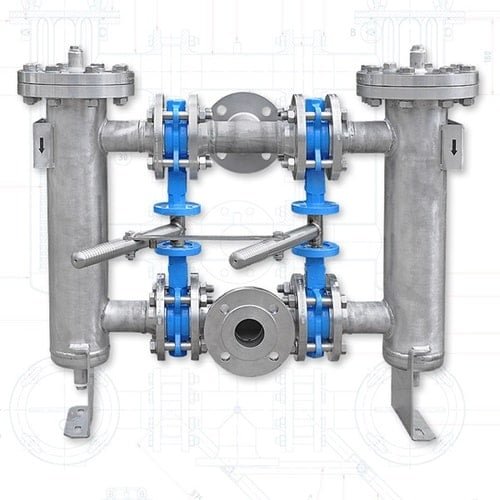

Duplex strainer

A duplex strainer, also known as a twin basket strainer, is a type of filter that is installed in a gas, oil, or water piping system to remove large particles of dirt and debris. In most cases, a duplex strainer system consists of two separate housings for strainer baskets. A valve handle is also included between the two boxes to redirect liquid flow to one strainer while the other is being cleaned.

In some strainers, the valve will operate automatically, and the strainer will perform a self-cleaning method.

These kind of strainers are used in pipeline systems when the flow cannot be stopped. They can filter up to 40 µm depending on the size of their NB. Basket strainers are used in industries where the majority of the pollutants are solids. These strainers, unlike other types of strainers, are very simple to maintain.

How does a Duplex Strainer Work?

A Duplex strainer, or a Basket strainer, is made up of two distinct strainer baskets that are housed together. The suspended solids are trapped in a cleanable basket.

A valve handle is put between the two baskets to restrict the flow of liquid to one strainer while the other is being cleaned. Butterfly valves are used to change the flow direction.

Lube oil system uses duplex filters. Only one filter is used at a time, while the other is kept clean.

What is the purpose of Duplex Strainer?

These strainers or filters are used where the flow of the fluid cannot be stopped. For example in Fuel Lines, Lube Oil lines etc where if the flow is stopped, it can lead to fatal failure of engines and equipments.

Cleaning of Duplex Filter

Filters are cleaned on a regular basis or whenever there is a pressure drop. To clean the filter, flip the filter over to the clean side.

Open the purge cock on the filter you’re using and make sure oil is flowing through it.

Open the filter’s purge cock which is not in use. After the oil has stopped flowing, open the cover and remove the filter element.

When using heavy fuel oil, use caution because it will be quite hot. The filter is made up of notched wire. The size of the notched wire is determined by the micron rate of filtering. It ranges in size from five to 35 microns.

Using kerosene and compressed air, clean the filter element. Replace the filter element and lid, then slowly switch over and expel the air from the filter housing.

How do self cleaning filters work?

Self-cleaning filters clean themselves by utilizing system pressure. The filter’s rigid cylinder screen strains particles from the water source, keeping the material inside.

This buildup can result in a pressure difference between the inlet and the outlet. A flush valve opens when the pressure differential reaches the set control (usually approximately 7psi). This produces a low-pressure flow, which allows the suction nozzles to vacuum the particles out of the filter.

Advantages of Self-Cleaning Filters

Automatic self-cleaning filters have a number of benefits, the most important of which is that they are low-maintenance, making them a great choice for remote sites because they do not require operator participation.

Another significant advantage of industrial self-cleaning filters is that they clean themselves while the system is still in operation. The user saves money, energy, and time as a result of this. They also usually feature a compact form that allows for installation flexibility.

Also Read :

Piston – Construction, Types, Working

Heat Exchanger | Types | Working | Uses