what is two stroke engine ?

A two-stroke engine is a type of internal combustion engine that completes its power cycle in just two strokes of the piston, unlike a four-stroke engine, which requires four strokes. The two-stroke engine is known for its simplicity and high power-to-weight ratio, making it popular for certain applications despite its disadvantages.

history of two stroke engine

The history of the two stroke engine dates back to the mid-19th century. Here are some key milestones in the development of the two-stroke engine:

Invention of the Atmospheric Valve Engine (1781):

Scottish engineer William Symington developed the atmospheric valve engine, which is considered an early precursor to the two-stroke engine. It utilized the weight of the atmosphere to open and close the engine’s valves, demonstrating the concept of the two-stroke cycle.

Development of the Free-Piston Engine (1878):

German engineer Karl Benz designed and patented a free-piston engine, an early type of internal combustion engine with a two-stroke cycle. However, it was not as successful as the four-stroke engine developed by Nicolaus Otto, which became more widely adopted.

Introduction of the Compression-Ignition Engine (1891):

German engineer Rudolf Diesel developed the first compression-ignition engine, which used the heat generated by compressing air to ignite the fuel. Although the first engines were four-stroke, later advancements led to the development of two-stroke diesel engines.

Invention of the Uniflow Scavenged Two-Stroke Engine (1903):

Scottish engineer Joseph Day patented the uniflow scavenged two-stroke engine. In this design, fresh air entered the cylinder through ports in the cylinder wall while exhaust gases exited through valves in the cylinder head, improving scavenging efficiency.

Introduction of the Loop Scavenging System (1920s):

English engineer Harry Ricardo introduced the loop scavenging system, which involved using a deflector on the piston crown to direct the incoming air-fuel mixture upward, creating a loop flow pattern for better scavenging.

Expansion of Two-Stroke Engines in Various Applications (Mid-20th Century):

The two-stroke engine gained popularity in various applications, including motorcycles, outboard boat motors, chainsaws, and small power tools. Their simplicity and high power-to-weight ratio made them suitable for these lightweight and portable applications.

Introduction of Exhaust-Driven Supercharging (1938):

German engineer Hans Stueken introduced exhaust-driven supercharging in two-stroke engines, which significantly increased their power output. This technology was later adopted in high-performance applications like racing motorcycles.

Challenges with Emissions and Fuel Efficiency:

As environmental concerns grew, the two-stroke engine faced criticism for its higher emissions and lower fuel efficiency compared to four-stroke engines. In response, advancements were made to improve the environmental performance of two-stroke engines.

Transition to Four-Stroke Engines in Some Applications:

In certain industries and regions, the use of two-stroke engines declined as more stringent emission regulations were imposed. Many manufacturers shifted towards four-stroke engines or alternative power sources to meet environmental standards.

Continued Innovation:

Despite facing challenges, research and development efforts continue to improve two-stroke engine technology. Direct fuel injection, advanced exhaust systems, and electronic engine management have been introduced to enhance efficiency and reduce emissions in modern two-stroke engines.

The history of the two-stroke engine reflects a continuous quest for efficiency, performance, and environmental responsibility, leading to its ongoing evolution and adaptation in various industries.

Must Read : Components Of IC Engine

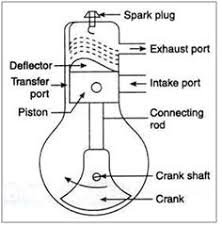

Construction of Two stroke engine

The construction of a two-stroke engine involves several key components and mechanisms that work together to complete the power cycle in just two strokes of the piston. Here’s a general overview of the construction of a typical two-stroke engine:

- Cylinder: The engine cylinder is a cylindrical chamber where the piston moves up and down. It forms the main part of the engine block.

- Piston: The piston is a cylindrical component that fits snugly inside the cylinder. It moves up and down within the cylinder, converting the pressure generated by the combustion process into mechanical motion.

- Crankcase: The crankcase is the lower part of the engine block that houses the crankshaft, connecting rod, and sometimes the gearbox. It also serves as an enclosure for the lubricating oil used in the engine.

- Crankshaft: The crankshaft is a long shaft connected to the piston through the connecting rod. It converts the reciprocating motion of the piston into rotary motion, which is used to drive the vehicle or power equipment.

- Connecting Rod: The connecting rod links the piston to the crankshaft. It transfers the reciprocating motion of the piston to the rotary motion of the crankshaft.

