In this article we are going to discuss about the different types of dies available, what are their uses along with their images. Before starting the classification of dies let’s understand What is a Die ?

What are dies ?

A die is a specialized machine tool that is used in the manufacturing industry to cut and/or form material to a specific shape or profile.

Dies, like molds, are typically customized to the item they are used to produce.

Or , It is a tool which is used for cutting or shaping the Materials in press.

Types of Dies

The dies are classified according to types of operations performed by them and their specific construction. The classification of dies and their functions are given below :

Classification / Types of Dies on the basis of Construction

- Simple

- Follow or progressive

- Compound

- Combination

- Rubber

- Multiple die

Types of Dies on the Basis of Operations Performed

1. Shearing

- Piercing

- Punching

- Perforating

- blanking

- Cutting off

- parting

- notching

- Slitting

- Lancing

2. Bending

- Angle bending

- Curling

- Forming

- Plunging

3. Drawing

- Cupping

4. Squeezing

- Coining

- Embossing

- Flattening or planishing

Some More Dies used for Thread Cutting

- Round split die

- Adjustable Die

- Die nut

- Pipe Die

- Acron die

- Die chaser

- Die stock

On the Basis of Construction

1. Simple Die

It is a simple machining tool which performs only one operation at each stroke of the ram. These types of dies are commonly used in the workplace for smaller applications. It could be useful in the production of simple metal parts. It is also known as single operation die.

2. Follow or Progressive Die

Follow or Progressive Die – In these types of dies two or more operations are performed simultaneously at a single stroke of the press by mounting separate sets of dies and punches at two or more different station. The metal progressed from one station to the other till the complete part is obtained.

Progressive punching and blanking die as illustrated in the figure.

The sheet metal 2 is fed into the first die where a hole is pierced by the piercing die set 6 in the first cutting stroke of the RAM 5. The plate 2 is then advanced in the next station and the correct spacing is obtained by the stop 1. In the second cutting stroke of the RAM, the pilot 3 enters into the pierced hole and correctly locates it.

While the blanking punch 4 descends and shears the plate to form a washer. By the time the blanking operation is performed, the hole for the next was washers is also pierced at the fastest station. This all though two strokes are required to complete a washer, each piece of washer was discharged on every strokes of the RAM due to continuity and operation.

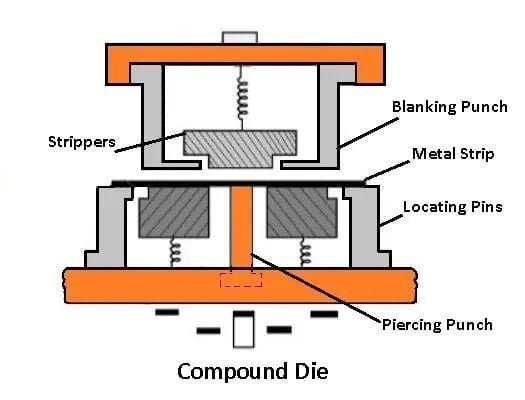

3. Compound Die

In a compound die two or more cutting operations are accomplished at one station of the press in every stroke of the RAM. figure illustrates a compound blanking and piercing die. The blanking die 4 and the piercing punch 3 are bolted to the ram. The spring loaded stripper plate 2 is housed within the blanking die 4. The lower die body 1 has cutting edges both on its outward and inward surfaces.

The outside cutting edges serve as punch for the blanking operations, and the inside cutting edges operate as a die for the piercing punch. The sheet metal 5 is placed on the lower the block, and as the ram descends, the plate is first blanked, and then pierced by the successive die sets. At end of the operation, the stripper plate 2 fitted on the upper die block 4 discharges the washer 7, and the knockout plate 6 fitted on the lower die block 1 ejects the blank.

4. Combination Die

Combination dies – In these types of dies both cutting and noncutting operations are accomplished at one station of the press in every stroke of the ram. Figure illustrates a combination blanking and drawing die showing different stages of the operation. The upper die block 2 serves as a blanking punch and houses a drawing punch 1 at its center. As the punch descend, the metal 3 is first sheared and the required size of the blank is obtained . The inner punch 1 now descends and draws out the metal, while the blanking punch 2 serves as a pressure pad. The drawn out cup is ejected at the end of the strike.

