How lubrication in 4 stroke engine Takes place ? It is done either by splash lubrication or Pressure lubrication system. In this article, I will describe step by step so that you can understand Lubrication in 4 four stroke engine ( auxiliary engine ) with diagram engine easily.

Try to understand the layout Lubricating system of 4 stroke or Auxiliary engine.It help you in visualising all the parts and how oil moves from sump to all parts and come back to sump of the engine.

Suggested Read : Types of Lubrication

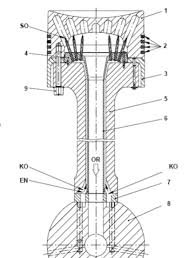

Layout of Lubricating system of 4 stroke or Auxiliary engine

Here is description of the lubrication system for a four-stroke engine highlights the key processes involved in ensuring the efficient functioning of engine components. Here’s a more structured breakdown of the layout and operation of the four-stroke engine’s lubricating system:

Lubricating System Overview:

The lubricating system of a four-stroke engine typically uses a wet sump lubrication system, where oil is stored in a sump located at the bottom of the engine. A lube oil pump, powered by the engine itself, circulates the lubricating oil through the engine’s various components in a closed loop.

Key Components and Process Flow:

1.Lube Oil Sump: The oil is stored in the sump located at the bottom of the engine. The sump holds the oil and acts as the source from which the lubricating oil pump draws oil.

2.Lube Oil Pump: The lube oil pump is driven by the engine and is responsible for circulating oil throughout the system. It pumps oil from the sump and directs it through the rest of the system.

3. Primary Filter: After being drawn from the sump, the oil first passes through a primary filter, which removes larger particles and impurities from the oil, ensuring cleaner oil flows through the system.

4. Oil Cooler: After filtration, the oil passes through an oil cooler, which reduces the temperature of the oil, ensuring that it can efficiently lubricate engine components while preventing overheating.

5. Main Filter: The oil then passes through the main filter for final filtration, removing any remaining impurities.

6. Oil Distribution: After passing through the cooler and main filter, the oil splits into two separate lines:

- Lubricating Main Bearings and Crankshaft:

- One line directs oil to the main bearings. From there, oil passes through holes in the crankshaft, reaching the crankpin for lubrication.

- The oil continues inside the crankshaft, moving toward the piston pin (gudgeon pin) for lubrication. The lubricated piston pin ensures the smooth movement of the piston inside the cylinder.

- Lubricating Cylinder Liners:

- Through the end of the gudgeon pin, oil also lubricates the cylinder liners, ensuring minimal friction between the piston and the cylinder walls.

- Scraper rings on the piston remove excess oil from the cylinder liner, directing it back to the sump.

7. Lubricating Gear System: The second line from the main filter goes to lubricate the engine’s gear system, which includes various pumps and components attached to the crankshaft.

- Components like the lube oil pump, jacket water pump, governor, rocker arm pump, and fuel oil pump are all lubricated from this line to ensure smooth operation.

Key Lubricated Components:

- Main Bearings: Support the crankshaft, allowing it to rotate smoothly.

- Crankshaft and Crankpin: Transmit the engine’s power; lubrication is critical to reduce wear due to friction.

