In this article we will learn about High Speed Steel, its composition, properties and uses and various types of it according to the composition.

What is High Speed Steel ?

It is an alloy tool steel that retains much of its hardness and toughness at red heat after heat treatment, allowing tools made of it to cut at high speeds even while red-hot through friction.

High-speed steel (HSS or HS) is a subset of tool steels, which is commonly used as cutting tool material.

High speed steels (HSS ) get their name from the fact that they may be operated as cutting tools at much higher cutting speeds than is possible with plain carbon tool steels. High-speed steels operate at cutting speed 2 to 3 times higher than for carbon steels.

When a hard material is machined at high speed with heavy cuts, sufficient heat may be developed to cause the temperature of the cutting edge to reach a red heat. This temperature would soften carbon tool steel containing even up to 1.5 per cent carbon to the extent of destroying their cutting ability. Certain highly alloyed steels, designated as high-speed steels, therefore, have been developed which must retain their cutting properties at temperatures up 600°C to 620°C.

Types of High Speed Steel

There are four general types of high-speed steel :

1. 18-4-1 High Speed Steel

This steel, containing 18 per cent tungsten, 4 per cent chromium, and 1 per cent vanadium with about 0.75 per cent carbon is considered to be one of the best of all-purpose tool steels. This steel is extensively used for lathe, planer and shaper tools, drills and milling cutters.

2. Cobalt High Speed Steel

This is known as super high speed steel. Normally cobalt is added from 5 to 8 per cent to increase better hot hardness and wear resistance than 18 : 4: 1 type. One analysis of cobalt high-speed steel contains 20 per cent tungsten, 4 per cent chromium, 2 per cent vanadium and 12 per cent cobalt.

The addition of cobalt increases heat resistance, and can give a Rockwell hardness up to 70 Min.

M35

M35 is similar to M2, but contains 5% cobalt. M35 is also referred to as Cobalt Steel, HSSE, or HSS-E. It will cut faster and for a longer period of time than M2. [13]

M42

M42 is a molybdenum-series high-speed steel alloy that contains an additional 8% cobalt. It is widely used in the metal manufacturing industries due to its superior red-hardness compared to more conventional high-speed steels, which allows for shorter cycle times in production environments due to higher cutting speeds or an increase in time between tool changes.

3. Vanadium High Speed Steel

This steel contains 0.70 per cent carbon and more than 1 per cent vanadium. High vanadium with carbon high-speed steel is superior to 18:4:1 type for difficult-to-machine materials. This has excellent abrasive resistance.

4. Molybdenum High Speed Steel

This steel containing 6 per cent molybdenum, 6 per cent tungsten, 4 per cent chromium and 2 per cent vanadium have excellent toughness and cutting ability.

Combining molybdenum, tungsten and chromium steel creates several alloys commonly called “HSS“, measuring 63–65 Rockwell “C” hardness.

M1

It lacks some of the red-hardness properties of M2, but is less susceptible to shock and flexes more.

M2

M2 is the “standard” and most widely used industrial HSS. It has small and evenly distributed carbides that provide high wear resistance, though its decarburization sensitivity is a little high. After heat treatment, its hardness is the same as T1, but its bending strength can reach 4700 MPa, and its toughness and thermo-plasticity are 50% higher than T1. It is commonly used to make a variety of tools such as drill bits, taps, and reamers. 1.3343 is the equivalent numeric designation for M2 material identified in ISO 4957.

M7

M7 is used to make heavier construction drills where flexibility and extended drill life are both important.

M50

M50 does not have the red-hardness of other grades of tungsten HSS, but it is excellent for drills where breakage is a problem due to flexing the drill. Typically used in hardware stores and by contractors. It is also used in high-temperature ball bearings. These steels are created by alloying steel with tungsten, chromium, vanadium, cobalt, and molybdenum.

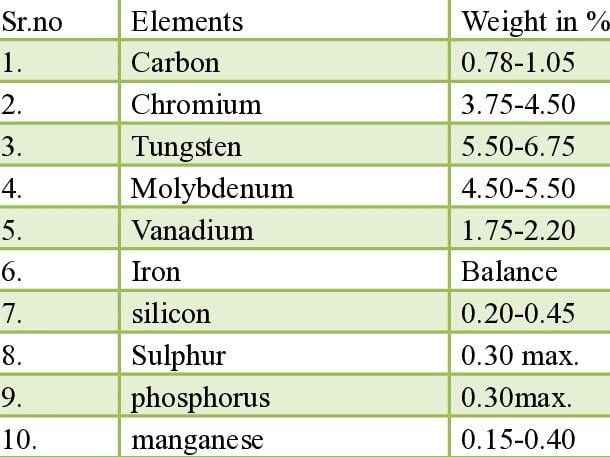

Composition of High Speed Steel

A common type of high-speed steel contains 18% tungsten, 4% chromium, 1% vanadium, and only 0.5–0.8% carbon. See also heat treating, stainless steel.

