An Oily Water Separator is machine which is used on ship for separating oil from oily water mixtures and from the emulsion.

In this article we are going to learn about Oily Water Separator, its working principle, Troubleshooting faults and very important how to solve faults.

And very important is that, this device is used on ship to separate oil from water. A small amount of oil discharged in sea water creates problems to chief engineer.

Must Read: Purifier

What is Oily Water Separator ?

The oily water separator (OWS) is a very important piece of equipment / device carried on board to separate the mixtures of oil and water into their separate components.

An oily water separator is used to treat the oil – water mixture from bilge spaces , oil in any compartment in the ship which has accumulated water ,before discharging into the sea.

Purpose of Oily Water Separator

Oily water separator is used on ship to prevent the discharge of oil overboard mainly when pumping out Bilges. ( When de ballasting or cleaning oil tanks ).

On Which Principle Oily Water Separator Works

Oily water separator Works on the Principle of Seperation – Gravity Differential between the oil and water.

Why we use Oily Water Separator ?

1. Because free oil and oily emulsions discharge in the water way can interfere with the natural process such as photosynthesis and re-aeration and induced the destruction of algae and plankton so essential to fish life .

2. Inshore discharge of oil can cause damage to birds life and Mass pollution of beaches .

Ships found discharging water containing more than hundred milligram per litre of why lord is charging more than 60 litre of oil for nautical mile can we have fined.

Must Read: Fresh Water Generator

Differences between Oily Water Separator and Centrifuge Purifier

-Oily water separator are required to handle large quantity of water from which usually a small amount of wall must be removed

-centrifuge are required to remove usually a small quantity of water from much larger amount of of oil

additionally the centrifuge must separate solids and it must with respect to fuel handle large quantity at the rate at which the fuel is consumed

Suggested Read: Air Compressor

Oily Water Separator Working Principle or Principle of operation :

The fundamental principle of separation by which oil / water separators work is the difference of gravity between oil and water.

The oil exists in oily water mixtures as a collection of globules of various sizes.

The force acting on such a globule which causes it to move in the water is proportional to the difference in weight between the oil particle and an equal volume water particle.

The resistance to movement of the globule depends on its size and the the fluid viscosity.

In the case of small particles moving under streamline flow conditions, the relationship between these properties can be expressed in Stoke ‘s Law.

Stroke ‘s law

Stokes law states that force that returns a sphere moving through a viscous fluid under streamline flow or laminar flow is directly proportional to the velocity of the sphere diameter of the sphere viscosity of the fluid

it is expressed as,

Fr=3πvud

Fr=resistance to movement

v= terminal velocity of particle

u= viscosity of road

d=diameter of particle

The separation of oil from oil/ water mixture only when separating force and terminal force equal.

In general , a high separation rate is encouraged by the large size of the oil globule, the elevated system temperature (which increases the specific gravity differential of oil and water and reduces the viscosity of the oil) and the use of seawater.

Turbulence or agitation should be avoided as it causes the oil to be mixed and re-entrained.

Laminar or streamlined flow is beneficial for good operation of OWS.

In addition, the heating coils provided to improve separation.

There are several other means used for improving and speeding up the operation.

The oil / water separator entrance area is large so that the flow is slow and large oil slugs can move quickly to the surface.

Suggested Read: Steering Gear

Oily Water Separator Working

How does an oily water separator work?

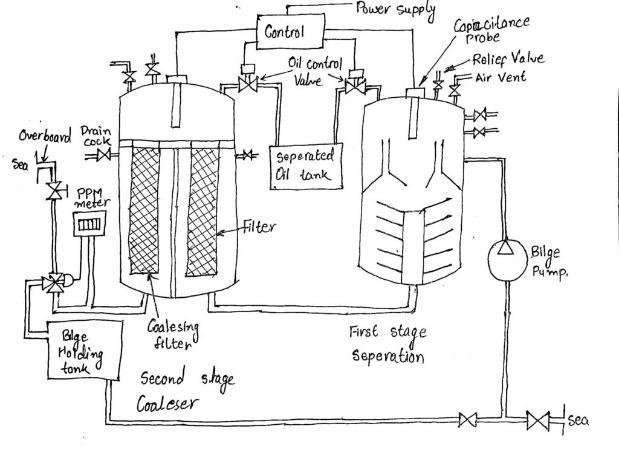

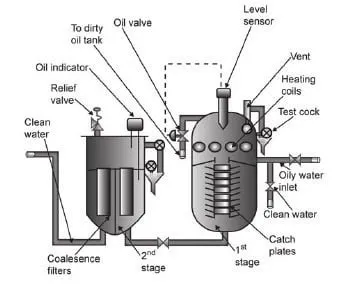

The complete unit is filled with clean water and after that the oil / water is pumped to the first stage of the coarse separating compartment. Here, oil with a lower density than water will rise to the surface with the aid of heating coils in this process. It’s known as a collection space.

