what is spark plug

A spark plug is a crucial component of an internal combustion engine, commonly used in vehicles such as cars, motorcycles, and small engines. Its primary function is to ignite the air-fuel mixture in the engine’s combustion chamber, initiating the combustion process that generates the power to drive the vehicle.

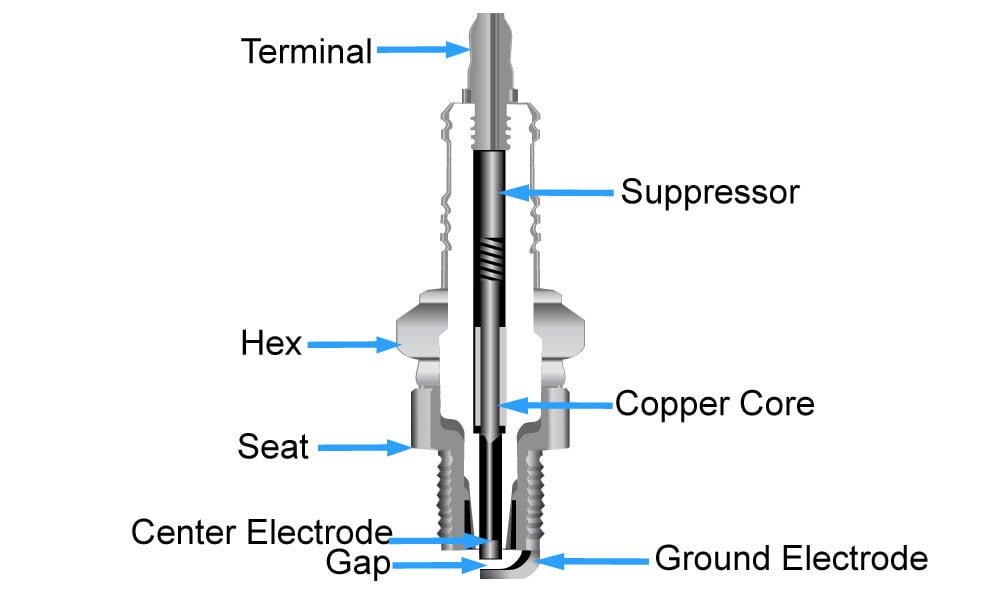

Spark plug construction

A spark plug, a fundamental component within internal combustion engines, boasts a multi-part construction that synergistically generates the vital electrical spark required for initiating the combustion of the air-fuel mixture within the combustion chamber. Let’s delve deeper into the intricate construction of a standard spark plug:

- Shell: The outer casing of the spark plug, known as the shell, is composed of metal and possesses threading at one end, enabling it to be securely affixed into the engine cylinder head. The shell serves a dual purpose: it provides mechanical reinforcement and efficiently dissipates the heat that emerges during the combustion process, thereby contributing to the overall thermal management of the engine.

- Insulator: Nestled within the shell is the insulator, meticulously crafted from a high-temperature-resistant ceramic material. This insulator envelops the central electrode, skillfully preventing the unwanted transmission of electrical current to the shell. The choice of ceramic material stems from its remarkable ability to endure elevated temperatures and the electrical stresses intrinsic to spark plug operation.

- Central Electrode: Extending from the center of the spark plug into the combustion chamber is the central electrode, a slender metal rod. Tasked with connecting to the ignition system, the central electrode facilitates the conduction of the electrical current emanating from the ignition coil to the minute gap existing between the electrodes.

- Ground Electrode: Adjacent to the central electrode, another essential component is situated— the ground electrode. Positioned in close proximity to the central electrode, it deliberately maintains a slight gap between the two. As the electrical current traverses this minuscule gap, a spectacular spark materializes, catalyzing the ignition of the air-fuel mixture, and setting the combustion process in motion.

- Gap: Revered as a pivotal element, the gap is the infinitesimal interval bridging the central electrode and the ground electrode. This diminutive space serves as the epicenter of spark formation, whereupon the electrical current adeptly leaps across, culminating in the spark that triggers the combustion sequence. Ensuring the precise gap dimension, in line with the engine’s specifications, is of paramount importance to orchestrate an efficient and potent ignition event.