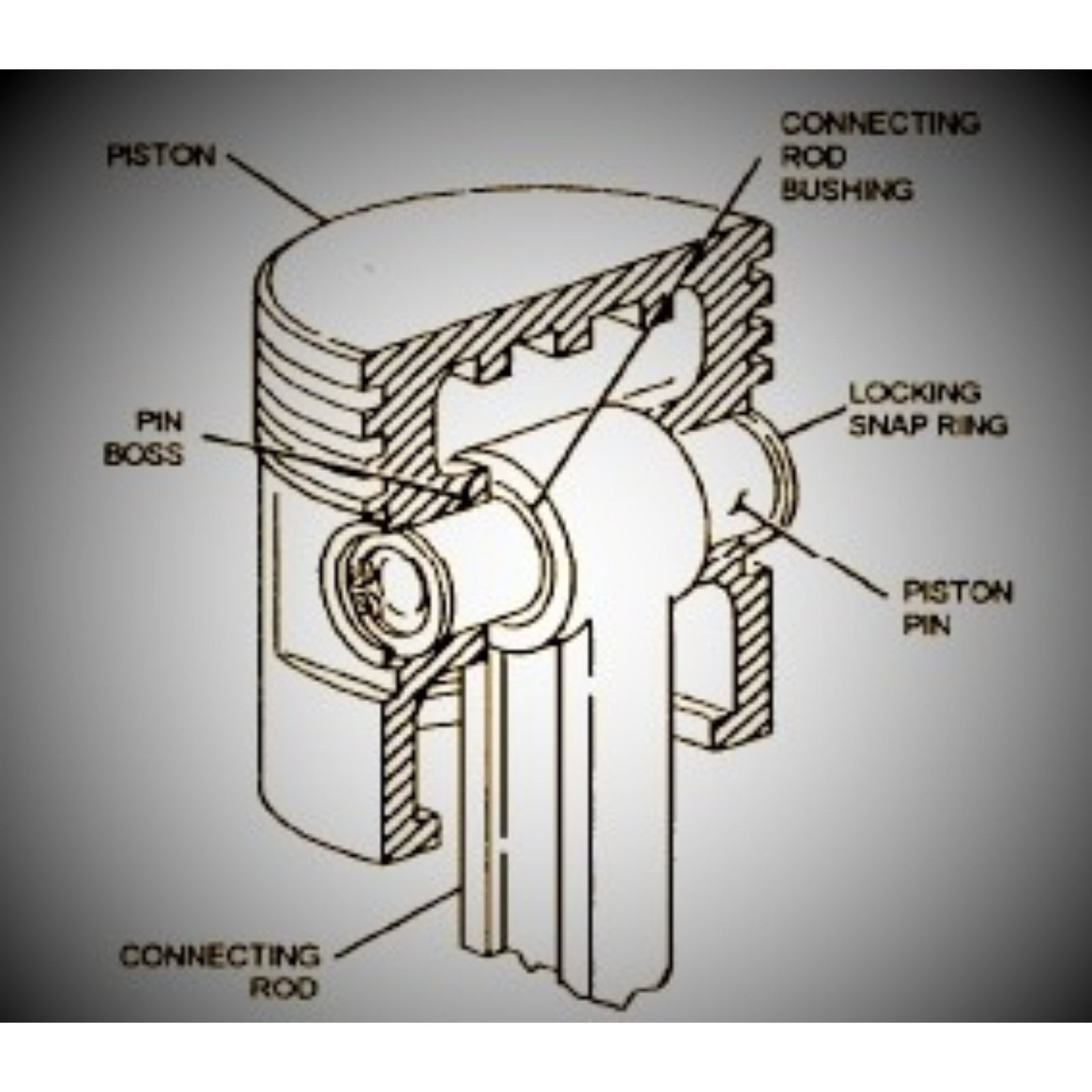

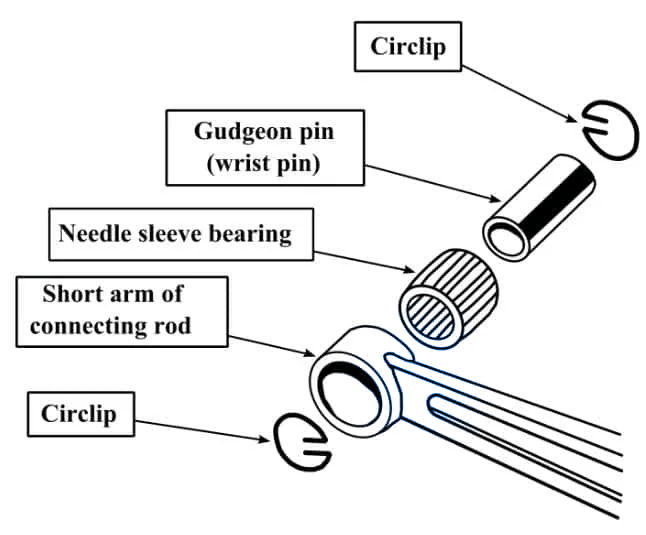

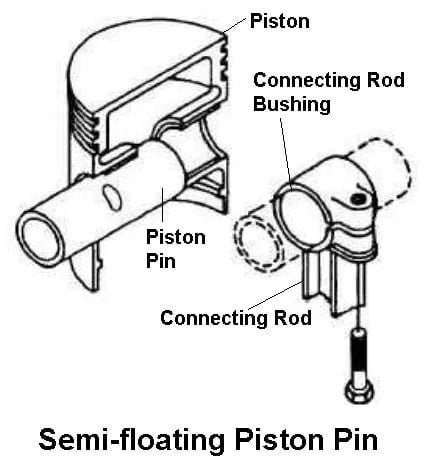

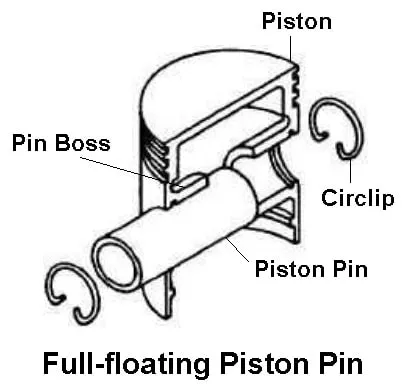

- Piston Pin (Gudgeon Pin): Connects the piston to the connecting rod, needing lubrication for smooth piston movement.

- Cylinder Liners: The inner walls of the cylinder where the piston moves up and down; lubricated to reduce friction and wear.

Piston Cooling (To be Discussed Later):

- In addition to lubricating the engine components, the lube oil system also plays a role in piston cooling, where oil circulates through or around the piston to regulate its temperature. You plan to explain this further in a future section.

Line Diagram of 4-stroke engine lubricating system

Lubricating oil from the oil sump tank >>> Primer filter >>> The lubricating oil pump >>> lubricating oil cooler >>> lubricating oil pressure relief valve >>> lubricating oil filter >>> lubricating oil main pipe.

Now lubricating oil main pipe branched into two lines :-

1. The one line lubricates the main bearing shell, crank pin bearing shell and piston pin bush.

2. While the other line lubricates the cam shaft bearing shell, tappet surroundings, governor and idle gear bush.

Then they will come together to drop into the sole plate. In some modes of engines, the valve rocker arm is lubricated in this circulation.

Pressure Type Lubrication System

This system ensures that all critical engine parts receive continuous lubrication, minimising wear and tear, reducing friction, and preventing overheating of components.

Here, a provided an in-depth explanation of the pressure-type lubrication system in a four-stroke engine, focusing on the key parts that require lubrication to ensure smooth engine operation. Here’s a clearer breakdown of the components and their lubrication process: …