A sensor then senses the oil level and the oil is then dumped (according to ppm ) to the dirty oil tank via an oil valve.

The remaining oil – water mixture moves down to the fine separation compartment and moves slowly between the catch plates.

On the underside of these plates,more oil will separate and move outwards until it is free to rise up to the collection space.

And then ,Almost oil free water passes on to the second stage of the unit.

In the second stage, two coalesce filters are situated. The first filter removes any physical impurities present and promotes some filtration, the 2nd filter uses coalesce filter elements to achieve final filtration.

Clean water then leaves the 2nd stage on to a clean water holding tank or via a 15ppm monitor with audible and visual alarms overboard.

Coalescence :- Breakdown if surface tension between the oil droplets in an oil-water mixture which causes them to join and increase in size.

Suggested Read: filter

Working and Construction

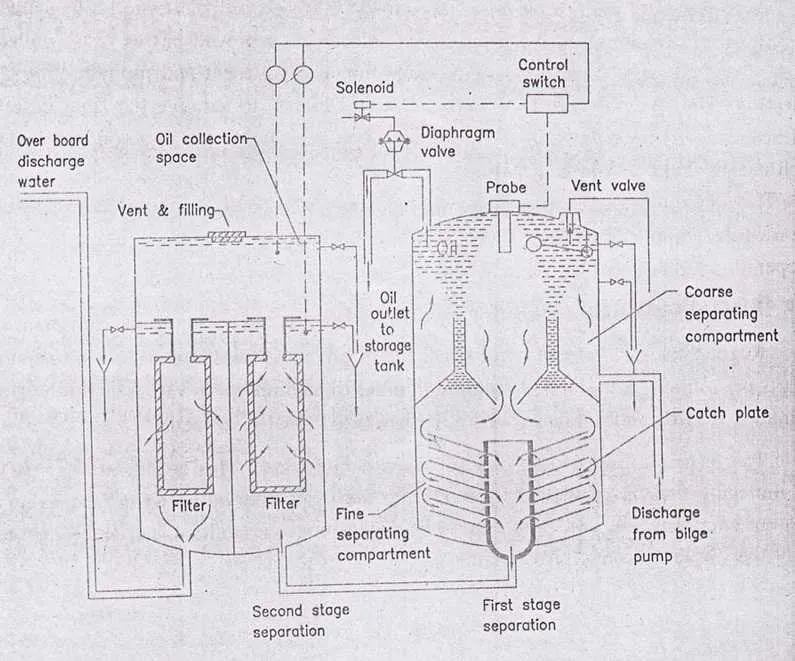

lt is the operation of an oily water separator with a fifteen ppm monitor. The separation of fine water in the separated fixed place in two stages, in the first stage of separation is by gravity whereas in the second stage the separation is by coalescing filter.

Oily water separator mainly consists of 3 units

- Separator unit

- Filter unit

- control unit (oil content monitoring)

A. Separator Unit

This unit consists of catch plates which are inside a coarse separating compartment and an oil collecting chamber.

The boost pump delivers clean sea water to the first stage of the separated through the inlet valve.

The vent is kept open till all the air is removed from the seperator;the oily water mixture is then pumped through the separator inlet pipe into course separating compartment .

Here, because of its lower density, some oil can separate and rise into the oil collection spaces.

The remaining oil-water mixture now flows down into the fine separating compartment and passes gradually between the catch plates.

More oil can separate on the underside of these plates and travel out until the oil-collecting space is free to rise.

Almost oil-free water passes through the central pipe and leaves the separator unit. The purity at this point will be hundred parts per million or less.

An automatically operated valve releases the oil into a storage tank.

(The oil drain valve from the top of the first stage separated is a diaphragm controlled piston valve control air and supplied to the diaphragm through for the solenoid operated pilot valve, the capacitance probe senses oil quantity in the collection space and energizes the form allied to the control switch, was a passive downwards from the first to the second phase coalesce the two central pipe)

Air is released from the Unit By A Vent valve .

Steam or electric heating coils are provided in the upper and sometimes the lower part of the separator, depending upon the type of oil to be separated. (heating reduces viscous drag of oil and thus makes separation of oil and water Easier)

where greater purity is required the almost oil free water passes to a filter unit,the water flow in turn through two filter stage and the oil removed passes to oil collecting spaces.

The first stage filter removes physical impurities present and promotes some points fine separation.

2.The Filter Unit

● This is a separate unit whose input comes from the discharge of the first unit.

● The unit consists of three stages – the filter stage, the coalescer stage and the collection chamber.