- Sealing Gasket: At the lower extremity of the spark plug, an integral sealing gasket, fashioned from a pliable material such as rubber or metal, is positioned. This gasket fervently embarks on the mission of establishing an airtight seal between the spark plug and the cylinder head. Through this meticulous sealing process, the gasket effectively prevents the escape of combustion gases, contributing to the engine’s immaculate gas confinement.

- Hexagonal Nut: Evident at the apex of the spark plug is a hexagonal nut configuration, thoughtfully integrated for effortless installation and extraction. This hexagonal feature conveniently accommodates a wrench or socket, simplifying the otherwise intricate process of spark plug manipulation.

Within the realm of spark plugs, diverse designs and materials cater to an array of engine types and operational conditions. Some spark plugs are thoughtfully engineered to withstand fouling, enhance fuel efficiency, or surmount the demands of high-performance scenarios. The meticulous selection of an appropriate spark plug tailored to the specific engine particulars remains pivotal for the realization of superlative combustion efficiency and unfaltering engine performance.

How do spark plugs work

The functionality of spark plugs is fundamental to the operation of internal combustion engines, which power a vast array of vehicles and machinery. Understanding how spark plugs work entails delving into the intricate process that transforms the potential energy stored in fuel into mechanical power. Here’s a comprehensive breakdown of how spark plugs operate:

- Combustion Process: Internal combustion engines rely on the combustion of an air-fuel mixture to produce energy. The process begins with the intake stroke, during which the engine draws in a precisely balanced mixture of air and fuel vapor into the combustion chamber.

- Compression Stroke: As the intake valve closes, the piston begins to move upward, compressing the air-fuel mixture within the combustion chamber. This compression increases the pressure and temperature of the mixture, resulting in a more volatile environment.

- Ignition Event: Just before the compression stroke reaches its peak, the spark plug initiates the critical ignition event. The spark plug is connected to the vehicle’s ignition system, which generates a high-voltage electrical pulse. This pulse traverses the gap between the central electrode and the ground electrode, ionizing the air and creating a conductive pathway.

- Electric Spark Formation: When the voltage between the electrodes reaches a certain level, it triggers a spark to jump across the gap. This spark is a concentrated burst of electrical energy that generates intense heat—upwards of thousands of degrees Celsius—within an infinitesimal fraction of a second.

- Ignition of Air-Fuel Mixture: The intense heat from the spark ignites the air-fuel mixture, causing it to combust rapidly. This combustion is akin to a controlled explosion, with the fuel molecules breaking down in the presence of oxygen and releasing a tremendous amount of energy in the form of heat and expanding gases.

- Expanding Gases: The combustion process produces rapidly expanding gases that exert pressure on the piston. This pressure drives the piston downward within the cylinder, converting the chemical energy of the fuel into mechanical motion.

- Power Stroke: The downward motion of the piston is known as the power stroke. As the piston moves, it transfers its energy to the connecting rod and subsequently to the crankshaft. The crankshaft converts the linear motion of the piston into rotational motion.

- Exhaust Stroke: Following the power stroke, the piston begins to move back upward, expelling the spent gases from the combustion chamber through the open exhaust valve. This marks the exhaust stroke, completing one full cycle of the four-stroke combustion process.

- Repeat Cycle: The engine continues its operation through a series of cycles, with each spark plug firing in sequence to initiate the combustion process in each cylinder. This cyclical process generates the rotational motion required to power the vehicle or machinery.

In essence, spark plugs play a pivotal role in igniting the air-fuel mixture within the engine’s combustion chamber, which sets off a sequence of events leading to the generation of mechanical power. The precise timing and efficacy of this ignition process influence factors such as engine performance, fuel efficiency, and emissions. Therefore, maintaining properly functioning spark plugs and ensuring they are compatible with the engine’s specifications are critical aspects of engine maintenance and optimization.

types of spark plug

Spark plugs, the small yet pivotal components in internal combustion engines, exhibit a diverse array of types, each meticulously designed to cater to distinct engine requisites, performance demands, and operational circumstances. Delve into the realm of spark plug variation with these comprehensive descriptions of prevalent spark plug types:

- Copper Core Spark Plugs: Carrying the mantle of tradition, It feature a central electrode fabricated from copper. This design offers commendable thermal conductivity, ensuring effective heat dissipation. However, due to the softer nature of copper, these plugs tend to wear out relatively quicker. While frequently found in older vehicle models, their budget-friendly nature remains appealing to those seeking an economical option.

