What is manufacturing process ?

A Manufacturing process is the production of workpieces having defined geometric shapes. It is one of the most important production technologies. Other technologies are process technology (production of chemicals etc.) and energy technology (production of electricity etc. ).

Classification of Manufacturing Process

Manufacturing processes can be classified in six groups, they are following :-

1. Primary Shaping Processes

Primary shaping or forming is manufacturing of solid body from a molten or gaseous state or from an Amorphous material.

Amorphous materials are gases, liquid, powders, fibers, chips. A primary shaping or forming tool contains a hollow space which, with the allowance for contraction usually corresponds to the form of the product. Some of the important priming shaping processes are ;

- Casting

- Powder metallurgy

- Plastic technology

2. Deforming Process

Deforming processes is manufacturing process which make use of suitable stresses like compression, tension, shear or combined stresses to cause plastic deformation of the materials to produce required shapes without changing its mass or material composition. In forming, no material is removed; they are deformed and displaced. Some of the forming processes are ;

- Forging

- Extrusion

- Rolling

- Sheet metal working

- Rotary swaging

- Thread rolling

- Explosive forming

- Electromagnetic forming

3. Machining/removing Processes

The principle used in all machining process to generate the surface required by providing suitable relative motion between the workpiece and the tool. In these processes material is removed from the unwanted regions of the input materials. In this ,the work material is subjected to a lower stress as compared to forming processes. Some of the machining processes are ;

- Turning

- Drilling

- Milling

- CP and planing

- Grinding

- EDM

- ECM

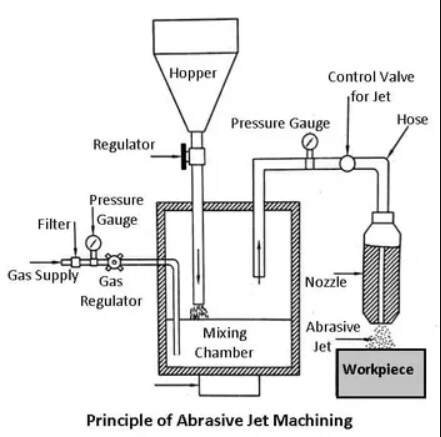

- Ultrasonic machining

4. Joining processes ( Types of manufacturing process )

In this process two or more pieces of metal parts are united together to make sub-assembly or final product. The joining process can be carried out by fusing pressing, rubbing, riveting or any other means of assembling.

Some of the important joining processes are are;

- Pressure welding

- Resistance welding

- Diffusion welding

- Explosive welding

- Brazing

- Soldering

5. Surface finishing processes

These processes are utilized to provide intended surface finish on the metal surface of a job. By Imparting a surface finishing process, dimension of the part is not changed functionally ; either a very negligible amount of metal is removed from or certain material is added to the surface of the job. Surface cleaning process is also accepted as a surface finishing process, Some of the surface finishing processes are :

- Plastic coating

- Metallic coating

- Organic finishes

- Inorganic finishes

- Anodizing

- Buffing

- Honing

- Tumbling

- Electro- plating

- Lapping

- Sanding

6. Material Properties Modification Process

In this type of manufacturing process, material properties of a workpiece is changed in order to achieve desirable characteristics without changing the shape. Many structural metals undergo some special treatment to modify their properties so that they will perform better for their intended use. Some of the properties are:

- Heat and surface treatment

- Annealing

- Surface relieving. etc..

In this article we learnt about Different types of manufacturing process along with their properties and processes involved.

Check Out Other Important Topics