Foundry tools and equipment may be classified into three groups, namely, hand tools, flasks, and mechanical tools.

1. Hand Tools

Hand Tools :- The hand tools uses are fairly numerous. A brief description of the most important tools is given here.

1. Shovel

A shovel mixing and tempering moving the sand from.

2. Riddle

A riddle, consists of a circular or fitted with a standard shown in Fig. 11.34. It is materials such as nails, wood, etc., from the moulding sand. Both hand and power riddles are available, the latter being used where large volumes of sand are to be riddled.

3. Sprue pin

Sprue foundry tools are a tapered (Fig. 11.35) pushed through the cope to the joint of the mould. As the peg is withdrawn it removes the sand, leaving an opening for the metal. This opening is called the sprue through which the metal is poured. The sprue pin forms the riser pin.

4. Bellow

Bellows are used to blow loose particles of sand from the pattern and the mould cavity. A hand blower is shown in Fig. 11.36.

Moulding machines are also provided with a compressed air jet to perform this operation.

5. Rammer

Hand rammer (Fig. 11.37) foundry tools are a wooden tool used for packing or ramming the sand into the mould. One end, called the peen, is wedge shaped, and the opposite end, called the butt, has a flat surface. Floor rammers are similar in construction but have long handles. Pneumatic rammers are used in large moulds saving considerable labour and time.

6. Trowel

A trowel consists of a metal blade fitted with a wooden handle (Fig. 11.38). Trowels are employed in order to smooth or sleek over the surfaces of moulds. A moulder also uses them in repairing the damaged portions of a mould. The usual trowel is rectangular in shape and has either a round or square end.

7. Slick

It is a small double-ended tool having a flat on one end and a spoon on the other end (Fig. 11.39). This tool is also made in a variety of shapes. The type most commonly used is the oval spoon. Slicks are used for repairing and finishing small surfaces of the mould.

8. Lifter

Lifters are made of thin sections of steel of various widths and lengths with one end bent at right angles as shown in Fig. 11.40. They are used to clean and finish the bottom and sides of deep, narrow openings in moulds.

9. Strike-off bar

The strike-off bar is a piece of metal or wood with a straight edge (Fig. 11.41). It is used to strickle or strike-off excess sand from the mould after ramming to provide a level surface.

10. Swab

A simple swab is a small brush foundry tools having long hemp fibers. A bulb swab has a rubber bulb to hold the water and a soft hair brush at the open end. A bulb swab is shown in Fig. 11.42. Swabs are used for moistening the sand around a pattern or for applying paint.

11. Gate Cutter

It is a small piece of tin plate shaped as shown in the figure. This serves as a tool for cutting gates and runners in the mould.

12. Mallet

A raw hide mallet is used to loosen the pattern in the mould so that it can be withdrawn without damage to the mould.

13. Vent rod

A vent rod or wire, as shown in Fig. 11.45, is used to make a series of small holes to permit gases to escape while the molten metal is being poured.

14. Draw spike or screw

The draw spike is a pointed steel rod, with a loop at one end. These foundry tools are used to rap and draw patterns from the sand. Fig. 11.46 illustrates two kinds of draw spikes. The draw spike is threaded on the end to engage metal patterns.

15. Rapping plate

A rapping or lifting plate, as shown in Fig. 11.47, is used to facilitate rapping and lifting of the pattern from the mould. The plate must be firmly attached to the pattern by long screws or even bolts in larger patterns. The moulder places a draw spike in the rapping hole and raps it to loosen the pattern, then fixes draw screws into the screw hole on the plate.

16. Pouring weight

A pouring weight is simply a plate of cast iron with a cross-shaped opening cast in it to give considerable liberty in placing the runner in the mould. It is used on the top of a mould for giving a weight to prevent the pressure of the liquid metal from forcing the mould apart causing a run-out.

17. Gaggers

Gaggers, sometimes called lifters, are iron rods bent at one end or both ends (Fig. 11.48). They are used for reinforcement of sand in the top part of a moulding box, and to support hanging bodies of sand.

18. Clamps

Clamps (Fig. 11.49) are foundry tools used for holding together the cope and drag of the completed mould to prevent he cope from floating or rising when the metal is introduced into the mould.

19. Spirit level

The spirit level in Fig. 11.50 is used by the moulder to ensure that his bed of sand moulding box or moulding machine table is horizontal

20. Moulding board and bottom board

A moulding board is a smooth wooden board on which the flask and patterns are placed when the mould is started. When the mould is turned over, the function of this board is ended the mould is placed on a similar board, called a bottom board, which acts as a support for the mould until it is poured.