- Spark Plug: In spark-ignition two-stroke engines, a spark plug is installed in the cylinder head. It ignites the air-fuel mixture at the start of the power stroke, generating the combustion that drives the piston downward.

- Ports: Instead of having separate valves like in a four-stroke engine, a two-stroke engine uses ports or passages in the cylinder walls and/or the piston to control the flow of air-fuel mixture and exhaust gases. These ports are crucial for the intake and exhaust functions of the engine.

- Reed Valve (Optional): In some two-stroke engines, a reed valve is used to control the intake of air-fuel mixture from the crankcase into the cylinder. The reed valve allows the mixture to flow in one direction only, improving engine efficiency.

- Exhaust System: The exhaust system is responsible for directing the burned gases from the combustion process out of the engine cylinder and into the atmosphere.

- Lubrication System: Two-stroke engines require a lubrication system to provide lubricating oil to the moving parts, such as the piston and crankshaft. The lubrication system is usually designed to mix the oil with the fuel before entering the cylinder.

It’s important to note that there are variations in the construction of two-stroke engines based on their specific applications, such as whether they are spark-ignition or compression-ignition (diesel) engines and the presence of additional features like direct fuel injection. However, the basic components and principles remain consistent across most two-stroke engine designs.

working of two stroke engine

The working of a two-stroke engine during the compression stroke and the power stroke in detail:

Compression Stroke:

- As the piston moves upward, it compresses the air-fuel mixture that has been drawn into the crankcase during the intake stroke.

- Both the intake port and the exhaust port are closed during the compression stroke to ensure that the air-fuel mixture remains trapped within the cylinder.

- As the volume within the cylinder decreases during the upward movement of the piston, the air-fuel mixture is compressed to a higher pressure and temperature.

Power Stroke:

- At the top of the compression stroke, just before the piston reaches its highest point (top dead center), the spark plug (in spark-ignition engines) or the high temperature from compression (in compression-ignition diesel engines) ignites the highly compressed air-fuel mixture.

- The ignition leads to a rapid and controlled combustion of the air-fuel mixture. The burning gases produce a significant increase in pressure within the cylinder.

- The pressure generated by the combustion drives the piston downward with considerable force. As the piston moves downward, it transfers this force to the connecting rod, which, in turn, rotates the crankshaft.

- The crankshaft converts the reciprocating motion of the piston into rotary motion, which is used to drive the vehicle’s wheels or power the equipment in various applications.

During the power stroke, the exhaust port remains closed, ensuring that the pressure generated by the combustion is effectively converted into mechanical work without allowing the gases to escape prematurely.

It’s essential to note that the two-stroke engine performs the compression and power strokes in one upward and one downward movement of the piston, completing one full power cycle in just two strokes. This design allows two-stroke engines to deliver higher RPMs and a higher power-to-weight ratio compared to four-stroke engines.

However, the simplicity and advantages of two-stroke engines come with certain trade-offs, such as higher emissions, lower fuel efficiency, and increased oil consumption, which have led to their reduced usage in certain applications in favor of cleaner and more efficient alternatives. Nonetheless, two-stroke engines remain prevalent in specific industries and applications where their benefits outweigh their drawbacks.

petrol two stroke engine

A petrol two-stroke engine, also known as a gasoline two-stroke engine, is a type of internal combustion engine that operates on a two-stroke cycle and uses petrol (gasoline) as its fuel. This type of engine completes one full power cycle in just two strokes of the piston: compression and power strokes. Here’s how a petrol two-stroke engine works:

A detailed explanation of the compression and power strokes in a petrol two-stroke engine:

Compression Stroke:

- The compression stroke is the first stroke in the two-stroke engine cycle.

- As the piston moves upward from bottom dead center (BDC) to top dead center (TDC), it compresses the air-fuel mixture that has been drawn into the crankcase during the previous stroke.

- Both the intake port and the exhaust port are closed during the compression stroke to ensure that the air-fuel mixture remains trapped within the cylinder.

- As the volume within the cylinder decreases during the upward movement of the piston, the air-fuel mixture is compressed to a higher pressure and temperature.

- At the end of the compression stroke, just before the piston reaches TDC, the spark plug ignites the highly compressed air-fuel mixture, initiating the power stroke.

Power Stroke:

- The power stroke is the second stroke in the two-stroke engine cycle and is responsible for generating power and driving the engine.

