and a blower.

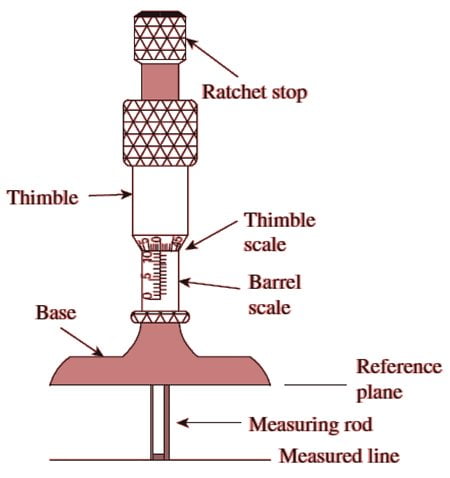

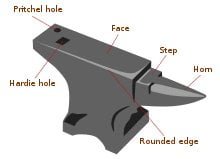

2. Anvil

The anvil is a type of forging tool that forms a support for blacksmiths work when hammering. It is used to perform different operations like, flatting metal surfaces and obtaining shapes with the used of hammer. The body of anvil is made up of steel with a tool steel face welded on the body, but the break or horn used for bending curves is not steel faced. The round hole in the anvil is called pritchel hole, which is used for bending rods of small diameter, and as a die for hot punching operations. The square or Hardie hole is used for holding square shanks of various fittings.

Anvils vary up to about 100 to 150 kg and should stand with the top face about 0.75 m from the floor. This height may be attained by resting the anvil on a cast iron or wooden base.

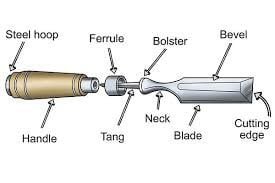

3. Chisels

Chisels are the forging tools used for cutting metals and for nicking prior to breaking. They may be hot or cold depending on whether the metal to be cut is hot or cold. The main difference between the two is in the edge. The edge of a cold chisel is hardened and tempered with an angle of about 60°, whilst the edge of a hot chisel is 30° and the hardening is not necessary. The edge is made slightly rounded for better cutting action.

It is made of high petroleum steel, has an octagonal cross-section, and one end has a tapered cutting edge. There are two types of chisels used in forging: hot and cold chisels. Hot forging is done with a hot chisel, and cold forging is done with a cold chisel.

4. Tongs

These types of forging tools are used to transport heated metal to the anvil. Tongs come in a variety of shapes and sizes to allow for proper gripping of various metal shapes and sizes.

The work to be forged is generally held with tongs. The tongs generally used for holding work are :

1. The gad tong used for general pick-up work, either straight or tapered

2. The straight-lip fluted tong used for square, circular and hexagonal bar stock.

3. The ring tong used for bolts, rivets and other work of circular section.

4. The flat tong used for holding work of rectangular section.

5. Hammer

Hammers are Smith tools that can be used in a variety of ways depending on the type of forging required, such as hot forging, cold forging, closed die forging, upset forging, press forging, and so on. The hammer is a forging tool that is used to shape work pieces. It is a striking tool that comes in two varieties: drop hammer and power hammer.

Hand hammers : Two kinds of hammers are used in hand forging: (1) the hand hammer used by the smith himself, and (2) the sledge hammer used by the striker (Fig. 8.5)

Hand hammers may be classified as : (a) Ball peen hammer (b) Straight peen hammer, and (c) Cross peen hammer. Hammer heads are made of cast steel, the ends hardened and tempered. The striking face is slightly convex. The weight of a hand hammer varies from about 0.5 to 2 kg while the weight of a sledge hammer varies from 4 to 10 kg.

6. Swage Block

This forging equipment is made of a rectangular cast iron or cast steel block with several holes in it. The holes come in a variety of sizes and shapes.

This forge shop tool is used for mainly squaring, sizing, heading, bending and forming operations. It is 0.25 m or more wide and may be used either flat or edgewise in its stand.

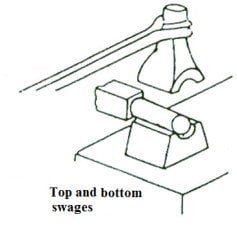

7. Swage

Swage are the forging tools that gives various shapes to the work piece. It is also made up of high-carbon steel.

Swages are used for work which has to be reduced and finished to round, square or hexagonal form. These are made with half grooves of dimensions to suit the work being reduced. Swages consist of two parts the top part having a handle and the bottom part having a square shank which fits in the hardie hole in the anvil face (Fig. 8.5).