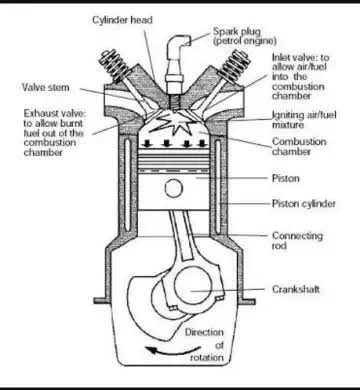

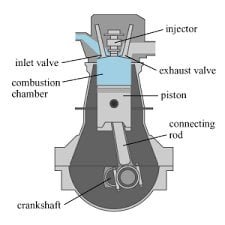

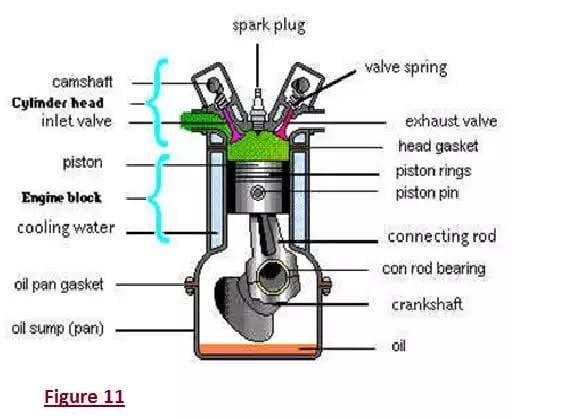

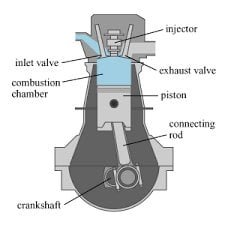

The above see that lubrication system is pressure type lubrication system. Now we see all the parts which is used for lubrication. The main parts which is lubricated are :-

- Main Bearings

- Crank Pin or Bottom end bearings

- Top end bearings or Gudgeon pin Or piston pin

- Cylinder liner lubrication

- Camshaft

- Crankshaft drive

- Governor drive

- Turbocharger

- Rocker arm system

Components and Lubrication Details:

- Main Bearings:

- The main bearings support the crankshaft and are connected to the connecting rod. Due to the heavy loads they bear, proper lubrication is critical to reduce wear and ensure smooth motion.

- Lubrication Process: Lube oil, under pressure from the lube oil pump, passes through holes in the bearings to provide continuous lubrication.

- Crank Pin Bearings (Bottom End Bearings):

- These bearings connect the crankshaft to the crank pin, allowing the conversion of reciprocating motion (up and down movement of the piston) into rotary motion.

- Lubrication Process: The oil is transferred from the main bearing through an internal passage in the crankshaft, which delivers the oil to the crank pin bearings.

- Gudgeon Pin (Piston Pin) or Top End Bearings:

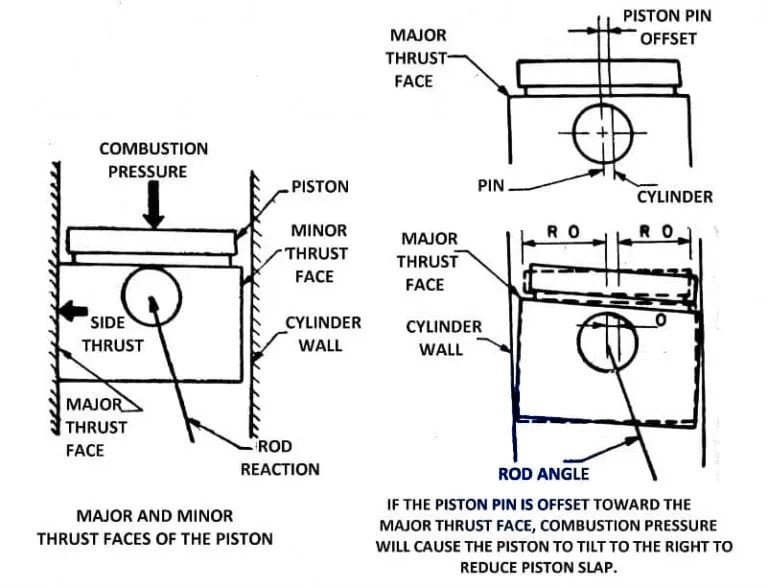

- The gudgeon pin connects the piston to the connecting rod, experiencing reciprocating motion. Proper lubrication is critical to prevent friction between the piston and the connecting rod.

- Lubrication Process: Oil is delivered to the gudgeon pin through passages inside the crankshaft, continuing the flow from the crank pin.

