The article covers What is group technology, Layout, benefits, advantages and disadvantages.

What is Group Technology ?

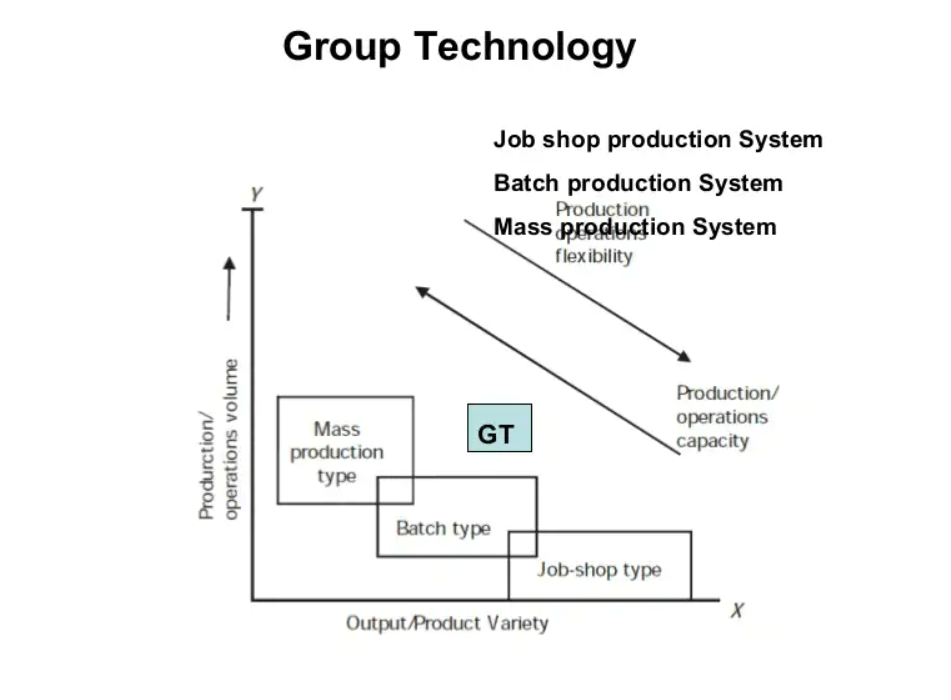

Group technology, or GT, is a manufacturing technique in which parts with similar geometry, manufacturing process, and/or functions are manufactured in a single location using a small number of machines or processes. It is based on the general principle that many problems are similar, and that by grouping similar problems, a single solution to a set of problems can be found, saving time and effort.

Define Group Technology

Group technology is an important technique in the planning of manufacture that allows the advantages of product line organization to be obtained in what otherwise would be jobbing or batch manufacture. This technique identifies the sameness of parts, equipment or processes. Machines are grouped according to the routing required for a

family of parts rather than by their functions.

By using this technique, production planning and control functions are also simplified as the group of machines can be treated as one work center, thereby decreasing the number of work centers and simplifying the routing of parts. Waiting time is reduced significantly and work center utilization in improved.

It offers its greatest benefits when it is extended to all phases of production and production preparation including drafting and part programming for NC machine.

Group Technology Layout

One of the most popular types of hybrid layouts is group technology (GT) or cell layouts. It has the advantage of bringing the efficiencies of a product layout to a process layout environment. Group technology is the process of creating groupings of products based on similar processing requirements.

Objectives of Group Technology

- Reduce average lot size

- Increase part variety

- Increase variety of materials

- Achieve close tolerance

- Improve scheduling

- Reduce tooling

- Increase equipment utilization

Advantages of Group Technology

The generally accepted benefits of group technology are :

- Reduction in setting up times and cost.

- Reduction in material handling costs.

- Reduction in inventory cost and thus reduction of lot size.

- Reduction in throughput time.

- Reduction in work-in-progress.

- Reduction in planning cost and simplifying the documentation and administration of the process planning function.

- Simplified estimating, accounting and work management.

- Output is improved due to improved resource utilization.

- Improved quality and less scrap.

- Smaller variety of tools, jigs and fixtures.

- Better space utilization

- Robots can be easily used for material handling.

This technique, along with good general management practices, therefore has a large contribution towards improving productivity in general and reducing inventory cost in particular.

Disadvantages of Group Technology

- The Additional cost of implementation of this system.

- The rate of change in product range and mix.

- Difficulties with out-of-cell operations.

- Coexistence with non-cellular systems.

- Involves less manufacturing flexibility.

- Increases the machine down time as machines are grouped as cells which may not be functional throughout the production process.

Uses of Group Technology

A classification system can be used to easily follow a GT technique. There are numerous parts in any assembly. These various parts can be classified into three broad categories, namely

1. Standard and proprietary parts (like nuts, bolts, screws, keys, washers, etc.)

2. Similar parts (like shafts, gears, bearings, levers, etc.)

3. Product specific parts (like gear box, bed, saddle, etc.)

It should be noted that the group technology is not concerned with categories I and (iii), but rather with category (ii). The goal is to group the range of parts under category (ii) in some way for manufacturing purposes.

Several classification systems have been developed, and one must carefully consider the system based on his needs. A company with a wide range of products requires a complex detailed system, but the same is not true for one with a limited range. Provision should always be made for future likely growth, and the classification system chosen should keep this requirement in mind.

Hope you enjoyed reading this article about the Group Technology. You can give your feedbacks in the comment below.

Check Out Other Important Topics

Plant Layout – Types, Objectives, Principles, Advantages

Types of Punches – Uses, Working, Applications, Pictures

Types of Dies – Classification, Uses, Pictures

Types of Rivets – Working & Their Uses [with Images]

Types of Fasteners – Uses & Examples [with Pictures]

| IC Engine | Important PDFs | Boilers | Synergy Maritime Exam | Naval Arch | MEO Class 4 |

| Interview Questions | Difference Between | Types of Pumps | Auxiliary Machines | Types of Valves | Home |