The below figure illustrates A sample of alloying compositions of common high speed steel grades (by %wt)(impurity limits are not included)

High Speed Steel Properties

High speed steel excels in hardness and abrasion resistance, with different grades trading toughness, hot hardness, or reduced brittleness for toughness. As a result, these alloys are widely used in industrial cutting tools such as tool bits, milling cutters, saw blades, drills, taps, broaches, and so on.

High speed steel tools typically retain a sharper edge for longer than other carbon steels, and the variety of grades and surface treatments available provide options for specialized applications. These products are used in a variety of applications ranging from woodworking to machining high-grade alloys.

Though, It is not traditionally considered to be cutting tools. Punches, dies and other tools in progressive stamping can also be made from high speed steel. Additionally, the properties of ( HSS ) high speed steels, particularly hardness and wear resistance, are desirable for hand tools such as chisels, files, blades for hand planes and kitchen and the pocket knives.

High Speed Steel Composition

It is a common type of high-speed steel, which contains 18% tungsten, 4% chromium, 1% vanadium, and only 0.5–0.8% carbon.

Tungsten – 18 %

Chromium – 4 %

Vanadium – 1 % and

Carbon – 0.5 to 0.8 percent.

Frequently Asked Questions

High Speed Steel are most suitable for

Because of their toughness (hence high resistance to fracture), HSS are suitable especially for (a) high positive rake-angle tools (i.e., those with small included angles), (b) interrupted cuts, (c) machine tools with low stiffness that are subject to vibration and chatter, and (d) complex and single-piece tools, such as drills, reamers, taps, and gear cutters.

High speed steel tools retain their hardness upto a temperature of

1. 250°C

2. 350°C

3. 500°C

4. 900°C

Right Answer is 4. 900°C

The average cutting speed for turning brass with a high speed tool is

A. 90 to 120 m/min

B. 60 to 90 m/min

C. 25 to 31 m/min

D. 15 to 19 m/min

Option B. 60 to 90 m/min is right answer.

The average cutting speed in machining mild steel by the single-point tool of HSS is

1. 10 m/min

2. 20 m/min

3. 30 m/min

4. 40 m/min

Right answer is 3. 30 m/min

For machining a mild steel workpiece by a high-speed steel single-point cutting tool, the average cutting speed is 30 m/min.

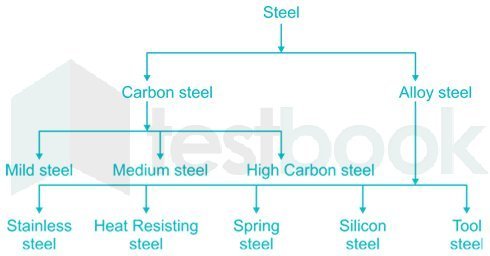

High speed steel belongs to the category of _________ steel

1. Stainless steel

2. Alloy

3. High carbon

4. Low carbon

Right answer 2. Alloy

Explanation :- It is an alloy tool steel that retains much of its hardness and toughness at red heat after heat treatment, allowing tools made of it to cut at high speeds even while red-hot through friction.

Brief explanation :- Steel is basically an alloy of iron and carbon in which the carbon content can be less than 1.7 % and carbon is present in the form of iron carbide to impart hardness and strength.

Two main categories of steel are:

A. Plain carbon steel

B. Alloy steel.

Steels in which carbon is the prime alloying element are termed plain carbon steels, whereas alloy steels contain appreciable concentrations of other elements. Alloying materials like chromium, nickel, molybdenum, copper, aluminum, sulphur, etc. are added to improve the properties of steel.

Example of alloy steel:

A High-speed steel

B. Stainless steel

Check Out Other Important Topics

Different Types of Steel & Constituents of Steel

Steel Making Process – Complete Overview with Flowchart

Cast Iron – Properties, Types & Uses

Recovery Recrystallization and Grain Growth – Working Process

Constrained Motion – Definition, Types, Examples, Images

| IC Engine | Important PDFs | Boilers | Synergy Maritime Exam | Naval Arch | MEO Class 4 |

| Interview Questions | Difference Between | Types of Pumps | Auxiliary Machines | Types of Valves | Home |