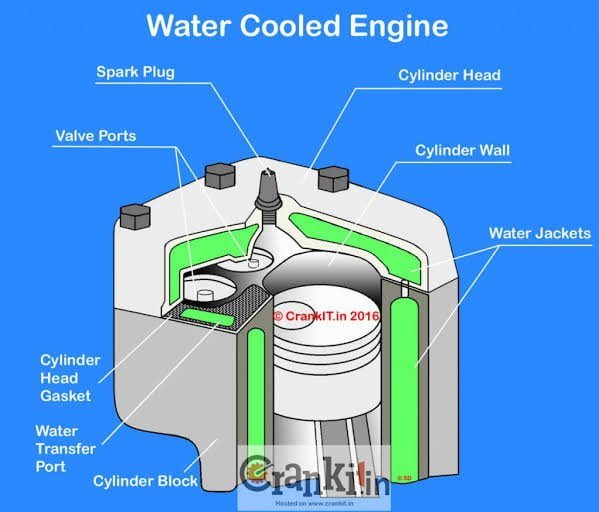

- Cylinder Liner Lubrication:

- The cylinder liner forms the sliding surface for the piston. Lubrication here is necessary to reduce friction between the piston and the liner.

- Lubrication Process: Oil from the gudgeon pin passes through the end of the piston pin and reaches the cylinder walls. Scraper rings on the piston distribute the oil over the liner, while excess oil is scraped back into the sump.

- Camshaft:

- The camshaft drives the operation of various pumps and other engine components by controlling the timing of the valve operation (inlet and exhaust valves).

- Lubrication Process: A nozzle is provided on top of the camshaft, where oil is sprayed to lubricate the gears involved in the camshaft’s operation.

- Crankshaft Drive:

- The crankshaft drive also requires lubrication, particularly in the areas where gears are involved in transmitting power to other components.

- Lubrication Process: A nozzle sprays oil onto the gear meshes to ensure proper lubrication and reduce friction.

- Governor Drive:

- The governor controls the engine’s speed by regulating fuel delivery based on load conditions.

- Lubrication Process: The governor mechanism is lubricated via oil delivered through a dedicated piping system to the gear mesh, ensuring smooth operation.

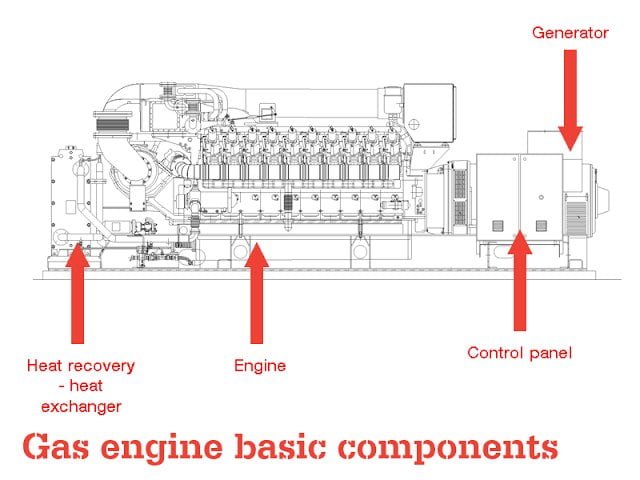

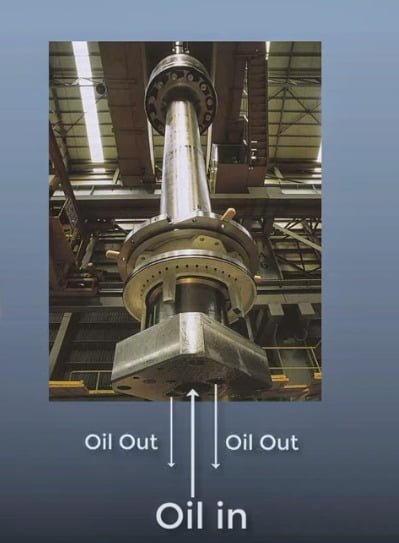

- Turbocharger:

- Some engines use the same lube oil system to lubricate the bearings of the turbocharger. The turbocharger has two main bearings: the turbine-side bearing and the blower-side bearing.