● The impurities and the particles are separated by a filter and settled down to the bottom for removal.

The second stage filter uses coalescer inserts for final de-oiling.

Coalescence is the breakdown of surface tension between oil droplets in and oil water mixture which causes them to join and increase in size.

Coalscer filter

Oil content of the final discharge is the last thing ppm,in case the discharge of water after the second stage is more than fifteen ppm .

The monitor synthesis and gives an audible and visual alarm in the engine room,at the same time the monitor and the signal to a three way valve on the overboard discharge line which closes the overboard and opens to be those tanks.

The sensor reports the normal operation, once the oil content drops below fifteen between the test cocks can be used to ascertain the levels of oil and water manually.

The oil from the collecting spaces is drained manually, as is usually required, about once a week.

Filter inserts will require a change in the period of useful life, depending on the operating conditions.

3. Oil Content Monitoring Unit

Regulations on the discharge of oily water, set a concentration limit of ,up to 15 parts per million.

A monitor is required to measure these values and to provide both continuous recordings and alarms where the level allowed is exceeded.

The principle used is that of ultra-violet fluorescence.

This is the emission of light by a light-absorbing molecule.

Energy is lost during the short time between absorption and emission, and light of a longer wavelength is emitted. Oil fluoresces more readily than water, so this provides the means to detect it.

A sample is drawn off from the overboard discharge and passes through sample cell (Figure ).

The ultraviolet light is directed to the sample and the fluorescence is monitored by a photoelectric cell.

The measured value is compared to that of the maximum desired value in the controller / recorder.

When an excessive level of contamination is detected, the alarm is sounded and the diverting valve is operated.

The discharging liquid is then passed to a slop Vault.

Alarms and shutdown

If the 15 ppm oil content monitoring device detect discharge of oil content over 15 ppm,it shuts the unit down and activates the alarm. But in some cases only alarm is there.

Oily Water Separator Requirements

1.As per MEPC 107(49), a bilge alarm or an Oil Content Control unit, which provides for an internal recording of alarm conditions, must be certified by an approved organization.

2.The OCM equipped with the oily –water separator must be tamper-proof.

3. When freshwater is used for cleaning or zeroing purposes, the OCM must trigger and sound an alarm.

4.Separator capable of achieving 15 ppm on type C emulsion

Reason for improper functioning of and Oily Water Separator

1. The principle of separation of Oily water separator on which the separator function is the gravity differential between oil and water.

The force acting on oil Globule to move in the water is proportional to the difference in weight between the oil particle and a particle of water of equal volume.

The resistance to the movement of globule depends on its size and viscosity of the fluids.

Thus in general, a High rate of separation is favoured by

- large size of globule.

- elevated temperature of the system *which affects both of specific gravity differential of the oil and water and the viscosity of the water) And the use of seawater

2. Pumping Consideration

Since the rate of separation depends on the oil Globule size it will be appreciated that any disintegration of oil globules in the oily feed to the separator should be avoided and this factor can be seriously affected by the type and rating of the pump used.

A large number of bilge pumps are centrifugal and often they are used as a supply pump for the separator.

Thus, Charan the supply and produce small oil droplets which dispersed throughout the water, which in turn ma y seriously affect the separation effectively

A positive displacement pump for example slow running double vane, screw, reciprocating or gear pump enables a much better performance to be achieved from the separator as they do not produce large quantity of a small droplets. using pump after the separator may give a discharge having less than 15 PPM concentration without using 2nd Stage filters.

From above two points it is evident that even if the separator is well maintained and correctly operated following factors can cause improper functioning of the separator.

- Throughput of the separator is excessive

- excessive rolling and pitching of the ship causing disintegration of wall globules.

- pump type or and rating is not matching causing too much of turbulence.

- Turbulence caused due to pumping rate.

Further Read:

In this Article, I have written answers to all Questions arises on the Topic Oily Water Separator which I have learned from my faculty or from books.

Anything I missed ? Please write it down in the comment section and don’t forget to share it, because sharing is caring.

FAQ ( Frequently Asked Questions )

What is the purpose of an oily water separator?

It’s Purpose is used to separate Oil from mixture of oil and water. It is used on ship to prevent from making impure sea water. Directly discharge of oily water in sea cause pollution and damage to life of birds and sea animals.

What are the types of oily water separator?

1. Coalescing plate oil water separators treat water to ~10 ppm oil content.

2. Hydrocyclone oil water separators treat water to ~5 ppm oil content.

3. Vertical gravity oil water separators water to ~50 ppm oil content.

What are the three segments of oily water separator?

1. Separator Unit

2. Filter Unit

3. Oil Monitoring Control Unit

Check Out Other Important Topics