- At the end of the compression stroke, the spark plug generates a spark, igniting the compressed air-fuel mixture.

- The ignition leads to a rapid and controlled combustion of the air-fuel mixture. The burning gases produce a significant increase in pressure within the cylinder.

- The pressure generated by the combustion forces the piston downward with considerable force. As the piston moves downward, it transfers this force to the connecting rod, which, in turn, rotates the crankshaft.

- The crankshaft converts the reciprocating motion of the piston into rotary motion, which is used to drive the vehicle’s wheels or power the equipment.

During the power stroke, the exhaust port remains closed to prevent the escape of the gases generated by the combustion process. The high-pressure gases exerted on the piston during this stroke provide the engine’s power output and rotational force, making the two-stroke engine deliver higher RPMs and a higher power-to-weight ratio compared to a four-stroke engine.

After the power stroke, the cycle repeats, with the piston moving back up to compress a new charge of air-fuel mixture and initiate another power stroke. This completes one full power cycle in just two strokes of the piston: compression and power strokes. The continuous repetition of these strokes generates the engine’s power and drives the vehicle or equipment powered by the petrol two-stroke engine.

application of two stroke engine

Two stroke engines have various applications across different industries and settings due to their simple design and high power-to-weight ratio. Here are some common applications of two-stroke engines:

- Small Vehicles: Two-stroke engines are commonly used in small vehicles such as motorcycles, scooters, mopeds, and small dirt bikes. Their compact size and lightweight nature make them ideal for these applications.

- Outboard Boat Motors: Many boats, especially smaller ones, are powered by two-stroke outboard engines. These engines are favored for their simplicity and ability to provide sufficient power for recreational boating.

- Chainsaws: Two-stroke engines are widely used in chainsaws due to their lightweight and high power output. The simplicity of these engines makes them suitable for the demanding tasks of cutting wood and other materials.

- Lawnmowers: Some lawnmowers utilize two-stroke engines for lawn maintenance. They are often employed in smaller lawnmowers designed for personal use or for maintaining smaller areas.

- Snowmobiles: The lightweight and high power output of two-stroke engines make them well-suited for snowmobiles used in cold climates and snowy terrains.

- Generators: Two-stroke engines can be found in portable generators used for camping, outdoor events, and emergency power backup due to their compact size and ease of use.

- Model Aircraft and Cars: In the realm of model aircraft and radio-controlled cars, two-stroke engines are often used due to their ability to deliver high RPMs and power, which is crucial for these small-scale applications.

- Garden Equipment: Various garden tools such as leaf blowers, trimmers, and small cultivators are powered by two-stroke engines, as they can provide the necessary power in a compact and lightweight package.

It is worth noting that while two-stroke engines have their advantages, they also tend to produce more emissions and are less fuel-efficient compared to four-stroke engines. As environmental concerns grow, the use of two-stroke engines is becoming less prevalent in some applications in favor of more eco-friendly alternatives.

advantages of two stroke engine

Two-stroke engines offer several advantages that make them appealing for specific applications:

- Simplicity: Two-stroke engines have a straightforward design with fewer moving parts compared to four-stroke engines. This simplicity makes them easier to manufacture, maintain, and repair.

- Lightweight and Compact: Due to their simpler construction, two-stroke engines are generally lighter and more compact than four-stroke engines with similar power outputs. This makes them ideal for applications where weight and size are critical factors, such as in small vehicles, portable equipment, and handheld tools.

- High Power-to-Weight Ratio: Two-stroke engines can deliver a higher power output relative to their size and weight. This characteristic makes them suitable for applications where a high power-to-weight ratio is crucial, such as in racing motorcycles and other performance-oriented vehicles.

- Higher RPMs: Two-stroke engines can achieve higher revolutions per minute (RPMs) compared to four-stroke engines. This capability is advantageous in applications that require rapid acceleration and high-speed operation, such as in racing and certain power tools.

- Lower Production Cost: As two-stroke engines have fewer components and are generally easier to manufacture, they often have a lower production cost compared to more complex four-stroke engines.

- Fewer Lubrication Points: Two-stroke engines do not have separate oil systems like four-stroke engines. Lubrication is typically mixed with the fuel, reducing the number of lubrication points and potential points of failure.