- Lubrication Process: A branch of the lube oil system is used to deliver oil to both bearings, ensuring proper lubrication for the high-speed rotating shaft of the turbocharger.

- Alternative Lubrication: In some engines, splash lubrication is used for the turbocharger bearings. The bearings dip into the oil in the sump, allowing them to be lubricated as they rotate.

- Rocker Arm System:

- The rocker arm controls the opening and closing of the inlet and outlet valves, and its lubrication is essential for smooth valve operation.

- Lubrication Process: In some engines, the rocker arm system is lubricated by the same lube oil pump. After passing through the filters, one oil line branches off to lubricate the rocker arm.

Special Pump: In Daihatsu diesel engines, a special rocker arm pump (internal gear pump) is provided exclusively for lubricating the rocker arm system, offering precise control of lubrication in this area.

Line diagram of rocker arm system

Lubrication of rocker arm system are explained below :-

The Rocker arm lube oil tank >>> torchoid pump ( with safety valve ) >>> lube oil filter >>> Supply oil main pipe >>> rocker arm shaft bush >>> rocker arm end >>> returning main pipe >>> rocker arm lube oil tank

Rocker Arm Lube Oil Tank:

This tank stores the lubricating oil specifically for the rocker arm system. It is separate from the engine’s main lubrication system to ensure that the oil remains clean and free from contamination.

Torchoid Pump (with Safety Valve):

The torchoid pump is responsible for pressurizing and pumping the lubricating oil from the tank. The safety valve ensures that oil does not exceed safe pressure levels, protecting the system from damage.

Lube Oil Filter:

After the oil is pumped, it passes through a lube oil filter, which removes contaminants and impurities. This step is crucial for maintaining the quality of the oil used for lubrication.

Supply Oil Main Pipe:

The filtered oil travels through the supply oil main pipe to reach various lubrication points in the rocker arm system.

Rocker Arm Shaft Bush:

The oil first reaches the rocker arm shaft bush, providing lubrication to the bushings that support the rocker arm’s pivot point.

Rocker Arm End:

The oil then flows to the rocker arm end, where it lubricates the contact points responsible for actuating the engine’s valves.

Returning Main Pipe:

After lubricating the rocker arm, the oil returns through the returning main pipe to be recirculated back into the rocker arm lube oil tank.

Rocker Arm Lube Oil Tank (Return):

Some oil returns directly to the rocker arm lube oil tank from the oil pressure relief valve located at the end of the supply oil main pipe. This valve allows excess oil to be returned to the tank, preventing overpressure in the system.