- Platinum Spark Plugs: Embracing innovation, It boast a central electrode adorned with a layer of platinum. This noble metal exhibits exceptional resistance to both wear and corrosion, culminating in an extended operational lifespan. Renowned for consistent performance and heightened fuel efficiency, these plugs find their niche across a broad spectrum of vehicle applications.

- Iridium Spark Plugs: Elevating durability to new heights, It proudly flaunt a minuscule iridium tip on the central electrode. The inherent durability of iridium, coupled with its remarkable heat and corrosion resistance, results in spark plugs capable of excelling in high-temperature environments. These plugs exhibit longevity and steadfast performance, rendering them a preferred choice for modern engines and those equipped with advanced ignition systems.

- Double Platinum Spark Plugs: Propelling durability even further, It showcase both central and ground electrodes cloaked in platinum. This dual-layer design further enhances corrosion resistance and ignition consistency, proving particularly advantageous in engines employing a waste spark ignition system.

- Double Iridium Spark Plugs: Mirroring the concept of double platinum plugs, It shine with iridium coatings on both central and ground electrodes. This amalgamation capitalizes on the longevity of iridium while maintaining a steadfast commitment to ignition performance.

- Silver Spark Plugs: Unveiling exceptional conductivity, It parade a silver central electrode, surpassing even copper in terms of electrical transfer efficiency. Widely embraced in high-performance and racing contexts, these plugs expertly cater to scenarios where efficient spark transfer holds paramount importance.

- V-Power Spark Plugs: Carrying the esteemed NGK emblem, It embark on a distinctive journey with a V-shaped cut adorning the ground electrode. This ingenuous configuration hones the spark’s capability to swiftly kindle the air-fuel mixture, resulting in enhanced ignition efficacy.

- Projected Tip Spark Plugs: Pioneering ignition precision, It showcase a central electrode that ventures slightly beyond the ground electrode. This subtle yet strategic extension promotes a more concentrated and effective spark, consequently refining the combustion process.

- Surface Discharge Spark Plugs: Championing innovation, It challenge convention by guiding the spark along the insulator surface instead of the customary gap. This inventive approach contributes to heightened combustion efficiency and is particularly harnessed in specific engine scenarios.

- Racing Spark Plugs: Engineered for the extraordinary, It embrace designs optimized for high-performance and racing engines. Constructed with materials tailored to endure extreme conditions encompassing elevated heat and pressure, these plugs empower engines to unleash their full potential on the racetrack.

Nurturing engine health and performance requires astute selection of the appropriate spark plug, a decision governed by engine specifics, performance objectives, and manufacturer guidelines. To traverse this intricate landscape, consulting your vehicle’s manual or engaging a qualified mechanic stands as an indispensable step.

spark plug gap size

The spark plug gap size refers to the distance between the center electrode and the ground electrode of a spark-plug. This gap is a critical factor in ensuring proper ignition and combustion within the engine’s cylinders. The correct spark plug gap size is specified by the vehicle manufacturer and is typically listed in the owner’s manual or in the manufacturer’s service information. Using the recommended gap size is crucial for optimal engine performance and efficiency.

The spark plug gap size can vary depending on the engine type, fuel type, ignition system, and other factors. It’s important to note that using the wrong gap size can lead to poor combustion, misfires, reduced power, increased emissions, and potential damage to the spark plug or ignition system.

If you need to adjust the spark plug gap, it’s recommended to use a proper gap tool designed for spark-plugs. Here are the general steps to adjust the gap size:

- Check Specifications: Refer to your vehicle’s manual or service information to find the recommended spark-plug gap size for your specific engine.

- Inspect the Gap: Before making any adjustments, check the gap size of the new spark plugs you’ve purchased. They may need to be adjusted to match the recommended gap size.

- Adjusting the Gap: If the gap needs adjustment, carefully use a spark-plug gap tool to gently bend the ground electrode to achieve the correct gap size. Be cautious not to apply too much force, as excessive bending can damage the electrode.

- Double-Check: After adjusting the gap, double-check it using a spark plug gap gauge to ensure it matches the recommended size precisely.