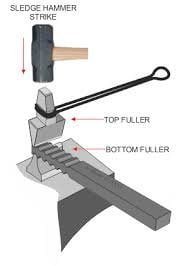

8. Fuller

Fuller helps to create groove or indentions in the forging process. It is also used to stretch the metal. Fuller works in pears, placing one beneath the metal and the other on top. This enables simultaneous indentation of both sides of the metal. Fullers are the forging tools used for necking down a piece of work. They are made in top and bottom tools as in the case of swages. Fullers are made in various shapes and sizes according to needs, the size denoting the width of the fuller edge.

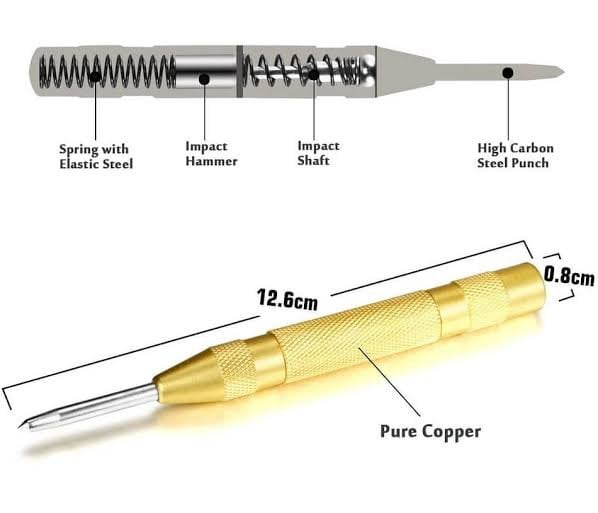

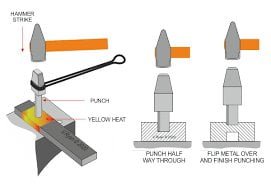

9. Punch and Drift

A punch is used for making holes in metal part when it is at forging heat, and holes are opened out by driving through a larger tapered punch called a drift.

These forging tools are made of high carbon steel, which helps in the formation of hot holes on hot metal pieces. This forging tool is available in a variety of sizes and shapes. Drift is a large size punch that is used to enlarge holes.

10. Flatter

This forging tool is used to flatten the work piece’s surface. It is made up of a plane face and a straight shank. Flatters are made of high carbon steel. Flatters are used to give smoothness and accuracy to articles which have already been shaped by fullers and swages.

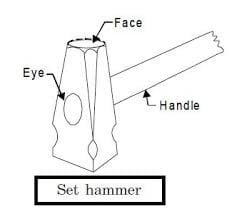

11. Set Hammer

A set hammer is a forging tool used for forming and forming corners, as well as making surface planes. This forging tool is shaped similarly to flatter. It’s made out of tool steel. Before using a set hammer, the work piece must be placed on an anvil.

It is really a form of flatter. A set hammer is used for finishing corners in shouldered work where the flatter would be inconvenient. It is also used for drawing out.

12. Clamping Vice

This forging equipment is used in the smithy show to hold workpieces. It is made up of two jaws, one spring, and a flat bottom. The work pieces are clamped between two jaws and tightened to ensure a firm grip.

13. Bick Iron

This forging equipment is made of hardened tool steel. It has a tapered tail on one side and the other resembles an anvil’s horn. Because of its taper shank, this forging equipment can also be used on an anvil.

14. Forging Die

This forging equipment is required to properly mold metal. It serves as molds into which malleable metals are pressed. Dies are essential in all forging projects; they are used for large production and complex jobs. There are two types of dies: open dies and close dies.

Open die: An open die does not completely encase the metal, allowing free flow everywhere except where the metal meets the die.

Closed die: closed die completely encased the metal when hammered or pressed against the metal.

15. Press Forging

This forging device requires excessive pressure to fold metal into the desired shape. This forging equipment can forge the entire product at once. Mechanical and hydraulic press forging are the two types of presses available.

1. Mechanical press forging: This is a mechanical device that has a motor, crank, flywheel, and other components to easily force the ram against the metal. This forging equipment is not appropriate for large or complex items, but it is useful for simple shaping effects.

2. Hydraulic press forging: This operation uses high-pressure fluid propelled by hydraulic pumps to force a ram against a metal. While forging an item, this forging equipment provides force. It is used and preferred when forging a large or complex item.

We have covered all the various types of Forging tools and equipment that are used along with their images and a brief description. Hope you like the article. Please leave your feedback in the comment section.

Check Out Other Important Topics

Foundry Tools And Equipment – List, Names & Images

Sand Testing Methods – Full Process

Types of Casting Defects – Complete Overview

Moulding Sand – Properties, Types, Process, MCQs

Plant Layout – Types, Objectives, Principles, Advantages

| IC Engine | Important PDFs | Boilers | Synergy Maritime Exam | Naval Arch | MEO Class 4 |

| Interview Questions | Difference Between | Types of Pumps | Auxiliary Machines | Types of Valves | Home |