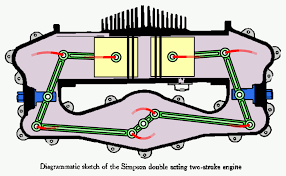

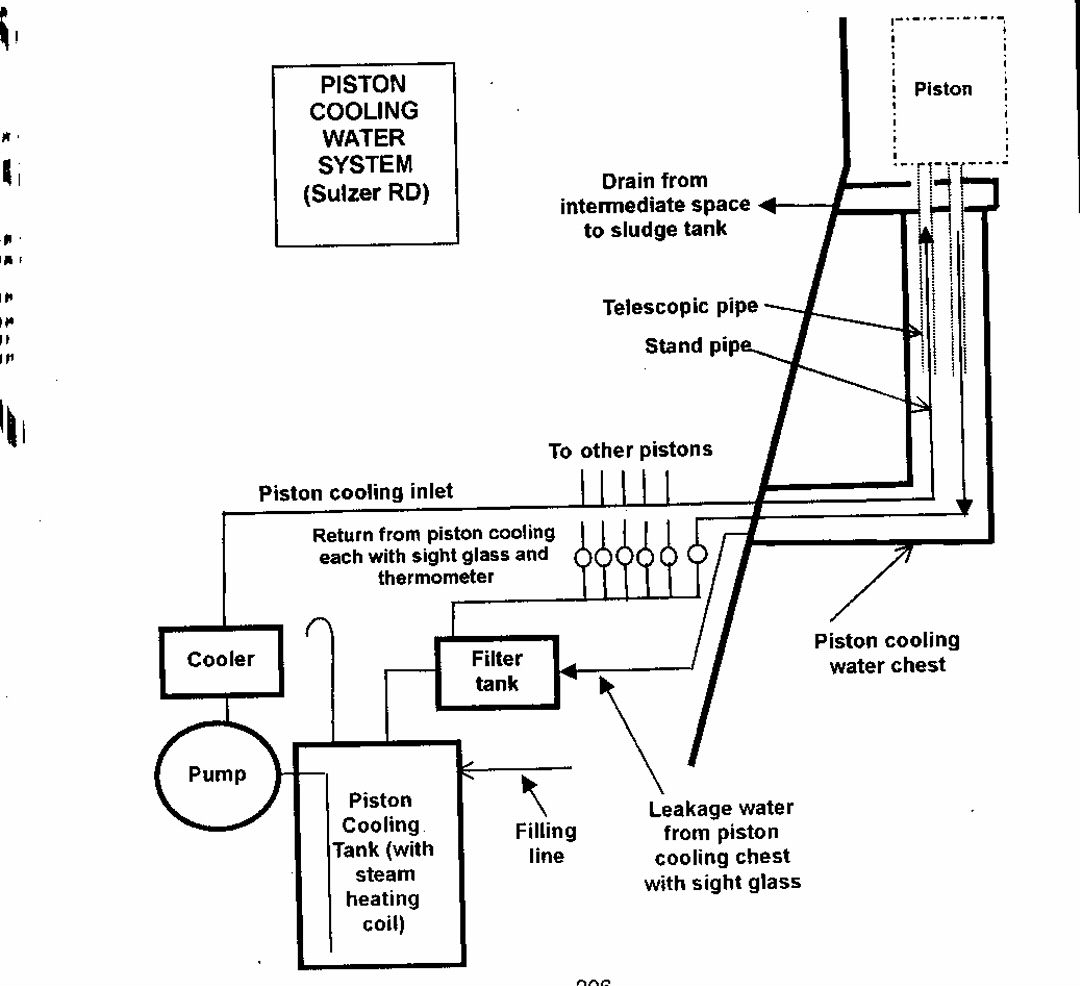

Line Diagram of 2-stroke engine lubricating system

Lubricating oil from the oil sump tank >>> Primer filter >>> The lubricating oil pump >>> lubricating oil cooler >>> lubricating oil pressure relief valve >>> lubricating oil filter >>> lubricating oil main pipe.

Now lubricating oil main pipe branched into two lines :-

1. The one line lubricates the main bearing shell, crank pin bearing shell and piston pin bush.

2. While the other line lubricates the cam shaft bearing shell, tappet surroundings, governor and idle gear bush.

Then they will come together to drop into the sole plate. In some modes of engines, the valve rocker arm is lubricated in this circulation.

Lubricating Oil pump :- lubricating oil pump used here is external gear pump. It is located at the front of the engine and is powered by the crankshaft via a coupling or a gear wheel.

Note :- In some engine splash lubrication system is used. In this lubrication system, lube oil is submerged partially. when crankshaft rotates, it splash the lube oil on surfaces.