- Install the Spark Plugs: Once the gap is correctly set, install the spark-plugs into the engine following proper torque specifications. Avoid over-tightening, as it can damage the threads or lead to other issues.

It’s important to exercise care and precision when adjusting the spark plug gap, as mishandling can lead to improper ignition and engine problems. If you’re not comfortable with performing this task yourself, it’s advisable to seek assistance from a qualified mechanic or technician who can ensure the correct gap size is achieved.

application of spark plug

Spark plugs find their application at the heart of internal combustion engines, which power a wide range of vehicles, machinery, and equipment. Their role is essential for initiating the combustion process that generates power from the air-fuel mixture. Here are some of the primary applications of spark plugs:

- Automotive Engines: It is extensively used in gasoline-powered vehicles, including cars, trucks, SUVs, and motorcycles. They play a crucial role in igniting the air-fuel mixture in each cylinder, which drives the pistons and generates the power needed to propel the vehicle.

- Motorcycles and Scooters: Similar to cars, motorcycles and scooters equipped with gasoline engines rely on spark plugs to ignite the air-fuel mixture and provide the necessary power for acceleration and movement.

- Small Engines: It is found in various small engines, such as those used in lawnmowers, chainsaws, leaf blowers, and generators. These engines require spark plugs to initiate combustion and power the mechanical components.

- Marine Engines: It is utilized in marine engines that power boats and watercraft. Whether for recreational boating or commercial marine applications, spark plugs enable the engines to generate the thrust needed to navigate water bodies.

- Power Equipment: Certain power equipment, such as pressure washers, snow blowers, and portable generators, utilize internal combustion engines with spark plugs to produce the mechanical power required for their respective functions.

- Industrial Engines: In industrial settings, It is employed in engines used for various purposes, including power generation, material handling, and industrial machinery. These engines require spark plugs to facilitate controlled combustion and energy production.

- Recreational Vehicles: It is integral components of recreational vehicles (RVs) that have gasoline engines. RVs encompass a wide range of vehicles, from motorhomes to camper vans, where spark-plugs contribute to engine performance and power generation.

- Agricultural Machinery: Farm equipment, such as tractors and combine harvesters, often feature internal combustion engines with spark plugs. These engines power the agricultural machinery needed for planting, cultivating, and harvesting crops.

- Construction Equipment: Many construction machines, including bulldozers, excavators, and skid-steer loaders, rely on spark plug-equipped engines to provide the power required for various construction tasks.

- Aviation: While most aircraft engines use a different ignition system called magnetos, some smaller aviation engines, particularly those used in general aviation, may utilize spark plugs for ignition.

- Racing and Performance Engines: In the world of motorsports, It is a critical component for achieving optimal engine performance. High-performance and racing engines require specialized spark plugs designed to withstand extreme conditions and deliver precise ignition timing.

In all these applications, spark plugs serve as the ignition source that initiates the combustion process, which generates the power required for the engines to function. The specific type of spark-plug used can vary depending on the engine’s design, fuel type, performance requirements, and operational conditions.

advantages of spark plug

It offer several advantages that make them essential components in internal combustion engines. Here are some of the key advantages of spark plugs:

- Ignition Source: It serve as the ignition source that initiates the combustion process in internal combustion engines. They generate the electrical spark necessary to ignite the air-fuel mixture, which powers the engine and produces mechanical energy.

- Efficient Combustion: It facilitate controlled combustion by igniting the air-fuel mixture at the right moment. This results in efficient energy conversion, translating into better fuel efficiency and reduced emissions.

- Reliable Ignition: It is designed to provide reliable ignition under a variety of operating conditions. They ensure consistent spark production, enabling smooth engine starting and stable idling.

- Smooth Engine Operation: Properly functioning spark plugs contribute to smooth and consistent engine operation. They help prevent engine misfires, which can lead to rough idling, poor acceleration, and reduced overall performance.

- Improved Fuel Efficiency: It ignite the air-fuel mixture effectively lead to better combustion efficiency. This, in turn, optimizes fuel consumption, helping to improve the vehicle’s overall fuel efficiency and reducing the frequency of refueling.

- Enhanced Power and Performance: It play a significant role in determining the engine’s power output. By ensuring efficient combustion, they contribute to improved engine performance, delivering better acceleration and overall driving experience.