2. Moulding Boxes

Another group of foundry tools are Moulding Boxes. Sand moulds are prepared in specially constructed boxes called flasks. The purpose of the flask is to impart the necessary rigidity and strength to the sand in moulding. They are usually made in two parts, held in alignment by dowel pins. The top part is called the cope and the lower part the drag.

If the flask is made in three sections, the centre is called the cheek (Fig. 11.3). These flasks can be made of either wood or metals depending upon the size required and the purpose the flasks must serve. Metal flasks are used when production is large, but when only a few castings are needed and a special flask must be obtained, the wooden flask is the most economical.

Two types of flasks are used in a foundry: (1) the snap flask, and (2) the tight or box flask. A snap flask (Fig. 11.51) is made with the hinge on one corner and a lock on the opposite corner so that the flask may be removed from the mould before it is poured. The snap flask is of advantage in that many moulds can be made for the same pouring from a single flask.

The tapered slip flask is another type of removal flask. It has rigid corners but the sides have a smooth inside surface and a 5-degree taper to allow the flask to be removed upward.

A box flask shown in Fig. 11.52 must remain in the mould until the pouring operation is completed. These boxes are usually made of metal and are very suitable for small and medium sized moulding.

A typical wooden moulding box is shown in Fig. 11.53. The side timbers are continued beyond the ends of the box to form two handles at each end. The sides are held together by strong cross timbers, reinforced with bolts. This is easier to handle and may be employed for large moulding.

3. Mechanical Tools

The third group of foundry tools are Mechanical Tools. The mechanical tools in the foundry include the many types of moulding machines that will ram the mould, roll it over, and draw the pattern. Besides, there are power operated riddles, sand mixers, sand conveyors, etc.

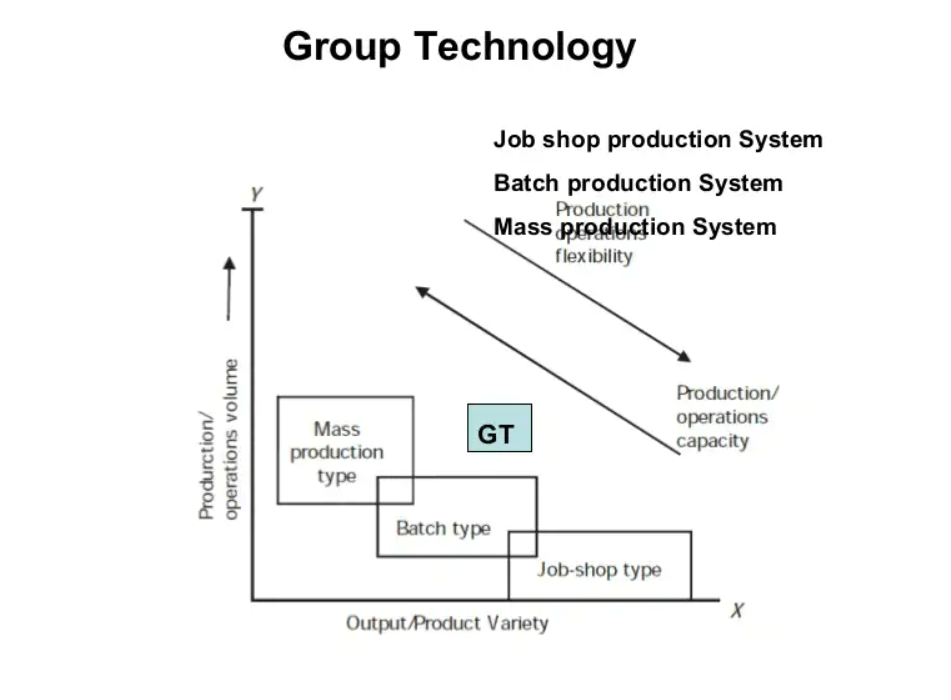

The mould is even poured and shaken out mechanically, and the casting is taken by machine to the cleaning department. The amount of mechanisation, however, varies considerably from one foundry to the other. Mass-production foundries making large quantities of relatively few types of castings are in a position to mechanise more completely than the job-shop foundries.

These were list of different types of foundry tools and equipment. Their work has also been mentioned. Hope you enjoyed the article. Gives your feedback in the comment section.

Check Out Other Important Topics

Plant Layout – Types, Objectives, Principles, Advantages

Types of Punches – Uses, Working, Applications, Pictures

Types of Dies – Classification, Uses, Pictures

Types of Rivets – Working & Their Uses [with Images]

Types of Fasteners – Uses & Examples [with Pictures]

Foundry Tools And Equipment – List, Names & Images

| IC Engine | Important PDFs | Boilers | Synergy Maritime Exam | Naval Arch | MEO Class 4 |

| Interview Questions | Difference Between | Types of Pumps | Auxiliary Machines | Types of Valves | Home |