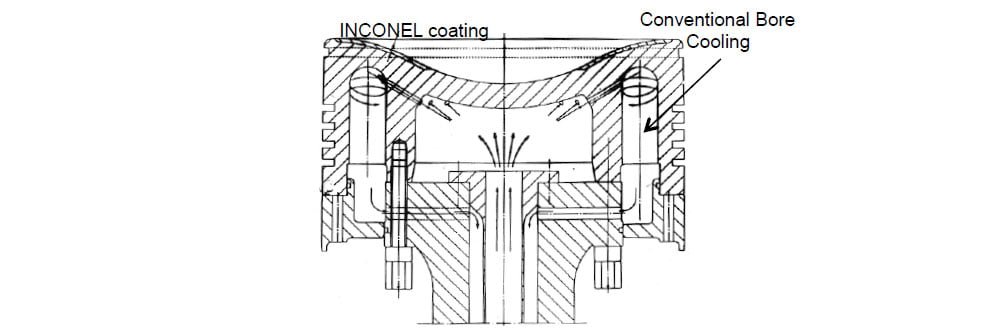

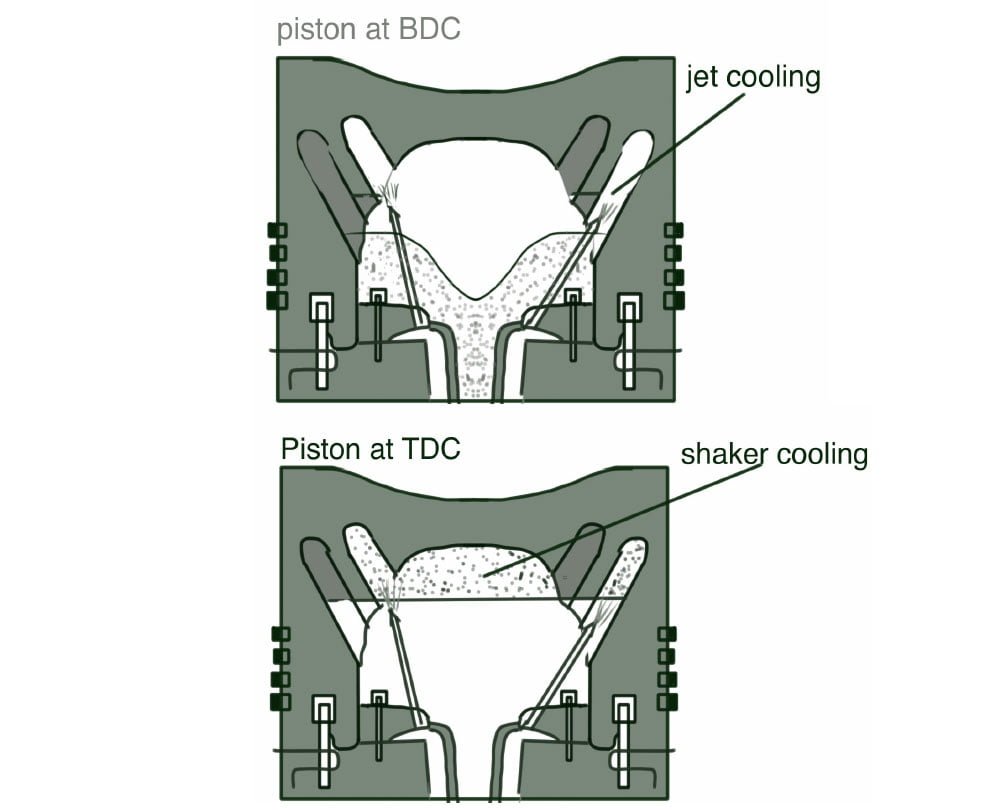

How piston cooling is done in 4 stroke engine ?

As piston get hot too much because it is directly in contact with combustion. So, we need to to cool it working properly. Otherwise failure of Piston. Piston cooling is done by the Nozzle provided near the under space of piston.

This is all about lubrication of 4 stroke engine or auxiliary engine.

FAQ ( Frequently Asked Questions )

Which type of lubrication system is used in stroke engine?

type of lubrication system used as a dry-sump type, wet-sump type, force-feed type, or splash type.

Check Out Other Important Topics