- Easy Start-up: Two-stroke engines are easier to start because they require fewer mechanical processes during each engine cycle. This feature is advantageous in applications where quick and reliable starting is essential, such as in emergency power equipment or handheld tools.

- Better Power Delivery: The power delivery in a two-stroke engine is more consistent and direct due to the engine completing one power stroke for every crankshaft revolution. This attribute is advantageous in certain applications, such as off-road motorcycles and chainsaws, where immediate power response is essential.

Despite these advantages, two-stroke engines also have some drawbacks, including higher emissions and lower fuel efficiency compared to four-stroke engines. As environmental concerns become more prominent, efforts have been made to address these issues or replace two-stroke engines with more environmentally friendly alternatives in some applications.

disadvantages of two stroke engine

Two-stroke engines have several disadvantages that limit their widespread use, especially in certain applications, including:

- Higher Emissions: Two-stroke engines tend to produce higher levels of exhaust emissions compared to four-stroke engines. This is mainly due to the fact that they do not have a dedicated exhaust stroke, which can result in incomplete combustion and the release of unburned fuel and pollutants into the atmosphere.

- Lower Fuel Efficiency: Two-stroke engines generally have lower fuel efficiency compared to four-stroke engines. This is partly due to the loss of fuel through the exhaust and the need to mix lubricating oil with the fuel, which affects the combustion process.

- Oil Consumption: Two-stroke engines require the continuous addition of lubricating oil to the fuel mixture. This oil consumption not only increases operating costs but also contributes to higher emissions as some of the oil is burned along with the fuel.

- Limited Torque: Two-stroke engines can lack low-end torque, making them less suitable for applications that require consistent and steady power at low RPMs. This limitation can impact their usability in certain vehicles and equipment.

- Noise and Vibration: Two-stroke engines tend to produce more noise and vibrations compared to four-stroke engines. This can be a concern in applications where noise reduction and user comfort are important, such as in motorcycles and other recreational vehicles.

- Shorter Engine Life: The simplicity of two-stroke engines can lead to increased wear and tear on certain components, potentially shortening their overall lifespan compared to more robust four-stroke engines.

- Environmental Impact: The higher emissions and lower fuel efficiency of two-stroke engines can contribute to environmental pollution and higher greenhouse gas emissions, which has led to stricter regulations and limited their use in certain regions.

- Overheating: Two-stroke engines tend to generate more heat during operation, which can lead to overheating issues if not properly managed. Cooling systems in two-stroke engines must be carefully designed to handle the extra heat.

Due to these disadvantages, two-stroke engines have seen reduced use in some applications, especially in places with stringent emission regulations. Many industries have shifted towards four-stroke engines or other alternative power sources that offer better efficiency and environmental performance.

difference between 4 stroke and 2 stroke engine

Below is a table comparing the main differences between 4-stroke and 2-stroke engines:

| Aspect | 4-Stroke Engine | 2-Stroke Engine |

|---|---|---|

| Operating Principle | Completes power cycle in 4 strokes: | Completes power cycle in 2 strokes: |

| 1. Intake | 1. Compression | |

| 2. Compression | 2. Power | |

| 3. Power | ||

| 4. Exhaust | ||

| Efficiency | Generally more fuel-efficient | Generally less fuel-efficient |

| Lubrication | Separate lubrication system for oil | Oil is mixed with fuel for |

| and fuel (requires oil sump) | lubrication | |

| Emissions | Lower emissions due to separate | Higher emissions due to incomplete |

| exhaust stroke and better combustion | combustion and mixed lubrication | |

| Power Delivery | More steady power delivery | More immediate and smoother power |

| delivery at high RPMs | ||

| Complexity | More complex design with additional | Simpler design with fewer moving |

| components like valves and camshaft | parts, easier to manufacture | |

| Weight | Heavier due to additional components | Lighter due to fewer components |

| Application | Common in cars, trucks, stationary | Common in motorcycles, scooters, |

| engines, and industrial applications | chainsaws, small equipment, etc. |

Both 4-stroke and 2-stroke engines have their own set of advantages and disadvantages, and their suitability depends on the specific application and desired characteristics. While 4-stroke engines are generally more fuel-efficient and produce lower emissions, 2-stroke engines are favored for applications that require a higher power-to-weight ratio and higher RPMs. However, due to environmental concerns and advancements in technology, four-stroke engines are becoming more popular in a wider range of applications.

Reference : https://en.wikipedia.org/wiki/Two-stroke_engine