5. Rubber Die

In a rubber die, the rubber is used as a medium of applying pressure on the sheet metal blanks. There are mainly two different processes of operating the rubber die . They are described below

A. Guerin process

The guerin process is employed for performing light drawing, forming or blanking operations by utilising only one half of the die, whereas the other half is supplied by the rubber, which act as a universal die.

B. Marform process

The marform process is practised in deep drawing operations. Figure showing the marform process.

6. Multiple Die

All of the above types of dies produce only one component per stroke; however, if more than one component must be produced, more than one of the above dies will be kept in parallel and referred to as multiple dies.

Advantages of Multiple Die

- Due to more dies, more components are produced.

- The time required is minimal.

- High output rate.

Dies used for Threads Cutting

1. Round Split Die

These are also known as slide dies. This is a one-piece die that is cut from one end. This die is fitted to the die stock in such a way that all three screws of the stock are set on the seat built on it.

This prevents the die from rotating in the stock. Before cutting threads, the center screw is tightened after it has been installed on the job. These types of dies are used for small jobs. The figure depicts a round split due.

2. Adjustable Die

This die is divided into two parts. The threads of the pieces are cut inside in both cases. Round grooves are cut in these threads as a result of the job of the cutting edge. These pieces have either a 1 or a 2 on them. With the outside screw, you can adjust the distance between them. There is a screw seat for this purpose.

With this die, threads can be cut on gib jobs. First, high threads are cut by slightly tightening both pieces, and then deeper threads are cut. This type of die is depicted in the figure.

3. Die nut

A die nut, also known as a thread chaser, is used to sharpen an existing thread. It is used to restore threads that have become damaged or blunted over time. It looks like a square or hexagonal nut in appearance.

4. Pipe Die

This die is designed specifically for cutting threads on water, gas, and oil pipes, among other things. It employs dies of two to four pieces, which are fitted in various types of die handles, as shown in the figure.

For adjusting the die, an adjusting screw is provided on the stock or handles. This stock or handle contains a guide that directs the die to move in the straight direction of the pipe. Because this die cuts threads in the taper, the threads cut with it are unique. As a result, the sockets installed on these pipes become gas and liquid proof.

5. Acron Die

This is the modern die. This type of die is used to cut outside threads on a pipe that has been fitted into a groove or a hole.

This die is also similar to a nut in that threads are cut inside and it is cut intermittently, as shown in the figure. This is tapered from one end for convenience. It is moved by placing it in a specific type of holder.

6. Die chaser

These types of dies are used in conjunction with a turret or capstan lathe. It’s a screw cutting die’s threaded section.

Six skids are fixed thereon, similar to a machine chuck, and dents for cutting threads are cut. These skids can be adjusted using the die head’s handle. This die can be used to cut threads of any length.

7. Die stock

It is also known as a die handle. In other words, the perfection of a die is with the skid of the die and this handle. The die skids are installed in the handle or the stock.

Die handles of various sizes are used for dies of various sizes. These are divided into two sections:

- Adjustable Die handle

- Solid die handle

Types of Dies Based on Operations Performed

A. Shearing

- Piercing

- Punching

- Perforating

- Blanking

- Cutting off

- Parting

- Notching.

- Slitting

- Lancing

B. Bending

- Angle bending

- Curling

- forming

- plunging

C. Drawing

- Cupping

D. Squeezing

- Coining

- Embossing

- Flattening or planishing

Methods of Using Die

- Before cutting outer threads, the end of the pipe or rod should be chamfered with a grinder or a file.

- When cutting threads on a pipe, rod, or any other job, it should be firmly held in a vice.

- Continue moving the die forward and backward.

- Equal pressure should be applied to the die handle.

- Threads of large diameter should be cut after adjusting two to three cuts.

- When cutting threads, use proper lubrication.

- After cutting the threads, they should be checked with a nut or ring gauge.

- After using the drill. It should be thoroughly cleaned and replaced in its proper location.

We have tried to cover all the topics related to types of dies and their uses along with their pictures for proper understanding. If you liked this article, then please share it with your friends also.

Check Out Other Important Topics