- Lower Emissions: Efficient combustion facilitated by spark plugs results in reduced emissions of harmful pollutants, such as unburned hydrocarbons and carbon monoxide. This aids in meeting environmental regulations and promoting cleaner air quality.

- Ease of Maintenance: While It require periodic inspection and replacement, they are relatively straightforward to maintain. Regular maintenance ensures that the spark plugs continue to function optimally, contributing to consistent engine performance.

- Wide Compatibility: It is available in a variety of types and designs to suit different engine configurations, fuel types, and performance requirements. This versatility allows them to be used across a range of vehicles and applications.

- Cost-Effective: It offer a cost-effective means of igniting the air-fuel mixture and generating power within internal combustion engines. Regular replacement of worn-out spark plugs can prevent more extensive engine issues and maintain engine efficiency.

- Engine Protection: Efficient ignition facilitated by spark plugs helps prevent engine knocking and detonation, which can lead to engine damage over time. Proper combustion reduces stress on engine components, contributing to longer engine life.

- Diagnostic Tool: It can provide insights into the engine’s condition and performance. Examining the appearance of a removed spark plug can reveal information about the combustion process, fuel mixture, and potential engine issues.

In summary, spark plugs are vital components that offer a range of advantages, from efficient ignition and improved fuel efficiency to enhanced engine performance and emissions reduction. Their role in generating the spark that ignites the air-fuel mixture is foundational to the operation of internal combustion engines in various applications, including vehicles, machinery, and equipment.

disadvantages of spark plug

While It play a crucial role in the functioning of internal combustion engines, they also come with certain disadvantages and limitations. Here are some of the disadvantages of spark plugs:

- Wear and Replacement: It is subject to wear and degradation over time due to the intense heat and electrical stress they endure. As a result, they need periodic replacement, adding to the overall maintenance cost of a vehicle.

- Misfires: Various factors, such as fouling, wear, or incorrect gap settings, can lead to spark plug misfires. Misfires can result in reduced engine performance, increased emissions, and potential damage to the catalytic converter.

- Fouling: It can become fouled due to deposits of carbon, oil, or other contaminants from the combustion process. Fouled plugs can lead to poor ignition, misfires, and decreased engine efficiency.

- Pre-Ignition and Knocking: If the spark plug fires prematurely, it can lead to pre-ignition, where the air-fuel mixture ignites before the intended spark. Pre-ignition can cause knocking, which can damage the engine over time.

- Dependence on Ignition System: It rely on the proper functioning of the ignition system to generate the necessary spark. Any issues with the ignition system, such as a malfunctioning ignition coil or control module, can affect spark-plug performance.

- Cold Weather Performance: In cold weather conditions, It may face challenges in generating a strong spark due to decreased conductivity of the air. This can lead to difficulty in starting the engine and rough idling until the engine warms up.

- Carbon Buildup: Over time, carbon deposits can accumulate on the spark plug electrodes and insulator, affecting spark quality and combustion efficiency. Carbon buildup can lead to misfires and reduced engine performance.

- Limited Spark Energy: The energy generated by spark plugs might be insufficient in certain high-performance or high-compression engines. In such cases, specialized spark-plug designs or ignition systems may be required.

- Compatibility Issues: Using the wrong type of spark plug or incorrect gap size can lead to engine performance problems and potential damage. Proper selection and installation are crucial to avoiding compatibility issues.

- High-Voltage Hazards: The electrical energy required for spark plug operation involves high voltages. Mishandling or improper removal of spark-plugs can lead to electrical shock or other safety hazards.

- Electromagnetic Interference: While modern spark plugs are designed with resistors to minimize electromagnetic interference, some level of interference can still occur. This can affect electronic components and communication systems in the vehicle and its surroundings.

- Not Suitable for All Engines: While It is the primary ignition source for gasoline engines, they are not suitable for all engine types. Diesel engines, for example, rely on compression ignition and do not use spark-plugs.

In conclusion, while spark plugs offer numerous advantages in facilitating combustion and powering internal combustion engines, they are not without their limitations. Regular maintenance, proper selection, and correct installation are essential to mitigate the disadvantages associated with spark plugs and ensure optimal engine performance.

Reference : https://en.wikipedia.org/wiki/Spark_plug